- DL manuals

- Wacker Neuson

- Construction Equipment

- WP 1550

- Operator's Manual

Wacker Neuson WP 1550 Operator's Manual

Summary of WP 1550

Page 1

Operator’s manual vibroplate wp 1550 wp 1550w 0 1 5 5 9 4 0 e n 0155940en / 008.

Page 3: Wp 1550

Wp 1550 table of contents wc_bo0155940en_008toc.Fm 1 foreword 3 1. Safety information 4 1.1 laws pertaining to spark arresters ...................................................... 5 1.2 operating safety .................................................................................. 6 1.3 operat...

Page 4: Table of Contents

Table of contents wp 1550 wc_bo0155940en_008toc.Fm 2 4. Maintenance 23 4.1 periodic maintenance schedule ..........................................................23 4.2 cleaning plate .....................................................................................25 4.3 drive belt ...............

Page 5

Wc_tx000001gb.Fm 3 california proposition 65 warning: engine exhaust, some of its constituents, and certain vehicle components, contain or emit chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. Foreword this manual provides information and proce...

Page 6: Safety Information

Safety information wp 1550 wpm_si000324gb.Fm 4 1. Safety information this manual contains danger, warning, caution, notice and note callouts which must be followed to reduce the possibility of personal injury, damage to the equipment, or improper service. This is the safety alert symbol. It is used ...

Page 7: Wp 1550

Wp 1550 safety information wpm_si000324gb.Fm 5 1.1 laws pertaining to spark arresters notice: state health safety codes and public resources codes specify that in certain locations spark arresters be used on internal combustion engines that use hydrocarbon fuels. A spark arrester is a device designe...

Page 8: Safety Information

Safety information wp 1550 wpm_si000324gb.Fm 6 1.2 operating safety familiarity and proper training are required for the safe operation of the machine. Machines operated improperly or by untrained personnel can be hazardous. Read the operating instructions contained in this manual and the engine man...

Page 9: Wp 1550

Wp 1550 safety information wpm_si000324gb.Fm 7 1.3 operator safety while using internal combustion engines internal combustion engines present special hazards during operation and fueling. Read and follow the warning instructions in the engine owner’s manual and the safety guidelines below. Failure ...

Page 10: Safety Information

Safety information wp 1550 wpm_si000324gb.Fm 8 1.4 service safety a poorly maintained machine can become a safety hazard! In order for the machine to operate safely and properly over a long period of time, periodic maintenance and occasional repairs are necessary. 1.4.1 do not attempt to clean or se...

Page 11: Wp 1550

Wp 1550 safety information wpm_si000324gb.Fm 9 1.5 label locations wpmgr005959 1 2 3 4 5 6 7 1 2 warning warnung advertencia avertissement 10w30

Page 12: Safety Information

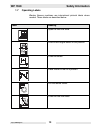

Safety information wp 1550 wpm_si000324gb.Fm 10 1.6 warning and informational labels wacker neuson machines use international pictorial labels where needed. These labels are described below: label meaning warning! To prevent hearing loss, wear hearing protec- tion when operating the machine. Read th...

Page 13: Wp 1550

Wp 1550 safety information wpm_si000324gb.Fm 11 warning! Hand injury if caught in moving belt. Always replace beltguard. Caution! Read and understand the supplied operator’s manual before operating this machine. Failure to do so increases the risk of injury to yourself or others. Notice lifting poin...

Page 14: Safety Information

Safety information wp 1550 wpm_si000324gb.Fm 12 company logo a nameplate listing the model number, item number, revision number, and serial number is attached to each unit. Please record the infor- mation found on this plate so it will be avail- able should the nameplate become lost or damaged. When...

Page 15: Wp 1550

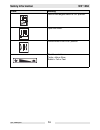

Wp 1550 safety information wpm_si000324gb.Fm 13 1.7 operating labels wacker neuson machines use international pictorial labels where needed. These labels are described below: label meaning open the fuel flow valve. Push or turn engine switch to on position. Close the choke. Place throttle in the idl...

