- DL manuals

- WAGNER

- Water Pump

- Jaguar 75-150

- Translation Of The Original Operation Manual

WAGNER Jaguar 75-150 Translation Of The Original Operation Manual - Contents

3

OPERATING MANUAL

VERSION 01/2013

ORDER NUMBER DOC 2333538

Contents

1 ABOUT

THESE

INSTRUCTIONS

6

1.1 Preface

6

1.2

Warnings, Notices and Symbols in these Instructions

6

1.3 Languages

7

1.4

Abbreviations in the Text

7

2 CORRECT

USE

8

2.1 Device

Types

8

2.2

Type of Use

8

2.3

Use in an Explosion Hazard Area

8

2.4 Safety

Parameters

8

2.5 Processible

Materials

9

2.6

Reasonably Foreseeable Misuse

9

2.7 Residual

Risks

10

3 IDENTIFICATION

11

3.1

Explosion Protection Identifi cation

11

3.2 Identifi cation X

11

4

GENERAL SAFETY INSTRUCTIONS

12

4.1

Safety Instructions for the Operator

12

4.1.1 Electrical

Equipment

12

4.1.2 Personnel

Qualifi cations

12

4.1.3 Safe

Work

Environment

12

4.2

Safety Instructions for Staff

13

4.2.1

Safe Handling of WAGNER Spray devices

13

4.2.2

Grounding the Device

14

4.2.3 Material

Hoses

14

4.2.4 Cleaning

15

4.2.5

Handling Hazardous Liquids, Varnishes and Paints

15

4.2.6

Touching Hot Surfaces

15

4.3

Use in Areas Subject to Explosion Hazards

16

4.3.1 Safety

Regulations

16

4.3.2

Operation without Fluid

16

5 DESCRIPTION

17

5.1

Areas of Application

17

5.1.1 Correct

Use

17

5.1.2 Processible

Materials

17

5.1.3

Recommended Application Areas

18

5.2

Scope of Delivery

18

5.3 Data

19

5.3.1

Materials of Wetted Parts

19

5.3.2 Recommended

Packings

19

5.3.3 Technical

Data

20

5.3.3.1 Technical Data for Wildcat and Puma

20

5.3.3.2 Measurements and Connections for Wildcat and Puma

21

5.3.3.3 Technical Data for Leopard and Jaguar

22

5.3.3.4 Measurements and Connections for Leopard and Jaguar

23

Summary of Jaguar 75-150

Page 1

B_03900 icebreaker piston pumps flow rate 40 cm 3 –150 cm 3 version 01/2013 translation of the original operating manual.

Page 3: Contents

3 operating manual version 01/2013 order number doc 2333538 contents 1 about these instructions 6 1.1 preface 6 1.2 warnings, notices and symbols in these instructions 6 1.3 languages 7 1.4 abbreviations in the text 7 2 correct use 8 2.1 device types 8 2.2 type of use 8 2.3 use in an explosion hazar...

Page 4: Contents

4 operating manual version 01/2013 order number doc 2333538 contents 5.3.4 volume flow 24 5.3.5 performance diagrams 24 5.4 function 30 5.4.1 pump 30 5.4.2 pressure regulator device 31 5.4.3 high-pressure filter (option) 31 5.4.3.1 high-pressure filter (option) 31 5.4.3.2 relief combination and inli...

Page 5: Contents

5 operating manual version 01/2013 order number doc 2333538 11.3.4 jaguar air motor 68 11.3.5 jaguar air motor regulator 72 11.4 fluid sections 73 11.4.1 fluid sections 40 cm3 73 11.4.2 fluid sections 70 cm3 76 11.4.3 fluid sections 110 cm3 79 11.4.4 fluid sections 150 cm3 82 11.5 inlet valve with v...

Page 6

6 operating manual version 01/2013 order number doc 2333538 1.2 warnings, notices and symbols in these instructions 1 about these instructions warning instructions in this operating manual highlight particular dangers to users and device and state measures for avoiding the hazard. These warning inst...

Page 7

7 operating manual version 01/2013 order number doc 2333538 1.3 languages the operating manual is available in the following languages: language order no. Language order no. Language order no. German 2333537 english 2333538 french 2333539 italian 2333540 spanish 2333541 japanese 233 the correspondin...

