- DL manuals

- Wacker Neuson

- Power Roller

- RD 27-100

- Operator's Manual

Wacker Neuson RD 27-100 Operator's Manual

Summary of RD 27-100

Page 1

Operator’s manual roller rd 27-100 rd 27-120 0171754en 003 1109 0 1 7 1 7 5 4 e n.

Page 2

Copyright notice © copyright 2009 by wacker neuson corporation. All rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permission from wack...

Page 3: Rd 27

Rd 27 foreword wc_tx000836gb.Fm 3 foreword machines covered in this manual machine documentation keep a copy of the operator’s manual with the machine at all times. Use the separate parts book supplied with the machine to order replacement parts. Refer to the separate repair manual for detailed inst...

Page 4: Foreword

Foreword rd 27 4 wc_tx000836gb.Fm california proposition 65 warning: engine exhaust, some of its constituents, and certain vehicle components, contain or emit chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. Laws pertaining to spark arresters n...

Page 5: Rd 27

Rd 27 table of contents wc_bo0171754en_003toc.Fm 5 foreword 3 1 safety information 9 1.1 signal words found in this manual ...................................................... 9 1.2 machine description and intended use ............................................. 10 1.3 safety guidelines for oper...

Page 6: Table of Contents

Table of contents rd 27 6 wc_bo0171754en_003toc.Fm 4.22 preliminary checks .............................................................................45 4.23 mounting and dismounting the machine .............................................45 4.24 starting the engine .................................

Page 7: Rd 27

Rd 27 table of contents wc_bo0171754en_003toc.Fm 7 5.34 cleaning the hydraulic oil strainer .................................................... 88 5.35 cleaning the radiator filler cap ........................................................ 89 5.36 checking the engine water pump .....................

Page 8: Table of Contents

Table of contents rd 27 8 wc_bo0171754en_003toc.Fm.

Page 9: Rd 27

Rd 27 safety information wc_si000247gb.Fm 9 1 safety information 1.1 signal words found in this manual this manual contains danger, warning, caution, notice, and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. Notice: u...

Page 10: Safety Information

Safety information rd 27 10 wc_si000247gb.Fm 1.2 machine description and intended use this machine is a dual drum, ride-on roller. The wacker neuson ride-on roller consists of an articulated frame onto which is mounted a gasoline or diesel engine, a fuel tank, a hydraulic tank, a water tank, a hydro...

Page 11: Rd 27

Rd 27 safety information wc_si000247gb.Fm 11 1.3 safety guidelines for operating the machine operator qualifications only trained personnel are permitted to start, operate, and shut down the machine. They also must meet the following qualifications: have received instruction on how to properly use t...

Page 12: Safety Information

Safety information rd 27 12 wc_si000247gb.Fm safe operating practices when operating this machine: always remain seated and wear the seat belt at all times while operating the machine. Remain aware of changing positions and the movement of other equipment and personnel on the job site. Be sure that ...

Page 13: Rd 27

Rd 27 safety information wc_si000247gb.Fm 13 1.4 safety guidelines while using internal combustion engines operating safety when running the engine: keep the area around exhaust pipe free of flammable materials. Check the fuel lines and the fuel tank for leaks and cracks before starting the engine. ...

Page 14: Safety Information

Safety information rd 27 14 wc_si000247gb.Fm 1.5 guidelines for service safety personal protective equipment (ppe) wear the following personal protective equipment (ppe) while servicing or maintaining this machine: close-fitting work clothes that do not hinder movement safety glasses with side shiel...

Page 15: Rd 27

Rd 27 safety information wc_si000247gb.Fm 15 lifting and transporting when lifting the machine: make sure slings, chains, hooks, ramps, jacks and other types of lifting devices are attached securely and have enough weight-bearing capacity to lift or hold the machine safely. Remain aware of the locat...

Page 16: Labels

Labels rd 27 16 wc_si000393gb.Fm 2 labels 2.1 label locations a k p s n v x n v t f d g g g r d g f g q i o d f w c k b u h l m j wc_gr005053.

Page 17: Rd 27

Rd 27 labels wc_si000393gb.Fm 17 2.2 safety and warning labels ref. Label definition b danger! Read and understand the supplied operator's manuals before operating this machine. Failure to do so increases the risk of injury to yourself and others. Do not run the machine indoors or in an enclosed are...

Page 18: Labels

Labels rd 27 18 wc_si000393gb.Fm f warning! Avoid crushing area. H warning! Disconnect battery before servicing. Read repair manual. Explosion hazard. Batteries can emit explo- sive hydrogen gas. Keep all sparks and flames away from the battery. L warning! Pinching hazard. Rotating machinery. M warn...

Page 19: Rd 27

Rd 27 labels wc_si000393gb.Fm 19 n warning! Avoid crushing area. S warning! Do not drill or weld the rops. Read the operator’s manual. T warning! Avoid crushing area. Articulated steering joint locking location. Lock the articulated steering joint before ser- vicing the machine. Read repair manual. ...

