- DL manuals

- WAGNER

- Paint Sprayer

- GM 4600AC

- Operating Instructions Manual

WAGNER GM 4600AC Operating Instructions Manual

Summary of GM 4600AC

Page 1

Gm 4600ac ii 2g x (atex 95) b_02669 aircoat spray gun for fl at - and round jet nozzles edition 02/2008 translation of the original operating manual.

Page 3: Gm 4600Ac

3 gm 4600ac operating manual edition 02/2008 part no. Doc394861 contents 1 about these instructions 5 1.1 languages 5 1.2 warnings, notes and symbols in these instructions 5 2 general safety instructions 6 2.1 safety instructions for the operator 6 2.1.1 electrical equipment 6 2.1.2 personnel qualif...

Page 4: Gm 4600Ac

4 gm 4600ac operating manual edition 02/2008 part no. Doc394861 contents 5.1.5 earthing 18 5.2 preparation of paints 18 5.3 start-up 19 5.3.1 general rules for handling the spray gun 19 5.3.2 preparation for starting up 20 5.4 works 21 5.4.1 start-up for spraying aircoat 21 5.4.2 adjusting the spray...

Page 5: Gm 4600Ac

5 gm 4600ac operating manual edition 02/2008 part no. Doc394861 1.2 warnings, notes and symbols in these instructions 1 about these instructions 1.1 languages 4hisoperatingmanualcontainsinformationontheoperationrepairandmaintenanceof theunit !Lwaysobservetheseinstructionswhenoperatingtheunit 4hise...

Page 6: Gm 4600Ac

6 gm 4600ac operating manual edition 02/2008 part no. Doc394861 2 general safety instructions 2.1 safety instructions for the operator 2.1.1 electrical equipment 2.1.2 personnel qualifications 2.1.3 a safe work environment 2.2 safety instructions for staff +eeptheseoperatinginstructionstohandneart...

Page 7: Gm 4600Ac

7 gm 4600ac operating manual edition 02/2008 part no. Doc394861 2.2.1 safe handling of wagner spray units 2.2.2 earth the unit 2.2.3 paint hoses the spray jet is under pressure and can cause dangerous injuries. Avoid injection of paint or cleaning agents: never point the spray gun at people. nev...

Page 8: Gm 4600Ac

8 gm 4600ac operating manual edition 02/2008 part no. Doc394861 2.2.4 cleaning 2.2.5 handling hazardous liquids, varnishes and paints 2.2.6 touching hot surfaces 2.3 correct use $eenergizetheunitelectrically $isconnectthepneumaticsupplyline 2elievethepressurefromtheunit %nsurethatthemashpoin...

Page 9: Gm 4600Ac

9 gm 4600ac operating manual edition 02/2008 part no. Doc394861 2.4.1 correct use 2.4.2 explosion protection identification 2.4.3 maximum surface temperature 2.4.4 safety instructions 2.4 use in hazardous locations 4heunitissuitableforworkingliquidmaterialsinaccordancewiththeclassilcationinto explos...

Page 10: Gm 4600Ac

10 gm 4600ac operating manual edition 02/2008 part no. Doc394861 3 product liability and warranty 3.1 important notes on product liability 3.2 warranty !Saresultofan%#regulationeffectiveasfrom*anuarythemanufacturershall onlybeliableforhisproductifallpartscomefromhimorareapprovedbyhimandifthe devices...

Page 11: Gm 4600Ac

11 gm 4600ac operating manual edition 02/2008 part no. Doc394861 3.3 ce-conformity 0394891 ce certificate of conformity the certificate is enclosed with this product.The certificate of conformity can be reordered from your wagner representative, quoting the product and serial number. Part number: he...

Page 12: Gm 4600Ac

12 gm 4600ac operating manual edition 02/2008 part no. Doc394861 4.1 fields of application, using in accordance with the instructions the gun is suitable for atomising liquid materials, particularly coating materials, using the aircoat process. 4.1.1 processible materials top-coat paints, primer pai...

