- DL manuals

- Wacker Neuson

- Engine

- WM 80

- Repair Manual

Wacker Neuson WM 80 Repair Manual

Summary of WM 80

Page 1

0162695en 003 0610 0 1 6 2 6 9 5 e n repair manual engine wm 80

Page 2

Copyright notice © copyright 2010 by wacker neuson corporation. All rights, including copying and distribution rights, are reserved. This publication may be photocopied by the original purchaser of the machine. Any other type of reproduction is prohibited without express written permission from wack...

Page 3: Foreword

Foreword wc_tx001528gb.Fm 3 foreword machine documentation keep a copy of the operator’s manual with the machine at all times. Use the separate parts book supplied with the machine to order replacement parts. If you are missing any of these documents, please contact wacker neuson corporation to orde...

Page 4: Foreword

Foreword 4 wc_tx001528gb.Fm.

Page 5: Wm 80

Wm 80 table of contents wc_br0162695en_003toc.Fm 5 foreword 3 1 safety information 9 1.1 signal words used in this manual ....................................................... 9 1.2 safety guidelines for operating the machine ..................................... 10 1.3 operator safety while using...

Page 6: Table of Contents

Table of contents wm 80 6 wc_br0162695en_003toc.Fm 4.3 inspecting the starter ..........................................................................32 4.4 assembling the starter ........................................................................33 4.5 replacing the starter rope ...............

Page 7: Wm 80

Wm 80 table of contents wc_br0162695en_003toc.Fm 7 7.9 bing carburetor exploded view ......................................................... 94 7.10 bing carburetor components ............................................................. 95 8 carburetor inspection and adjustment 96 8.1 inspection ...

Page 8: Table of Contents

Table of contents wm 80 8 wc_br0162695en_003toc.Fm 10.21 crankshaft bearings ..........................................................................132 10.22 bearing installation ............................................................................134.

Page 9: Wm 80

Wm 80 safety information wc_si000509gb.Fm 9 1 safety information 1.1 signal words used in this manual this manual contains danger, warning, caution, notice, and note signal words which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. Notice...

Page 10: Safety Information

Safety information wm 80 10 wc_si000509gb.Fm 1.2 safety guidelines for operating the machine operator qualifications only trained personnel are permitted to start, operate, and shut down the machine. They also must meet the following qualifications: • have received instruction on how to properly use...

Page 11: Wm 80

Wm 80 safety information wc_si000509gb.Fm 11 1.2.6 never tamper with or disable the function of operating controls. 1.2.7 never use the choke to stop the engine. 1.2.8 never operate the machine in areas where explosions may occur. 1.2.9 read, understand, and follow procedures in the operator’s manua...

Page 12: Safety Information

Safety information wm 80 12 wc_si000509gb.Fm 1.3 operator safety while using internal combustion engines operating safety when running the engine: • keep the area around exhaust pipe free of flammable materials. • check the fuel lines and the fuel tank for leaks and cracks before starting the engine...

Page 13: Wm 80

Wm 80 safety information wc_si000509gb.Fm 13 • do not refuel if the machine is positioned in a truck fitted with a plastic bed liner. Static electricity can ignite the fuel or fuel vapors. 1.4 service safety a poorly maintained machine can become a safety hazard! In order for the machine to operate ...

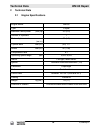

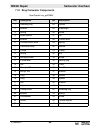

Page 14: Technical Data

Technical data wm 80 repair 14 wc_td000166gb.Fm 2 technical data 2.1 engine specifications engine model wm 80 type 2-cycle maximum rated power (kw) hp 3.0 (4.0) number of cylinders 1 piston displacement cc (cu.In.) 80 (4.9) cylinder bore mm (in.) (45) 1.77 stroke mm (in.) 50 (1.96) compression ratio...

Page 15: Wm 80 Repair

Wm 80 repair technical data wc_td000166gb.Fm 15 2.2 tune-up specifications * on models with adjustable air gap ** must be used on models with oil injection engine model wm 80 ring gap: new maximum mm (in.) mm (in.) 0.2–0.4 (0.008–0.016) 1.0–1.2 (0.039–0.047) cylinder wear: maximum bore taper mm (in....

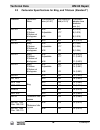

Page 16: Technical Data

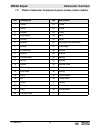

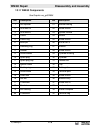

Technical data wm 80 repair 16 wc_td000166gb.Fm 2.3 carburetor specifications for bing, and tillotson (standard**) machine carburetor make low-speed jet size (x 0.01) high-speed jet size (x 0.01) carburetor adapter bore diameter mm (in.) bs 45y •bing •tillotson •tillotson w/ idle bypass #35 adjustab...

Page 17: Wm 80 Repair

Wm 80 repair technical data wc_td000166gb.Fm 17 bs 500 7550 rev. 111–121 tillotson w/ idle bypass #36 #70 13 (0.512) bs 500 7550 rev. >121 #36 #70 11 (0.433) bs 500 8048 rev. 100–102 #36 #78 13 (0.512) bs 500 8048 rev. 103–110 #36 #66 13 (0.512) bs 500 8048 rev. 111–118 #36 #70 13 (0.512) bs 500 804...

Page 18: Technical Data

Technical data wm 80 repair 18 wc_td000166gb.Fm * single-needle tillotson carburetors only. Dual-needle tillotson carburetors use an adjustable needle for high-speed adjustment. ** standard sizes listed. Operation at altitudes above 3000 m (5000 feet) may require different jet and carburetor adapter...