Page 20: Labels

Labels rd 27 20 wc_si000393gb.Fm 2.3 informational labels ref. Label definition a operator’s manual must be stored on machine. Replacement operator’s manual can be ordered through your local wacker neuson distributor. E a nameplate listing the model number, item number, revision number, and serial n...

Page 21: Rd 27

Rd 27 labels wc_si000393gb.Fm 21 k water tank fill. O engine oil drain. P key switch positions. Power to glowplugs. Engine stopped (off). Engine on. Power to starter motor. Q throttle lever positions. High speed. Low speed. Ref. Label definition engine oil motoroel aceite de motor huile À moteurs st...

Page 22: Labels

Labels rd 27 22 wc_si000393gb.Fm r vibration activation and deactivation switch. Forward/reverse lever positions. U fuse identifications. V tighten screw to reduce vibration. Read operator’s manual. W guaranteed sound power level in db(a). X rops certification label y biodegradable hydraulic oil res...

Page 23: Rd 27

Rd 27 lifting and transporting wc_tx001351gb.Fm 23 3 lifting and transporting 3.1 lifting the machine prerequisites lifting equipment (crane or hoist) capable of supporting 2722 kgs. (6000 lbs.) four lifting hooks and chains capable of supporting 2722 kgs. (6000 lbs.) procedure follow the procedure ...

Page 24: Lifting and Transporting

Lifting and transporting rd 27 24 wc_tx001351gb.Fm 3.2 tying down/transporting the machine prerequisites engine shut down parking brake on procedure follow the procedure below to tie down the machine. 1. Make sure that the transport vehicle is capable of handling the weight and size of the machine. ...

Page 25: Rd 27

Rd 27 operation wc_tx000814gb.Fm 25 4 operation 4.1 preparing the machine for first use preparing for first use to prepare your machine for first use: 1. Make sure all loose packaging materials have been removed from the machine. 2. Check the machine and its components for damage. If there is visibl...

Page 26: Operation

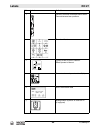

Operation rd 27 26 wc_tx000814gb.Fm 4.3 operation & maintenance locations ref. Description ref. Description a throttle lever l vibration mode switch b ignition key block m vibration on/off switch c alternator warning light n water pump switch d engine oil pressure warning light o engine temperature ...

Page 27: Rd 27

Rd 27 operation wc_tx000814gb.Fm 27 wc_gr005016 v p a f 10 2 4 5 12 3 10 10 10 6 8 m 9 1 11 7 t n l g j b k r w q i u s c h o d e.

Page 28: Operation

Operation rd 27 28 wc_tx000814gb.Fm 4.4 unlocking/locking the articulated joint locking install the articulated steering joint pin in the locked position (a) before you lift the machine, transport the machine, or perform maintenance near the center of the machine. Unlocking install the articulated s...

Page 29: Rd 27

Rd 27 operation wc_tx000814gb.Fm 29 4.5 using the roll over protection structure (rops) background the machine is equipped with a roll over protection structure (rops). The rops is designed to protect the operator in a rollover accident. Positioning follow the procedure below to position the rops in...

Page 30: Operation

Operation rd 27 30 wc_tx000814gb.Fm checking each month, check: the torque on all of the screws holding the rops in place the rops frame for rust, cracks, and any other damage rules for re- installing when reinstalling the rops: use the original nuts and bolts. Use oil to lubricate the bolts before ...

Page 31: Rd 27

Rd 27 operation wc_tx000814gb.Fm 31 4.7 using the seat belt precaution always use the seat belt when operating the machine. To use to use the seat belt: 1. Pull seat belt (c) out of the retractor in a continuous motion. 2. Fasten seat belt catch (b) into buckle (a). 3. Position the seat belt low acr...

Page 32: Operation

Operation rd 27 32 wc_tx000814gb.Fm 4.8 adjusting the seat background adjust the seat position and tension (firmness) according to working conditions and operator’s weight. To adjust the seat can be adjusted in three ways: tension use knob (a) for adjusting seat tension. Turn from a minimum of 60 kg...

Page 33: Rd 27

Rd 27 operation wc_tx000814gb.Fm 33 4.9 adjusting the steering column background adjust the angle of the steering column according to working conditions and the operator’s height and personal preference. To adjust the angle of the steering column can be adjusted as follows: 1. Loosen the four mounti...

Page 34: Operation

Operation rd 27 34 wc_tx000814gb.Fm 4.11 using the anti-vandalism protection devices background parts of the machine may be subject to theft or vandalism when the machine is unattended. These parts can be locked to prevent unauthorized access or use. Lockable parts include: engine cover control cons...

Page 35: Rd 27

Rd 27 operation wc_tx000814gb.Fm 35 4.12 using the water spray system switch positions water from the tank is fed to the spray nozzles by an electric pump. The switch controls the water pump motor. The switch has three positions: guidelines when using when using the water spray system: check that th...

