- DL manuals

- Wacker Neuson

- Power Tool

- PV 35A

- Operator's Manual

Wacker Neuson PV 35A Operator's Manual

Summary of PV 35A

Page 1

Handheld gas vibrator pv 35a operator’s manual 0171882en 002 0708 0 1 7 1 8 8 2 e n.

Page 3: Table of Contents

Table of contents pv 35a wc_bo0171882en_002toc.Fm 3 1. Foreword 4 2. Safety information 5 2.1 laws pertaining to spark arresters .......................................................5 2.2 operating safety ...................................................................................6 2.3 oper...

Page 4: Foreword

Foreword wc_tx000001gb.Fm 4 california proposition 65 warning: engine exhaust, some of its constituents, and certain vehicle components, contain or emit chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. 1 foreword this manual provides informatio...

Page 5: Safety Information

Safety information pv 35a wc_si000224gb.Fm 5 2. Safety information this manual contains danger, warning, caution, notice and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is used to...

Page 6: Pv 35A

Pv 35a safety information wc_si000224gb.Fm 6 2.2 operating safety familiarity and proper training are required for the safe operation of the machine. Machines operated improperly or by untrained personnel can be dangerous. Read the operating instructions contained in both this manual and the engine ...

Page 7: Safety Information

Safety information pv 35a wc_si000224gb.Fm 7 2.3 operator safety while using internal combustion engines internal combustion engines present special hazards during operation and fueling. Read and follow the warning instructions in the engine owner’s manual and the safety guidelines below. Failure to...

Page 8: Pv 35A

Pv 35a safety information wc_si000224gb.Fm 8 2.4 service safety a poorly maintained machine can become a safety hazard! In order for the machine to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. 2.4.1 do not attempt to clean or serv...

Page 9: Safety Information

Safety information pv 35a wc_si000224gb.Fm 9 notes:.

Page 10: Pv 35A

Pv 35a safety information wc_si000224gb.Fm 10 2.5 label locations wc_gr004853.

Page 11: Safety Information

Safety information pv 35a wc_si000224gb.Fm 11 2.6 warning and informational labels wacker neuson machines use international pictorial labels where needed. These labels are described below: label meaning danger! Engines emit carbon monoxide; operate only in well-ventilated area. Read the operator’s m...

Page 12: Pv 35A

Pv 35a operation wc_tx000754gb.Fm 12 3. Operation 3.1 application this machine is intended for on-site vibration of concrete for foundations, walls, columns, slab work, etc. The self-contained design allows free movement about the jobsite without the restrictions of an electrical cord. 3.2 recommend...

Page 13: Operation

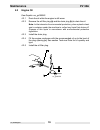

Operation pv 35a wc_tx000754gb.Fm 13 3.4 stopping the engine see graphic: wc_gr004492 3.4.1 reduce engine rpm to idle by moving throttle completely to right. 3.4.2 turn engine switch to off (d2) . D1 d2 wc_gr004492.

Page 14: Pv 35A

Pv 35a operation wc_tx000754gb.Fm 14 3.5 operating the machine the pv 35a vibrator features a unique pendulous design. This design causes the vibrator to rattle and possibly feel off-center in rotation. This is normal; the vibrator is not broken or damaged. To prepare the machine for operation: see ...

Page 15: Operation

Operation pv 35a wc_tx000754gb.Fm 15 operating tips: 3.5.1 never turn the vibrator off while it is submerged in the concrete. 3.5.2 during use, insert the head quickly into the mix and then pull it out slowly. Rapid removal is the main cause of poor concrete consolidation. For best results, submerge...

Page 16: Pv 35A

Pv 35a operation wc_tx000754gb.Fm 16 3.7 tumble cage accessory see graphic: wc_gr004867 an optional “tumble cage” assembly is available to protect the unit from accidental dropping. The cage is not intended to protect the unit from misuse, mishandling, or abuse. Contact your wacker neuson dealer for...

Page 17: Operation

Operation pv 35a wc_tx000754gb.Fm 17 notes:.

