- DL manuals

- Wacker Neuson

- Floor Machine

- Trowel CT 24-4A

- Operator's Manual

Wacker Neuson Trowel CT 24-4A Operator's Manual

Summary of Trowel CT 24-4A

Page 1

0171799en 005 1010 0 1 7 1 7 9 9 e n operator’s manual trowel ct 24-4a.

Page 2

Copyright notice © copyright 2010 by wacker neuson corporation. All rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permission from wack...

Page 3: Ct 24-4A

Ct 24-4a foreword wc_tx001519gb.Fm 3 foreword machines covered in this manual machine documentation keep a copy of the operator’s manual with the machine at all times. Use the separate parts book supplied with the machine to order replacement parts. If you are missing either of these documents, plea...

Page 4: Foreword

Foreword ct 24-4a 4 wc_tx001519gb.Fm laws pertaining to spark arresters notice: state health safety codes and public resources codes specify that in certain locations spark arresters be used on internal combustion engines that use hydrocarbon fuels. A spark arrester is a device designed to prevent a...

Page 5: Ct 24-4A

Ct 24-4a table of contents wc_bo0171799en_004toc.Fm 5 foreword 3 1 safety information 7 1.1 signal words found in this manual ....................................................... 7 1.2 machine description and intended use ............................................... 8 1.3 operating safety .......

Page 6: Table of Contents

Table of contents ct 24-4a 6 wc_bo0171799en_004toc.Fm 5 maintenance 29 5.1 periodic maintenance schedule ..........................................................29 5.2 engine oil ............................................................................................30 5.3 air cleaner ...........

Page 7: Ct24-4A

Ct24-4a safety information wc_si000504gb.Fm 7 1 safety information 1.1 signal words found in this manual this manual contains danger, warning, caution, notice, and note signal words which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. Not...

Page 8: Safety Information

Safety information ct24-4a 8 wc_si000504gb.Fm 1.2 machine description and intended use this machine is a walk-behind concrete finishing trowel. The wacker neuson walk-behind trowel consists of a frame onto which are mounted a gasoline engine, a fuel tank, a gearbox, and a control handle. A set of fo...

Page 9: Ct24-4A

Ct24-4a safety information wc_si000504gb.Fm 9 to protect yourself and others, make sure you thoroughly read and understand the safety information presented in this manual before operating the machine. 1.3 operating safety familiarity and proper training are required for the safe operation of the mac...

Page 10: Safety Information

Safety information ct24-4a 10 wc_si000504gb.Fm • safety-toed footwear 1.3.2 do not allow anyone to operate this equipment without proper training. People operating this equipment must be familiar with the risks and hazards associated with it. 1.3.3 do not touch the engine or muffler while the engine...

Page 11: Ct24-4A

Ct24-4a safety information wc_si000504gb.Fm 11 1.3.20 do not transport the machine while it is running. 1.3.21 do not tip the machine for cleaning or for any other reason. 1.4 operator safety while using internal combustion engines operating safety when running the engine: • keep the area around exh...

Page 12: Safety Information

Safety information ct24-4a 12 wc_si000504gb.Fm • do not refuel a hot or running engine. • do not refuel the engine near sparks or open flames. • do not refuel if the machine is positioned in a truck fitted with a plastic bed liner. Static electricity can ignite the fuel or fuel vapors. 1.5 service s...

Page 13: Ct24-4A

Ct24-4a safety information wc_si000504gb.Fm 13 1.5.2 do not crank a flooded engine with the spark plug removed on gasoline-powered engines. Fuel trapped in the cylinder will squirt out the spark plug opening. 1.5.3 do not test for spark on gasoline-powered engines if the engine is flooded or the sme...

Page 14: Labels

Labels ct24-4a 14 wc_si000505gb.Fm 2 labels 2.1 label locations.

Page 15: Ct24-4A

Ct24-4a labels wc_si000505gb.Fm 15 2.2 label meanings label meaning a danger! Asphyxiation hazard. Engines emit carbon monoxide. Do not run the machine indoors or in an enclosed area unless adequate ventilation, through such items as exhaust fans or hoses, is provided. Read the operator’s manual. No...

Page 16: Labels

Labels ct24-4a 16 wc_si000505gb.Fm e warning! Cutting hazard. Always replace blade guard! F variable speed throttle g caution! Read and understand the supplied operator’s manual before operating this machine. Failure to do so increases the risk of injury to yourself and others. H notice lifting poin...