Page 36: Operation

Operation rd 27 36 wc_tx000814gb.Fm 4.13 using the forward/reverse lever background both roller drums are driven. An infinitely variable displacement pump and hydrostatic transmission drive the hydraulic motors fitted to each drum. The machine moves forward or reverse by using the forward/reverse le...

Page 37: Rd 27

Rd 27 operation wc_tx000814gb.Fm 37 4.14 backup alarm location the backup alarm (e) is located on the rear of the machine. Operation start the engine and move the forward-reverse lever to the reverse position. The backup alarm should sound immediately. The backup alarm will continue to sound until t...

Page 38: Operation

Operation rd 27 38 wc_tx000814gb.Fm 4.15 using the flow divider (if equipped) background this machine may be equipped with an optional flow divider. Non-uniform soil conditions, such as a combination of loose sandy material and large particles, may cause the drums to rotate at unequal speeds. This m...

Page 39: Rd 27

Rd 27 operation wc_tx000814gb.Fm 39 4.16 using the vibration system background the machine has an exciter on each drum. The exciters are driven by gear-type hydraulic motors. The exciter motors are fed by a fixed-displacement, gear-type hydraulic pump. Vibration mode switch vibration on-off switch f...

Page 40: Operation

Operation rd 27 40 wc_tx000814gb.Fm 4.17 using the parking brakes background to aid in holding the machine in a stopped position (parked), there is a mechanical parking brake on each drum drive motor. The mechanical parking brakes are spring-activated and hydraulically released (sahr) type brakes. T...

Page 41: Rd 27

Rd 27 operation wc_tx000814gb.Fm 41 4.18 warning lights warning light description action required engine oil pressure this light (d) illuminates when the key switch is in the on position; it goes out once the engine has started, if engine oil pres- sure is ok. Turn off the engine immedi- ately if th...

Page 42: Operation

Operation rd 27 42 wc_tx000814gb.Fm 4.19 using the lights and horn background the rotary switch on the control panel controls power to the machine’s lights. Identifying the lights headlights (a) working light (b) front turn signal lights / roading lights (c) rear turn signal lights / roading lights ...

Page 43: Rd 27

Rd 27 operation wc_tx000814gb.Fm 43 4.20 machine stability surface conditions pay attention to changing surface conditions while operating the machine. Adjust speed and travel direction as necessary to maintain safe operation. Machine stability and traction may be severely reduced when operating on ...

Page 44: Operation

Operation rd 27 44 wc_tx000814gb.Fm 4.21 operating on slopes background when operating on slopes or hills, special care must be taken to reduce the risk of personal injury or damage to the machine. Procedure always operate the machine up and down slopes rather than from side to side. For safe operat...

Page 45: Rd 27

Rd 27 operation wc_tx000814gb.Fm 45 4.22 preliminary checks prerequisites machine on a flat, level surface before starting before starting the machine, check the following items: engine coolant level engine oil level engine air filter indicator hydraulic oil level diesel fuel level condition of oil ...

Page 46: Operation

Operation rd 27 46 wc_tx000814gb.Fm 4.24 starting the engine procedure follow the procedure below to start the engine. 1. Sit down in the operator’s seat and fasten the seat belt. 2. Move the forward/reverse (f) lever to the neutral position. 3. Push the parking brake push button (h) to engage the p...

Page 47: Rd 27

Rd 27 operation wc_tx000814gb.Fm 47 4.25 stopping the engine prerequisites flat surface with a suitable load-bearing capacity procedure follow the procedure below to stop the engine. 1. Stop the machine on a flat surface with a suitable load bearing capacity. 2. Move the forward/reverse (f) lever to...

Page 48: Operation

Operation rd 27 48 wc_tx000814gb.Fm 4.26 understanding the operator present system background the machine is equipped with an operator present system. This system prevents machine movement if the operator is not seated in the operator’s seat. The system includes the seat switch and the neutral switc...

Page 49: Rd 27

Rd 27 operation wc_tx000814gb.Fm 49 notes:.

Page 50: Maintenance

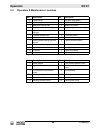

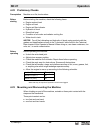

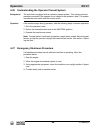

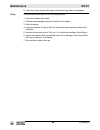

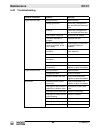

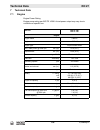

Maintenance rd 27 50 wc_tx000815gb.Fm 5 maintenance 5.1 periodic maintenance schedule tasks designated with check marks may be performed by the operator. Tasks designated with square bullet points require special training and equipment. Interval* (hours of service) (10) (100) (250) (500) (1000) (300...

Page 51: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 51 * use whichever comes first, calendar time or service hours. Exciter shaft bearings re-pack fuel system water separa- tor element replace 3 fuel tank cap and strainer clean 3 hydraulic oil filter change 3 radiator/hydraulic oil cooler clean 3 shock mounts check ...