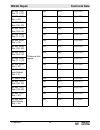

Page 19: Wm 80 Repair

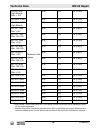

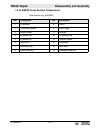

Wm 80 repair technical data wc_td000166gb.Fm 19 2.4 operating and idle speeds machine idle speed ±100 rpm full speed ±100 rpm bs 45y 1800 4300 bs 52y 1800 4300 bs 60y 1800 4600 bs 62y 1800 4500 bs 65y 1500 4400 bs 100y 1500 4300 bs 105y/92y 1500 4400 bps 1330 1500 4800 bps 1350 1500 4800 bvnpn 1700 ...

Page 20: Maintenance

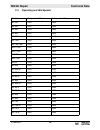

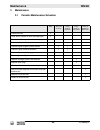

Maintenance wm 80 20 wc_tx000520gb.Fm 3 maintenance 3.1 periodic maintenance schedule daily after first 5 hours every week or 25 hours every month or 100 hours every 3 months or 300 hours check fuel level. • clean and/or inspect air filter (cartridge type). • clean and oil foam precleaner where equi...

Page 21: Wm 80

Wm 80 maintenance wc_tx000520gb.Fm 21 3.2 storage if storing the unit for a long period of time (more than 30 days) carry out the following: 3.2.1 drain fuel from the tank. 3.2.2 start the engine and run it until all the fuel in the carburetor is used. 3.2.3 remove the spark plug and pour 30 ml (1 o...

Page 22: Maintenance

Maintenance wm 80 22 wc_tx000520gb.Fm 3.4 cartridge-type air filter see graphic: wc_gr002875 3.4.1 this type of air filter is found on rammers with bing carburetors and on early rammers with tillotson carburetors. To service: 3.4.2 unsnap the spring clips (1) on the protective cover (2) and remove t...

Page 23: Wm 80

Wm 80 maintenance wc_tx000520gb.Fm 23 3.5 disc-type air filter see graphic: wc_gr002876 the disc-type air filter with oil-wetted foam precleaner is used on bps 1330, bps 1350, bvpn 50, and the bhf 30s. To service the filter: 3.5.1 close the carburetor choke. Loosen the clamp (1) around the carbureto...

Page 24: Maintenance

Maintenance wm 80 24 wc_tx000520gb.Fm 3.6 low-maintenance air filter see graphic: wc_gr002877 this type of air filter is found on rammers. The air filter is self-cleaning and uses the movement of the machine to shake dust and dirt loose from the air filter element while the rammer is operating.Under...

Page 25: Wm 80

Wm 80 maintenance wc_tx000520gb.Fm 25 3.7 dual-element air cleaner see graphic: wc_gr000046 never use gasoline or other types of low flash-point solvents for cleaning the air cleaner. A fire or explosion could result. Notice: never run engine without air cleaner. Severe engine damage will occur. The...

Page 26: Maintenance

Maintenance wm 80 26 wc_tx000520gb.Fm 3.8 three-stage air cleaners see graphic: wc_gr001168 never use gasoline or other types of low flash point solvents for cleaning the air filter. A fire or explosion could result. Notice: never run engine without main paper filter element (b). Severe engine damag...

Page 27: Wm 80

Wm 80 maintenance wc_tx000520gb.Fm 27 wc_gr001168 a b c d k i h.

Page 28: Maintenance

Maintenance wm 80 28 wc_tx000520gb.Fm 3.9 engine cleaning the wacker wm 80 engine is air cooled and depends on the cylinder cooling fins to dissipate heat. Dirt and debris caught in the cooling fins can prevent them from dissipating heat causing the engine to overheat. For this reason, it is importa...

Page 29: Wm 80

Wm 80 maintenance wc_tx000520gb.Fm 29 3.11.3 clean the exhaust port using a blunt scraper. Inspect the gasket (3, 4) and replace it if torn or cracked. 3.11.4 soak the muffler in carburetor cleaner until the carbon deposits break up. Drain the muffler and blow dry it dry with compressed air..

Page 30: Maintenance

Maintenance wm 80 30 wc_tx000520gb.Fm 3.12 fuel filter see graphic: wc_gr002879 dirt is the primary cause of carburetor problems. Unfiltered fuel can quickly plug the passages in the carburetor and cause poor performance. Two different styles of fuel filters are used with the wm 80 engine. One is an...

Page 31: Wm 80 Repair

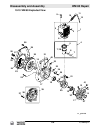

Wm 80 repair starting and ignition wc_tx000521gb.Fm 31 4 starting and ignition 4.1 starter assembly exploded view see graphic: wc_gr002880 ref description ref description 1 starter assembly 8 spring 2 rope 9 ratchet wheel 3 handle 10 cover 4 wear plate 11 lock washer 5 return spring 12 locknut 6 sta...

Page 32: Starting and Ignition

Starting and ignition wm 80 repair 32 wc_tx000521gb.Fm 4.2 disassembling the starter see graphic: wc_gr002880 4.2.1 remove the starter assembly from the fan cover and release the spring tension as described in section replacing the starter rope. 4.2.2 untie the rope (2) and remove the handle (3). 4....

Page 33: Wm 80 Repair

Wm 80 repair starting and ignition wc_tx000521gb.Fm 33 4.4 assembling the starter see graphic: wc_gr002880 and wc_gr002881 4.4.1 clean all the components of the starter before reassembling the starter. 4.4.2 note: to reduce dirt and dust from collecting between the spring windings, avoid using greas...