Page 17: Ct24-4A

Ct24-4a labels wc_si000505gb.Fm 17 this machine may be covered by one or more patents. Label meaning j to start the machine: 1. Open the fuel flow valve. 2. Close the choke. 3. Push or turn engine switch to on position. 4. Place throttle in the idle position. 5. Engage operator present lever. 6. Pul...

Page 18: Lifting and Transporting

Lifting and transporting ct 24-230e 18 wc_tx001520gb.Fm 3 lifting and transporting 3.1 lifting the machine see graphic: wc_gr004390 never lift the machine solely by the handle. The component may fail, causing the machine to fall, possibly injuring bystanders. See technical data for the weight of the...

Page 19: Ct 24-230E

Ct 24-230e lifting and transporting wc_tx001520gb.Fm 19 3.2 transporting required • transport vehicle capable of handling the weight of the trowel • suitable ropes or chains procedure follow the procedure below to tie down and transport the machine. 3.2.1 lift the trowel onto the transport vehicle. ...

Page 20: Operation

Operation ct 24-4a 20 wc_tx001521gb.Fm 4 operation 4.1 preparing for first use preparing for first use to prepare your machine for first use: 4.1.1 make sure all loose packaging materials have been removed from the machine. 4.1.2 check the machine and its components for damage. If there is visible d...

Page 21: Ct 24-4A

Ct 24-4a operation wc_tx001521gb.Fm 21 4.4 installing blades see graphic: wc_gr004417 there are two types of blades available for the trowels. Float pans are large “pizza pan” style blades, which hook on over finish blades. Float blades are used in the earliest stages of work, and are not pitched. F...

Page 22: Operation

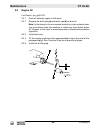

Operation ct 24-4a 22 wc_tx001521gb.Fm 4.5 unfolding handle see graphic: wc_gr004384 on new machines the pipe handle comes folded with the following components attached: twist pitch control (a),operator present lever (b), throttle lever (c), hinge pin (d), and adjustable lever (e). To unfold and sec...

Page 23: Ct 24-4A

Ct 24-4a operation wc_tx001521gb.Fm 23 4.6 controls see graphic: wc_gr004384 4.7 operator present lever see graphic: wc_gr004384 when the operator present lever (b) is released, the engine will shut off. Watch for spinning blades! Even after the engine has shut off, the trowel blades will continue t...

Page 24: Operation

Operation ct 24-4a 24 wc_tx001521gb.Fm 4.8 before starting before starting trowel, check the following: • oil level in engine • oil level in gearbox • fuel level • condition of air filter • condition of fuel lines • condition of trowel arms and blades • condition of ring guard • label descriptions •...

Page 25: Ct 24-4A

Ct 24-4a operation wc_tx001521gb.Fm 25 4.10 to stop see graphic: wc_gr004384, wc_gr001098 4.10.1 reduce engine rpm to idle by moving the throttle lever to idle position (c1). 4.10.2 release the operator present lever (b). 4.10.3 turn engine switch to “off” (h2). 4.10.4 close fuel valve by moving lev...

Page 26: Operation

Operation ct 24-4a 26 wc_tx001521gb.Fm 4.11 position of the operator safe and efficient use of this machine is the operator’s responsibility. Full control of the machine is not possible unless the operator maintains the proper working position at all times. While operating this machine the operator ...

Page 27: Ct 24-4A

Ct 24-4a operation wc_tx001521gb.Fm 27 do not attempt to clean, service or perform adjustments on the trowel while it is running. 4.13 emegency shutdown procedure procedure if a breakdown or accident occurs while the machine is operating, follow the procedure below: 4.13.1 stop the engine. 4.13.2 cl...

Page 28: Operation

Operation ct 24-4a 28 wc_tx001521gb.Fm 4.14 pitch adjustment see graphic: wc_gr004108 to adjust blade pitch (angle): a = twist pitch: turn the pitch adjusting knob (a) clockwise to increase pitch and counterclockwise to decrease pitch. Ref. B = working condition of concrete c = suggested working pit...

Page 29: Ct 24-4A

Ct 24-4a maintenance wc_tx001522gb.Fm 29 5 maintenance 5.1 periodic maintenance schedule the table below lists basic machine and engine maintenance. Tasks designated with check marks may be performed by the operator. Tasks designated with square bullet points require special training and equipment. ...

Page 30: Maintenance

Maintenance ct 24-4a 30 wc_tx001522gb.Fm 5.2 engine oil voir dessin : wc_gr004132 5.2.1 drain oil while the engine is still warm. 5.2.2 remove the oil fill plug (a) and drain cap (b) to drain oil. Note: in the interests of environmental protection, place a plastic sheet and a container under the mac...

