- DL manuals

- Wacker Neuson

- Water Pump

- PS 2 500

- Operator's Manual

Wacker Neuson PS 2 500 Operator's Manual

Summary of PS 2 500

Page 1

Pump ps 2 500 ps 2 750 psa 2 500 operator’s manual 0154625en 003 0409 0 1 5 4 6 2 5 e n.

Page 3: Ps 2 500/ps 2 750/psa 2 500

Ps 2 500/ps 2 750/psa 2 500 table of contents wc_bo0154625003entoc.Fm 3 1. Foreword 4 2. Safety information 5 2.1 operating and electrical safety ............................................................ 6 2.2 information labels .......................................................................

Page 4: Foreword

Foreword 4 1. Foreword this manual provides information and procedures to safely operate and maintain this wacker model. For your own safety and protection from injury, carefully read, understand and observe the safety instructions described in this manual. Keep this manual or a copy of it with the ...

Page 5: Safety Information

Ps 2 500 / ps 2 750 / psa 2 500 safety information wc_si000040gb.Fm 5 2. Safety information this manual contains danger, warning, caution, noticeand note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety ale...

Page 6: Safety Information

Safety information ps 2 500 / ps 2 750 / psa 2 500 wc_si000040gb.Fm 6 2.1 operating and electrical safety to reduce risk of electric shock, connect only to a properly grounded, grounding-type receptacle. Risk of electric shock - this pump has not been investigated for use in swimming pool areas. An ...

Page 7: Technical Data

Ps 2 500 / ps 2 750 / psa 2 500 technical data wc_td000040gb.Fm 7 3. Technical data machines discussed in this manual: 3.1 standard specifications part no. Ps2 500 0008793, 0008794 0008795, 0008796 0009176, 0009177 0009178, 0620124 psa 2 500 0008787, 0008790 0008791, 0008792 0009179, 0009180 0009181...

Page 8: Technical Data

Technical data ps 2 500 / ps 2 750 / psa 2 500 wc_td000040gb.Fm 8 3.2 operating specifications (50 hz) * the weight (mass) given above is the operating weight of the pump itself, not including the cable assembly. Part no. Ps 2 500 psa 2 500 ps 2 750 0008793 0008794 0008795 0008796 0009176 0009177 06...

Page 9: Technical Data

Ps 2 500 / ps 2 750 / psa 2 500 technical data wc_td000040gb.Fm 9 3.3 dimensions ps 2 750 185 (7.3) 185 (7.3) 414 (16.3) psa 2 500 ps 2 500 305 (12) 305 (12) 229 (9) 200 (11) 229 (9) 200 (11) 185 (7.3) 185 (7.3) 185 (7.3) 222 (8.8) mm (in.).

Page 10: Operation

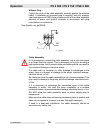

Operation ps 2 500 / ps 2 750 / psa 2 500 wc_tx000121gb.Fm 10 4. Operation 4.1 names of parts see graphic: wc_gr001185 ref. Description ref. Description 1. Lifting handle 8. Seal-mechanical 2. Coupling 9. Lubricant 3. Oil lifter 10. Seal-dust 4. Oil plug 11. Sleeve 5. Cover-suction 12. Housing-oil 6...

Page 11: Operation

Ps 2 500 / ps 2 750 / psa 2 500 operation wc_tx000121gb.Fm 11 4.2 prior to operation when the pump is delivered, first perform the following checks: • inspection while unpacking, inspect the product for damage during shipment, and make sure all bolts and nuts are tightened properly. • specification ...

Page 12: Operation

Operation ps 2 500 / ps 2 750 / psa 2 500 wc_tx000121gb.Fm 12 preparing for installation before installing the pump at a work site, you will need to have the following tools and instruments ready: • insulation resistance tester (megohmmeter) • ac voltmeter • ac ammeter (clamp-on type) • bolt and nut...

Page 13: Operation

Ps 2 500 / ps 2 750 / psa 2 500 operation wc_tx000121gb.Fm 13 precautions during installation do not under any circumstances install or move the pump by suspending it from the cable assembly. The cable may be damaged, causing electrical leakage, shock, or fire. When installing the pump, pay close at...

Page 14: Operation

Operation ps 2 500 / ps 2 750 / psa 2 500 wc_tx000121gb.Fm 14 if large quantities of earth are sucked up, damage resulting from friction in the pump can lead to electrical leakage and shock. 4.3.5 use the pump in the upright position. To prevent the pump from becoming submerged in mud, mount it on a...

Page 15: Operation

Ps 2 500 / ps 2 750 / psa 2 500 operation wc_tx000121gb.Fm 15 4.4 electrical wiring performing electrical wiring electrical wiring should be performed by a qualified person in accord with all applicable regulations. Failure to observe this precaution not only risks breaking the law but is extremely ...

Page 16: Operation

Operation ps 2 500 / ps 2 750 / psa 2 500 wc_tx000121gb.Fm 16 without plug – tighten the ends of the cable assembly securely against the terminal board. If installation of grounded plug is required, use only properly rated and approved cee plug and secure ends of the cable assembly securely to power...

Page 17: Operation

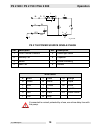

Ps 2 500 / ps 2 750 / psa 2 500 operation wc_tx000121gb.Fm 17 4.5 electrical circuit diagrams see graphic: wc_gr001261, wc_gr001259, wc_gr001260 ps 2 500 power source single phase ref. Description ref. Description 1. Capacitor 4. Protector 2. Main coil 5. Frame grounding 3. Auxiliary coil 6. Ground ...

