- DL manuals

- WAGNER

- Water Pump

- Cobra 40-10

- Translation Of The Original Operating Manual

WAGNER Cobra 40-10 Translation Of The Original Operating Manual

Summary of Cobra 40-10

Page 1

B_04233 b_04234 high-pressure double diaphragm pumps version 07/2014 translation of the original operating manual.

Page 3: Table of Contents

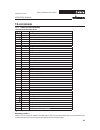

3 operating manual version 07/2014 order number doc2340851 table of contents 1 about this manual 6 1.1 preface 6 1.2 warnings, notices, and symbols in this operating manual 6 1.3 languages 7 1.4 abbreviations in the text 7 1.5 terminology for the purpose of this manual 7 2 correct use 8 2.1 device t...

Page 4: Table of Contents

4 operating manual version 07/2014 order number doc2340851 6 assembly and commissioning 26 6.1 training assembly/commissioning staff 26 6.2 storage conditions 26 6.3 installation conditions 26 6.4 transportation 26 6.5 assembly and installation 27 6.5.1 ventilation of the spray booth 28 6.5.2 air su...

Page 5

5 operating manual version 07/2014 order number doc2340851 12 disposal 53 13 accessories 54 13.1 cobra 40-10 accessories 54 13.2 cobra 40-25 accessories 56 14 spare parts 58 14.1 how can spare parts be ordered? 58 14.2 overview of the cobra 40-10 components 59 14.3 cobra 40-10 air motor 60 14.4 cobr...

Page 6

6 operating manual version 07/2014 order number doc2340851 1 about this manual 1.1 preface 1.2 warnings, notices, and symbols in this operating manual warning instructions in this operating manual highlight particular dangers to users and to the device and state measures for avoiding the hazard. The...

Page 7

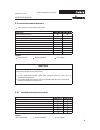

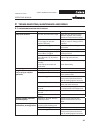

7 operating manual version 07/2014 order number doc2340851 1.3 languages the operating manual is available in the following languages: language order no. Language order no. German 2340850 english 2340851 french 2340852 italian 2340853 spanish 2340854 russian 2345830 japanese 2346196 1.4 abbreviation...

Page 8

8 operating manual version 07/2014 order number doc2340851 2 correct use 2.1 device types double diaphragm pump and spray pack: 2.2 type of use 2.3 use in potentially explosive areas the device is suitable for processing liquid materials like paints and lacquers in accordance with the classifi catio...

Page 9: Notice

9 operating manual version 07/2014 order number doc2340851 application water-dilutable products solvent-based lacquers and paints two-component coating products emulsions uv lacquers primers epoxy and polyurethane lacquers, phenolic lacquers liquid plastics wax-based underside protection shear-sensi...

Page 10

10 operating manual version 07/2014 order number doc2340851 2.6 reasonably foreseeable misuse the following is prohibited: coating work pieces which are not grounded, unauthorized conversions and modifi cations to the double diaphragm pump, processing dry or similar coating products, and using defec...

Page 11

11 operating manual version 07/2014 order number doc2340851 3.1 explosion protection identification as defi ned in directive 94/9/ec (atex 95), the device is suitable for use in potentially explosive areas. European communities symbol for explosion protection device class ii category 2 (zone 1) ex-a...

Page 12

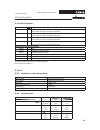

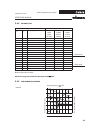

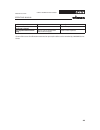

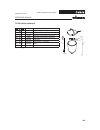

12 pumpentyp/ pump type/ type de pompe max. Materialdruck/ fluid pressure/ pression fluid Übersetzungsverhältnis/ ratio/ rapport fördermenge dh/ delivery ds/ débit cd max. Luftdruck/ air pressure/ pression d`air max. Temp. Material/ fluid serie nr. / serie no. / n. Serie vor gebrauch betriebsanleitu...

Page 13

13 operating manual version 07/2014 order number doc2340851 4 general safety instructions 4.1 safety instructions for the operator 4.1.1 electrical equipment 4.1.2 staff qualifications 4.1.3 safe work environment keep this operating manual on hand near the device at all times. Always follow local re...

