- DL manuals

- Wacker Neuson

- Water Pump

- PTK 4

- Operator's Manual

Wacker Neuson PTK 4 Operator's Manual

Summary of PTK 4

Page 1

Pump pts 4v ptk 4 operator’s manual 0154628en 005 0107 0 1 5 4 6 2 8 e n.

Page 3: Pts 4V / Ptk 4

Pts 4v / ptk 4 table of contents wc_bo0154628en_005toc.Fm 1 1. Foreword 3 2. Safety information 4 2.1 laws pertaining to spark arresters ...................................................... 4 2.2 operating safety .................................................................................. 5 ...

Page 4: Table of Contents

Table of contents pts 4v / ptk 4 wc_bo0154628en_005toc.Fm 2 5. Maintenance 19 5.1 periodic maintenance schedule ..........................................................19 5.2 engine lubrication ...............................................................................20 5.3 changing oil filte...

Page 5

Wc_tx000001gb.Fm 3 california proposition 65 warning: engine exhaust, some of its constituents, and certain vehicle components, contain or emit chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. 1. Foreword this manual provides information and pr...

Page 6: Safety Information

Safety information pts 4v / ptk 4 wc_si000130gb.Fm 4 2. Safety information this manual contains danger, warning, caution, and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is used t...

Page 7: Pts 4V / Ptk 4

Pts 4v / ptk 4 safety information wc_si000130gb.Fm 5 2.2 operating safety familiarity and proper training are required for the safe operation of equipment. Equipment operated improperly or by untrained personnel can be dangerous. Read the operating instructions contained in both this manual and the ...

Page 8: Safety Information

Safety information pts 4v / ptk 4 wc_si000130gb.Fm 6 2.2.13 always store the equipment properly when it is not being used. Equipment should be stored in a clean, dry location out of the reach of children. 2.2.14 always wear hearing protection when operating equipment. 2.3 operator safety while using...

Page 9: Pts 4V / Ptk 4

Pts 4v / ptk 4 safety information wc_si000130gb.Fm 7 2.4 service safety poorly maintained equipment can become a safety hazard! In order for the equipment to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. 2.4.1 do not attempt to cle...

Page 10: Safety Information

Safety information pts 4v / ptk 4 wc_si000130gb.Fm 8 2.5 label locations wc_gr001479 precaution precaucion vorsicht caution.

Page 11: Pts 4V / Ptk 4

Pts 4v / ptk 4 safety information wc_si000130gb.Fm 9 2.6 safety labels wacker machines use international pictorial labels where needed. These labels are described below: label meaning danger! Engines emit carbon monoxide; operate only in well-ventilated area. Read the operator’s manual. No sparks, f...

Page 12: Safety Information

Safety information pts 4v / ptk 4 wc_si000130gb.Fm 10 guaranteed sound power level in db(a) key switch: off on start throttle control lever: rabbit = full or fast turtle = idle or slow a nameplate listing the model number, item num- ber, revision number, and serial number is attached to each unit. P...

Page 13: Pts 4V / Ptk 4

Pts 4v / ptk 4 technical data wc_td000132gb.Fm 11 3. Technical data 3.1 engine item no. Pts 4v 0007683 rev 115 & lower 0007691 rev 116 & lower 0007692 pts 4v 0007683 rev 116 & higher 0007691 rev 117 & higher engine engine make briggs and stratton engine model vanguard 303447- 1256-e2 vanguard 305447...

Page 14: Technical Data

Technical data pts 4v / ptk 4 wc_td000132gb.Fm 12 3.2 pump item number: pts 4v 0007683, 0007691, 0007692 pump weight kg (lbs.) 163 (360) *max. Suction lift m (ft.) 7.5 (25) max. Total head m (ft.) 32 (106) mechanical seal lubrication oil grade ml (oz.) sae 30 150 (5) suction / discharge diameter mm ...

Page 15: Pts 4V / Ptk 4

Pts 4v / ptk 4 technical data wc_td000132gb.Fm 13 3.3 sound measurements the required sound specifications per appendix 1, paragraph 1.7.4 of the ec-machine regulations, is: • the guaranteed sound power level (l wa ) = 104 db(a) these sound values were determined according to iso 3744 for the sound ...

Page 16: Operation

Operation pts 4v / ptk 4 wc_tx000339gb.Fm 14 4. Operation 4.1 application this pump is intended for removing clean water and water containing some debris and solids. Refer to “technical data” for maximum solid size. 4.1.1 never pump volatile, flammable or low flash point fluids. These fluids could i...

Page 17: Pts 4V / Ptk 4

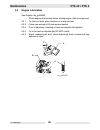

Pts 4v / ptk 4 operation wc_tx000339gb.Fm 15 4.3.5 check that hoses are securely attached to pump. Suction hose (b) must not have any air leaks. Tighten hose clamps (c) and couplings (d). Check that discharge hose (e) is not restricted. Lay hose out as straight as possible. Remove any twists or shar...

Page 18: Operation

Operation pts 4v / ptk 4 wc_tx000339gb.Fm 16 4.4 to start see graphic: wc_gr001480 follow the instructions below and read starting and stopping instuctions found in the engine owner’s manual. 4.4.1 open the fuel valve (b1). 4.4.2 if the engine is cold, pull out the choke control (a1). If the engine ...