Page 52: Maintenance

Maintenance rd 27 52 wc_tx000815gb.Fm 5.2 major component locations 1 2 3 4 5 6 7 8 11 12 13 8 14 15 16 17 4 10 9 wc_gr005054.

Page 53: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 53 5.3 major components ref. Description ref. Description 1 forward/reverse lever 10 seat switch solenoid 2 hydraulic tank 11 hydraulic oil filter 3 oil cooler 12 suction strainer 4 front vibration motor 13 suction strainer 5 steering cylinder 14 drive pump 6 steer...

Page 54: Maintenance

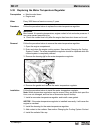

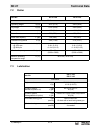

Maintenance rd 27 54 wc_tx000815gb.Fm 5.4 safety-related spare parts overview this machine is equipped with several features to enhance operator safety. These include the rops, the seat belt, and the operator presence switch. For your convenience, we have provided the following diagrams and lists of...

Page 55: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 55 rops parts list ref. Part no. Qty. Description measurement 1 0161542 4 screw 2 0161617 2 shim 4 0162243 2 control lever 5 0174257 1 rops frame 7 0161769 1 label—warning 8 0162357 2 label 9 0162007 2 nut m16 x 2 10 0162011 2 bolt m16 x 2 11 0162017 4 bolt m16 x 2...

Page 56: Maintenance

Maintenance rd 27 56 wc_tx000815gb.Fm seat assembly diagram wc_gr007044.

Page 57: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 57 seat assembly parts list ref. Part no. Qty. Description measurement 1 0161620 1 skirt replacement kit 2 0161621 1 seat slide kit 3 0161622 1 indicator kit 4 0161744 1 adjustable seat kit 5 0161853 1 seat switch kit 6 0161855 1 seat 7 0161854 1 arm rest kit 8 016...

Page 58: Maintenance

Maintenance rd 27 58 wc_tx000815gb.Fm seat switch diagram wc_gr007045.

Page 59: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 59 seat switch parts list 5.5 maintaining the seat and seat belt background in order for the seat and seat belt to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. Poorly maintained equipment can bec...

Page 60: Maintenance

Maintenance rd 27 60 wc_tx000815gb.Fm 5.6 checking the air filter indicator prerequisites engine running parking brake on when every 10 hours of service or daily l procedure follow the procedure below to check the air filter indicator. 1. Open the engine compartment. 2. Start the engine. 3. Place th...

Page 61: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 61 5.7 cleaning the air cleaner and primary air filter element prerequisites machine shut down source of clean, dry, and low-pressure (less than 207 kpa (30 psi)) compressed air background the air intake system is equipped with a filter indicator (a), which indicat...

Page 62: Maintenance

Maintenance rd 27 62 wc_tx000815gb.Fm 5.8 changing the air filter elements prerequisites machine shut down new primary air filter element new secondary air filter element if required notice: do not use the air filters as a starting aid (e.G., ether) intake. Primary filter element follow the procedur...

Page 63: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 63 continued from the previous page. 6. Install the new primary air filter element. 7. Replace the cover (b). Position it so that the breather (d) is not obstructed. 8. Reset the filter indicator (a). 5.9 testing the backup alarm background the backup alarm is loca...

Page 64: Maintenance

Maintenance rd 27 64 wc_tx000815gb.Fm 5.10 checking the engine coolant level prerequisites machine shut down engine cool when every 10 hours of service or daily l procedure follow the procedure below to check the engine coolant level. 1. Open the engine compartment. 2. Open the radiator filler cap (...

Page 65: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 65 5.11 checking the engine oil prerequisites park the machine on a level surface shut down the machine apply the parking brake when every 10 hours of service or daily procedure follow the procedure below to check the engine oil. 1. Clean around the dipstick (a). 2...

Page 66: Maintenance

Maintenance rd 27 66 wc_tx000815gb.Fm 5.12 checking hydraulic oil level prerequisites machine shut down hydraulic oil warm when every 10 hours of service or daily l procedure follow the procedure below to check the hydraulic oil level. 1. Open the engine compartment. 2. Observe the hydraulic oil lev...

Page 67: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 67 5.13 checking the neutral switch prerequisites parking brake engaged when every 10 hours of service or daily procedure follow the procedure below to check the neutral switch. 1. Turn off the engine. 2. Engage the parking brake. 3. Move the forward/reverse lever ...

Page 68: Maintenance

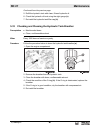

Maintenance rd 27 68 wc_tx000815gb.Fm 5.14 adjusting the scraper bars prerequisites machine shut down parking brake engaged when every 10 hours of service or daily l procedure follow the procedure below to adjust the scraper bars. 1. Loosen the bolts (a). 2. Adjust the scraper so that it touches the...

Page 69: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 69 5.15 inspecting the seat belt prerequisites machine shut down parking brake engaged when daily, before starting the machine. L procedure follow the procedure below to inspect the seat belt. 1. Check the seat belt mounting hardware (a) for wear and damage. Replac...