Page 18: Pv 35A

Pv 35a maintenance wc_tx000755gb.Fm 18 4. Maintenance 4.1 periodic maintenance schedule the chart below lists basic machine and engine maintenance. Refer to your engine operator’s manual for additional information on engine maintenance. Daily before starting after first 10 hrs. After first 25 hrs. E...

Page 19: Maintenance

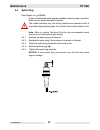

Maintenance pv 35a wc_tx000755gb.Fm 19 4.2 engine oil see graphic: wc_gr000020 4.2.1 drain the oil while the engine is still warm. 4.2.2 remove the oil filler plug (a) and the drain plug (b) to drain the oil. Note: in the interests of environmental protection, place a plastic sheet and a container u...

Page 20: Pv 35A

Pv 35a maintenance wc_tx000755gb.Fm 20 4.3 air cleaner see graphic: wc_gr004366 the engine is equipped with a foam element air cleaner. Service the air cleaner frequently to prevent carburetor malfunction. Notice: never run engine without the air cleaner. Severe engine damage will occur. Never use g...

Page 21: Maintenance

Maintenance pv 35a wc_tx000755gb.Fm 21 4.4 spark plug see graphic: wc_gr000028 clean or replace the spark plug as needed to ensure proper operation. Refer to your engine operator’s manual. The muffler becomes very hot during operation and remains hot for a while after stopping the engine. Do not tou...

Page 22: Pv 35A

Pv 35a maintenance wc_tx000755gb.Fm 22 4.5 head and shaft disassembly see graphic: wc_gr005377 4.5.1 disassembling the flexible casing and core: 4.5.1.1 place the vibrator head assembly (a) in a vise equipped with a set of “v” jaws. 4.5.1.2 unscrew the casing assembly (b) from the vibrator head asse...

Page 23: Maintenance

Maintenance pv 35a wc_tx000755gb.Fm 23 4.5.2 lubricating the core assembly: 4.5.2.1 a light coat of grease (i.E. Dubois tpg, wacker neuson part number 0161045) should be applied to the entire length of the core assembly. Apply grease to the core assembly at least twice a year. 4.5.3 disassembling th...

Page 24: Pv 35A

Pv 35a maintenance wc_tx000755gb.Fm 24 see graphic: wc_gr005377 4.5.5 disassembling the eccentric assembly: 4.5.5.1 place the bearing case (l) in a standard vise with the male threads positioned upward. 4.5.5.2 using a hammer, gently tap the upper portion of the eccentric weight (t) . Note: place yo...

Page 25: Maintenance

Maintenance pv 35a wc_tx000755gb.Fm 25 4.5.7 maintenance notes: 4.5.7.1 bearing (v) and oil seal (x) should be replaced after 200 hours of use. The bearing must be greased with orelube g- 1/3 grease or equivalent. 4.5.7.2 inspect the angled end of the eccentric weight (t) for wear. If visible wear i...

Page 26: Pv 35A

Pv 35a maintenance wc_tx000755gb.Fm 26 4.6 storage if power unit is to be stored for more than 30 days: 4.6.1 change engine oil and follow procedures described in engine manual for engine storage. 4.6.2 clean entire power unit and engine. 4.6.3 cover entire machine and store in a clean, dry area. 4....

Page 27: Technical Data

Technical data pv 35a wc_td000226gb.Fm 27 5. Technical data 5.1 engine engine power rating net power rating per sae j1349. Actual power output may vary due to conditions of specific use. Part no. Pv 35a 0620401 engine engine type 4-stroke, overhead valve, single cylinder engine make honda engine mod...

Page 28: Pv 35A

Pv 35a technical data wc_td000226gb.Fm 28 5.2 power unit 5.3 sound and vibration data the required sound specification, paragraph 1.7.4.F of 89/392/eec machinery directive, is: • the sound pressure level at operator’s location (l pa ) = 92.0 db(a) • the guaranteed sound power level (l wa ) =104.3 db...

Page 30

Wacker construction equipment ag · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02 - 0 · fax: +49 - (0)89-3 54 02-3 90 wacker neuson corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker asia pacific ope...