Page 34: Starting and Ignition

Starting and ignition wm 80 repair 34 wc_tx000521gb.Fm 4.5 replacing the starter rope see graphic: wc_gr002882 the starter rope can be replaced without removing the rope reel pulley from the starter assembly. Removal: 4.5.1 remove the starter assembly from the flywheel housing. 4.5.2 lift the rope t...

Page 35: Wm 80 Repair

Wm 80 repair starting and ignition wc_tx000521gb.Fm 35 wc_gr002882 a d e b c.

Page 36: Starting and Ignition

Starting and ignition wm 80 repair 36 wc_tx000521gb.Fm 4.6 ignition system diagram wc_gr002883 a f e aa aaa g c d b s n.

Page 37: Wm 80 Repair

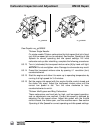

Wm 80 repair starting and ignition wc_tx000521gb.Fm 37 4.7 ignition system operation see graphic: wc_gr002883 the ignition system consists of the ignition module (a), flywheel (b), shutoff switch (c) or (d), and spark plug (e). During each engine revolution, a permanent magnet (f) embedded in the fl...

Page 38: Starting and Ignition

Starting and ignition wm 80 repair 38 wc_tx000521gb.Fm 4.8 checking spark remove the spark plug and inspect the electrode and insulator for damage. Also check electrode for proper gap. See section tune-up specifications. Return the spark plug to the cylinder before checking for spark. Do not check f...

Page 39: Wm 80 Repair

Wm 80 repair starting and ignition wc_tx000521gb.Fm 39 • poor wire connections • defective stop switch • incorrect air gap • weak or dead flywheel magnet • insufficient rpm (must have 500 min.) 4.9 using ignition tester see graphic: wc_gr002884 a more accurate test of the ignition module can be made...

Page 40: Starting and Ignition

Starting and ignition wm 80 repair 40 wc_tx000521gb.Fm 4.10 setting air gap see graphic: wc_gr002885 newer engines use guide sleeve pins to automatically set the air gap; however, older models still require the proper air gap to be set manually. If the air gap is set incorrectly, the engine may be h...

Page 41: Wm 80 Repair

Wm 80 repair starting and ignition wc_tx000521gb.Fm 41 wc_gr002885 s n d a c b.

Page 42: Starting and Ignition

Starting and ignition wm 80 repair 42 wc_tx000521gb.Fm 4.11 replacing the ignition module see graphic: wc_gr002886 removal: the engine does not have to be removed from the machine to replace the ignition module. 4.11.1 disconnect the ignition wire from the spark plug. 4.11.2 remove the seven m5 scre...

Page 43: Wm 80 Repair

Wm 80 repair starting and ignition wc_tx000521gb.Fm 43 wc_gr002886 a d f f e k c g i h j b.

Page 44: Starting and Ignition

Starting and ignition wm 80 repair 44 wc_tx000521gb.Fm see graphic: wc_gr002887 installation: 4.11.12 apply a light coating of oil to the ground (a) and ignition wires (b) and slide them through the protective sleeve (c). 4.11.13 slide the ignition wire through the boot (d) in the side of the crankc...

Page 45: Wm 80 Repair

Wm 80 repair starting and ignition wc_tx000521gb.Fm 45 wc_gr002887 k e a b j f n o l h g m d c i b.

Page 46: Carburetor Basics

Carburetor basics wm 80 repair 46 wc_tx000522gb.Fm 5 carburetor basics 5.1 brands used see graphic: wc_gr005089 three brands of carburetors are used on the wm 80 engine: walbro (1), tillotson (2), and bing (3). The walbro and tillotson carburetors have internal fuel pumps while the bing uses gravity...

Page 47: Wm 80 Repair

Wm 80 repair carburetor basics wc_tx000522gb.Fm 47 5.2 walbro carburetor operation fuel pump the fuel pump is made up of a diaphragm (a) and a series of check valves (b & c). The power to operate the fuel pump comes from the crankcase impulse. As the engine’s piston moves up into the cylinder it cre...

Page 48: Carburetor Basics

Carburetor basics wm 80 repair 48 wc_tx000522gb.Fm fuel metering there are four components of the fuel metering system: the metering diaphragm (a), the metering lever (b), the spring (c), and the inlet needle (d). The metering lever transfers the pressure of the spring to the inlet needle, holding t...

Page 49: Wm 80 Repair

Wm 80 repair carburetor basics wc_tx000522gb.Fm 49 start up a rich fuel-to-air mixture is required at startup because of the lower cranking speed (compared to running) which causes less air flow, and the fact that the engine is usually cold. (a cold engine is not efficient at vaporizing fuel because...

Page 50: Carburetor Basics

Carburetor basics wm 80 repair 50 wc_tx000522gb.Fm idle once the engine starts, the choke (a) is opened and the throttle (b) nearly closed. The engine is at the idle state. During idle, low pressure exists on the engine side of the throttle and atmosphere pressure (high) on the other. Atmosphere air...

Page 51: Wm 80 Repair

Wm 80 repair carburetor basics wc_tx000522gb.Fm 51 partial throttle operation at partial throttle, the choke (a) remains in the open position and the throttle (b) is partially opened. During partial throttle, low pressure exists on the engine side of the throttle plate. The low pressure draws fuel f...

