- DL manuals

- WAGNER

- Paint Sprayer

- GM 1-350

- Operating Manual

WAGNER GM 1-350 Operating Manual

Summary of GM 1-350

Page 1

B_5040 airless manual gun version 02/2015 translation of the original operating manual.

Page 2: Gm 1-350/530

2 gm 1-350/530 operating manual version 02/2015 order number doc2349369 table of contents 1 about these instructions 3 1.1 preface 3 1.2 warnings, notices and symbols in these instructions 4 1.3 languages 4 2 correct use 5 2.1 safety parameters 5 2.2 reasonably foreseeable misuse 5 2.3 residual risk...

Page 3: Gm 1-350/530

3 gm 1-350/530 operating manual version 02/2015 order number doc2349369 table of contents 11 disposal 26 12 accessories 27 12.1 nozzles 27 12.2 intermediate piece 27 13 spare parts 27 13.1 how can spare parts be ordered? 27 13.2 spare parts list gm 1-350/530 28 14 warranty and conformity declaration...

Page 4: Gm 1-350/530

4 gm 1-350/530 operating manual version 02/2015 order number doc2349369 1.2 warnings, notices and symbols in these instructions warning instructions in this operating manual highlight particular dangers to users and to the device and state measures for avoiding the hazard. These warning instructions...

Page 5: Gm 1-350/530

5 gm 1-350/530 operating manual version 02/2015 order number doc2349369 2 correct use 2.1 safety parameters wagner accepts no liability for any damage arising from incorrect use. Use the device only to work with the products recommended by wagner. Only operate the device as a whole. Do not deactivat...

Page 6: Gm 1-350/530

6 gm 1-350/530 serial-no. Xxxxx j. Wagner ag 9450 altstaetten swiss made warning skin injection hazard read instruction manual ii 2g x 1 6 5 b_5041 gm 1-530 max wpr 530 bar 7687 psi max temp 85 °c 185 °f 3 4 2 fire and explosion hazard read instruction manual 7 8 operating manual version 02/2015 ord...

Page 7: Gm 1-350/530

7 gm 1-350/530 operating manual version 02/2015 order number doc2349369 4 general safety instructions 4.1 safety instructions for the operator 4.1.1 electrical equipment 4.1.2 personnel qualifications 4.1.3 safe work environment keep this operating manual at hand near the device at all times. Always...

Page 8: Gm 1-350/530

8 gm 1-350/530 operating manual version 02/2015 order number doc2349369 4.2.1 safe handling of wagner spray devices the spray jet is under pressure and can cause dangerous injuries. Avoid injection of paint or fl ushing agents: never point the spray gun at people. Never reach into the spray jet. Bef...

Page 9: Gm 1-350/530

9 gm 1-350/530 operating manual version 02/2015 order number doc2349369 4.2.3 product hoses ensure that the hose material is chemically resistant to the sprayed products and the used fl ushing agents. Ensure that the product hose is suitable for the pressure generated. Ensure that the following info...

Page 10: Gm 1-350/530

10 gm 1-350/530 operating manual version 02/2015 order number doc2349369 4.2.5 handling hazardous liquids, varnishes and paints when preparing or working with lacquer and when cleaning the device, follow the working instructions of the manufacturer of the lacquers, solvents and cleaning agents being...

Page 11: Gm 1-350/530

11 gm 1-350/530 a d b c e f g b_5042 a d b c e f g b b_5302 e operating manual version 02/2015 order number doc2349369 5 description designation designation a preload nut e nozzle holder b trigger locking device f reversible nozzle (not included in scope of delivery) c product connection with swivel...

Page 12: Gm 1-350/530

12 gm 1-350/530 operating manual version 02/2015 order number doc2349369 metals plastics carbide stainless steel 1.4305 aluminum uhmw-pe stainless steel 1.4301 stainless steel 1.4104 5.7.1 materials of paint-wetted parts 5.7 data 5.7.2 processible materials top-coat paints, primer paints, corrosion ...

Page 13: Gm 1-350/530

13 gm 1-350/530 a b c d e g h j i k b_05044 f operating manual version 02/2015 order number doc2349369 6.2.1 typical airless spraying system a material pump b pressure air shut-off valve c pressure regulator d grounding cable e high-pressure paint hose, electrically conductive the airless manual gun...

Page 14: Gm 1-350/530

14 gm 1-350/530 operating manual version 02/2015 order number doc2349369 6.2.2 ventilation of the spray booth 6.2.3 product supply notice impurities in the spraying system! Spray gun blockage, materials harden in the spraying system flush the spray gun and paint supply with a suitable fl ushing agen...

Page 15: Gm 1-350/530

15 gm 1-350/530 operating manual version 02/2015 order number doc2349369 1. Secure the spray gun. 2. Connect the product hose to the spray gun and product supply system. 3. For spray guns with fi lters insert a suitable fi lter (fi lter insert, see chapter 13.2). 4. Insert the saddle and seal into t...

Page 16: Gm 1-350/530

16 gm 1-350/530 operating manual version 02/2015 order number doc2349369 7 operation 7.1 training the operating staff 7.2 safety instructions observe the safety instructions in chapters 4.1, 4.1.3, 4.2, and 4.2.1. 7.3 work ensure that: the regular safety checks are carried out in accordance with cha...