Page 13: Gm 4600Ac

13 gm 4600ac b_02670 a b ccc operating manual edition 02/2008 part no. Doc394861 4.2.4 spray gun configuration basis number gm 4600ac - a b c c c -> key 0 3 9 4 0 2 0 - 1 1 4 1 1 -> for example: part number table a: maxi. Material pression selection 1 160 bar; 16 mpa; 2320 psi 2 250 bar; 25 mpa; 362...

Page 14: Gm 4600Ac

14 gm 4600ac a d e c b b_02671 f g operating manual edition 02/2008 part no. Doc394861 metal plastics tungsten carbide stainless steel 1.4305 pom fpm stainless steel 1.4301 stainless steel 1.4104 ptfe pa 4.3 data 4.3.1 materials of the parts transporting paint 4.3.2 technical data aircoat spray gun ...

Page 15: Gm 4600Ac

15 gm 4600ac b_02672 a h i j k b c d e f g operating manual edition 02/2008 part no. Doc394861 description a suspension hook b fan air regulator c tension nut d trigger e trigger safety f air connection g paint connection h union nut with nozzle guard i nozzle / air cap j gun housing k filter housin...

Page 16: Gm 4600Ac

16 gm 4600ac c d e f g k a h j l i m b b_02673 operating manual edition 02/2008 part no. Doc394861 5 starting up and operating 5.1.1 typical aircoat spraying system a material pump b pressure air shut off valve c pressure regulator d air pressure regulator with fi lter e earthing cable f air hose, e...

Page 17: Gm 4600Ac

17 gm 4600ac operating manual edition 02/2008 part no. Doc394861 5.1.2 ventilation of the spray booth 5.1.3 air supply the use of an air fi lter with the air regulator (d) ensures that only dry, clean atomising air gets into the spray gun. Dirt and moisture in the atomising air reduce the spraying q...

Page 18: Gm 4600Ac

18 gm 4600ac operating manual edition 02/2008 part no. Doc394861 5.1.5 earthing any material containers and the unit must be connected by a potential equalisation (earth) cable. 5.2 preparation of paints the viscosity of the paints is of great importance. The best results are usually obtained with p...

Page 19: Gm 4600Ac

19 gm 4600ac b_02674 operating manual edition 02/2008 part no. Doc394861 5.3 start-up trigger safety catch in on (safe) position air material 5.3.1 general rules for handling the spray gun ➞ observe general safety instructions in chapter 2. Caution cleaning agent in the air duct! Functional faults c...

Page 20: Gm 4600Ac

20 gm 4600ac b_02261 x operating manual edition 02/2008 part no. Doc394861 5.3.2 preparation for starting up 1. Secure the spray gun. 2. Connect material hose to the spray gun and material supply system. 3. Connect air hose to spray gun and to oil-free, dry air supply with regulator. 4. Insert suita...

Page 21: Gm 4600Ac

21 gm 4600ac b_00071 b_02262 operating manual edition 02/2008 part no. Doc394861 5.4 works 5.4.1 start-up for spraying aircoat 1. Start up with material supply set to approx. 8 mpa; 80 bar; 1160 psi operating pressure. 2. Spray (release trigger safety catch and pull trigger) and check the atomisatio...

Page 22: Gm 4600Ac

22 gm 4600ac b_02261 x a b c d b_02675 operating manual edition 02/2008 part no. Doc394861 5.4.3 replacing aircoat nozzle 1. Relieve spray gun and unit pressure. 2. Secure gun with trigger safety catch. 3. Screw off the union nut (a). 4. Remove air cap (b). 5. Press aircoat nozzle (c) out of the air...

Page 23: Gm 4600Ac

23 gm 4600ac b_02261 x a b c d b_02676 operating manual edition 02/2008 part no. Doc394861 5.4.4 cleaning aircoat nozzle for disassembly and assembly of aircoat nozzles see chapter 5.4.3. The aircoat nozzle (c) can be placed into a cleaning solvent which has been recommend- ed by the paint manufactu...