Page 52: Carburetor Basics

Carburetor basics wm 80 repair 52 wc_tx000522gb.Fm wide-open throttle operation at wide-open throttle, the choke (a) remains in the open position and the throttle (b) is wide open. During this state, the throttle plate has little affect on high- and low-pressure areas within the carburetor throat. T...

Page 53: Wm 80 Repair

Wm 80 repair carburetor basics wc_tx000522gb.Fm 53 air purge system the walbro carburetor has an air purge system. The air purge system removes air from the fuel passages so that only fuel fills the carburetor and the fuel lines. The heart of the air purge system is the bulb. The bulb works in conju...

Page 54: Carburetor Basics

Carburetor basics wm 80 repair 54 wc_tx000522gb.Fm 5.3 versions of tillotson carburetor see graphic: wc_gr002889 1) dual needle dual needle carburetors have mixture needle valves that are adjustable. One of the valves (a) adjusts the high-speed jet (h) and the other valve (b) adjusts the low-speed j...

Page 55: Wm 80 Repair

Wm 80 repair carburetor basics wc_tx000522gb.Fm 55 5.4 tillotson carburetor operation see graphic: wc_gr002891 fuel pump: the tillotson carburetor uses a flexible diaphragm fuel pump (a) to operate an inlet valve (b) which controls fuel flow to the carburetor fuel reservoir (c) . The fuel pump opera...

Page 56: Carburetor Basics

Carburetor basics wm 80 repair 56 wc_tx000522gb.Fm see graphic: wc_gr002892 inlet needle valve: the inlet needle valve (e) controls fuel flow into the fuel chamber. This valve is operated by a second diaphragm called the control diaphragm (f) . The control diaphragm is activated by the vacuum create...

Page 57: Wm 80 Repair

Wm 80 repair carburetor basics wc_tx000522gb.Fm 57 see graphic: wc_gr002893 start-up mode (choke): during cold start-up, the choke shutter (butterfly) (k) is closed and the throttle shutter (l) is partially open. As the engine is turned over, engine suction draws fuel from the primary (m), secondary...

Page 58: Carburetor Basics

Carburetor basics wm 80 repair 58 wc_tx000522gb.Fm in single-needle versions (2), the throttle shutter does not open and there is no idle speed screw; instead, a small hole (q) in the shutter regulates the air flow. The idle speed is also regulated by the slow speed mixture needle valve (t) . By tur...

Page 59: Wm 80 Repair

Wm 80 repair carburetor basics wc_tx000522gb.Fm 59 see graphic: wc_gr002895 partial throttle: at partial throttle, the throttle shutter is partially opened, allowing a greater amount of air through the carburetor. The throttle has opened wide enough to expose the secondary idle discharge port (a) wh...

Page 60: Carburetor Basics

Carburetor basics wm 80 repair 60 wc_tx000522gb.Fm see graphic: wc_gr002896 full throttle: the wider the throttle shutter opens, the more air that will flow through the carburetor. As the air reaches the venturi (c) , it is forced to flow faster to keep the same volume of air flowing. The faster the...

Page 61: Wm 80 Repair

Wm 80 repair carburetor basics wc_tx000522gb.Fm 61 5.5 bing carburetor operation see graphic: wc_gr002897 fuel feed: the bing carburetor does not use a fuel pump; instead, the fuel supply is gravity fed. A priming button (a) is used during the initial start-up to manually open the inlet needle valve...

Page 62: Carburetor Basics

Carburetor basics wm 80 repair 62 wc_tx000522gb.Fm partial throttle: at partial throttle, the throttle shutter is partially opened allowing a greater amount of air through the carburetor. The throttle has opened wide enough to expose the secondary-idle discharge port and the engine suction draws fue...

Page 63: Wm 80 Repair

Wm 80 repair carburetor basics wc_tx000522gb.Fm 63 notes.

Page 64: Carburetor Basics

Carburetor basics wm 80 repair 64 wc_tx000522gb.Fm 5.6 carburetor adapters see graphic: wc_gr007414 the function of the carburetor adapter is to control the amount of fuel/ air mixture that can reach the engine. When used in combination with the carburetor fuel jets, the power and speed of the engin...

Page 65: Wm 80 Repair

Wm 80 repair carburetor basics wc_tx000522gb.Fm 65 d d d d d 1 2 3 e 4 f g 5 6 h wc_gr007414.

Page 66: Carburetor Replacement

Carburetor replacement wm 80 repair 66 wc_tx000522gb.Fm 6 carburetor replacement 6.1 replacing the walbro carburetor (auto-release choke models) removal 6.1.1 stop the machine and allow it to cool. 6.1.2 remove the carburetor guard (a) . 6.1.3 loosen the hose clamp and remove the air duct (b) . 6.1....

Page 67: Wm 80 Repair

Wm 80 repair carburetor replacement wc_tx000522gb.Fm 67 continued from the previous page. 6.1.7 have a container ready, then remove the oil hose (h) and drain it. 6.1.8 make sure the throttle is in the off position. This position also closes the fuel valve. Then, remove the fuel hose (n) and drain i...

Page 68: Carburetor Replacement

Carburetor replacement wm 80 repair 68 wc_tx000522gb.Fm installation perform the procedure below to install the carburetor 6.1.1 assemble the adapter (j) , lower gasket (l) , flange (k), and upper gasket (o) to the carburetor (i) . Note: the gaskets are not interchangeable. 6.1.2 connect the oil hos...