Page 8

8 operating manual version 01/2013 order number doc 2333538 10-70 28-40 35-70 75-150 18-40 15-70 35-150 21-110 48-110 15-150 2 correct use 2.1 device types 2.2 type of use 2.3 use in an explosion hazard area pneumatic pump with spraypack: the device is suitable for processing liquid materials like p...

Page 9: Notice

9 operating manual version 01/2013 order number doc 2333538 2.5 processible materials fluid materials like paints and varnishes. Abrasive materials and pigments! Greater wear of the parts carrying the material. Use the application-oriented model (fl ow rate/cycle, material, valves, etc.) as indicate...

Page 10

10 operating manual version 01/2013 order number doc 2333538 2.7 residual risks residual risks are risks which cannot be excluded even in the event of correct use. If necessary, warning and prohibition signs at the relevant points of risk indicate residual risks. Residual risk source consequences sp...

Page 11

11 operating manual version 01/2013 order number doc 2333538 3.1 explosion protection identification 3.2 identification x as defi ned in the directive 94/9/ec (atex 95), the device is suitable for use in areas where there is an explosion hazard. European communities symbol for explosion protection d...

Page 12

12 operating manual version 01/2013 order number doc 2333538 4 general safety instructions 4.1 safety instructions for the operator 4.1.1 electrical equipment 4.1.2 personnel qualifications 4.1.3 safe work environment keep this operating manual at hand near the device at all times. Always follow loc...

Page 13

13 operating manual version 01/2013 order number doc 2333538 4.2.1 safe handling of wagner spray devices the spray jet is under pressure and can cause dangerous injuries. Avoid injection of paint or cleaning agents: never point the spray gun at people. Never reach into the spray jet. Before all work...

Page 14

14 operating manual version 01/2013 order number doc 2333538 ensure that the hose material is chemically resistant to the sprayed materials. Ensure that the material hose is suitable for the pressure generated in the device. Ensure that the following information can be seen on the high pressure hose...

Page 15

15 operating manual version 01/2013 order number doc 2333538 4.2.6 touching hot surfaces touch hot surfaces only if you are wearing protective gloves. When operating the device with a coating material with a temperature of > 43 °c; 109.4 °f: - identify the device with a warning sticker "warning - ho...

Page 16

16 operating manual version 01/2013 order number doc 2333538 4.3 use in areas subject to explosion hazards the pneumatic pump may be used in areas subject to explosion hazards. The following safety regulations must be observed and followed. 4.3.1 safety regulations safe handling of wagner spray devi...

Page 17: Notice

17 operating manual version 01/2013 order number doc 2333538 5 description 5.1 areas of application 5.1.2 processible materials 5.1.1 correct use application water-dilutable materials solvent based varnish and paints primers epoxy and polyurethane paints and varnish, phenolic paints and varnish liqu...

Page 18

18 operating manual version 01/2013 order number doc 2333538 5.2 scope of delivery 5.1.3 recommended application areas application furniture industry kitchen manufacturers joinery window factories steel fabrication construction of vehicles shipbuilding pneumatic piston pump consists of: - fluid sect...

Page 19

19 operating manual version 01/2013 order number doc 2333538 5.3.2 recommended packings 5.3 data 5.3.1 materials of wetted parts housing stainless steel piston stainless steel and hard chrome valve balls stainless steel valve seats carbide o-rings ptfe packings standard = ultra high molecular weight...

Page 20

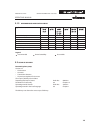

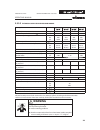

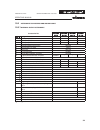

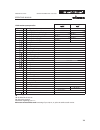

20 operating manual version 01/2013 order number doc 2333538 description devices pump ratio 10 :1 18 :1 28 : 1 15 :1 21:1 15 :1 volume fl ow per double stroke cm3; cc 70 40 40 70 110 150 maximum operating pressure mpa 8 14.4 22.4 12 16.8 12 bar 80 144 224 120 168 120 psi 1,160 2,089 3,249 1,740 2,43...

