- DL manuals

- Wacker Neuson

- Water Pump

- PS 2 1503

- Operator's Manual

Wacker Neuson PS 2 1503 Operator's Manual

Summary of PS 2 1503

Page 1

Pump ps (3-phase) series operator’s manual 0154626en 002 0 4 0 9 0 1 5 4 6 2 6 e n.

Page 3: Ps (3-Phase) Series

Ps (3-phase) series table of contents wc_bo0154626002entoc.Fm 1 1. Foreword 3 2. Safety information 4 2.1 operating and electrical safety ............................................................ 5 2.2 information labels ...............................................................................

Page 4: Table Of Contents

Table of contents ps (3-phase) series wc_bo0154626002entoc.Fm 2.

Page 5: Foreword

Foreword wc_tx000001gb electric.Fm 3 1. Foreword this manual provides information and procedures to safely operate and maintain this wacker model. For your own safety and protection from injury, carefully read, understand and observe the safety instructions described in this manual. Keep this manual...

Page 6: Safety Information

Safety information ps 3-phase series wc_si000041gb.Fm 4 2. Safety information this manual contains danger, warning, caution, and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is use...

Page 7: Ps 3-Phase Series

Ps 3-phase series safety information wc_si000041gb.Fm 5 2.1 operating and electrical safety to reduce risk of electric shock, connect only to a properly grounded, grounding-type receptacle. Risk of electric shock - this pump has not been investigated for use in swimming pool areas. An acceptable mot...

Page 8: Technical Data

Technical data ps (3-phase) series wc_td000041gb.Fm 6 3. Technical data 3.1 standard specifications applicable liquids, consistency and temperature work drainage and sand-carrying water 0–40°c (32–104°f) pump impeller open type shaft seal double mechanical seal bearing shielded ball bearing motor sp...

Page 9: Ps (3-Phase) Series

Ps (3-phase) series technical data wc_td000041gb.Fm 7 3.2 operating specifications (50 hz) *the weight (mass) given above is the operating weight of the pump itself, not including the cable assembly. Ps 2 1503 0009186 0008801- 0008806 ps 3 1503 0009187 0009188 0008807- 0008812 ps 2 2203 0009189 0009...

Page 10: Technical Data

Technical data ps (3-phase) series wc_td000041gb.Fm 8 *the weight (mass) given above is the operating weight of the pump itself, not including the cable assembly. Ps 2 3703 0009193 0009194 0008825- 0008830 ps 3 3703 0009195 0009196 0008831- 0008836 ps 4 3703 0009197 0009198 0008837- 0008842 pump bor...

Page 11: Ps (3-Phase) Series

Ps (3-phase) series technical data wc_td000041gb.Fm 9 *the weight (mass) given above is the operating weight of the pump itself, not including the cable assembly. Ps 3 5503 0009199 0009200 0008843-0008848 ps 4 5503 0009201 0009202 0008849-0008854 pump bore mm (in.) 80 (3) 100 (4) phase 3 3 starting ...

Page 12: Technical Data

Technical data ps (3-phase) series wc_td000041gb.Fm 10 *the weight (mass) given above is the operating weight of the pump itself, not including the cable assembly. Ps 4 7503hh 0009203 0009204 0008855- 0008860 ps 4 7503hf 0009205 0009206 0008861- 0008866 ps 4 11003hh 0009207 0009208 0008867- 0008870 ...

Page 13: Ps (3-Phase) Series

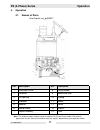

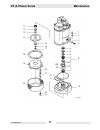

Ps (3-phase) series operation wc_tx000123gb.Fm 11 4. Operation 4.1 names of parts see graphic: wc_gr000327 note: this diagram shows the parts layout of a typical ps (three-phase) model. The external appearance and the internal construction may vary slightly, depending on your particular model. Ref. ...

Page 14: Operation

Operation ps (3-phase) series wc_tx000123gb.Fm 12 4.2 prior to operation when the pump is delivered, first perform the following checks: • inspection while unpacking, inspect the product for damage during shipment, and make sure all bolts and nuts are tightened properly. • specification check check ...