Page 69: Wm 80 Repair

Wm 80 repair carburetor replacement wc_tx000522gb.Fm 69 6.1.4 slide the throttle cable (e) through the adapter (f) and reconnect it to the clamp (d) . 6.1.5 install the air duct (b) with the hose clamp. 6.1.6 using loctite® 243 on the screws, install the carburetor guard (a) . Result the installatio...

Page 70: Carburetor Replacement

Carburetor replacement wm 80 repair 70 wc_tx000522gb.Fm 6.2 removing walbro carburetor (standard choke models) 6.2.1 stop the machine and allow it to cool. 6.2.2 place the throttle in the off position. 6.2.3 disconnect the ignition wire (a) from the spark plug. 6.2.4 remove the carburetor guard (b) ...

Page 71: Wm 80 Repair

Wm 80 repair carburetor replacement wc_tx000522gb.Fm 71 notes.

Page 72: Carburetor Replacement

Carburetor replacement wm 80 repair 72 wc_tx000522gb.Fm 6.3 removal, tillotson with composite adapter see graphic: wc_gr002929 6.3.1 stop the machine and allow it to cool. 6.3.2 close the fuel valve (a) (if equipped). 6.3.3 disconnect the ignition wire (b) at the spark plug. 6.3.4 remove the carbure...

Page 73: Wm 80 Repair

Wm 80 repair carburetor replacement wc_tx000522gb.Fm 73 d e f g wc_gr002929 i m c a b e d f g h m j k l i.

Page 74: Carburetor Replacement

Carburetor replacement wm 80 repair 74 wc_tx000522gb.Fm 6.4 tillotson with straight-through adapters see graphic: wc_gr002898 6.4.1 turn off the fuel valve at the tank and disconnect the spark plug lead wire. 6.4.2 remove the air filter pipe (loosen both clamps). 6.4.3 disconnect the throttle cable....

Page 75: Wm 80 Repair

Wm 80 repair carburetor replacement wc_tx000522gb.Fm 75 6.6 bing see graphic: wc_gr002900 6.6.1 turn off the fuel valve at the tank and disconnect the spark plug lead wire. 6.6.2 remove the air filter pipe (loosen both clamps). 6.6.3 disconnect the throttle cable. 6.6.4 loosen the clamp which secure...

Page 76: Carburetor Overhaul

Carburetor overhaul wm 80 repair 76 wc_tx000522gb.Fm 7 carburetor overhaul 7.1 walbro carburetor exploded view (auto-release choke models).

Page 77: Wm 80 Repair

Wm 80 repair carburetor overhaul wc_tx000522gb.Fm 77 7.2 walbro carburetor components (auto-release choke models) ref description ref description 1 screw 21 screw 2 cover 22 screw 3 gasket 23 cover 4 diaphragm 24 bulb 5 screen 25 valve 6 washer 26 air purge body assembly 7 spring 27 diaphragm 8 chok...

Page 78: Carburetor Overhaul

Carburetor overhaul wm 80 repair 78 wc_tx000522gb.Fm 7.3 rebuilding the walbro carburetor (auto-release choke models) disassembly 7.3.1 remove the cover (a) from the fuel-pump side of the carburetor. 7.3.2 remove the fuel pump diaphragm and gasket (b) . 7.3.3 remove the bracket and the air purge bul...

Page 79: Wm 80 Repair

Wm 80 repair carburetor overhaul wc_tx000522gb.Fm 79 7.3.7 remove the shutter (l) (butterfly). 7.3.8 remove the screw (m) , lever (n) , washer (o) , and spacer (p) . 7.3.9 remove the retaining ring (q) , then remove the choke shaft (r) . 7.3.10 remove the shutter (t) (butterfly) from the throttle sh...

Page 80: Carburetor Overhaul

Carburetor overhaul wm 80 repair 80 wc_tx000522gb.Fm 7.3.13 non-epa regulated countries only. Remove the high- and low-speed needle valves (x and y) . 7.3.14 using a punch, remove the welch plug (z) . 7.3.15 non-epa regulated countries only. Press out the main nozzle (zz) . 7.3.16 remove the screen(...

Page 81: Wm 80 Repair

Wm 80 repair carburetor overhaul wc_tx000522gb.Fm 81 reassembly 7.3.1 align the hole in the main nozzle (zz) with the passage of the high- speed needle. Press the main nozzle into the carburetor body until the top of the main nozzle is flush with the carburetor body. 7.3.2 install the welch plug (z)...

Page 82: Carburetor Overhaul

Carburetor overhaul wm 80 repair 82 wc_tx000522gb.Fm continued from the previous page. 7.3.7 install the shutter (t) (butterfly). 7.3.8 install the spring and washer on the choke shaft, then install the choke shaft (r) into the carburetor body. 7.3.9 align the spring (ee) as shown, then secure the c...

Page 83: Wm 80 Repair

Wm 80 repair carburetor overhaul wc_tx000522gb.Fm 83 continued from the previous page. 7.3.12 install the screw (j) , metering lever (h) , pin (k) , spring (g) , and inlet needle (i) . 7.3.13 install the metering diaphragm (f) . 7.3.14 install the combination valve (e) into the air purge body assemb...

Page 84: Carburetor Overhaul

Carburetor overhaul wm 80 repair 84 wc_tx000522gb.Fm 7.4 walbro carburetor exploded view (standard choke models) wc_gr005118.

Page 85: Wm 80 Repair

Wm 80 repair carburetor overhaul wc_tx000522gb.Fm 85 7.5 walbro carburetor components (standard choke models) ref description ref description 1 screw 20 bulb 2 cover 21 combination valve 3 gasket 22 air purge body assembly 4 diaphragm 23 diaphragm 5 screen 24 gasket 6 washer 25 nozzle 7 spacer 26 id...