Page 21

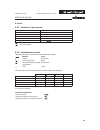

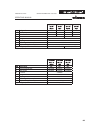

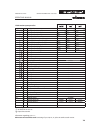

21 r s h q g g/2 o p b_03902 i l1 j c f t h n d (e) a g k b b_03901 m l2 operating manual version 01/2013 order number doc 2333538 5.3.3.2 measurements and connections for wildcat and puma wall mount mm; inch mm; inch mm; inch mm; inch mm; inch mm; inch a 736; 29 722; 28.4 736; 29 1034; 40.7 b 169; ...

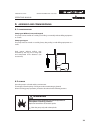

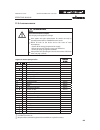

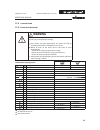

Page 22: Warning

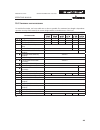

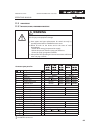

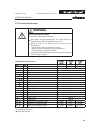

22 operating manual version 01/2013 order number doc 2333538 description units pump ratio 35 : 1 48 :1 35 : 1 75:1 volume fl ow per double stroke ( ) cm3; cc 70 110 150 150 maximum operating pressure mpa 25 37 27 53 bar 250 370 270 530 psi 3,626 5,366 3,916 7,687 maximum possible strokes in operatio...

Page 23

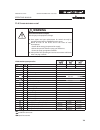

23 j c f t h n d (e) a g k b b_03903 m l1 l2 r s h q o p b_03905 g g/2 i (i b xi h ) i b i h r s h o p b_03904 g g/2 q i (i b xi h ) i b i h operating manual version 01/2013 order number doc 2333538 wall mount jaguar 5.3.3.4 measurements and connections for leopard and jaguar mm; inch mm; inch mm; i...

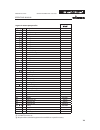

Page 24

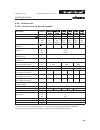

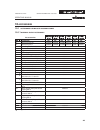

24 bar bar bar bar bar bar "? Operating manual version 01/2013 order number doc 2333538 5.3.4 volume flow volume fl ow refers to water. Maximum ranges for continuous operation at 50 /min. 5.3.5 performance diagrams stroke frequency m a te rial pr essur e in bar air c onsumption nl/min water delivery...

Page 25

25 ! " # bar-0a psi nlmin scfm ! " # lmin gpm "? 0 80 (8) 60 (60) 40 (4) 0 10 20 30 40 50 60 0 a b c a b c 3.5 2.8 0.7 0 l/min 20 (2) nl/min bar (mpa) 100 200 300 400 b_01849 1.4 2.1 4.2 operating manual version 01/2013 order number doc 2333538 diagram for wildcat 18-40 stroke frequency /min m a te ...

Page 26

26 ! " # bar-0a psi nlmin scfm ! " # lmin gpm "? ! " # bar-0a psi nlmin scfm lmin gpm ! " # "? Operating manual version 01/2013 order number doc 2333538 diagram for puma 15-70 water delivery rate a = 8 bar; 0.8 mpa; 116 psi air pressure b = 6 bar; 0.6 mpa; 87 psi air pressure c = 4 bar; 0.4 mpa; 58 ...

Page 27

27 "? ! " # bar-0a psi nlmin scfm ! " # lmin gpm 0 150 (15) 100 (10) 500 (5) 0 10 20 30 40 50 60 900 600 300 0 6.6 5.5 4.4 3.3 2.2 1.1 0 a b c bar (mpa) nl/min l/min a b c 200 (20) 1200 b_03483 operating manual version 01/2013 order number doc 2333538 diagram for puma 21-110 water delivery rate a = ...

Page 28

28 0 300 (30) 200 (20) 100 (10) 0 10 20 30 40 50 60 2250 1500 750 0 6.6 5.5 4.4 3.3 2.2 1.1 0 a b c bar (mpa) nl/min l/min a b c 400 (40) 3000 b_02755 ! " # bar-0a psi nlmin scfm lmin gpm ! " # "? Operating manual version 01/2013 order number doc 2333538 diagram for leopard 48 - 110 water delivery r...

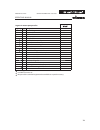

Page 29

29 ! " # bar-0a psi nlmin scfm lmin gpm ! " # "? 0 0 10 20 30 40 50 60 3000 2000 1000 0 a b c nl/min a b c 9 7.5 6 4.5 3 1.5 0 l/min 300 (30) 200 (20) 100 (10) bar (mpa) b_00319 operating manual version 01/2013 order number doc 2333538 diagram for jaguar 75-150 water delivery rate a = 7.1 bar; 0.71 ...