Page 14

14 operating manual version 07/2014 order number doc2340851 4.2.1 safe handling of wagner spray devices 4.2 safety instructions for staff always follow the information in these instructions, particularly the general safety instructions and the warning instructions. Always follow local regulations co...

Page 15

15 operating manual version 07/2014 order number doc2340851 4.2.3 product hoses 4.2.2 grounding the device in order to avoid electrostatic charging of the device, the device must be grounded. Friction, fl owing liquids, and air or electrostatic coating processes create charges. Flames or sparks can ...

Page 16

16 operating manual version 07/2014 order number doc2340851 4.2.5 handling hazardous liquids, lacquers and paints when preparing or working with lacquer and when cleaning the device, follow the working instructions of the manufacturer of the lacquers, solvents and cleaning agents being used. Take th...

Page 17

17 operating manual version 07/2014 order number doc2340851 4.2.6 touching hot surfaces only touch hot surfaces if you are wearing protective gloves. When operating the device with a coating product with a temperature of > 43 °c; 109.4 °f: - mark the device with a warning label "warning – hot surfac...

Page 18

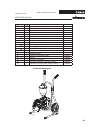

18 1 4 6 9 3 5 2 7 13 14 10 11 12 15 8 b_04237 cobra 40-10 1 4 6 9 3 5 2 7 14 10 11 12 15 8 b_04238 cobra 40-25 13 operating manual version 07/2014 order number doc2340851 5 description the double diaphragm pump is driven with compressed air. This compressed air moves the air piston in the air motor...

Page 19: Warning

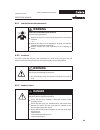

19 b_01205 "? B_01207 operating manual version 07/2014 order number doc2340851 the cobra pump may only be operated in a horizontal or vertical position as shown in the diagrams. Overhead operation is not permitted. Vertical positioning horizontal positioning overhead positioning overpressure! Risk o...

Page 20

20 operating manual version 07/2014 order number doc2340851 5.3 scope of delivery inlet housing consital (aluminum alloy) fluid section consital (aluminum alloy) valve balls stainless steel valve seats/valve cone carbide diaphragms resistant pa valve fi tting 1.4104 description devices pump ratio 40...

Page 21: Warning

21 operating manual version 07/2014 order number doc2340851 * a-rated sound pressure level measured at 1 m distance, lpa1m, in accordance with din en 14462: 2005. Reference measurements have been made by suva (swiss accident insurance institute). Description devices air inlet (inside thread) inch g ...

Page 22

22 b_02943 g p q n o r f b d e f h i k l m g a c b_04235 cobra 40-10 b_04236 b d e f h i l g a c cobra 40-25 k m operating manual version 07/2014 order number doc2340851 5.4.3 measurements and connections measurement mm; inch mm; inch a 505; 19.88 605; 23.82 b 313; 12.32 379; 14.92 c 322; 12.68 373;...

Page 23

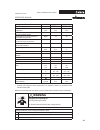

23 bar bar bar bar bar bar "? Operating manual version 07/2014 order number doc2340851 5.4.4 volume flow 5.4.5 performance diagrams stroke frequency ( /min) p roduc t pr essur e (bar) air c onsumption (nl/min) water fl ow rate (nl/min) wagner al nozzles volume fl ow in l/min.* inch mm spray angle at...

Page 24

24 nl/min l/min b_01203 c nl/min bar (mpa) 250 (25) 200 (20) 150 (15) 100 (10) 50 (5) 0 0 0.4 0.8 1.2 1.6 2 2.4 l/min 0 1000 800 600 400 200 0 40 80 120 160 200 240 a a b b c b_02947 c nl/min bar (mpa) 250 (25) 200 (20) 150 (15) 100 (10) 50 (5) 0 0 1 2 3 4 5 6 l/min 0 1500 1200 900 600 300 0 40 80 1...