Page 86: Carburetor Overhaul

Carburetor overhaul wm 80 repair 86 wc_tx000522gb.Fm 7.6 rebuilding the walbro carburetor (standard choke models) disassembly 7.6.1 remove the cover (a) from the fuel-pump side. 7.6.2 remove the fuel pump diaphragm and gasket (b) . 7.6.3 remove the bracket and the air purge bulb (c) . Separate the b...

Page 87: Wm 80 Repair

Wm 80 repair carburetor overhaul wc_tx000522gb.Fm 87 7.6.7 remove the shutter (l) (butterfly). 7.6.8 remove the choke shaft (m) and spacer (n) . Also remove the ball (o) and the spring (p) from the carburetor body. 7.6.9 remove the throttle lever (q) , spacer (r) , and washer (s) . 7.6.10 remove the...

Page 88: Carburetor Overhaul

Carburetor overhaul wm 80 repair 88 wc_tx000522gb.Fm 7.6.13 non-epa regulated countries only. Press out the main nozzle (zz) . The procedure is now complete. Reassembly 7.6.1 align the hole in the main nozzle (zz) with the passage of the high- speed needle. Press the main nozzle into the carburetor ...

Page 89: Wm 80 Repair

Wm 80 repair carburetor overhaul wc_tx000522gb.Fm 89 7.6.4 install the spring (v) to the throttle shaft (u) . Install the throttle shaft into the carburetor body and install the shutter (t) (butterfly). This procedure continues on the next page. X y wc_gr005128.

Page 90: Carburetor Overhaul

Carburetor overhaul wm 80 repair 90 wc_tx000522gb.Fm continued from the previous page. 7.6.5 install the washer (s) , spacer (r) , and the throttle lever (q) . Note the positioning of the throttle lever (q) compared to the throttle shaft (u) . 7.6.6 install the spring (p) and ball (o) . Install the ...

Page 91: Wm 80 Repair

Wm 80 repair carburetor overhaul wc_tx000522gb.Fm 91 continued from the previous page. 7.6.10 install the combination valve (e) . Install the air purge body assembly (d) , bracket, and air purge bulb (c) . 7.6.11 install the new fuel pump diaphragm then the new gasket (b) . Be sure to align each wit...

Page 92: Carburetor Overhaul

Carburetor overhaul wm 80 repair 92 wc_tx000522gb.Fm 7.7 tillotson carburetor exploded view wc_gr002901 1 2 3 4 6 5 40 8 9 10 38 37 11 7 13 12 14 27 26 25 24 23 15 16 17 18 19 22 21 20 39 21 20 20 21 22 43 41 42 43 41 29 28 30 32 31 28 33 28 35 35 7 34 44.

Page 93: Wm 80 Repair

Wm 80 repair carburetor overhaul wc_tx000522gb.Fm 93 7.8 tillotson components see graphic: wc_gr002901 ref description ref description 1 screw 23 control lever 2 cover 24 plug 3 gasket 25 retaining ring 4 diaphragm 26 screen 5 screen 27 plug 6 elbow fitting 28 bushing 7 screw w/ lock washer 29 bushi...

Page 94: Carburetor Overhaul

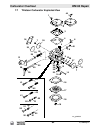

Carburetor overhaul wm 80 repair 94 wc_tx000522gb.Fm 7.9 bing carburetor exploded view wc_gr002902 1 2 3 4 5 6 7 8 9 11 19 38 18 20 10 14 12 13 23 15 17 21 24 22 22 21 25 26 28 29 27 30 31 32 33 34 35 36 39 41 40 42 41 40 43 44 45 46 5 37 16.

Page 95: Wm 80 Repair

Wm 80 repair carburetor overhaul wc_tx000522gb.Fm 95 7.10 bing carburetor components see graphic: wc_gr002902 ref description ref description 1 retaining ring 24 gasket 2 washer 25 diaphragm 3 spring 26 screw 4 brake control 27 pin 5 washer 28 control lever 6 throttle control lever 29 spring 7 carbu...

Page 96: Wm 80 Repair

Carburetor inspection and adjustment wm 80 repair 96 wc_tx000522gb.Fm 8 carburetor inspection and adjustment 8.1 inspection diaphragms: • check for tears, punctures, and distortion in the elastic material. Replace the diaphragm if it appears stretched or puckered. • be certain diaphragms are install...

Page 97: Wm 80 Repair

Wm 80 repair carburetor inspection and ad- wc_tx000522gb.Fm 97 8.2 adjusting the inlet control lever see graphic: wc_gr002903 walbro: use the special tool (e) to set height of metering lever. Tillotson: set the inlet control lever (a) so that it is flush with the floor of the fuel chamber (b) . Bend...

Page 98: Wm 80 Repair

Carburetor inspection and adjustment wm 80 repair 98 wc_tx000522gb.Fm 8.3 carburetor adjustments walbro: procedures apply in only non-epa regulated applications. Both high- and low-speed mixture adjustment is possible. A special tool is required. Seesection operating & idle speeds for correct operat...

Page 99: Wm 80 Repair

Wm 80 repair carburetor inspection and ad- wc_tx000522gb.Fm 99 see graphic: wc_gr002904 tillotson dual needle: both high- and low-speed mixture adjustment is required on dual needle models. Seesection operating & idle speeds for correct operating and idle speed settings. For best accuracy use a tach...