Page 30: Warning

30 b_03906 10 9 8 7 5 3 2 1 4 11 6 operating manual version 01/2013 order number doc 2333538 5.4.1 pump 5.4 function general information the piston pump is driven with compressed air. This compressed air moves up and down the air piston in the air motor (4) and thus also the pump piston in the fl ui...

Page 31

31 b_03909 3 4 5 1 2 1 2 3 b_03907 b_03908 2 3 1 b_03910 b_04064 2 3 1 operating manual version 01/2013 order number doc 2333538 5.4.2 pressure regulator device 1 pressure regulator 2 ball valve 3 pressure gauge 4 compressed air inlet 5 aircoat regulator (option) positions of the ball valve 1 closed...

Page 32

32 b_03911 2 1 3 4 5 b_03913 1 3 2 b_03912 1 3 2 b_03703 4 operating manual version 01/2013 order number doc 2333538 instead of the standard high-pressure fi lter the lower-cost fi lter-relief combination and an inline fi lter can be used if only a small volume of material will be processed. Applica...

Page 33: Warning

33 operating manual version 01/2013 order number doc 2333538 6 assembly and commissioning 6.2 storage 6.1 transportation only pumps without trolleys may be lifted by the ring nut or ring bolt and transported short distances (see accessories). Store the pump in a closed and dry environment. Thoroughl...

Page 34: Warning

34 b_03914 5 6 4 1 3 2 5 6 7 4 1 3 2 b_03915 operating manual version 01/2013 order number doc 2333538 6.3 assembling the pump note this pump can be used as part of a spraying system for airless or aircoat applications. The individual components are shown in the accessories, or can be arranged with ...

Page 35: Warning

35 b_00304 r max Ω operating manual version 01/2013 order number doc 2333538 6.4 grounding grounding scheme (example) paint container work piece conveyor spraying stand floor, derivable discharge of electrostatically charged components in atmospheres containing solvents! Explosion hazard from electr...

Page 36

36 b_03916 operating manual version 01/2013 order number doc 2333538 cable cross sections pump 4 mm2; paint container 6 mm2; conveyor 16 mm2; booth 16 mm2; spraying stand 16 mm2; procedure 1. Screw on grounding cable with eye. 2. Clamp the grounding cable clip to a grounding connection on site. 3. E...

Page 37: Warning

37 operating manual version 01/2013 order number doc 2333538 6.5 commissioning before carrying out any work, the following points must be observed in accordance with the operating instructions: - observe all safety regulations in accordance with chapter 4. - carry out commissioning properly. 6.5.1 s...

Page 38: Notice

38 b_03918 b_03917 3 2 operating manual version 01/2013 order number doc 2333538 before every start-up, the following points should be observed as laid down in the operating manual: - secure gun with safety clip - check the permissible pressures. - check all connections for leaks. - check hoses for ...

Page 39

39 1 b_03919 5 3 4 2 6 7 operating manual version 01/2013 order number doc 2333538 6.5.3 basic cleaning closed open 1. Place empty container (5) under return pipe (4). 2. Place suction hose (7) in the container with fl ushing agent (6). 3. Adjust the pressure regulator (1) to approx. 0.05 mpa; 0.5 b...

Page 40

40 1 b_03919 5 3 4 2 6 7 operating manual version 01/2013 order number doc 2333538 7 operation 1. Place empty container (5) under return pipe (4). 2. Place suction hose (7) in the container with working material (6). Note: if the pump is equipped with a rigid suction system, it should only be dipped...

Page 41: Notice

41 1 b_03919 5 3 4 2 6 7 operating manual version 01/2013 order number doc 2333538 7.2.1 spraying 7.2 work 7.2.2 pressure relief / work interruption open closed if the system has been used with 2-component materials: 1. Secure gun and place nozzle in the gun. 2. Slowly open the ball valve (2). 3. Se...

Page 42: Warning

42 operating manual version 01/2013 order number doc 2333538 7.2.3 decommissioning and cleaning 7. Put the whole system back together. 8. Check the level of the separating fl uid -> chapter 6.5.2. 9. Fill the system with fl ushing agent as laid down in chapter 7.1 "filling with working material". Wh...