Page 25

25 b_04300 2 3 1 4 5 b_04301 2 3 1 operating manual version 07/2014 order number doc2340851 5.5 pressure regulator unit for cobra positions of the ball valve 1 open: working position 2 closed: the air motor can still be under pressure. 3 vent: operating pressure in the air motor is vented (control p...

Page 26: Warning

26 operating manual version 07/2014 order number doc2340851 6 assembly and commissioning 6.1 training assembly/commissioning staff incorrect installation/operation! Risk of injury and damage to the device. The assembly and commissioning staff must have the technical skills to safely undertake commis...

Page 27: Warning

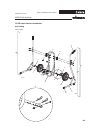

27 b_04239 1 6 7 2 4 5 operating manual version 07/2014 order number doc2340851 6.5 assembly and installation procedure: 1 mount the pump on a frame, trolley (6), or wall mount. 2 for aircoat systems: mount the additional fi lter pressure regulator (7) (option). 3 mount suction system (5). 4 mount r...

Page 28: Warning

28 operating manual version 07/2014 order number doc2340851 6.5.1 ventilation of the spray booth toxic and/or fl ammable vapor mixtures! Risk of poisoning and burns operate the device in a spray booth approved for the working materials. – or – operate the device on an appropriate spraying wall with ...

Page 29: Warning

29 "? 2max-7 operating manual version 07/2014 order number doc2340851 6.6 grounding grounding scheme (example) pump paint tank work piece conveyor spraying stand floor, static dissipative discharge of electrostatically charged components in atmospheres containing solvents! Explosion hazard from elec...

Page 30: Warning

30 "? Operating manual version 07/2014 order number doc2340851 cable cross sections pump 4 mm2; paint tank 6 mm2; conveyor 16 mm2; booth 16 mm2; spraying stand 16 mm2; procedure: 1 screw on grounding cable with eye. 2 clamp the grounding cable clip to a grounding connection on site. 3 ground the pro...

Page 31: Warning

31 operating manual version 07/2014 order number doc2340851 6.8.1 safety instructions 6.8 commissioning every time before starting up, the following points should be observed as laid down in the operating manual: - observe all safety regulations in accordance with chapter 4. - carry out commissionin...

Page 32: Notice

32 "? 6 1 9 2 7 4 5 b_04240 3 operating manual version 07/2014 order number doc2340851 6.8.2 preparation for commissioning impurities in the spraying system! Clogging of the spray gun flush the spray gun and paint supply with a suitable fl ushing agent before commissioning. Notice 6.8.3 basic flushi...

Page 33

33 b_04301 2 3 1 b_04303 operating manual version 07/2014 order number doc2340851 6.8.4 filling with working material relief valve circulation mode spraying mode 1 place suction hose (7) and return tube (4) into the tank with the working material (6). 2 adjust the pressure regulator (1) to approx. 0...

Page 34: Warning

34 operating manual version 07/2014 order number doc2340851 7 operation 7.1 training the operating staff incorrect operation! Risk of injury and damage to the device. The operating staff must be qualifi ed and fi t to operate the entire system. The operating staff must be familiar with the potential...

Page 35

35 b_04302 b_04303 1 2 b_04099 operating manual version 07/2014 order number doc2340851 ➁ ➀ emergency stop in the event of unforeseen occurrences, the ball valve (1) should be vented immediately and the relief valve (2) opened. Vent open switch position circulation 7.3 emergency deactivation.

Page 36

36 b_04301 2 3 1 operating manual version 07/2014 order number doc2340851 7.4 work 1 secure gun and place nozzle in the gun. 2 slowly open the ball valve. 3 set the required working pressure on the pressure regulator. 4 optimize the spraying results as laid down in the gun instructions. 5 start work...

Page 37: Notice

37 operating manual version 07/2014 order number doc2340851 process for relieving pressure 1 close gun. 2 close ball valve. 3 vent air motor. 4 release the system by opening the gun. 5 close and secure gun. If the system has been used with 2k products: hardened working material in the spraying syste...