Page 18: Operation

Operation ps 2 500 / ps 2 750 / psa 2 500 wc_tx000121gb.Fm 18 psa 2 500 power source single phase ref. Description ref. Description 1. Level relay unit 6. Main coil 2. Transformer 7. Auxiliary coil 3. Electrode 8. Miniature protector 4. Capacitor 9. Frame grounding 5. Triac 10. Ground wire colors b ...

Page 19: Operation

Ps 2 500 / ps 2 750 / psa 2 500 operation wc_tx000121gb.Fm 19 ps 2 750 power source single phase if connected to a circuit protected by a fuse, use a time-delay fuse with this pump. Ref. Description ref. Description 1. Circle thermal protector 5. Centrifugal switch 2. Auxiliary coil 6. Capacitor 3. ...

Page 20: Operation

Operation ps 2 500 / ps 2 750 / psa 2 500 wc_tx000121gb.Fm 20 4.6 operation before starting 4.6.1 make sure once again that the product is of the correct voltage and frequency rating. Notice : using the product at other than rated voltage and frequency will not only lower its performance but may dam...

Page 21: Operation

Ps 2 500 / ps 2 750 / psa 2 500 operation wc_tx000121gb.Fm 21 countermeasure: if the supply voltage is outside the tolerance, possible causes are the power supply capacity or an inadequate extension cable. Look again at electrical wiring and make sure the conditions are proper. In case of very exces...

Page 22: Operation

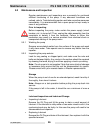

Operation ps 2 500 / ps 2 750 / psa 2 500 wc_tx000121gb.Fm 22 see graphic: wc_gr001225 operating water level (ps 2 500, ps 2 750). Operating water level (psa 2 500 only) starting the pump: this pump starts when water reaches the electrodes on the level relay unit, conducting current between them. No...

Page 23: Operation

Ps 2 500 / ps 2 750 / psa 2 500 operation wc_tx000121gb.Fm 23 the pump has a built-in motor protection system. If an excessive current is detected (ps 2 750) or the motor overheats, for reasons such as the following, the pump will automatically stop operating regardless of the water level, to protec...

Page 24: Operation

Operation ps 2 500 / ps 2 750 / psa 2 500 wc_tx000121gb.Fm 24 see graphic: wc_gr000312 1 2 3 4 5 a b a b wc_gr000312.

Page 25: Maintenance

Ps 2 500 / ps 2 750 / psa 2 500 maintenance wc_tx000114gb.Fm 25 5. Maintenance 5.1 periodic maintenance table (1) if the insulation resistance has become noticeably lower than the previous inspection, an inspec- tion of the motor will be necessary. (2) see lubricant inspection and lubricant change i...

Page 26: Maintenance

Maintenance ps 2 500 / ps 2 750 / psa 2 500 wc_tx000114gb.Fm 26 5.2 maintenance and inspection regular maintenance and inspections are a necessity for continued efficient functioning of the pump. If any abnormal conditions are noticed, refer to troubleshooting section and take corrective measures im...

Page 27: Maintenance

Ps 2 500 / ps 2 750 / psa 2 500 maintenance wc_tx000114gb.Fm 27 note: worn lubricant and other waste products should be disposed of by a qualified agent, in accord with applicable laws. The oil plug gasket should be replaced each time the lubricant is inspected or changed. See graphic: wc_gr001204 r...

Page 28: Maintenance

Maintenance ps 2 500 / ps 2 750 / psa 2 500 wc_tx000114gb.Fm 28 5.3 disassembly/reassembly before disassembling the pump, make certain the power supply (circuit breaker, etc.) is turned off. Then, unplug the cable assembly from the receptacle or detach it from the terminals. To avoid electrical shoc...

Page 29: Maintenance

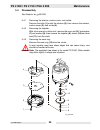

Ps 2 500 / ps 2 750 / psa 2 500 maintenance wc_tx000114gb.Fm 29 5.4 disassembly see graphic: wc_gr001206 5.4.1 removing the strainer, suction cover, and volute: remove the bolts (1) under the strainer (2), then remove the strainer, suction cover (3), and volute (4). 5.4.2 removing the impeller: with...

Page 30: Maintenance

Maintenance ps 2 500 / ps 2 750 / psa 2 500 wc_tx000114gb.Fm 30 5.5 reassembly see graphic: wc_gr001206, wc_gr001205 5.5.1 mount the dust seal (11) onto the outside of the sleeve (10) as shown in the drawing. When doing so, do not apply oil or other lubrication to the surface where the dust seal con...

Page 31: Maintenance

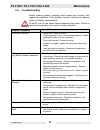

Ps 2 500 / ps 2 750 / psa 2 500 maintenance wc_tx000114gb.Fm 31 5.6 troubleshooting before ordering repairs, carefully read through this manual, then repeat the inspection. If the problem remains, contact your nearest dealer or wacker representative. Always turn off the power before inspecting the p...

Page 32: Maintenance

Maintenance ps 2 500 / ps 2 750 / psa 2 500 wc_tx000114gb.Fm 32 notes.

Page 45

2008-ce-ps2-500-750_q.Fm william lahner dan domanski vice president of engineering manager, product engineering wacker neuson corporation date / datum / fecha / date ec declaration of conformity ce-konformitÄtserklÄrung declaraciÓn de conformidad de la ce dÉclaration de conformitÉ c.E. Wacker neuson...

Page 46

Wacker construction equipment ag · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02 - 0 · fax: +49 - (0)89-3 54 02-3 90 wacker corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker asia pacific operations...