Page 70: Maintenance

Maintenance rd 27 70 wc_tx000815gb.Fm 5.16 cleaning the water spray nozzles prerequisites machine shut down clean, nonflammable solvent when every 10 hours of service or daily l procedure follow the procedure below to clean the water spray nozzles. 1. Locate the water spray nozzles. 2. Remove the ca...

Page 71: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 71 5.17 cleaning the water spray system filter prerequisites machine shut down water spray system shutoff valve in closed position when every 10 hours of service or daily l procedure follow the procedure below to clean the water spray system filter. 1. Locate the w...

Page 72: Maintenance

Maintenance rd 27 72 wc_tx000815gb.Fm 5.18 cleaning and changing the fuel filter/water separator prerequisites machine shut down new filter when drain every 100 hours; change element every 500 hours draining water separator follow the procedure below to drain the fuel/water separator. 1. Open the en...

Page 73: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 73 5.19 priming the fuel system prerequisites machine shut down engine cool l procedure follow the procedure below to prime the fuel system. 1. Open the engine compartment. 2. Locate the fuel filter/water separator. 3. Push the plunger (a) to fill the filter elemen...

Page 74: Maintenance

Maintenance rd 27 74 wc_tx000815gb.Fm 5.20 draining water and sediment from the fuel tank prerequisites machine shut down suitable container when every 100 hours of service or every 2 weeks l procedure follow the procedure below to drain water and sediment from the fuel tank. 1. Locate the drain plu...

Page 75: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 75 5.21 cleaning the water tank strainer prerequisites machine shut down when every 100 hours of service or every 2 weeks l procedure follow the procedure below to clean the water tank strainer. 1. Remove the filler cap (a). 2. Remove the water tank strainer (b). 3...

Page 76: Maintenance

Maintenance rd 27 76 wc_tx000815gb.Fm 5.22 adjusting alternator belt tension prerequisites machine shut down engine cool when every 250 hours of service or every 3 months l procedure follow the procedure below to inspect the alternator belt. 1. Open the engine compartment. 2. Remove the fan guard an...

Page 77: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 77 5.23 lubricating the articulated steering joint prerequisites grease gun machine shut down when every 250 hours of service or every 3 months l procedure follow the procedure below to lubricate the articulated steering joint. 1. Clean the fitting caps. 2. Clean t...

Page 78: Maintenance

Maintenance rd 27 78 wc_tx000815gb.Fm 5.24 lubricating the steering cylinder prerequisites machine shut down grease gun when every 250 hours of service or every 3 months l procedure follow the procedure below to lubricate the steering cylinder. One end (a) of the steering cylinder is located in the ...

Page 79: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 79 5.25 testing the brake system prerequisites 15° slope when every 500 hours of service or yearly l precaution use this test to determine if the parking brake is functioning on the specified slope. This test is not intended to measure the maximum brake holding eff...

Page 80: Maintenance

Maintenance rd 27 80 wc_tx000815gb.Fm 5.26 changing the engine oil and filter prerequisites engine warm 15w40 engine oil and new filter when every 500 hours of service or yearly procedure follow the procedure below to change the engine oil. 1. Open the engine hood. 2. Locate the engine oil drain hos...

Page 81: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 81 continued from the previous page. 12.Stop the engine and make the following checks: check the oil level and top off if necessary. Check the new filter for leaks. 5.27 cleaning the fuel tank cap and fuel strainer prerequisites machine shut down clean, nonflammabl...

Page 82: Maintenance

Maintenance rd 27 82 wc_tx000815gb.Fm 5.28 changing the hydraulic oil filter prerequisites hydraulic oil filter strap-type wrench suitable container machine parked on a flat, level surface when every 500 hours of service or yearly l procedure follow the procedure below to change the hydraulic oil. N...

Page 83: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 83 5.29 cleaning the hydraulic oil cooler prerequisites machine shut down parking brake engaged when every 500 hours of service or yearly l procedure follow the procedure below to clean the hydraulic oil cooler. 1. Open the engine compartment. 2. Locate the hydraul...

Page 84: Maintenance

Maintenance rd 27 84 wc_tx000815gb.Fm 5.30 disconnecting/connecting the battery dispose of dead batteries in accordance with local environmental regulations. Disconnecting to disconnect the battery: 1. Stop the machine and shut down the engine. 2. Place all electrical switches in the off position. 3...

Page 85: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 85 5.31 adjusting the forward/reverse lever prerequisites machine shut down parking brake engaged when every 1000 hours of service or yearly procedure follow the procedure below to adjust the tension (i.E., the amount of force required to move) of the forward/rever...

Page 86: Maintenance

Maintenance rd 27 86 wc_tx000815gb.Fm 5.32 changing the hydraulic oil prerequisites hydraulic oil suitable container machine parked on a flat, level surface when every 1000 hours of service or yearly l draining follow the procedure below to drain the hydraulic oil tank. Note: take care to keep the h...

