- DL manuals

- Wacker Neuson

- Water Pump

- PST2-400

- Operator's Manual

Wacker Neuson PST2-400 Operator's Manual

Summary of PST2-400

Page 1

Operator’s manual pump pst2-400, pstf2-400 type pst2-400, pstf2-400 document 5000188001 date 1215 version 06 language en 5 0 0 0 1 8 8 0 0 1.

Page 2

Copyright notice © copyright 2015 by wacker neuson production americas llc all rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permissio...

Page 3: Foreword

Foreword wc_tx001173gb.Fm 3 foreword machines covered in this manual this manual provides information and procedures to safely operate and maintain this wacker neuson model. For your own safety and protection from injury, carefully read, understand and observe the safety instructions described in th...

Page 4: Foreword

Foreword wc_tx001173gb.Fm 4.

Page 5: Pst2/pstf2 400

Pst2/pstf2 400 table of contents wc_bo0154618en_005toc.Fm 5 foreword 3 1. Safety information 7 1.1 operating and electrical safety ............................................................ 8 1.2 informational labels ............................................................................. 8 2...

Page 6: Table of Contents

Table of contents pst2/pstf2 400 wc_bo0154618en_005toc.Fm 6.

Page 7: Pst2/pstf2 400

Pst2/pstf2 400 safety information wc_si000034gb.Fm 7 1. Safety information this manual contains danger, warning, caution, notice and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is...

Page 8: Safety Information

Safety information pst2/pstf2 400 wc_si000034gb.Fm 8 1.1 operating and electrical safety to reduce risk of electric shock, connect only to a properly grounded, grounding-type receptacle. Risk of electric shock—this pump has not been investigated for use in swimming pool areas. An acceptable motor-co...

Page 9: Pst2/pstf2 400

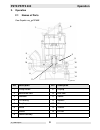

Pst2/pstf2 400 operation wc_tx000111gb.Fm 9 2. Operation 2.1 names of parts see graphic: wc_gr001699 ref description ref description 1 lifting handle 9 oil plug 2 mechanical seal 10 dust seal 3 lubricant 11 sleeve 4 oil housing 12 impeller 5 coupling 13 stirrer nut 6 volute 14 strainer 7 gasket 15 o...

Page 10: Operation

Operation pst2/pstf2 400 wc_tx000111gb.Fm 10 2.2 prior to operation when the pump is delivered, first perform the following checks: • inspection while unpacking, inspect the product for damage during shipment, and make sure all bolts and nuts are tightened properly. • specification check check the m...

Page 11: Pst2/pstf2 400

Pst2/pstf2 400 operation wc_tx000111gb.Fm 11 preparing for installation before installing the pump at a work site, you will need to have the following tools and instruments ready: • insulation resistance tester (megohmmeter) • ac voltmeter • ac ammeter (clamp-on type) • bolt and nut tighteners • pow...

Page 12: Operation

Operation pst2/pstf2 400 wc_tx000111gb.Fm 12 2.3.2 install the pump in a location with sufficient water level, where water collects readily. Note: see operation (“operating water level”) for the water level necessary for operation. Note: the discharge end of the hose should be located higher than th...

Page 13: Pst2/pstf2 400

Pst2/pstf2 400 operation wc_tx000111gb.Fm 13 2.4 installing the float (if equipped) see graphic: wc_gr005664 2.4.1 set the length of the float lead wire to the dimension indicated below. Failure to set the correct lead wire length will lead to improper operation of the pump. Notice: install the floa...

Page 14: Operation

Operation pst2/pstf2 400 wc_tx000111gb.Fm 14 notes:.

Page 15: Pst2/pstf2 400

Pst2/pstf2 400 operation wc_tx000111gb.Fm 15 2.5 electrical wiring performing electrical wiring electrical wiring should be performed by a qualified person in accord with all applicable regulations. Failure to observe this precaution not only risks breaking the law but is extremely dangerous. Incorr...

Page 16: Operation

Operation pst2/pstf2 400 wc_tx000111gb.Fm 16 see graphic: wc_gr000242 cable assembly if it is necessary to extend the cable assembly, use a core size equal to or larger than the original. This is necessary not only to avoid a performance drop, but to prevent cable overheating which can result in fir...

Page 17: Pst2/pstf2 400

Pst2/pstf2 400 operation wc_tx000111gb.Fm 17 2.6 electrical circuit diagrams see graphic: wc_gr006190 if connected to a circuit protected by a fuse, use a time-delay fuse with this pump. Ref. Description ref. Description 1 capacitor 5 frame grounding 2 main coil 6 ground 3 auxiliary coil 8 float swi...

Page 18: Operation

Operation pst2/pstf2 400 wc_tx000111gb.Fm 18 wire colors b black v violet or orange g green w white pr purple l blue y yellow sh shield p pink br brown ll light blue r red cl clear g/y green/yellow t tan gr gray.

Page 19: Pst2/pstf2 400

Pst2/pstf2 400 operation wc_tx000111gb.Fm 19 2.7 operation before starting 2.7.1 make sure once again that the product is of the correct voltage and frequency rating. Notice: using the product at other than rated voltage and frequency will not only lower its performance but may damage the product. N...

Page 20: Operation

Operation pst2/pstf2 400 wc_tx000111gb.Fm 20 countermeasure: if the supply voltage is outside the tolerance, possible causes are the power supply capacity or an inadequate extension cable. Look again at the wiring diagram and make sure the conditions are proper. In case of very excessive vibration, ...