Page 38: Warning

38 operating manual version 07/2014 order number doc2340851 8 cleaning and maintenance cleaning work should be undertaken regularly and carefully by qualifi ed and trained staff . They should be informed of specifi c hazards during their training. The following hazards may arise during cleaning work...

Page 39: Danger

39 operating manual version 07/2014 order number doc2340851 8.1.4 long-term storage note: the device should be cleaned for maintenance purposes, etc. Ensure that no remaining product dries on and sticks to the device. Procedure: 1 carry out work interruption -> chapter 7.5. 2 carry out the basic fl ...

Page 40: Danger

40 operating manual version 07/2014 order number doc2340851 8.2 maintenance maintenance work should be undertaken regularly and carefully by qualifi ed and trained staff . They should be informed of specifi c hazards during their training. The following hazards may arise during maintenance work: - h...

Page 41

41 operating manual version 07/2014 order number doc2340851 8.2.3.1 grounding check every day before starting work, carry out a visual check to ensure that the earthing connection is present in the device and in all relevant components. 8.2.3 safety checks wagner recommends having all spraying devic...

Page 42: Danger

42 operating manual version 07/2014 order number doc2340851 bursting hose, bursting threaded joints! Danger to life from injection of product and from fl ying parts. Ensure that the hose material is chemically resistant to the sprayed products and the used fl ushing agents. Ensure that the spray gun...

Page 43: Notice

43 b_04241 1 b_04242 b_04243 a 5 x operating manual version 07/2014 order number doc2340851 8.2.4 hydraulic stage maintenance 8.2.5 checking the oil level dismount the device onto a frame as shown in the picture and turn it upside down. Observe the fi ll level marking (x) on the oil tank. 1 start up...

Page 44: Notice

44 b_04241 1 4 3 b_04244 2 operating manual version 07/2014 order number doc2340851 discharging oil procedure: 1 decommission and clean the device -> chapter 8.1.3 up to and including point 6. 2 position device as shown in the picture and dismount the hood and casing. 3 unscrew piston cover (1). 4 p...

Page 45: Caution

45 b_04245 8 7 4 9 5 6 b_04246 17 mm; 0.67in operating manual version 07/2014 order number doc2340851 filling hydraulic stage with oil procedure: 1 turn pump (mounted on the frame) upside down. 2 unscrew and remove threaded plug (5). 3 unscrew 2 locking screws (4) and replace with 2 screw fi ttings ...

Page 46

46 b_04243 a 5 x b_04247 9 1 5 operating manual version 07/2014 order number doc2340851 vent procedure: 1 turn the pump upside down. Remove the threaded plug (5). 2 slowly start up (vent) the pump until no air bubbles appear from the oil suction fi tting. 3 oil level a in the oil tank has to be with...

Page 47

47 operating manual version 07/2014 order number doc2340851 9 troubleshooting, maintenance, and repair problem cause remedy pump does not work. Air motor does not work or stops. Open and close ball valve on the pressure regulator unit or briefl y disconnect compressed air supply. No pressure indicat...

Page 48

48 operating manual version 07/2014 order number doc2340851 problem cause remedy pump runs fast when the spray gun is closed. Valves worn. Replace the parts. Loss of power due to severe icing. There is a lot of condensation water in the air supply. Install a water separator. If none of the causes of...

Page 49: Danger

49 operating manual version 07/2014 order number doc2340851 10 repair work 10.1 repair staff repair work must be carried out carefully by qualifi ed and trained staff . They should be informed of specifi c hazards during their training. The following hazards may arise during repair work: - health ha...

Page 50: Attention

50 operating manual version 07/2014 order number doc2340851 10.3 cleaning the parts after disassembly in chapter 14 the order numbers for device spare parts can be found, as well as for wearing parts such as seals. Please note: all reusable parts (except for the electrical components) should be clea...

Page 51

51 operating manual version 07/2014 order number doc2340851 11 functional check after repair after all repairs, the device must be checked for safe condition before recommissioning. The necessary scope of inspection and testing depends on the repair carried out and must be documented by the repair s...