Page 24: Gm 4600Ac

24 gm 4600ac operating manual edition 02/2008 part no. Doc394861 6.0 maintenance ➞ observe general safety instructions in chapter 2. The spray gun and the unit must be cleaned every day. Use only the cleaning solvent rec- ommended by the material manufacture. Caution cleaning agent in the air duct! ...

Page 25: Gm 4600Ac

25 gm 4600ac operating manual edition 02/2008 part no. Doc394861 note: methylene chloride is not recommended as a fl ushing or cleaning solvent with this gun or any system components. 1. Relieve spray gun and unit pressure. 2. Secure gun with trigger safety catch. 3. Connect cleaning supply. 4. Remo...

Page 26: Gm 4600Ac

26 gm 4600ac b_02678 b c a d b_02679 operating manual edition 02/2008 part no. Doc394861 6.2 replacing the material hose or air hose 1. Finishing work and cleaning. 2. Relieve spray gun and unit pressure. 3. Secure gun with trigger safety catch. Paint hose 4. Place open-ended wrench sw a on fl ats o...

Page 27: Gm 4600Ac

27 gm 4600ac b_02677 b a 64 30 67 66 65 b_02679 operating manual edition 02/2008 part no. Doc394861 6.3 changing or cleaning filter insert 1. Finishing work and cleaning. 2. Relieve spray gun and unit pressure. 3. Secure gun with trigger safety catch. 4. Place open-ended wrench a on fl ats of fi lte...

Page 28: Gm 4600Ac

28 gm 4600ac b_02680 5 2 3 4 18 50 51 52 53 34 21 22 19 20 a b 10 11 12 operating manual edition 02/2008 part no. Doc394861 6.4 replacing parts on the valve rod 6.4.1 disassembling 1. Finishing work and cleaning. 2. Relieve spray gun and unit pressure. 3. Secure gun with trigger safety catch. 4. Uns...

Page 29: Gm 4600Ac

29 gm 4600ac b_02268 21 22 35 84 50 51 52 53 b_02274 b_02688 operating manual edition 02/2008 part no. Doc394861 6.4.2 replacement of valve rocker seals 6.4.3 replacing the rod seal (35) 1. Carefully pull the rod seal (35) out of the gun housing. 2. Clean sealing surfaces in the gun housing. 3. Moun...

Page 30: Gm 4600Ac

30 gm 4600ac b_02681 17 16 14 (f) 13 36 33 operating manual edition 02/2008 part no. Doc394861 6.5 replacing the nozzle seal 1. Finishing work and cleaning. 2. Relieve spray gun and unit pressure. 3. Secure gun with trigger safety catch. 4. Unscrew the union nut with nozzle guard (33). 5. Remove air...

Page 31: Gm 4600Ac

31 gm 4600ac b_02682 14 (f) 13 36 33 / 0 1 2 operating manual edition 02/2008 part no. Doc394861 1. Finishing work and cleaning. 2. Relieve spray gun and unit pressure. 3. Secure gun with trigger safety catch. 4. Unscrew the union nut with nozzle guard (33). 5. Remove air cap (36) and nozzle (13) . ...

Page 32: Gm 4600Ac

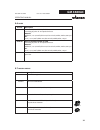

32 gm 4600ac operating manual edition 02/2008 part no. Doc394861 malfunction cause remedy see chapter insuffi cient material discharge nozzle too small select larger nozzle 9 material pressure to low increase material pressure filter of gun or high- pressure fi lter at pump clogged clean or replace ...

Page 33: Gm 4600Ac

33 gm 4600ac b_02276 9.1 9.1.2 9.1.1 b_02277 b_02278 operating manual edition 02/2008 part no. Doc394861 9.1.1 nozzle inserts rxx part no. Description marking volume fl ow* jet ø ** 0132720 nozzle insert r11 11 0.16; 160 approx. 250; 9.84 0132721 nozzle insert r12 12 0.22; 220 approx. 250; 9.84 0132...