Page 15: Ps (3-Phase) Series

Ps (3-phase) series operation wc_tx000123gb.Fm 13 4.3 installation if the pump is used for outdoor fountains, garden ponds and similar places, or to drain a swimming pool, the pump must be supplied my an isolating transformer or connected to a residual current device (rcd) with a residual operating ...

Page 16: Operation

Operation ps (3-phase) series wc_tx000123gb.Fm 14 checks to make before installation with the megohmmeter, measure the insulation resistance between each of the power wires and grounding wire to verify the insulation resistance of the motor. Reference insulation resistance: 20m w or greater note: th...

Page 17: Ps (3-Phase) Series

Ps (3-phase) series operation wc_tx000123gb.Fm 15 companion coupling is securely fastened with proper gaskets. Barbed discharge fitting (barb) – place hose clamp over hose and push hose to the base of the discharge fitting. Tighten the hose clamp to secure the hose in place. 4.3.2 avoid dropping the...

Page 18: Operation

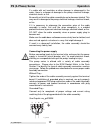

Operation ps (3-phase) series wc_tx000123gb.Fm 16 4.4 electrical wiring performing electrical wiring electrical wiring should be performed by a qualified person in accord with all applicable regulations. Failure to observe this precaution not only risks breaking the law but is extremely dangerous. I...

Page 19: Ps (3-Phase) Series

Ps (3-phase) series operation wc_tx000123gb.Fm 17 if a cable with cut insulation or other damage is submerged in the water, there is a danger of damage to the pump, electrical leakage, electrical shock, or fire. Be careful not to let the cable assembly be cut or become twisted. This may result in da...

Page 20: Operation

Operation ps (3-phase) series wc_tx000123gb.Fm 18 wiring diagram direct-on-line starting wiring diagram see graphic: wc_gr000340 if connected to a circuit protected by a fuse, use a time-delay fuse with this pump. Ref. Description ref. Description 1. Coil 2. Circle thermal protector wire colors b bl...

Page 21: Ps (3-Phase) Series

Ps (3-phase) series operation wc_tx000123gb.Fm 19 4.5 operation before operation improper voltage and frequency of the power supply will prevent the pump from attaining its full potential, and may also lead to current leakage, electrical shock, or fire. 4.5.1 once again, check the nameplate of the p...

Page 22: Operation

Operation ps (3-phase) series wc_tx000123gb.Fm 20 countermeasure: interchange two of the three wires designated u, v and w respectively (c), or follow control system manufacturer's instructions to utilize rotary field control and phase inverter function of the control system supplied with the pump. ...

Page 23: Ps (3-Phase) Series

Ps (3-phase) series operation wc_tx000123gb.Fm 21 operation the pump may be extremely hot during operation. To prevent burns, do not touch the pump with bare hands. Do not insert your finger or a stick into the pump’s inlet opening. Doing so may cause injury, electrical shock, short, or fire. When t...

Page 24: Operation

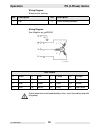

Operation ps (3-phase) series wc_tx000123gb.Fm 22 water level during operation do not operate the pump below continuous running water level (a), as doing so will damage the pump, causing current leakage and electrical shock. The table below shows the water level during operation by output. Make sure...

Page 25: Ps (3-Phase) Series

Ps (3-phase) series maintenance wc_tx000124gb.Fm 23 5. Maintenance 5.1 periodic maintenance schedule pump monthly every 3000 hrs. Every 6000 hrs. Every 2–5 years measure insulation resistance. Reference insulation resistance = 1m w or greater. (1) • measure operating current. Compare with rated curr...

Page 26: Maintenance

Maintenance ps (3-phase) series wc_tx000124gb.Fm 24 5.2 maintenance and inspection regular maintenance and inspections are a necessity for continued efficient functioning of the pump. If any abnormal conditions are noticed, refer to troubleshooting section and take corrective measures immediately. I...