Page 21: Pst2/pstf2 400

Pst2/pstf2 400 operation wc_tx000111gb.Fm 21 operating water level do not operate the pump below the c.W.L. (continuous running water level) indicated below. Failure to observe this condition may result in damage to the pump, current leakage or electrical shock. See graphic: wc_gr001222 npt 45-degre...

Page 22: Operation

Operation pst2/pstf2 400 wc_tx000111gb.Fm 22 2.8 automatic operation (pstf2 400 only) see graphic: wc_gr005666 the pstf2 400 pump is equipped with a float switch to detect the water level. The float switch (a) enables the pump to perform an automatic drainage operation when connected to a continuous...

Page 23: Pst2/pstf2 400

Pst2/pstf2 400 operation wc_tx000111gb.Fm 23 2.9 residue plate see graphic: wc_gr001144 the residue plate kit contains the residue plate, washers, and bolts. Reuse nuts from pump assembly. 2.9.1 remove the strainer (3) by loosening the three nuts (1) and removing the three bolts (2). Keep nuts for r...

Page 24: Maintenance

Maintenance pst2/pstf2 400 wc_tx000112_orig_gb.Fm 24 3. Maintenance 3.1 periodic maintenance table (1) if the insulation resistance has become noticeably lower than the previous inspection, an inspec- tion of the motor will be necessary. (2) see lubricant inspection and lubricant change in this sect...

Page 25: Pst2/pstf2 400

Pst2/pstf2 400 maintenance wc_tx000112_orig_gb.Fm 25 3.2 maintenance and inspection regular maintenance and inspections are a necessity for continued efficient functioning of the pump. If any abnormal conditions are noticed, refer to the troubleshooting section and take corrective measures immediate...

Page 26: Maintenance

Maintenance pst2/pstf2 400 wc_tx000112_orig_gb.Fm 26 see graphic: wc_gr000245 replacement parts the table lists the parts that need to be replaced periodically. Replace these using the recommended frequency as a guideline. Ref. Description ref. Description 1 oil inlet 3 oil plug 2 gasket 4 allen wre...

Page 27: Pst2/pstf2 400

Pst2/pstf2 400 maintenance wc_tx000112_orig_gb.Fm 27 3.3 disassembly and reassembly before disassembling the pump, make certain the power supply (circuit breaker, etc.) is turned off. Then, unplug the cable assembly from the receptacle or detach it from the terminals. To avoid electrical shock, do n...

Page 28: Maintenance

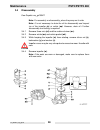

Maintenance pst2/pstf2 400 wc_tx000112_orig_gb.Fm 28 3.4 disassembly see graphic: wc_gr000411 note: for assembly or disassembly, place the pump on its side. Note: it is not necessary to drain the oil for disassembly and inspect ion of the impeller (w) or volute (aa). However, drain oil if further di...

Page 29: Pst2/pstf2 400

Pst2/pstf2 400 maintenance wc_tx000112_orig_gb.Fm 29 3.5 impeller inspection see graphic: wc_gr000411 3.5.1 visually inspect impeller (w) for corrosion, wear or damage. Worn impellers compromise peak performance. 3.5.2 visually inspect impeller key and rotor shaft keyway for signs of uneven wear. 3....

Page 30: Maintenance

Maintenance pst2/pstf2 400 wc_tx000112_orig_gb.Fm 30 3.6 impeller reassembly see graphic: wc_gr000411 note: if, upon inspection and testing, a pump component requires replacement, use only original manufacturer’s replacement parts. 3.6.1 turn pump on its side. 3.6.2 pre-assemble the dust seal (u) an...

Page 31: Pst2/pstf2 400

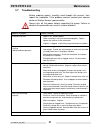

Pst2/pstf2 400 maintenance wc_tx000112_orig_gb.Fm 31 3.7 troubleshooting before ordering repairs, carefully read through this manual, then repeat the inspection. If the problem remains, contact your nearest dealer or wacker neuson representative. Always turn off the power before inspecting the pump....

Page 32: Technical Data

Technical data pst2/pstf2 400 wc_td000034gb.Fm 32 4. Technical data 4.1 standard specifications applicable liquids, consistency and temperature rain water, ground water, sand-carrying water 0–40°c (32–104°f) pump impeller semi-vortex type shaft seal double mechanical seal bearing shielded ball beari...

Page 33: Pst2/pstf2 400

Pst2/pstf2 400 technical data wc_td000034gb.Fm 33 4.2 operating specifications * the weight (mass) given above is the operating weight of the pump itself, not including the cable assembly. Part no. Pst2 400 / pstf2 400 pump electric power v/ph/hz 110/1/60 rated current a 5.4 starting method capacito...

Page 34: Technical Data

Technical data pst2/pstf2 400 wc_td000034gb.Fm 34 4.3 dimensions 4.3.1 *start range ** stop range *** minimum **** maximum 185 (7.3) 250 (9.8) 330 (13.0) pst2 400 pstf2 400 wc_gr006191 385**** (15.2) 40** (1.6) 328 (12.9) 90* (3.5) 120*** (4.8) 255 (10.1) 207 (8.1) 340*** (13.5) 185 (7.3) 162 (6.4) ...

Page 48

Important: for spare parts information, please see your wacker neuson dealer, or visit the wacker neuson website at http://www.Wackerneuson.Com/. Wichtig! Informationen über ersatzteile erhalten sie von ihrem wacker neuson händler oder besuchen sie die wacker neuson website unter http://www.Wackerne...