Page 43

43 operating manual version 01/2013 order number doc 2333538 8 trouble shooting and rectification problem cause remedy the pump does not work air motor does not work or stops. Open and close ball valve on the pressure regulator unit or disconnect compressed air supply shortly. No pressure indication...

Page 44: Warning

44 operating manual version 01/2013 order number doc 2333538 9 maintenance 1. Check the level of separating fl uid in the separating fl uid cup every day, and top up if necessary. 2. Check and clean the high pressure fi lter every day or as required. 3. Every shut down should be carried out as laid ...

Page 45: Danger

45 operating manual version 01/2013 order number doc 2333538 9.1 high-pressure hoses the lifetime of the fl uid hoses is, even with appropriate handling, reduced due to environmental infl uences. Check hoses, pipes, and couplings every day and replace if necessary. As a precaution fl uid hoses shoul...

Page 46

46 operating manual version 01/2013 order number doc 2333538 list accessories designation no. No. No. No. No. No. A piston pump pe/tg 2329460 2329456 2329467 2329471 2329517 2329475 a piston pump pe/t 2329462 2329458 2329469 2329473 2330614 2329477 1 separating fl uid 250 ml; 250 cc 9992504 2 ground...

Page 47

47 b_03920 2 3 a 4 5 24 1 19 20 21 22 23 x 9 x 270 bar 14 12 13 7 15 16/17 18 10 11 270 bar 530 bar 6 y y y 26 25 operating manual version 01/2013 order number doc 2333538.

Page 48

48 operating manual version 01/2013 order number doc 2333538 for trouble-free intake, use hoses which are as short as possible. The maximun hose length is dependent upon the viscosity of the material, the suction height and the nominal diameter of the hose. List accessories designation no. No. No. N...

Page 49

49 1 2 3 4 10 14 13 17 18 12 11 16 15 13 8 5 8 5 9 6 7 30l 200l 19 dn16 dn25 dn25 dn16 dn25 dn16 dn16 dn25 b_03921 operating manual version 01/2013 order number doc 2333538.

Page 50

50 1 2 3 operating manual version 01/2013 order number doc 2333538 list accessories designation no. No. No. No. No. No. A piston pump pe/tg 2329460 2329456 2329467 2329471 2329517 2329475 a piston pump pe/t 2329462 2329458 2329469 2329473 2330614 2329477 1 trolley 4", complete 2325901 2 rack 4", com...

Page 51

51 operating manual version 01/2013 order number doc 2333538.

Page 52

52 operating manual version 01/2013 order number doc 2333538 10.2 accessories for leopard and jaguar pumps 10.2.1 material outlet accessories accessories list designation no. No. No. No. A piston pump pe/tg 2329479 2329484 2329490 2329501 a piston pump pe/t 2329481 2329486 2329493 2329505 a piston p...

Page 53

53 b_03923 2 3 a 19 20 21 23 22 24 x y y y 25 26 1 9 x 270 bar 14 12 13 4 5 7/8 15 16/17 18 10 11 270 bar 530 bar 6 operating manual version 01/2013 order number doc 2333538.

Page 54

54 operating manual version 01/2013 order number doc 2333538 10.2.2 material inlet accessories for trouble-free intake, use hoses which are as short as possible. The maximun hose length is dependent upon the viscosity of the material, the suction height and the nominal diameter of the hose. Accessor...

Page 55

55 1 2 11 12 14 13 11 30l 200l 10 9 dn16 dn25 8 6 3 6 3 7 4 5 dn25 dn16 dn25 dn16 15 16 dn16 dn25 17 operating manual version 01/2013 order number doc 2333538.

Page 56

56 1 3 4 2 b_03925 operating manual version 01/2013 order number doc 2333538 10.2.3 trolley and wall bracket accessories list accessories designation no. No. No. No. A piston pump pe/tg 2329479 2329484 2329490 2329501 a piston pump pe/t 2329481 2329486 2329493 2329505 a piston pump pe/l -- -- 232949...