Page 100: Wm 80 Repair

Carburetor inspection and adjustment wm 80 repair 100 wc_tx000522gb.Fm see graphic: wc_gr002905 tillotson single needle: on single-needle tillotson carburetors the high-speed fuel jet is fixed; only the low-speed jet can be adjusted. See section operating & idle speeds for correct operating and idle...

Page 101: Wm 80 Repair

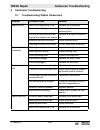

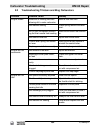

Wm 80 repair carburetor troubleshooting wc_tx000522gb.Fm 101 9 carburetor troubleshooting 9.1 troubleshooting walbro carburetors problem probable cause remedy engine floods. Worn inlet needle body or tip. Replace the inlet needle. Inlet needle sticking check spring tension and metering lever. Dirt o...

Page 102: Carburetor Troubleshooting

Carburetor troubleshooting wm 80 repair 102 wc_tx000522gb.Fm 9.2 troubleshooting tillotson and bing carburetors problem probable cause remedy engine floods. Defective or missing fuel filter allowing dirt to enter carburetor install a new fuel filter. Inlet needle sticking check spring tension and ax...

Page 103: Wm 80 Repair

Wm 80 repair carburetor troubleshooting wc_tx000522gb.Fm 103 engine runs rich. High-speed adjustment incor- rect readjust the high speed. High-speed mixture needle valve damaged replace the high-speed mixture needle valve. The size of the fixed jet is incor- rect. Replace the fixed jet with cor- rec...

Page 104: Disassembly and Assembly

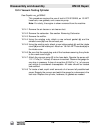

Disassembly and assembly wm 80 repair 104 wc_tx000523gb.Fm 10 disassembly and assembly 10.1 tools because all possible problems encountered while repairing the machine cannot be anticipated, it is up to the mechanic to use common sense and good judgement in tool selection. The use of any special too...

Page 105: Wm 80 Repair

Wm 80 repair disassembly and assembly wc_tx000523gb.Fm 105 10.3 ordering parts the repair procedures contained in this manual do not include part numbers. For parts replacement information, refer to the parts book originally supplied with the machine. If the original parts book has been lost, a repl...

Page 106: Disassembly and Assembly

Disassembly and assembly wm 80 repair 106 wc_tx000523gb.Fm 10.6 removing the wm 80 engine from bs rammers (auto-release choke models) requirements • engine cool • carburetor removed removal perform the procedure below to remove the engine. 10.6.1 remove the carburetor. See topic removing the carbure...

Page 107: Wm 80 Repair

Wm 80 repair disassembly and assembly wc_tx000523gb.Fm 107 installation perform the procedure below to install the engine. 10.6.6 install the engine (d) to the machine with three screws. Torque the screws to 28 nm (20 ft.Lbs.). 10.6.7 reconnect the wiring (c) to the switches. 10.6.8 install the brac...

Page 108: Disassembly and Assembly

Disassembly and assembly wm 80 repair 108 wc_tx000523gb.Fm 10.7 removing engine from bs model rammers (standard choke models) see graphic:wc_gr002935 removal: 10.7.1 stop the machine and allow it to cool. 10.7.2 remove the carburetor. See section removing carburetor. 10.7.3 remove the muffler guard ...

Page 109: Wm 80 Repair

Wm 80 repair disassembly and assembly wc_tx000523gb.Fm 109 wc_gr002935 d a b e c d.

Page 110: Disassembly and Assembly

Disassembly and assembly wm 80 repair 110 wc_tx000523gb.Fm 10.8 removing engine from bh 23 breakers see graphic: wc_gr002937 removal: 10.8.1 stop the machine and allow it to cool. 10.8.2 remove the screws (a) and lock washers which secure the two shells together. 10.8.3 remove the shell (b) opposite...

Page 111: Wm 80 Repair

Wm 80 repair disassembly and assembly wc_tx000523gb.Fm 111 wc_gr002937 a b d e c f.

Page 112: Disassembly and Assembly

Disassembly and assembly wm 80 repair 112 wc_tx000523gb.Fm 10.9 removing clutch see graphic: wc_gr002941 this procedure requires special tool p/n 0117972, puller. Do not run the engine while it is off the machine unless the clutch has been removed. Running the engine with the clutch attached to the ...

Page 113: Wm 80 Repair

Wm 80 repair disassembly and assembly wc_tx000523gb.Fm 113 wc_gr002941 a b c.

Page 114: Disassembly and Assembly

Disassembly and assembly wm 80 repair 114 wc_tx000523gb.Fm 10.10 wm 80 exploded view 9 10 11 12 3 2 1 4 8 7 5 6 7 41 14 13 15 16 17 18 19 20 21 36 19 35 34 32 33 40 31 17 22 37 38 39 23 24 25 26 27 28 29 30 15 wc_gr002906.

Page 115: Wm 80 Repair

Wm 80 repair disassembly and assembly wc_tx000523gb.Fm 115 10.11 wm 80 components see graphic: wc_gr002906 ref description ref description 1 set-cylinder 21 needle bearing 2 stud m6x18 22 screw m5x55 3 stud m5x20 23 ignition module 4 piston 24 sleeve 5 piston ring 25 screw m5x20 6 wrist pin 26 nut m...

Page 116: Disassembly and Assembly

Disassembly and assembly wm 80 repair 116 wc_tx000523gb.Fm 10.12 wm 80 cross section wc_gr002920 6 7 10 9 11 12 13 15 16 1 2 3 4 5 8 14.