Page 16: Safety Information

Safety information wp 1550 wpm_si000324gb.Fm 14 push or turn engine switch to off position. Open the choke. Place throttle in the fast position. Throttle control lever: turtle = idle or slow rabbit = full or fast label meaning 1.

Page 17: Wp 1550

Wp 1550 technical data wpm_td000333gb.Fm 15 2. Technical data 2.1 engine data engine power rating net power rating per sae j1349. Actual power output may vary due to conditions of specific use. Wp 1550, wp 1550 w 0009325, 0009324, 0009548 engine engine make wacker engine model wm170 max. Rated power...

Page 18: Technical Data

Technical data wp 1550 wpm_td000333gb.Fm 16 2.2 plate data 2.3 sound and vibration specifications products are tested for sound pressure level in accordance with en iso 11204. Sound power level is tested in accordance with european directive 2000/14/ec - noise emission in the environment by equipmen...

Page 19: Wp 1550

Wp 1550 technical data wpm_td000333gb.Fm 17 2.4 dimensions mm (in.) 19.5 (500) 34.5 (875) 38 (965) wpmgr005986.

Page 20: Operation

Operation wp 1550 wpm_tx001125gb.Fm 18 3. Operation 3.1 recommended fuel the engine requires regular grade unleaded gasoline. Use only fresh, clean gasoline. Gasoline containing water or dirt will damage fuel system. Consult engine owner’s manual for complete fuel specifications. 3.2 before starting...

Page 21: Wp 1550

Wp 1550 operation wpm_tx001125gb.Fm 19 3.3 to start see graphic: wc_gr000655 3.3.1 open fuel valve by moving lever down (a1). Note: if engine is cold, move choke lever to close position (d2). If engine is hot, set choke to open position (d1). 3.3.2 turn engine switch to “on” (b2). 3.3.3 open throttl...

Page 22: Operation

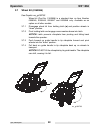

Operation wp 1550 wpm_tx001125gb.Fm 20 3.5 application this plate is designed for compacting loose, granular soils, gravel, and paving stones. It is intended to be used in confined areas and areas next to structures such as walls, curbs, and foundations. Plates equipped with water tanks can be used ...

Page 23: Wp 1550

Wp 1550 operation wpm_tx001125gb.Fm 21 3.6 operation see graphic: wpmgr006016 run engine at full throttle and allow plate to pull itself along at its normal speed. When operating on an incline it may be necessary to assist plate by pushing it forward slightly. Depending on the material being compact...

Page 24: Operation

Operation wp 1550 wpm_tx001125gb.Fm 22 3.7 wheel kit (0162986) see graphic: wc_gr002793 wheel kit (part no. 0162986) is a standard item on item number 0009545, 0009546, 0009547 and 0009548 only. Available as an option on all other models. 3.7.1 disengage wheel kit from holding latch (a) and position...

Page 25: Wp 1550

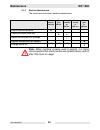

Wp 1550 maintenance wpm_tx001126gb.Fm 23 4. Maintenance 4.1 periodic maintenance schedule 4.1.1 engine maintenance the chart below lists basic engine maintenance. Refer to the engine manufacturer’s operation manual for additional information. Daily before starting after first 20 hrs. Every 2 weeks o...

Page 26: Maintenance

Maintenance wp 1550 wpm_tx001126gb.Fm 24 4.1.2 machine maintenance the chart below lists basic machine maintenance. Note: when machine is being used in asphalt, it is highly recommended that shockmounts are replaced every year or after 300 hours of usage. Daily before starting after first 20 hrs. Ev...

Page 27: Wp 1550

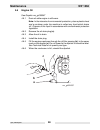

Wp 1550 maintenance wpm_tx001126gb.Fm 25 4.2 cleaning plate clean plate after use to remove dirt, stones, and mud caught under the engine console. If plate is being used in a dusty area, check engine cylinder cooling fins for heavy dirt accumulation. Keep engine cylinder fins clean to prevent engine...