Page 52

52 operating manual version 07/2014 order number doc2340851 activities aid tools 1.5 general inspections - check tightening torque of various screws. Tighten hexagon screws m12x65 (40-10) or m16x80 (40-25) and input valve housing with the prescribed torque. (see chapter 14) - check all threaded conn...

Page 53

53 operating manual version 07/2014 order number doc2340851 12 disposal when the equipment must be scrapped, please diff erentiate the disposal of the waste materials. The following materials have been used: - stainless steel - aluminum - elastomers - plastics - carbide consumable products (lacquers...

Page 54

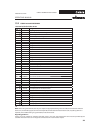

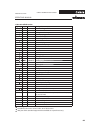

54 operating manual version 07/2014 order number doc2340851 accessories list for cobra 40-10 order no. Designation a 2329519 diaphragm pump cobra 40-10 1 322912 hydraulic oil (for pressure stage) 250 ml; 250 cc 2 236219 grounding cable 3 m; 9.8 ft 3 2333479 aircoat fi lter pressure regulator 4 34143...

Page 55

55 b_04234 11 17 13 24 21 20 25 15 12 14 12 7 a 51 52 b_04248 3 cobra 40-10 aircoat 16 1 4 2 53 26 28 27 29 30,31 32 22 14 6 9 10,19 8 18 55 56 57 33 34 58 operating manual version 07/2014 order number doc2340851 note: when the fi tting at the material outlet is replaced (item 55/57), a new sealing ...

Page 56

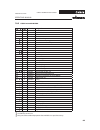

56 operating manual version 07/2014 order number doc2340851 13.2 cobra 40-25 accessories accessories list for cobra 40-25 order no. Designation a 2329523 diaphragm pump cobra 40-25 1 322912 hydraulic oil (for pressure stage) 250 ml; 250 cc 2 236219 grounding cable 3 m; 9.8 ft 3 2333479 aircoat fi lt...

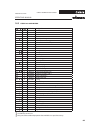

Page 57

57 28 27 29 30,31 21 20 25 6 1 a 51 4 2 b_04249 cobra 40-25 aircoat 3 11 17 13 24 12 12 53 52 7 33 34 18 9 8 10,19 55 56 32 57/58 60/61 22 59 55 operating manual version 07/2014 order number doc2340851 note: when the fi tting is replaced at the material output (item 55/57/58/59), a new sealing ring ...

Page 58: Warning

58 operating manual version 07/2014 order number doc2340851 14 spare parts 14.1 how can spare parts be ordered? Incorrect maintenance/repair! Risk of injury and damage to the device. Have repairs and part replacements carried out only by specially trained staff or a wagner service center. Before all...

Page 59

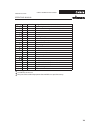

59 13 3 2 6 7 25 nm; 18 lbft 10 12 11 1 9 5 4 8 7 b_04250 15 16 operating manual version 07/2014 order number doc2340851 14.2 overview of the cobra 40-10 components order no. Designation 1 1 - air motor 3/53 2 1 - preassembled cobra 40-10 fl uid section 3 1 322436 air motor casing 4 1 322437 pressur...

Page 60

60 operating manual version 07/2014 order number doc2340851 14.3 cobra 40-10 air motor order no. Designation 1 1 9998718 drive fastener 2 1 367318 shoulder screw 4 3 1 9925033 washer 4 1 367311 hood 4 5 1 367319 sound absorbing mat 4 6 1 9999152 velcro fastener coating part 7 1 9999151 velcro fasten...

Page 61

61 58 58 59 60 60 * 59 59 cobra 40-10 1 2 3 4 54 5 8 9 10 31* 30 46* 32 11* 12* 13 14 15 16 52 17 18 19 20 21 34 56 56 57 27 33 35 36* 37* 38 39 40 41* d 25 22 43* d 42 44 47 48 45 44 49 51 50* 46* 26 26 55 28 29 27* 6 7 10-15 nm; 7-11 lbft 20-25 nm; 15-18 lbft 2-3 nm; 1.5-2.2 lbft b_04251 53 50* op...