Page 34: Gm 4600Ac

34 gm 4600ac b_02280 operating manual edition 02/2008 part no. Doc394861 9.2 aircoat nozzles acf3000 part no. Marking diameter of bore mm; inches spray- angle recommended edge filter use natural paint transparent lacquer oils synthetic resin paints pvc paint paints undercoat priming paint filler fil...

Page 35: Gm 4600Ac

35 gm 4600ac b_02280 operating manual edition 02/2008 part no. Doc394861 rustproofing paint latex paint mica paint zinc dust coating rustproofing paint distemper part no. Marking diameter of bore mm; inches spray- angle recommended edge filter use 60 mesh.

Page 36: Gm 4600Ac

36 gm 4600ac b_02257 b_02256 "? "? "? B_02689 b_02687 b_02689 b_02687 operating manual edition 02/2008 part no. Doc394861 9.4 filter insert 9.3 air caps part no. Description 0394910 air cap lv complete (red) for low viscosity paints 0394911 air cap hv complete (blue) for high viscosity paints part n...

Page 37: Gm 4600Ac

37 gm 4600ac b_02685 b_02686 operating manual edition 02/2008 part no. Doc394861 9.7 miscellaneous part no. Description 9997001 nozzle cleaning brush 0394941 service-set gm 4600ac 0394904 conversion kit 16 mpa; 160 bar; 2320 ps 0394905 conversion kits 25 mpa; 250 bar; 3625 psi 0367560 double connect...

Page 38: Gm 4600Ac

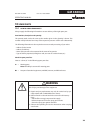

38 gm 4600ac operating manual edition 02/2008 part no. Doc394861 10 spare parts 10.1 how to order spare parts? Sihi_0004_gb warning incorrect maintenance/repair! Risk of injury and damage to the equipment repairs and part replacement may only be carried out by spe- cially trained staff or a wagner...

Page 39: Gm 4600Ac

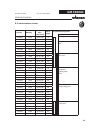

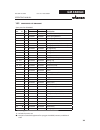

39 gm 4600ac operating manual edition 02/2008 part no. Doc394861 10.2 spare parts list gm 4600ac spare parts list gm 4600ac pos k qty 16 mpa 25 mpa description part no. Part no. 1 1 0394004 03940014 gm 4600ac; xx mpa; npsm1/4“ 2 1 9999501 9999501 screw spring material 3 1 9999500 9999500 screw sprin...

Page 40: Gm 4600Ac

40 gm 4600ac b_02748 5 1 5 2 3 82 24 35 36 36 23 22 20 21 14 15 16 13 17 64 65 66 67 4 18 50 51 52 53 34 19 10 11 12 82 83 b 84 6 80 55 56 57 58 59 60 61 62 63 operating manual edition 02/2008 part no. Doc394861 mounting materials pos k part no. Description 80 ● 9992831 loctite 542 81 ● 9992833 loct...

Page 41: Gm 4600Ac

41 gm 4600ac operating manual edition 02/2008 part no. Doc394861 spare parts list gm 4600ac pos k qty 16 mpa 25 mpa description part no. Part no. 57 ◆ ● 1 0132516 0132516 nozzle screwed connection compl. 58 ● 1 0132351 0132351 nozzle screwed connection holder 59 ● 1 0394308 0394308 union nut 60 ● 1 ...

Page 42: Gm 4600Ac

42 gm 4600ac operating manual edition 02/2008 part no. Doc394861 germany j. Wagner gmbh otto-lilienthal-str. 18 postfach 1120 d- 88677 markdorf telephone: ++49/ (0)7544 / 5050 telefax: ++49/ (0)7544 / 505200 e-mail:service.Standard@wagner-group.Com switzerland j. Wagner ag industriestrasse 22 postfa...

Page 44: Cert

Cert if ie d /rdernumber 'ermany *7!'.%2'mb( /tto,ilienthal3tr 0ostfach $-arkdorf 4elephone 4elefax %-ailservicestandard wagnergroupcom 3witzerland *7!'.%2!' )ndustriestrasse 0ostfach #(!LtstËtten 4elephone 4elefax %-ailrepch wagnergroupch wwwwagnergroupcom 394861.