Page 31: Ct 24-4A

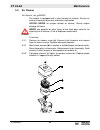

Ct 24-4a maintenance wc_tx001522gb.Fm 31 5.3 air cleaner voir dessin : wc_gr000025 the engine is equipped with a dual element air cleaner. Service air cleaner frequently to prevent carburetor malfunction. Notice: never run engine without air cleaner. Severe engine damage will occur. Never use gasoli...

Page 32: Maintenance

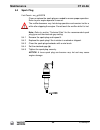

Maintenance ct 24-4a 32 wc_tx001522gb.Fm 5.4 spark plug voir dessin : wc_gr000028 clean or replace the spark plug as needed to ensure proper operation. Refer to your engine operator’s manual. The muffler becomes very hot during operation and remains hot for a while after stopping the engine. Do not ...

Page 33: Ct 24-4A

Ct 24-4a maintenance wc_tx001522gb.Fm 33 5.5 cleaning sediment cup voir dessin : wc_gr000029 5.5.1 turn the fuel valve off. 5.5.2 remove the sediment cup (a) and the o-ring (b). 5.5.3 wash both thoroughly in a nonflammable solvent. Dry and reinstall them. 5.5.4 turn the fuel valve on and check for l...

Page 34: Maintenance

Maintenance ct 24-4a 34 wc_tx001522gb.Fm 5.6 adjusting idle speed voir dessin : wc_gr001122 remove the drive belt before making any adjustment to the carburetor. See belt replacement. The blades will engage unless the belt is removed from the machine. Adjust engine to the no load or idle speed per t...

Page 35: Ct 24-4A

Ct 24-4a maintenance wc_tx001522gb.Fm 35 5.7 carburetor adjustment voir dessin : wc_gr0001061 remove the drive belt before making any adjustment to the carburetor. See belt replacement. The blades will engage unless the belt is removed from the machine. The pilot screw (a) is fitted with a limiter c...

Page 36: Maintenance

Maintenance ct 24-4a 36 wc_tx001522gb.Fm 5.8 belt replacement voir dessin : wc_gr004429 the trowel is equipped with a self-adjusting clutch. This clutch automatically tightens the belt and compensates for belt wear. Replace the belt if the clutch can no longer tighten belt enough to engage gearbox w...

Page 37: Ct 24-4A

Ct 24-4a maintenance wc_tx001522gb.Fm 37 5.9 trowel lubrication voir dessin : wc_gr0014389 grease trowel arms (b) with shell alvania rl2 grease or equivalent. Oil the pitch control cable and other parts of trowel on an as needed basis. Oil in the gearbox should not require replacement unless it was ...

Page 38: Maintenance

Maintenance ct 24-4a 38 wc_tx001522gb.Fm 5.10 storage if trowel is being stored for more than 30 days: • change engine oil. • drain fuel from engine. • remove spark plug and pour 15 ml (½ ounce) of sae 30 engine oil into the cylinder. Replace spark plug and crank engine to dis- tribute oil. Refer to...

Page 39: Ct 24-4A

Ct 24-4a troubleshooting wc_tx001523gb.Fm 39 6 troubleshooting 6.1 basic troubleshooting problem / symptom reason / remedy trowel does not develop full speed. • remove deposits built up in engine cylinder and engine head. • engine speed too low. Adjust speed. • clean or replace air filter. • clean d...

Page 40: Technical Data

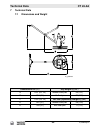

Technical data ct 24-4a 40 wc_td000219gb.Fm 7 technical data 7.1 dimensions and weight dimensions mm (in.) dry weight kg (lbs.) a 1537 (60-1/2) without float pan 64 (141) b 610 (24) with float pan 70 (153) c 1003 (39-1/2) full wet (operating) weight kg (lbs.) d 940 (37) without float pan 66 (145) e ...

Page 41: Ct 24-4A

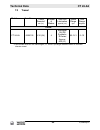

Ct 24-4a technical data wc_td000219gb.Fm 41 7.2 engine engine power rating net power rating per sae j1349. Actual power output may vary due to conditions of specific use. Item no. Ct 24-4a 0620105, 0620849 engine engine make honda engine model gx 120 ut1 qx2 max. Rated power @ rated speed kw (hp) 2....

Page 42: Technical Data

Technical data ct 24-4a 42 wc_td000219gb.Fm 7.3 trowel *trowel blades must not be interchanged, i.E., do not put larger diameter blades on a smaller diameter trowel. Model item no. Trowel diameter* mm (in.) number of blades gear box lubrication type/ml (oz.) speed range rpm pitch range degrees trowe...