Page 62

62 operating manual version 07/2014 order number doc2340851 order no. Designation 43 1 9971137 o-ring 44 4 9900316 hexagon socket head cap screw m6x50 45 2 9907039 hexagon socket head cap screw m6x80 46 1 9971313 o-ring 47 1 2341175 manometer with air regulator 0-10 bar, g1/8" 48 1 2309972 pressure ...

Page 63

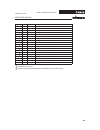

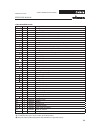

63 51 53 54 55 53 57 59 60 61 62 70 63 108 7 7 b_04252 29 59 30 31 32 33 34 35 109 111 111 operating manual version 07/2014 order number doc2340851 14.4 cobra 40-10 fluid section cobra 40-10 fl uid section order no. Designation 1 1 2329898 sealing sleeve 2 4 9900204 hexagon screw 3 4 9920102 washer ...

Page 64

64 1 2 3 5 6 7 8 9 10 11 14 15 100 110 99 98 97 96 95 94 18 93 17 35 33 34 32 31 46 47 49 50 41 101 27 102 26 66 67 38 40 16 91 19 69 20 21 22 23 92 24 25 67 26 102 27 4 89 90 78 110 110 13 112 105 78 70 nm; 52 lbft 90 nm; 66 lbft 30 nm; 22 lbft 50 nm; 37 lbft 2 nm; 1.5 lbft 103 20 nm; 15 lbft 20 nm...

Page 65

65 operating manual version 07/2014 order number doc2340851 cobra 40-10 fl uid section order no. Designation 6 8 9907234 hexagon screw 7 10 9920107 washer 8 2 9974184 o-ring 9 2 322411 valve fi tting 10 2 341336 clasp 11 1 322914 inlet valve set, complete (comprising 2 valves), see chapter 14.9 13 1...

Page 66

66 operating manual version 07/2014 order number doc2340851 cobra 40-10 fl uid section order no. Designation 54 1 9974181 piston sealing profi le z5 55 1 322426 piston air motor 3 57 1 9974115 o-ring 59 2 9974185 seal wiper ring, profi le em 60 1 322425 air motor fl ange 61 1 367258 grounding, compl...

Page 67

67 20 15 1 8 7 17 5 20 4 3 3 10 14 12 2 9 16 16 b_04254 20 6 13 22 25 nm; 18 lbft 21 operating manual version 07/2014 order number doc2340851 14.5 overview of the cobra 40-25 components order no. Designation 1 1 - cobra 40-25 air motor 2 1 -- preassembled cobra 40-25 fl uid section 3 4 9920106 washe...

Page 68

68 operating manual version 07/2014 order number doc2340851 14.6 cobra 40-25 air motor order no. Designation 1 1 9998718 drive fastener 2 1 367318 shoulder screw 4 3 1 9925033 washer 4 1 367311 hood 4 5 1 367319 sound absorbing mat 4 6 1 9999152 velcro fastener coating part 7 1 9999151 velcro fasten...

Page 69

69 58 58 d 24 d 59 47 50 48* 25 43 44 60 61* 62* 63 49* 65 59 63 64 26 42 cobra 40-25 66 * 1 2 3 4 54 5 8 9 10 53 31* 30 46 32 11* 12* 13 14 15 16 52 17 18 19 20 21 34 56 56 57 27 33 35 36* 37* 38 39 40 41* 26 26 55 28 29 27* 6 7 10-15 nm; 7-11 lbft 20-25 nm; 15-18 lbft 2-3 nm; 1.5-2.2 lbft b_04255 ...

Page 70

70 operating manual version 07/2014 order number doc2340851 order no. Designation 43 1 2309973 pressure regulator valve lr-1/2-d-o-midi 44 1 2341176 manometer with air regulator 0-10 bar, g1/4" 47 1 m262.00 elbow screw-in connection 48 1 3105540 o-ring 49 1 9971018 o-ring 50 2 m396.00 reducing fi tt...

