- DL manuals

- WAGNER

- Paint Sprayer

- 524009

- Operating Manual

WAGNER 524009 Operating Manual

Summary of 524009

Page 1

Edition 4 / 2012 0524 831f gb operating manual models: 0524009 0524019 finish 230 ac compact spray system.

Page 2: Warning!

2 finish 230 ac compact gb warning! Attention: danger of injury by injection! Aircoat units develop extremely high spraying pressures. Be safety conscious! 1 2 3 never put your fingers, hands or any other parts of the body into the spray jet! Never point the spray gun at yourself, other persons or a...

Page 3

Finish 230 ac compact 3 gb contents contents page 1. Safety regulations for aircoat spraying ............................... 4/5 1.1 explanation of symbols used .............................................................. 4 1.1 earthing instructions ...................................................

Page 4

4 finish 230 ac compact gb safety regulations 1. Safety regulations for aircoat spraying 1.1 explanation of symbols used this manual contains information that must be read and understood before using the equipment. When you come to an area that has one of the following symbols, pay particular attent...

Page 5

Finish 230 ac compact 5 gb safety regulations hazard: explosion or fire solvent and paint fumes can explode or ignite. Severe injury and/or property damage can occur. Prevention: • provideextensiveexhaustandfreshairintroductionto keep the air within the spray area free from accumulation of flammable...

Page 6

6 finish 230 ac compact gb safety regulations general description 1.2 earthing instructions electric models must be earthed. In the event of an electrical short circuit, earthing reduces the risk of electric shock by providing an escape wire for the electric current. This product is equipped with a ...

Page 7

Finish 230 ac compact 7 gb setup 3. Setup use this procedure to set up the spray system. 1. Make sure the diaphragm pump on/off switch and the compressor on/off switch are in the off position. 2. Make sure the pressure control knob is turned fully counterclockwise to its lowest pressure setting. 3. ...

Page 8

8 finish 230 ac compact gb operation 4. Operation use the following procedures to operate the spray system. 4.1 preparing to prime 1. Fill the inlet valve with water or with a light household oil. 2. Makesurethattheprime/sprayvalveissettoprimeandthat the pressure control knob is turned counterclockw...

Page 9

Finish 230 ac compact 9 gb operation 1c 1d 4.3 priming with optional suction set (p/n 0508194a) 1. Attach the suction set to the pump. A. Remove the hopper return tube fitting. Screw the suction set return tube fitting into the return tube port on the side of the pump. I do not over-tighten. Hand ti...

Page 10

10 finish 230 ac compact gb spraying 5. Spraying the aircoat spray system has two different painting modes. The aircoat mode is used for fine finish work with low to medium viscositymaterials(oil,stains,lacquers,etc...).Theairlessmodeis usedforgeneralpaintingwithhighviscositymaterials(latex). 5.1 sp...

Page 11

Finish 230 ac compact 11 gb spraying spraying technique 5.3 pressure relief procedure be sure to follow the pressure relief procedure when shutting the unit down for any purpose, including servicing or adjusting any part of the spray system, changing or cleaning spray tips, or preparing for cleanup....

Page 12

12 finish 230 ac compact gb cleanup 7. Cleanup 7.1 overnight storage shutdown 1. Turn the pressure control knob counterclockwise to the minimum setting. 2. Turntheprime/sprayvalvetoprime. 3. Move the pump on/off switch to the off position. 4. Move the compressor on/off switch to the off position. 5....

Page 13

Finish 230 ac compact 13 gb cleanup maintenance 7.5 clearing the spray hose 1. Turn the pressure control knob counterclockwise to the minimum pressure setting. 2. Turntheprime/sprayvalvetospray. 3. Unlock the spray gun trigger. 4. Carefully trigger the gun with the spray tip removed against the insi...

Page 14

14 finish 230 ac compact gb maintenance electrical schematic 8. Tightentheoutletvalvenut(a)securelywithanadjustable wrench. Do not over-tighten. (b) (a) (c) (d) (e) (f) (g) i wear on the ball is almost impossible to detect visually. To test for a worn outlet valve assembly, turn the pressure control...