Page 57: Warning

57 operating manual version 01/2013 order number doc 2333538 11 spare parts 11.1 how can spare parts be ordered? The service instructions are available separately. See chapter 1. Incorrect maintenance/repair! Risk of injury and equipment damage. Have repairs and part replacements be carried out only...

Page 58

58 b_03926 3 2 4 5 10 9 1 operating manual version 01/2013 order number doc 2333538 11.2 overview of components designation no. No. No. No. 1 piston pump 2329460 2329462 2329456 2329458 2 fluid section 2329645 2329647 2329641 2329643 3 air motor 2329613 4 spring 367530 5 coupling 367579 367529 9 gro...

Page 59

59 operating manual version 01/2013 order number doc 2333538 designation no. No. No. No. 1 piston pump 2329467 2329469 2329471 2329473 2 fluid section 2329641 2329643 2329645 2329647 3 air motor 2329617 4 spring 367530 5 coupling 367529 367579 9 grounding cable, complete 236219 10 molykote dx grease...

Page 60

60 operating manual version 01/2013 order number doc 2333538 designation no. No. No. No. 1 piston pump 2329479 2329481 2329484 2329486 2 fluid section 2329645 2329647 2329650 2329652 3 air motor 2329621 2329623 4 spring 368530 5 coupling 368529 9 grounding cable, complete 236219 10 molykote dx greas...

Page 61

61 operating manual version 01/2013 order number doc 2333538 designation no. No. No. 1 piston pump (npsm) 2329501 2329505 2329503 2 fluid section 2329650 2329652 2329664 3 air motor 2329625 4 spring 368530 5 coupling 368529 9 grounding cable, complete 236219 10 molykote dx grease 9992616 tightening ...

Page 62: Warning

62 operating manual version 01/2013 order number doc 2333538 11.3 air motors 11.3.1 wildcat, puma, leopard air motors air motor spare parts list designation no. No. No. No. No. 1 air motor 1 2329613 2329617 2329619 2329621 2329623 2 flange 1 367316 368316 3 piston rod 1 367302 367402 368302 368402 4...

Page 63

63 14 23 37 8 25 54 48 35 57 8 37 74 75 75 47 31 81 40 30 9 45 44 13 18 69 16 49 12 46 17 16 49 11 42 55 56 10 43 52 50 60 59 61 34 41 5 41 6 39 32 2 3 53 33 53 36 51 36 4 47 15 58 2-3 nm; appr. 2 lbft 40 nm; 30 lbft 10-15 nm; 7-11 lbft 20-25 nm; 15-19 lbft 28 25 nm; 19 lbft 29 b_03927 29 30 110 1 1...

Page 64

64 operating manual version 01/2013 order number doc 2333538 air motor spare parts list designation no. No. No. No. No. 30 pilot valve 2 369290 31 spool-sleeve combination assembly 1 9943080 9943081 32 permaglide bushing 1 9962018 9962019 33 complete piston 1 9998663 9998661 9998662 34 seal wiper ri...

Page 65

65 operating manual version 01/2013 order number doc 2333538 air motor spare parts list designation no. No. No. No. No. 81 spool & sleeve assembly iso1 or iso 2 1 9943097 9943098 100 pressure control device, complete. 1 2328606 2328607 106 loctite 222 50ml; 50cc 1 9992590 107 loctite, 243 50 ml; 50 ...

Page 66

66 b_03935 1 6 10 9 8 2 3 7 7 6 11 5 4 6 12 12 13 12 13 14 14 14 operating manual version 01/2013 order number doc 2333538 11.3.2 wildcat and puma air motor regulators air motor regulator spare parts list designation order no. 1 pressure regulator unit 4", complete 1 2328606 2 pressure regulator val...

Page 67

67 b_03936 1 7 12 11 10 2 3 9 8 6 13 5 4 7 15 14 15 15 16 16 14 16 operating manual version 01/2013 order number doc 2333538 11.3.3 leopard air motor regulator air motor regulator spare parts list designation order no. 1 pressure regulator unit 6", complete 1 2328607 2 pressure regulator valve 6" 1 ...

Page 68: Warning

68 operating manual version 01/2013 order number doc 2333538 11.3.4 jaguar air motor jaguar air motor spare parts list designation no. 1 1 air motor 2329625 2 1 flange 369316 3 1 piston rod 368402 4 1 cylinder pipe 369403 5 2 compressed air pipe 368404 6 1 control air pipe 367405 8 1 sealing plug 36...