Page 87: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 87 continued from the previous page. 5. Refill the hydraulic tank with clean, filtered hydraulic oil. 6. Check the hydraulic oil level using the sight gauge (c). 7. Re-install the hydraulic tank filler cap (b). 5.33 checking and cleaning the hydraulic tank breather...

Page 88: Maintenance

Maintenance rd 27 88 wc_tx000815gb.Fm 5.34 cleaning the hydraulic oil strainer prerequisites machine shut down clean, nonflammable solvent when every 1000 hours of service or yearly l procedure follow the procedure below to clean the hydraulic oil strainer. 1. Open the engine compartment. 2. Remove ...

Page 89: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 89 5.35 cleaning the radiator filler cap prerequisites machine shut down engine cool when every 1000 hours of service or yearly procedure follow the procedure below to clean the radiator filler cap. 1. Open the engine compartment. 2. Remove the radiator filler cap ...

Page 90: Maintenance

Maintenance rd 27 90 wc_tx000815gb.Fm 5.36 checking the engine water pump prerequisites machine shut down engine cool when every 3000 hours of service or 2 years l background if the water pump fails, the engine will overheat which can cause: cracks in the cylinder head piston seizure procedure follo...

Page 91: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 91 5.37 changing the cooling system coolant prerequisites machine shut down engine cool when every 12,000 hours of service or 6 years l draining follow the procedure below to drain the cooling system coolant. 1. Open the engine compartment. 2. Open the radiator fil...

Page 92: Maintenance

Maintenance rd 27 92 wc_tx000815gb.Fm 9. Flush the cooling system with water until the draining water is transparent. Filling follow the procedure below to fill the cooling system. 1. Close the radiator drain valve. 2. Add the recommended amount of coolant to the radiator. 3. Start the engine. 4. Le...

Page 93: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 93 5.38 replacing the water temperature regulator prerequisites machine shut down engine cool when every 3000 hours of service or every 2 years l procedure follow the procedure below to replace the water temperature regulator. Removal follow the procedure below to ...

Page 94: Maintenance

Maintenance rd 27 94 wc_tx000815gb.Fm 5.39 draining the water spray system prerequisites machine shut down parking brake engaged when prior to working in or experiencing freezing conditions. L procedure follow the procedure below to drain the water tank. 1. Remove the water tank filler cap. 2. Remov...

Page 95: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 95 5.40 towing the machine prerequisites second machine of greater size and rigid towing equipment, or two machines of equal size to towed machine if non-rigid towing equipment is being used shielding for all machines being used note: the strength of the towing lin...

Page 96: Maintenance

Maintenance rd 27 96 wc_tx000815gb.Fm continued from the previous page. 6. Connect the tow lines at the tie down bars (b and c). 7. Attach tow lines to the towing machine. 8. Remove the blocks from the drums. 9. Tow the machine as needed. 10.Once the machine is at the desired location, block the dru...

Page 97: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 97 5.41 manually releasing the parking brakes prerequisites machine shut down blocks procedure follow the procedure below to manually release the parking brakes. 1. Block the drums to prevent the machine from moving. 2. Remove the two plugs from each drive motor. 3...

Page 98: Maintenance

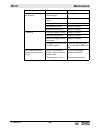

Maintenance rd 27 98 wc_tx000815gb.Fm 5.42 troubleshooting problem / symptom reason remedy engine does not start empty fuel tank refill fuel tank. Wrong type of fuel drain tank, change fuel fil- ter, and refill with the proper fuel. Old fuel drain tank, change fuel fil- ter, and refill with fresh fu...

Page 99: Rd 27

Rd 27 maintenance wc_tx000815gb.Fm 99 no travel, or travel only in one direction sheared pin on forward/ reverse control replace pin. Loose or broken control cable tighten or replace. Damaged drive motor repair or replace. Damaged drive pump repair or replace. Defective relief valve(s) repair or rep...

Page 100: Schematics

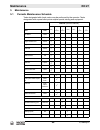

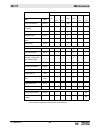

Schematics rd 27 100 wc_tx000863gb.Fm 6 schematics 6.1 electrical schematic.

Page 101

Schematics rd 27 wc_tx000863gb_1.Fm electrical schematic page 1 of 3 101.

Page 102

Wc_tx000863gb_1.Fm rd 27 schematics electrical schematic page 2 of 3 102.

Page 103

Schematics rd 27 wc_tx000863gb_1.Fm electrical schematic page 3 of 3 103.

Page 104: Schematics

Schematics rd 27 104 wc_tx000863gb.Fm notes:.

Page 105: Rd 27

Rd 27 schematics wc_tx000863gb.Fm 105 notes:.

Page 106: Schematics

Schematics rd 27 106 wc_tx000863gb.Fm 6.2 hydraulic schematic.

Page 107

Wc_tx000863gb_3.Fm rd 27 schematics hydraulic schematic with flow divider sheet 1 of 2 wc_gr004930_a3 wc_gr004930_a3 a b p neutral brake solenoid mf 408 cc r l x 1 mf 408 cc r l x 1 rear drive motor front drive motor p a b dr s flow divider seat switch solenoid 350 bars 350 bars a b l1 p s l2 b1 b a...