Page 71

71 105 106 109 51 53 54 55 53 57 59 60 61 62 70 63 58 58 b_04256 40 nm; 29.5 lbft 111 111 29 59 30 31 15 16 32 33 34 35 operating manual version 07/2014 order number doc2340851 14.7 cobra 40-25 cobra 40-25 fl uid section order no. Designation 1 1 2329898 sealing sleeve 2 4 9900204 hexagon screw 3 4 ...

Page 72

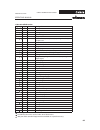

72 73 b_04257 1 2 3 5 6 7 8 9 10 11 14 100 99 98 97 96 95 94 18 93 17 35 33 34 32 31 15 16 46 47 49 50 41 101 27 102 26 66 67 38 40 91 19 69 20 21 22 23 24/92 25 67 26 102 27 4 71 13 100 nm; 74 lbft (8 x) 120 nm; 89 lbft (2 x) 50 nm; 37 lbft 2 nm; 1.5 lbft 105 104 20 nm; 15 lbft 20 nm 14.8 lbft 40 n...

Page 73

73 operating manual version 07/2014 order number doc2340851 cobra 40-25 fl uid section order no. Designation 8 2 2306183 o-ring 9 2 2306164 valve fi tting 10 2 341336 clasp 11 1 2308753 inlet valve set, complete (comprising 2 valves), see chapter 14.8 13 1 2330810 connection piece 14 1 2337668 fluid...

Page 74

74 operating manual version 07/2014 order number doc2340851 cobra 40-25 fl uid section order no. Designation 58 2 9920107 washer 59 1 9974090 seal wiper ring, profi le em 60 1 2306202 air motor fl ange 61 1 367258 grounding, complete 62 1 369290 pilot valve 63 2 9998675 threaded plug 66 1 9998780 co...

Page 75

75 2 3 4 5 6 7 11 6 8 1 10 1.9 ±0.1 b_01230 b_01232 7 4 5 6 3 2 1 operating manual version 07/2014 order number doc2340851 14.8 cobra 40-10 inlet valve order no. Designation 1 1 322914 complete cobra 40-10 inlet valve set 2 2 9912100 hexagon nut with clamp 3 2 344334 spring guide 4 2 190304 compress...

Page 76

76 b_02942 2 2.3 4 7 6 1 5 9 11 8 3 10 0 -0.1 operating manual version 07/2014 order number doc2340851 order no. Designation 1 1 2308753 complete cobra 40-25 inlet valve set 2 2 9912100 hexagon nut with clamp 3 2 253324 spring guide 4 2 9994304 compression spring 5 2 341344 valve guide 6 2 341330 se...

Page 77

77 8 5 7 3 6 4 1 2 1.5 b_01231 operating manual version 07/2014 order number doc2340851 14.11 relief valve order no. Designation 1 1 169248 relief valve, complete 2 1 9920602 adjusting washer 3 1 169346 compression spring 4 1 9920202 washer 5 1 9971395 o-ring, 10x1.25 6 1 9971486 o-ring 4x2 7 1 9992...

Page 78

78 90 nm; 66 lbft 140 nm 103 lbft 12 21 11 10 1 4 7 33 2 3 5 b_05065 23 36 35 36 34 34 20 34 operating manual version 07/2014 order number doc2340851 14.12 high-pressure filter (up to 530 bar; 7687 psi) identifi cation of the fi lter tighten pos. 3 by hand.

Page 79

79 operating manual version 07/2014 order number doc2340851 ball valve version in: carbon steel designation order no. 1 1 hp fi lter dn12-pn530, complete 2335334 2 1 filter housing 2324542 3 1 union nut 2324543 4 1 fitting-df-mm-g1/2-g3/8-pn530-sst 2330780 5 1 o-ring 9955863 7 1 distribution housing...

Page 80

80 b_05066 3 2 4 5 1 6 operating manual version 07/2014 order number doc2340851 14.13 inline filter 90° (up to 270 bar; 3,916 psi) order no. Designation 1 1 2329026 inline fi lter hl dn6-pn270-g1/4"-sst 2 1 2326045 filter inlet housing, pre-assembled 3 1 -- filter insert, yellow (middle), 100 mesh p...