Page 117: Wm 80 Repair

Wm 80 repair disassembly and assembly wc_tx000523gb.Fm 117 10.13 wm 80 cross section components see graphic: wc_gr002920 ref description ref description 1 crankcase 9 piston 2 crankcase gasket 10 piston rings 3 recoil starter 11 cylinder 4 flywheel key 12 connecting rod 5 flywheel fan 13 cylinder ga...

Page 118: Disassembly and Assembly

Disassembly and assembly wm 80 repair 118 wc_tx000523gb.Fm 10.14 vacuum testing cylinder see graphic: wc_gr002940 this procedure requires the use of test kit p/n 0155268, an 1/8 npt hose barb, new gaskets, and a vacuum pump. Note: for clarity, the engine is shown removed from the machine. 10.14.1 re...

Page 119: Wm 80 Repair

Wm 80 repair disassembly and assembly wc_tx000523gb.Fm 119 wc_gr002940 a c d e f b.

Page 120: Disassembly and Assembly

Disassembly and assembly wm 80 repair 120 wc_tx000523gb.Fm 10.15 cylinder and piston removal see graphic: wc_gr002907 the cylinder and cylinder head is of a one-piece design providing easy access to the cylinder and piston and eliminating the need for a head gasket. The cylinder bore is coated with ...

Page 121: Wm 80 Repair

Wm 80 repair disassembly and assembly wc_tx000523gb.Fm 121 b c f e g d c wc_gr002907.

Page 122: Disassembly and Assembly

Disassembly and assembly wm 80 repair 122 wc_tx000523gb.Fm 10.16 cylinder and piston inspection see graphic: wc_gr002908 ring gap: remove the cylinder from the crankcase. Check the ring gap at the lower part of the cylinder by placing the ring (h) in the cylinder and measuring the gap between the en...

Page 123: Wm 80 Repair

Wm 80 repair disassembly and assembly wc_tx000523gb.Fm 123 h wc_gr002908.

Page 124: Disassembly and Assembly

Disassembly and assembly wm 80 repair 124 wc_tx000523gb.Fm 10.17 cylinder and piston installation see graphic: wc_gr002909 this procedure requires the use of special tool p/n 0031986, ring compressor. It also requires the use of new retaining rings, p/n 0012257. 10.17.1 remove all old gasket materia...

Page 125: Wm 80 Repair

Wm 80 repair disassembly and assembly wc_tx000523gb.Fm 125 1 2 3 4 wc_gr002909 c a b e d g f h i.

Page 126: Disassembly and Assembly

Disassembly and assembly wm 80 repair 126 wc_tx000523gb.Fm 10.18 inspecting connecting rod and crankshaft see graphic: wc_gr002910 10.18.1 with the cylinder removed, check the needle bearing (a) for damage or wear. Replace it if necessary. 10.18.2 insert the wrist pin into the needle bearing and che...

Page 127: Wm 80 Repair

Wm 80 repair disassembly and assembly wc_tx000523gb.Fm 127 a wc_gr002910 b ok ok.

Page 128: Disassembly and Assembly

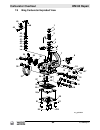

Disassembly and assembly wm 80 repair 128 wc_tx000523gb.Fm 10.19 disassembling crankcase see graphic: wc_gr002911 10.19.1 remove the clutch, starter, flywheel, cylinder, and piston. Place the nut back on the shaft to protect shaft threads. 10.19.2 remove eight m5 screws (a) which secure the crankcas...

Page 129: Wm 80 Repair

Wm 80 repair disassembly and assembly wc_tx000523gb.Fm 129 wc_gr002911 a b c e f d g h.

Page 130: Disassembly and Assembly

Disassembly and assembly wm 80 repair 130 wc_tx000523gb.Fm 10.20 assembling crankcase see graphic: wc_gr002912 this procedure requires a propane torch or equivalent heat source. 10.20.1 lubricate the shaft seals (a) using 2-cycle engine oil. Position one of the seals over the bore in the crankcase s...

Page 131: Wm 80 Repair

Wm 80 repair disassembly and assembly wc_tx000523gb.Fm 131 wc_gr002912 f e a h g d a b c a f e.

Page 132: Disassembly and Assembly

Disassembly and assembly wm 80 repair 132 wc_tx000523gb.Fm 10.21 crankshaft bearings see graphic: wc_gr002913 press method removal: this procedure requires special tools p/n 0023338, split ring puller (a) ; and p/n 0023339, crank support tube (b) . It also requires the use of an arbor press or equiv...

Page 133: Wm 80 Repair

Wm 80 repair disassembly and assembly wc_tx000523gb.Fm 133 a c d wc_gr002913 e b.

Page 134: Disassembly and Assembly

Disassembly and assembly wm 80 repair 134 wc_tx000523gb.Fm 10.22 bearing installation see graphic: wc_gr002914 this procedure requires special tools p/n 0048585, pusher tube (f); p/n 0032028, crank support plate (g); and p/n 0023339 crank support tube (h). 10.22.1 slide the support plate between the...

Page 136

Wacker neuson se · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02-0 · fax: +49 - (0)89-3 54 02-390 wacker neuson corporation · n92w15000 anthony ave. · menomonee falls, wi 53051 · tel. : (262) 255-0500 · fax: (262) 255-0550 ·tel. : (800) 770-0957 wacker neuson limited - room 1701–03 & ...