Page 27: Ps (3-Phase) Series

Ps (3-phase) series maintenance wc_tx000124gb.Fm 25 • lubricant capacity: specified capacity (refer to the table, “specified lubricant capacity”.) inspecting lubricant remove the oil plug and take out a small amount of oil. The oil can be extracted easily by tilting the pump so that the oil plug fac...

Page 28: Maintenance

Maintenance ps (3-phase) series wc_tx000124gb.Fm 26 replacement parts the table lists the parts that need to be replaced periodically. Replace these using the recommended frequency as a guideline. 5.3 disassembly and reassembly prior to disassembling and reassembling before disassembling and reassem...

Page 29: Ps (3-Phase) Series

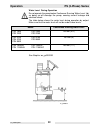

Ps (3-phase) series maintenance wc_tx000124gb.Fm 27 1 2 3 4 5 aa cc 8 9 10 bb dd 11 12 13 14 15 16 17 18 19 20 21 22 23 24 wc_gr000337.

Page 30: Maintenance

Maintenance ps (3-phase) series wc_tx000124gb.Fm 28 parts list see graphic: wc_gr000337 disassembly procedure for 1.5 kw, 2.2 kw, 3.7 kw and 5.5 kw note: before disassembling, be sure to drain the lubricant from the pump. The breakdown of pump shown is based on the construction of 1.5 kw model ps2 (...

Page 31: Ps (3-Phase) Series

Ps (3-phase) series maintenance wc_tx000124gb.Fm 29 a worn impeller may have sharp edges that can cause injury, and should be handled with care. 5.3.4 if necessary, remove the volute (10) and remove the mechanical seal (5). After removing the bolt (1) and the lockwasher (2), remove the volute (10) f...

Page 32: Maintenance

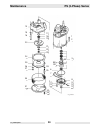

Maintenance ps (3-phase) series wc_tx000124gb.Fm 30 wc_gr000338 1 2 3 10 8 9 bb dd aa cc 11 6 7 12 13 15 16 17 14 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33.

Page 33: Ps (3-Phase) Series

Ps (3-phase) series maintenance wc_tx000124gb.Fm 31 parts list see graphic: wc_gr000338 disassembly procedure for 7.5 kw and 11 kw note: before disassembling, be sure to drain the lubricant from the pump. The breakdown of pump shown is based on the construction of 7.5 kw model ps4 7503hh/hf. 5.3.1 r...

Page 34: Maintenance

Maintenance ps (3-phase) series wc_tx000124gb.Fm 32 5.3.3 removing the impeller (20): using a box wrench, remove the acorn nut (23), nut (22), and the thread cover (21); then remove the impeller (20) and the sleeve (13) from the main shaft. A worn impeller may have sharp edges that can cause injury,...

Page 35: Ps (3-Phase) Series

Ps (3-phase) series maintenance wc_tx000124gb.Fm 33 5.4 troubleshooting before ordering repairs, carefully read through this manual, then repeat the inspection. If the problem remains, contact your nearest dealer or wacker representative. Always turn off the power before inspecting the pump. Failure...

Page 36: Maintenance

Maintenance ps (3-phase) series wc_tx000124gb.Fm 34 the pump's head and pump- ing volume is decreased. • the impeller is worn. Replace. • the hose may be kinked or clogged. Minimize the number of bends in the hose. (in an area with a large amount of debris, use the pump in a meshed enclo- sure.) • t...

Page 49

2008-ce-ps3-phase_q.Fm william lahner dan domanski vice president of engineering manager, product engineering wacker neuson corporation date / datum / fecha / date ec declaration of conformity ce-konformitÄtserklÄrung declaraciÓn de conformidad de la ce dÉclaration de conformitÉ c.E. Wacker neuson c...

Page 50

Wacker construction equipment ag · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-354 02 - 0 · fax: +49 - (0)89-354 02-390 wacker corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : +1-(1)(262) 255-0500 · fax: +1-(1)(262) 255-0550 · tel. : (800) 770-0957 wacker asia pacific o...