Page 69

69 14 23 37 8 25 54 89 35 57 92 37 74 93 94 31 40 9 13 105 109 110 110 110 18 83 82 49 95 96 97 81 12 46 17 16 54 80 11 36 55 56 10 103 43 52 50 60 59 61 34 41 5 41 71 72 6 39 32 2 3 53 88 51 75 36 4 47 15 58 8-10 nm / 6-7 lbft 140 nm / 103 lbft 40 nm / 30 lbft 70 nm / 52 lbft 28 87 77 48 76 79 106 ...

Page 70

70 operating manual version 01/2013 order number doc 2333538 jaguar air motor spare parts list designation no. 33 1 piston 9 369385 34 1 seal wiper ring 9974125 35 1 safety valve 368286 36 2 o-ring 9974133 37 2 o-ring 9971056 39 2 o-ring 9974089 40 2 o-ring 9974132 41 4 o-ring 9971137 43 1 o-ring 99...

Page 71

71 operating manual version 01/2013 order number doc 2333538 jaguar air motor spare parts list designation no. 89 1 control fl ange 369317 90 1 air hose back 369026 91 1 air hose front 369025 92 1 lock space 9 369326 93 2 damper iso 3 369329 94 1 spool & sleeve assembly 9943131 95 1 velcro fastener ...

Page 72

72 b_03937 1 7 11 10 2 4 9 8 6 9 3 5 6 5 7 14 9 12 12 12 13 14 14 operating manual version 01/2013 order number doc 2333538 11.3.5 jaguar air motor regulator jaguar air motor spare parts list designation no. 1 1 pressure regulator unit 9", complete 2328609 2 1 pressure regulator valve 9" 2309974 3 1...

Page 73: Warning

73 operating manual version 01/2013 order number doc 2333538 11.4 fluid sections 11.4.1 fluid sections 40 cm3 fluid sections spare parts list designation no. No. 1 1 fluid section 2329641 2329643 2 1 pipe 367502 3 1 cylinder 367503 4 1 inlet housing 40 2322467 5 1 piston 367505 6 1 valve screw 36750...

Page 74

74 32 31 44 16 21 20 21 20 21 40 17 2 41 19 23 22 23 103 104 100 101 22 23 18 5 43 28 10 6 25 12 11 3 13 46 25 7 42 27 9 4 50 51 45 8 71 70 nm +10 nm 51 1 52 60 52 lbft + 7 lbft b_03929 53 39 40 nm/ 30 lbft 60 60 70 25 nm; 18 lbft 60 60 60 61 62 61 60 111 100 nm 74 lbft 61 operating manual version 0...

Page 75

75 operating manual version 01/2013 order number doc 2333538 fluid sections spare parts list designation no. No. 21 3 sealing collar pe (small) 123427 123427 103 1 packing pe/tg complete (large) 367991 104 1 packing pe/t complete (large) 367992 22 2 sealing collar tg (large) 367522 22 2 sealing coll...

Page 76: Warning

76 operating manual version 01/2013 order number doc 2333538 11.4.2 fluid sections 70 cm3 fluid sections spare parts list designation no. No. No. 1 1 fluid section 2329645 - 2329647 2 1 pipe 368502 3 1 cylinder 368503 4 1 inlet housing 70 2322465 5 1 piston 368505 6 1 valve screw 368506 7 1 ball gui...

Page 77

77 50 70 nm +10 nm 60 70 52 lbft + 7 lbft 40 nm/ 30 lbft 60 60 25 nm 18 lbft 60 60 60 60 61 62 61 60 32 31 44 16 21 20 21 20 21 40 17 2 41 19 23 22 23 103 104 105 100 101 102 22 23 18 5 43 28 10 6 25 12 11 3 13 46 25 7 42 27 9 4 51 45 8 71 a) 51 52 b_03930 53 39 57 1 111 100 nm 74 lbft 61 operating ...

Page 78

78 operating manual version 01/2013 order number doc 2333538 fluid sections spare parts list designation no. No. No. 20 2 sealing collar tg (small) 367522 20 2 sealing collar t (small) 367900 20 2 sealing collar l (small) 367922 21 3 sealing collar pe (small) 367523 367523 367523 103 1 packing pe/tg...