Page 28: Maintenance

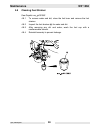

Maintenance wp 1550 wpm_tx001126gb.Fm 26 4.4 exciter lubrication see graphic: wpmgr006021 the exciter assembly is a self-contained, sealed unit. The bearings are lubricated using automatic transmission fluid (see technical data for type). Change fluid once every year or 300 hours of operation. When ...

Page 29: Wp 1550

Wp 1550 maintenance wpm_tx001126gb.Fm 27 4.5 spark plug see graphic: wc_gr000028 clean or replace the spark plug as needed to ensure proper operation. Refer to your engine operator’s manual. The muffler becomes very hot during operation and remains hot for a while after stopping the engine. Do not t...

Page 30: Maintenance

Maintenance wp 1550 wpm_tx001126gb.Fm 28 4.6 engine oil see graphic: wc_gr000087 4.6.1 drain oil while engine is still warm. Note: in the interests of environmental protection, place a plastic sheet and a container under the machine to collect any liquid which drains off. Dispose of this liquid in a...

Page 31: Wp 1550

Wp 1550 maintenance wpm_tx001126gb.Fm 29 4.7 air cleaner see graphic: wc_gr000656 never use gasoline or other types of low-flash point solvents for cleaning the air cleaner. A fire or explosion could result. Notice: never run the engine without the air cleaner. Severe engine damage will occur. The e...

Page 32: Maintenance

Maintenance wp 1550 wpm_tx001126gb.Fm 30 4.8 cleaning fuel strainer see graphic: wc_gr001093 4.8.1 to remove water and dirt, close the fuel lever and remove the fuel strainer. 4.8.2 inspect the fuel strainer (a) for water and dirt. 4.8.3 after removing any dirt and water, wash the fuel cup with a no...

Page 33: Wp 1550

Wp 1550 maintenance wpm_tx001126gb.Fm 31 4.9 troubleshooting 4.10 storage if plate is being stored for more than 30 days: 4.10.1 remove loose stones and dirt from plate. 4.10.2 clean engine cylinder cooling fins. 4.10.3 clean or replace air filter. 4.10.4 change exciter oil. 4.10.5 change engine oil...

Page 34: Maintenance

Maintenance wp 1550 wpm_tx001126gb.Fm 32 4.11 lifting machine see graphic: wpmgr006037 see technical data for the weight of the machine. To lift machine manually: 4.11.1 stop the engine. 4.11.2 obtain help from a partner and plan the lift. 4.11.3 grasp the machine by its cage (a) and lifting slot (b...

Page 35: Wp 1550

Wp 1550 maintenance wpm_tx001126gb.Fm 33 4.12 transporting machine see graphic: wpmgr006055 to avoid burns or fire hazards, let engine cool before transporting machine or storing indoors. 4.12.1 turn fuel valve to the off position and keep the engine level to prevent fuel from spilling. 4.12.2 tie d...

Page 37

Wp1550-q_2009_wn.Fm heinz gengnagel president & ceo wacker neuson manila, inc. Date / datum / fecha / date ec declaration of conformity eg-konformitÄtserklÄrung ce-declaraciÓn de conformidad dÉclaration de conformitÉ de la cee wacker neuson manila, inc., dasmariÑas, cavite, philippines hereby certif...

Page 38

Wacker construction equipment ag · preußenstraße 41 · d-80809 münchen · tel.: +49-(0)89-3 54 02 - 0 · fax: +49 - (0)89-3 54 02-3 90 wacker neuson corporation · p.O. Box 9007 · menomonee falls, wi 53052-9007 · tel. : (262) 255-0500 · fax: (262) 255-0550 · tel. : (800) 770-0957 wacker asia pacific ope...