Page 19: Pts 4V / Ptk 4

Pts 4v / ptk 4 operation wc_tx000339gb.Fm 17 4.5 to stop see graphic: wc_gr001480 4.5.1 reduce engine rpm by moving the throttle completely to the idle position (c2). 4.5.2 turn the engine switch to the stop position (d1). 4.5.3 close the fuel valve (b2). 4.6 operation pump should begin pumping wate...

Page 20: Operation

Operation pts 4v / ptk 4 wc_tx000339gb.Fm 18 4.8 accessories wacker offers a complete line of fittings, hoses, and clamps to properly connect the pump to match various job conditions. 4.9 hoses and clamps see graphic: wc_gr000021 suction hoses (a) must be rigid enough not to collapse when pump is op...

Page 21: Pts 4V / Ptk 4

Pts 4v / ptk 4 maintenance wc_tx000340gb.Fm 19 5. Maintenance 5.1 periodic maintenance schedule the chart below lists basic machine and engine maintenance. Refer to the engine manufacturer’s operator’s manual for additional information on engine maintenance. Daily before starting after first 5 hrs. ...

Page 22: Maintenance

Maintenance pts 4v / ptk 4 wc_tx000340gb.Fm 20 5.2 engine lubrication see graphic: wc_gr000562 check engine oil level daily before starting engine. Add oil as required. 5.2.1 to check oil level, place machine on a level surface. 5.2.2 clean area around oil fill and remove dipstick. 5.2.3 pour oil (a...

Page 23: Pts 4V / Ptk 4

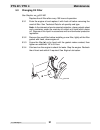

Pts 4v / ptk 4 maintenance wc_tx000340gb.Fm 21 5.3 changing oil filter see graphic: wc_gr001482 replace the oil filter after every 100 hours of operation. 5.3.1 drain the engine oil and replace it with fresh oil before removing the used oil filter. See technical data for oil quantity and type. Note:...

Page 24: Maintenance

Maintenance pts 4v / ptk 4 wc_tx000340gb.Fm 22 5.4 air cleaner see graphic: wc_gr000564 service air cleaner frequently to prevent carburetor malfunction. Caution: never run the engine without the air cleaner. Severe engine damage will occur. Never use gasoline or other types of low flash point solve...

Page 25: Pts 4V / Ptk 4

Pts 4v / ptk 4 maintenance wc_tx000340gb.Fm 23 5.5 spark plug see graphic: wc_gr000028 clean or replace the spark plug as needed to ensure proper operation. Refer to the engine owner’s manual. The muffler becomes very hot during operation and remains hot for a while after stopping the engine. Do not...

Page 26: Maintenance

Maintenance pts 4v / ptk 4 wc_tx000340gb.Fm 24 5.6 fuel filter see graphic: wc_gr001483 5.6.1 change in-line fuel filter (a) once a year. 5.6.2 check fuel lines and fittings frequently for cracks or leaks. Replace as needed. Allow engine to cool and close fuel valve before replacing fuel filter. 5.7...

Page 27: Pts 4V / Ptk 4

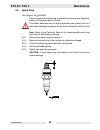

Pts 4v / ptk 4 maintenance wc_tx000340gb.Fm 25 5.8 mechanical seal lubrication see graphic: wc_gr001484 change seal lubricant every 50 hours using sae 30w oil. 5.8.1 remove plugs (a) from both sides of pump housing for venting. 5.8.2 remove bottom plug (b) and allow oil to drain from oil cavity. 5.8...

Page 28: Maintenance

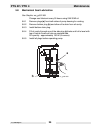

Maintenance pts 4v / ptk 4 wc_tx000340gb.Fm 26 5.9 adjusting impeller clearance see graphic: wc_gr001485 if it is necessary to replace impeller or volute insert, be sure clearance between impeller and insert is adjusted correctly. The impeller (e) should be as close to the insert (a) as possible wit...

Page 29: Pts 4V / Ptk 4

Pts 4v / ptk 4 maintenance wc_tx000340gb.Fm 27 5.10 cleaning pump see graphic: wc_gr001486 after pumping water containing a large amount of dirt or debris, clean out inside of pump housing. 5.10.1 remove drain plug (a) from pump housing and drain any water left in pump. 5.10.2 loosen the four knobs ...

Page 30: Maintenance

Maintenance pts 4v / ptk 4 wc_tx000340gb.Fm 28 5.11 storage if pump is being stored for more than 30 days: never open priming plug, discharge plug, or cover when pump is hot. 5.11.1 remove discharge plug from pump casing and drain out any water left in the housing after pump has cooled. 5.11.2 remov...

Page 31: Pts 4V / Ptk 4

Pts 4v / ptk 4 maintenance wc_tx000340gb.Fm 29 5.13 troubleshooting problem / symptom reason / remedy pump does not take in water. • not enough priming water in housing. • engine speed too low. Adjust speed. • strainer plugged. Clean strainer. • suction hose damaged. Replace or repair hose. • air le...

Page 32: Maintenance

Maintenance pts 4v / ptk 4 wc_tx000340gb.Fm 30 notes.

Page 45

2005-ce-pts4v-q.Fm william lahner dan domanski vice president of engineering manager, product engineering wacker corporation date / datum / fecha / date ec declaration of conformity ce-konformitÄtserklÄrung declaraciÓn de conformidad de la ce dÉclaration de conformitÉ c.E. Wacker corporation, n92 w1...

Page 46

Wacker construction equipment ag · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02 - 0 · fax: +49 - (0)89-3 54 02-3 90 wacker corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker asia pacific operations...