Page 15

Finish 230 ac compact 15 gb troubleshooting problem a. The unit does not start up. B. The pump starts up but does not draw in paint when the prime/sprayvalveissetto prime. C. The pump draws up paint but the pressure drops when the gun is triggered. D. The paint pattern is tailing. E. The thermal ove...

Page 16

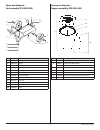

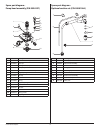

16 finish 230 ac compact 16 17 18 19 1 2 5 3 4 8 10 11 12 14 15 20 22 23 24 13 9 6 7 21 28 26 27 25 29 30 31 32 0524475 (model 0524009) 0524520 (model 0524019) spare part diagram • main assembly item part # description 1 0524386 powercord(model0524009) 0524520 powercord(model0524019) 2 0551980 lock ...

Page 17

Finish 230 ac compact 17 spare part diagram • diaphragm pump (p/n 0550007) 17 18 19 4 5 6 7 8 9 10 11 12 13 14 15 16 1 2 3 20 21 22 23 24 25 note: whenever pump head is removed for service, the diaphragm (#3) should be replaced. Item part # description 1 0524227 pumphead(includesitems#2-3) 2 0270494...

Page 18

18 finish 230 ac compact spare part diagram • cart assembly (p/n 0508190) 3 1 2 5 6 7 4 9 8 10 12 11 spare part diagram • hopper assembly (p/n 0524242) 1 2 3 4 6 5 7 item part # description 1 0508381 paint cup 2 9890104 cap(2) 3 0294534 wheelspacer(10) 4 0508517 cart weldment 5 0090005 pad 6 9820305...

Page 19

Finish 230 ac compact 19 1 2 5 6 3 4 7 8 9 10 11 12 13 15 14 1 2 3 4 5 6 8 7 spare part diagram • pump head assembly (p/n 0524227) spare part diagram • optional suction set (p/n 0508194a) item part # description 1 0278242 inlet valve assembly 2 0278655 inlet cap 3 0089482 sealing washer, nylon 4 027...

Page 20

20 finish 230 ac compact www.Wagner-group.Com a j. Wagner ges.M.B.H. Ottogasse 2/20 2333 leopoldsdorf Österreich tel. +43/ 2235 / 44 158 telefax +43/ 2235 / 44 163 office@wagner-group.At dk wagner wagner scandinavia a/s helgeshøj allé 28 2630 taastrup denmark tel. +45/43/ 27 18 18 telefax +45/43/ 43...

Page 21

Finish 230 ac compact 21 important notes on product liability as a result of an ec regulation being effective as from january 1, 1990, the manufacturer shall only be liable for his product if all parts come from him or are released by him, and if the devices are properly mounted and operated. If the...

Page 22

22 finish 230 ac compact note on disposal: in observance of the european directive 2002/96/ ec on waste electrical and electronic equipment and implementation in accordance with national law, this product is not to be disposed of together with household waste material but must be recycled in an envi...

Page 23

Finish 230 ac compact 23 23 finish 230 ac compact j. Wagner gmbh otto lilienthal-str.18 d-88677 markdorf wagner finish 230 ac compact en iso 12100-1/-2, en 1953 :1998+a1 :2009, en 60204-1 :2007, en 55014-1:2006, en 55014-2 :1997, en 61000-3-2 :2005, en 61000-3-3 :1994 bgr 500 /2/ kapitel 2.29, 2.36 ...

Page 24

24 finish 230 ac compact j. Wagner gmbh otto lilienthal-str.18 d-88677 markdorf wagner finish 230 ac compact en iso 12100-1/-2, en 1953 :1998+a1 :2009, en 60204-1 :2007, en 55014-1:2006, en 55014-2 :1997, en 61000-3-2 :2005, en 61000-3-3 :1994 bgr 500 /2/ kapitel 2.29, 2.36 i dichiarazione di confor...