Page 17: Gm 1-350/530

17 gm 1-350/530 operating manual version 02/2015 order number doc2349369 7.3.2 pressure relief / work interruption the pressure must always be relieved: - when the spraying tasks are fi nished, - before carrying out maintenance work on the spraying system, - before carrying out cleaning tasks on the...

Page 18: Gm 1-350/530

18 gm 1-350/530 b_5049 operating manual version 02/2015 order number doc2349369 7.3.3 changing the airless nozzle defective airless nozzle! Insuffi cient paint application quality do not use sharp-edged objects on the carbide on the airless nozzle. Nozzles can be easily removed and replaced without ...

Page 19: Gm 1-350/530

19 gm 1-350/530 b_5054 b_5303 operating manual version 02/2015 order number doc2349369 7.3.5 eliminate nozzle clogging 1. Relieve the pressure on the spray gun and product pressure generator in accordance with chapter 7.3.2. 2. Secure the spray gun with the locking device. 3. Rotate the reversing no...

Page 20: Gm 1-350/530

20 gm 1-350/530 operating manual version 02/2015 order number doc2349369 8 cleaning and maintenance cleaning work should be undertaken regularly and carefully by qualifi ed and trained staff . They should be informed of specifi c hazards during their training. The following hazards may arise during ...

Page 21: Gm 1-350/530

21 gm 1-350/530 b_5045 operating manual version 02/2015 order number doc2349369 8.1.3 flushing and cleaning the spray gun observe safety instructions in chapter 4. The spray gun and the device must be cleaned and fl ushed daily. The cleaning/fl ushing agents used for cleaning or fl ushing must corre...

Page 22: Gm 1-350/530

22 gm 1-350/530 operating manual version 02/2015 order number doc2349369 8.2 maintenance 8.2.1 maintenance staff maintenance work should be undertaken regularly and carefully by qualifi ed and trained staff . They should be informed of specifi c hazards during their training. The following hazards m...

Page 23: Gm 1-350/530

23 gm 1-350/530 operating manual version 02/2015 order number doc2349369 the service life of the complete hoses between product pressure generator and application device is reduced due to environmental infl uences even when handled correctly. Check hoses, pipes, and couplings every day and replace i...

Page 24: Gm 1-350/530

24 gm 1-350/530 b_5048 b a b_5051 a b d c operating manual version 02/2015 order number doc2349369 1. Flush and clean the spray gun as described in chapter 8.1.3. 2. Relieve the pressure on the spray gun and product pressure generator in accordance with chapter 7.3.2. 3. Secure the spray gun with th...

Page 25: Gm 1-350/530

25 gm 1-350/530 b_5047 a b c d c f e operating manual version 02/2015 order number doc2349369 1. Flush and clean the spray gun as described in chapter 8.1.3. 2. Relieve the pressure on the spray gun and product pressure generator in accordance with chapter 7.3.2. 3. Secure the spray gun with the loc...

Page 26: Gm 1-350/530

26 gm 1-350/530 operating manual version 02/2015 order number doc2349369 functional fault cause remedy see chapter insuffi cient product output. Nozzle too small. Select larger nozzle. 12 product pressure too low. Increase product pressure. Spray gun fi lter or high-pressure fi lter clogged at pump....

Page 27: Gm 1-350/530

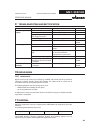

27 gm 1-350/530 10° 20° 30° 40° 50° 60° inch (mm) l/min (gal/min) 07 407 200 0,007 (0,18) 0,23 (0,061) 09 209 309 409 509 609 0,009 (0,23) 0,26 (0,069) 11 111 211 311 411 511 611 50 0,011 (0,28) 0,38 (0,100) 13 113 213 313 413 513 613 813 150 0,013 (0,33) 0,55 (0,145) 15 115 215 315 415 515 615 815 ...

Page 28: Gm 1-350/530

28 gm 1-350/530 operating manual version 02/2015 order number doc2349369 danger incorrect maintenance/repair! Danger to life and equipment damage. Only a wagner service center or a suitably trained person may carry out repairs and replace parts. Only repair and replace parts that are listed in the c...

Page 29: Gm 1-350/530

29 gm 1-350/530 1 2 3 14 15 11 4 4 13 12 8 16 17 9 18 10 9 19 16 nm ; 11.8 lbft 70 nm; 51.6 lbft 6 5 7 6 3 nm; 2.2 lbft b_5304 operating manual version 02/2015 order number doc2349369 16 1 2353548 2353548 seal kit pt-hd gm1 – 5 pieces 17 1 2353549 2353549 nozzle holder pt-hd gm1 18 1 9992590 9992590...

Page 30: Gm 1-350/530

30 gm 1-350/530 operating manual version 02/2015 order number doc2349369 14.1 important notes regarding product liability 14.2 warranty claim 14 warranty and conformity declarations as a result of an ec regulation eff ective from january 1, 1990, the manufacturer shall only be liable for his product...

Page 31: Gm 1-350/530

31 gm 1-350/530 operating manual version 02/2015 order number doc2349369 14.3 ce declaration of conformity herewith we declare that the supplied version of gm 1-350 gm 1-530 comply with the following guidelines: 2006/42/ec 94/9/ec applied standards, in particular: din en iso 12100: 2010 din en iso 1...

Page 32: Cert

Cert if ie d order no. 2349369 edition 02/2015 germany phone telefax e-mail switzerland phone telefax more contact addresses on the internet at: company/locations/wagner worldwide subject to changes without notice document no . 11165362 v ersion -.