Page 108

Schematics rd 27 wc_tx000863gb_3.Fm hydraulic schematic without flow divider sheet 2 of 2 wc_gr004931_a3 wc_gr004931_a3 a b l1 p s l2 b1 b a 350 bars 350 bars neutral brake solenoid pv 22 cc p t b a r l 105 bars t p a c b d t p 100 bars 250 bars 150 bars m1 drum vibe solenoid 1 vibe on/off solenoid ...

Page 109: Rd 27

Rd 27 schematics wc_tx000863gb.Fm 109 notes:.

Page 110: Technical Data

Technical data rd 27 110 wc_td000249gb.Fm 7 technical data 7.1 engine engine power rating engine power rating per iso/tr 14396. Actual power output may vary due to conditions of specific use. Item no. Rd 27-100 rd 27-120 engine engine make perkins engine model 403d-15 engine type liquid-cooled diese...

Page 111: Rd 27

Rd 27 technical data wc_td000249gb.Fm 111 7.2 roller 7.3 lubrication item no. Rd 27-100 rd 27-120 roller operating weight kg (lb) 2617 (5770) 2824 (6226) dry weight kg (lb) 2375 (5236) 2582 (5692) drum width mm (in.) 1000 (39.4) 1200 (47.2) drum diameter mm (in.) 700 (27.6) 700 (27.6) water tank cap...

Page 112: Technical Data

Technical data rd 27 112 wc_td000249gb.Fm 7.4 sound measurements the operating sound level, measured per the requirements of appendix 1, paragraph 1.7.4.F of the ec-machine regulations, is: the guaranteed sound power level (l wa ) = 106 db(a). The sound pressure level at operator’s location (l pa ) ...

Page 113: Rd 27

Rd 27 technical data wc_td000249gb.Fm 113 7.6 dimensions see graphic: wc_gr004619 rd 27-100 rd 27-120 ref. Dimension mm (inches) a 2500 (98.4) b 1105 (43.5) 1305 (51.4) c 2775 (109.3) d 2680 (105.5)—eu version e 2000 (78.7) f 1800 (70.9) g 1000 (39.4) 1200 (47.2) h Ø700 (27.5) j 1800 (70.9) k 262 (1...

Page 115: Safety Alert Symbol

Notice of copyright protection copyright, 2008, by the association of equipment manufacturers. All rights reserved. This work may not be reproduced or disseminated in whole or in part by any means with- out the prior written permission of the association of equipment manufacturers. Safety alert symb...

Page 116: Contents

Word of explanation................................................................................ 2 foreword.......................................................................................................... 4 a word to the user .................................................................

Page 117: Word of Explanation

3 this safety manual covers many different types of roller compactors … including steel wheel rollers, vibratory rollers, rubber-tired rollers, segmented pad/sheepsfoot soil compactors and landfill compactors. These may be either self-propelled ride-on, walk-behind or towed rollers. They may be used...

Page 118: A Word to The User

It is your responsibility to read and understand this safety manual and the manufacturer's manual(s) before operating your machine. This safety manual takes you step-by-step through your working day. Remember that you are the key to safety. Good safety practices not only protect you but also protect...

Page 119: Follow A Safety Program

7 know what it is? Consult your supervisor for specific instructions on a job, and the personal safety equipment required. For instance, you may need: • hard hat • safety shoes • eye protection • face protection • heavy gloves • reflector vests • hearing protection • respirators do not wear loose cl...

Page 120: Prepare For Safe Operation

Learn to be safe read the operator’s manual. If one has not been provided, get one and study it before operating the machine. If you have any questions, contact the manufacturer. Know the positions and understand the functions of all controls before attempting to operate a machine. Know the meaning ...

Page 121: Prepare For Safe Operation

Fire prevention never allow flammable fluids or materials to contact hot surfaces. Never refuel: • when engine is running • while smoking • near open flames or sparks • in poorly ventilated area never overfill fuel tank or fluid reservoirs. Clean up spills immediately. Replace fuel cap securely afte...

Page 122: Prepare For Safe Operation

Before starting, carefully inspect your machine for any evidence of physical damage such as cracking, bending or deformation of plates or welds. Check for cracking or flaking of paint, which may indicate an excessive strain or dangerous crack in the material below. Check for loose, broken or missing...

Page 123: Start Safely

Walk around your machine once more just prior to mounting it – checking for people and objects that might be in the way – then mount properly using steps and handholds provided. Always use seat belts if your machine is equipped with a rops. Just before starting, check all controls … such as forward ...

Page 124: Start Safely

Cold weather operation consult the engine manufacturer’s operation manual for proper cold weather starting procedure. When using cold weather starting aids, be sure to follow the engine manufacturer’s instructions. (fig. 16) after starting, operate all systems slowly and gently until properly warmed...