Page 43: Ct 24-4A

Ct 24-4a technical data wc_td000219gb.Fm 43 7.4 sound and vibration data the required sound specification, paragraph 1.7.4.F of 89/392/eec machinery directive, is: • the sound pressure level at operator’s location (l pa ) : 97 db(a) • the guaranteed sound power level (l wa ) = 83 db(a) these sound v...

Page 45

Aem_concretepowertrowel.Qxd 7/23/03 6:31 am page 1.

Page 46: Word of Explanation

Safety alert symbol this safety alert symbol means attention is required! The safety alert symbol identifies important safety messages on machines, safety signs, in manuals or elsewhere. When you see this symbol, be alert to the possibility of personal injury or death. Follow the instructions in the...

Page 47: Table of Contents

3 table of contents page word of explanation ................................................................2 foreword........................................................................................4 a word to the user ....................................................................5 fo...

Page 48: A Word to The User

Remember that you are the key to safety. Good safety practices not only protect you but also protect the people around you. It is your responsibility to study this manual and the manufacturer’s manual(s) for your specific machine before operating your machine. Make them a working part of your safety...

Page 49: Prepare For Safe Operation

Learn to be safe • read the operator’s manual. If one has not been provided, get one and study it before operating the equipment. • learn the location and understand the functions of all controls before attempting to operate the equipment. • know the meaning of all identification symbols on the cont...

Page 50: Prepare For Safe Operation

Fire prevention always stop the engine and allow it to cool before refueling. Never refuel – • when engine is running • near open flame or sparks • while smoking • in poorly ventilated areas never overfill fuel tanks or fluid reservoirs. In the event of a fuel spill, do not attempt to start the engi...

Page 51: Start Safely

Start correctly – start safely before starting, check for proper functioning of all operation and shutdown controls. Check all controls to be sure they are in the correct startup position. Know the proper starting procedure for your trowel. Follow the manufacturer’s operational instructions. Walk-be...

Page 52: Work Safely

Safe working procedures danger – carbon monoxide exhaust from the engine contains poisonous carbon monoxide gas that is not easily detected as it is colorless and odorless. Exposure to carbon monoxide can cause loss of consciousness and may lead to death! Do not operate your trowel indoors or in an ...

Page 53: Shut Down Safely

Shut down procedures never disable or disconnect the safety devices! Always close fuel valves when the machine is not being used. Refer to the manufacturer’s manuals for specific shut down procedures. 15 shut down safely trowel.Qxd 11/24/04 10:18 am page 15 precautions • power trowels are heavy and ...

Page 54: Perform Maintenance Safely

Service and maintenance safety poorly maintained equipment can become a safety hazard! In order for your trowel to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. Do not attempt to clean, service, or perform adjustments on the trowel...

Page 55: Perform Maintenance Safely

Fire prevention avoid fire hazards. Always stop the engine and allow it to cool before you refuel the trowel. Do not refuel while smoking or near open flame or sparks. Never overfill fuel tanks or fluid reservoirs. Remove all trash or debris. Make sure oily rags or other flammable materials are not ...

Page 56: Perform Maintenance Safely

Trowel blades and pans • do not attempt to clean, service or perform adjustments on the trowel while it is running. • do not remove while the trowel is hanging overhead. Always support the trowel securely on a flat, level surface before changing blades or pans. • always handle blades and pans carefu...

Page 57: A Final Word to The User

Remember that you are the key to safety. Good safety practices not only protect you but protect the people around you. You have read this safety manual and the manufacturer’s manual(s) for your specific trowel. Make them a working part of your safety program. Keep in mind that this safety manual is ...

Page 58

Aem_concretepowertrowel.Qxd 7/23/03 6:31 am page 1.

Page 59

William lahner scott v. Grahl vice president of engineering manager, product engineering wacker neuson corporation 20 10 -c e- c t 24 _e n.Fm ec declaration of conformity wacker neuson corporation, n92w15000 anthony avenue, menomonee falls, wisconsin usa hereby certifies that the construction equipm...

Page 60

Wacker neuson se · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02-0 · fax: +49 - (0)89-3 54 02-390 wacker neuson corporation · n92w15000 anthony ave. · menomonee falls, wi 53051 · tel. : (262) 255-0500 · fax: (262) 255-0550 ·tel. : (800) 770-0957 wacker neuson limited - room 1701–03 & ...