Page 81

81 b_05085 3 2 4 5 1 6 operating manual version 07/2014 order number doc2340851 14.14 straight inline filter (up to 270 bar; 3,916 psi) order no. Designation 1 1 2324558 inline fi lter dn6-pn270-g1/4"-sst 2 1 2324550 filter inlet housing 3 1 128389 seal 4 1 -- filter insert, yellow (middle), 100 mes...

Page 82

82 b_02292 1 2 3 4 6 7 8 5 operating manual version 07/2014 order number doc2340851 order no. Designation 1 1 322052 cobra 40-10 frame 2 1 322442 frame pressed 3 1 322443 frame pipe 4 2 9990861 plug 5 4 9999209 saddle feet for round tubes 6 2 9910204 self-locking hexagon nut, m6 7 2 9900202 hexagon ...

Page 83

83 4 1 2 17 15 10 6 5 9 7 8 5 13 11 12 b_03932 3 14 16 a b operating manual version 07/2014 order number doc2340851 14.17 trolley distance: and order no. Designation 1 1 2325901 trolley, complete 2 1 -- frame, left, 4"-6" (welded) 3 1 -- frame, right, 4"-6" (welded) 4 4 9907140 hexagon screw din931 ...

Page 84

84 b_05001 4 3 1 2 5 6 8 7 14 12 11 9 15 10 16 5 a a 13 17 18 operating manual version 07/2014 order number doc2340851 14.18 cobra trolley horizontal axle setting cobra trolley.

Page 85

85 b_05002 operating manual version 07/2014 order number doc2340851 name order no. 1 1 cobra trolley complete 2341375 2 1 frame, left 4"-6" - 3 1 frame, right 4"-6" - 4 4 hexagon screw 9907140 5 6 self-locking hexagon nut, m6 9910204 6 2 wheel, d250 2304440 7 4 washer 340372 8 4 cotter pin 9995302 9...

Page 86

86 b_04258 2 6 4 5 3 7 operating manual version 07/2014 order number doc2340851 order no. Designation 1 1 2344505 hopper set ex, 5 l; 1.3 gal 2 2 9902313 cylinder self-tapping screw 3 1 3756 filter disk, mesh 0.4 mm; 0.02 inch 3a 1 37607 filter disk, mesh 0.8 mm; 0.03 inch 4 1 340265 hopper ex 5 1 2...

Page 87

87 5 4 3 7 2 10 9 8 6 1 b_03642 11 operating manual version 07/2014 order number doc2340851 14.20 small quantity cup order no. Designation 1 2321424 small quantity cup 1 1 2320844 union nut with bayonet 2 1 2321426 low-pressure mini ball valve g1/2 3 1 2320841 gravity feed cup adapter hsm 4 2 232142...

Page 88

88 operating manual version 07/2014 order number doc2340851 14.21 2l tank 4 2 10 8 6 1 b_05018 7 3 5 11 9 * replace for the following pumps: • cobra 40-10 with date of product before november 2013 * order no. Designation 1 2344741 2l cobra tank 1 1 2320844 union nut with bayonet 2 1 2321426 low-pres...

Page 89

89 operating manual version 07/2014 order number doc2340851 15.2 warranty claim 15.1 important notes regarding product liability 15 warranty and conformity declarations as a result of an ec regulation eff ective from january 1, 1990, the manufacturer shall only be liable for his product if all parts...

Page 90

90 operating manual version 07/2014 order number doc2340851 15.3 ce declaration of conformity cobra 40-10 cobra 40-25 complies with the following guidelines: 2006/42/ec 94/9/ec (atex directive) applied standards, in particular: din en iso 12100: 2011 din en 1127-1: 2011 din en iso 4413: 2011 din en ...

Page 92: Cert

Order no. 2340851 edition 07/2014 germany phone fax e-mail switzerland phone fax more contact addresses on the internet at: company/locations/wagner worldwide subject to changes without notice document no . 11156044 v ersion a cert if ie d.