Page 125: Work Safely

For maximum safety on machines with more than one operator’s position, operate from the position giving the greatest visibility of potential hazards. Never allow unqualified or unauthorized personnel to operate your machine. Never allow other personnel to ride on your machine unless appropriate seat...

Page 126: Work Safely

21 avoid operating your machine too close to an overhang, deep ditch or hole. If your machine inadvertently gets close to a tipping condition or drop-off, stop and get off the machine after applying the parking brake … plan your moves carefully before proceeding. Reversal is often the best move. Be ...

Page 127: Work At Night Safely

Night operations are different than daylight oper- ations. Pay close attention and stay alert. Others passing through the work site may not be aware of hazards. Plan the job, communicate the plan and inspect the work area during daylight. Mark obstacles ahead of time with reflective material. Wear a...

Page 128: Park and Shut Down Safely

25 park safely park in an off the road area, out of traffic, or as instructed. If necessary to park in a traffic lane, use the appropriate flags, barriers, flares, lights and warning signals. Provide advance warning signals in the traffic lane to warn approaching traffic. Park on level ground whenev...

Page 129: Transporting Safely

27 loading and unloading machines always involves potential hazards. Extreme caution should be used. Know the correct loading and unloading procedures for your machine. All machines are not loaded and unloaded the same way. The procedures recommended by the manufacturer should always be followed. Se...

Page 130: Transporting Safely

29 towing always use extra care when towing a trailer or machine … when maneuvering in tight places, when back- ing (visibility is reduced, and jackknifing must be avoided) and when towing on steep grades. Know and obey all local, state and federal laws and regulations. Never travel at speeds above ...

Page 131: Perform Maintenance Safely

31 perform maintenance safely clothing and personal protective items keep hands and clothing well away from engine fan and moving parts while engine is running. Always wear appropriate safety glasses, goggles or face shield when working. (fig. 34) proper eye protection can keep flying particles from...

Page 132: Perform Maintenance Safely

33 before beginning welding or burning operations, drain fuel lines and tank and move all flammable material to a safe distance, and be certain a fire extinguisher is readily available. When welding fuel tanks, either gasoline or diesel, always drain the tank, fill with water and leave cap off durin...

Page 133: Perform Maintenance Safely

35 fire prevention checklist (fig. 40) • remove debris such as rags, coal dust, oil, leaves and pine needles. • check and repair fuel and hydraulic leaks. • check and repair damaged wiring. • prevent hose and electrical wire harness abrasion. • tighten loose clamps and fittings. • secure loose wirin...

Page 134: Perform Maintenance Safely

37 servicing cooling system when checking coolant level: • stop the engine and let the engine and radiator cool before checking. (fig. 42) if an overheated engine requires a shutdown: • wait for the radiator to cool. The hot pressurized coolant can cause burn injuries. Never add coolant to an overhe...

Page 135: Perform Maintenance Safely

39 battery servicing to prevent a battery explosion: (fig. 44) • maintain the electrolyte at the recommended level. Check level frequently. Add distilled water to batteries only before starting up, never when shutting down. With electrolyte at the proper level, less space is available for gases to a...

Page 136: Perform Maintenance Safely

41 hydraulic systems (cont’d) if you are struck by escaping hydraulic fluid under pressure, serious injury can occur if proper medical treatment is not administered immediately. During operation, hydraulic fluid and air in an unvented hydraulic tank becomes heated and will tend to expand. This will ...

Page 137: Perform Maintenance Safely

43 pneumatic tires changing tires or adding air can be a hazardous business. Special tools and procedures are required for changing off-highway tires. Explosion and separation of a tire and/or rim parts can cause serious injury or death. (fig. 48) always follow the manufacturer’s recommendations or ...

Page 138

45 parking and transporting always select a level area to park in and, if possible, one where children are unlikely to be present. Always chock the front and rear of the roller … even if leaving the machine unattended for short periods. Always use extra care when towing a roller … when maneuvering i...

Page 139

47 for landfill compactors general operators of landfill compactors should carefully handle fill materials that could be picked up and thrown by the wheels, become lodged in the machine or that are highly flammable. Frequent checks should be made for wire, cable or other material wound around the ax...

Page 140: Test Your Knowledge

49 do you understand this aem safety manual and items such as … • your safety program? • your machine manufacturer’s manual(s)? • proper clothing and personal safety equipment? • your machine’s controls, warning signs and devices, and safety equipment? • how to properly inspect, mount and start your...

Page 142

Form rc-0809 printed in u.S.A..

Page 143

William lahner paul sina vice president of engineering manager, product engineering wacker neuson corporation 20 10 -c e -rd2 7- en .Fm ec declaration of conformity wacker neuson corporation, n92w15000 anthony avenue, menomonee falls, wisconsin usa hereby certifies that the construction equipment sp...

Page 144

Wacker neuson se · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02-0 · fax: +49 - (0)89-3 54 02-390 wacker neuson corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker neuson limited - room 1701–03 & 171...