Page 79: Warning

79 operating manual version 01/2013 order number doc 2333538 11.4.3 fluid sections 110 cm3 fluid sections spare parts list designation no. No. No. 1 1 fluid section 2329654 2329658 2329656 2 1 pipe 368434 3 1 cylinder 368435 4 1 inlet housing 150 2327888 5 1 piston 368433 6 1 valve screw 367506 7 1 ...

Page 80

80 70 nm +10 nm 52 lbft + 7 lbft 60 60 60 106 50 nm 27 lbft 50 nm 27 lbft 60 60 60 60 61 61 62 62 61 60 32 31 44 16 21 20 21 20 21 40 17 2 41 19 23 22 23 103 104 105 100 101 102 22 23 18 5 43 28 10 6 25 12 11 3 13 46 25 7 42 27 9 4 50 51 57 45 8 107 54 55 b_03931 56 160 nm 118 lbft 1 100 nm 74 lbft ...

Page 81

81 operating manual version 01/2013 order number doc 2333538 fluid sections spare parts list designation no. No. No. 20 2 sealing collar l (small) 368437 21 3 sealing collar pe (small) 368427 368427 368427 103 1 packing pe/tg complete (large) 368299 104 1 packing pe/t complete (large) 368296 105 1 p...

Page 82: Warning

82 operating manual version 01/2013 order number doc 2333538 11.4.4 fluid sections 150 cm3 fluid sections spare parts list designation no. No. No. 1 1 fluid section 2329650 2329664 2329652 2 1 tube 368552 3 1 cylinder 368553 4 1 inlet housing 150 2327888 5 1 piston 368555 6 1 valve screw 368506 7 1 ...

Page 83

83 70 nm +10 nm 52 lbft + 7 lbft 60 60 60 106 50 nm 27 lbft 50 nm 27 lbft 60 60 60 60 61 61 62 62 61 60 32 31 44 16 21 20 21 20 21 40 17 2 41 19 23 22 23 103 104 105 100 101 102 22 23 18 5 43 28 10 6 25 12 11 3 13 46 25 7 42 27 9 4 50 51 57 45 8 107 54 55 b_03931 56 160 nm 118 lbft 1 100 nm 74 lbft ...

Page 84

84 operating manual version 01/2013 order number doc 2333538 fluid sections spare parts list designation no. No. No. 20 2 sealing collar tg (small) 367522 20 2 sealing collar t (small) 367900 20 2 sealing collar l (small) 367922 21 3 sealing collar pe (small) 367523 367523 367523 103 1 packing pe/tg...

Page 85

85 b_04072 1 2 3 4 5 6 7 8 operating manual version 01/2013 order number doc 2333538 designation order no. For fl uid section 40 cm3 order no. For fl uid section 70 cm3 1 1 inlet valve with valve depressor 2329689 2329688 2 1 ball guide, inlet 367507 368507 3 1 ball 9941513 9943082 4 1 o-ring 367527...

Page 86

86 b_04068 1 2 4 6 3 5 3 7 7 8 100 nm 74 lbft 7 9 operating manual version 01/2013 order number doc 2333538 11.6 relief combination (up to 270 bar; 3916 psi) order no. Designation 1 1 2329023 relief combination 2 1 2324549 relief housing 3 2 2323718 hexagon plug 4 1 169248 relief valve, complete 5 1...

Page 87

87 b_04070 3 2 4 5 1 6 operating manual version 01/2013 order number doc 2333538 11.7 straight inline filter (up to 270 bar; 3,916 psi) order no. Designation 1 1 2324558 inline fi lter dn6-pn270-g1/4"-sst 2 1 2324550 filter inlet housing 3 1 128389 seal 4 1 2315706 filter insert, yellow 5 1 2324551 ...

Page 88

88 b_04071 3 2 4 5 1 6 operating manual version 01/2013 order number doc 2333538 11.8 curved inline filter (up to 270 bar; 3,916 psi) order no. Designation 1 1 2329026 inline fi lter hl dn6-pn270-g1/4"-sst 2 1 2326045 filter inlet housing, pre-assembled 3 1 2315706 filter insert, yellow 4 1 2311491 ...

Page 89

89 operating manual version 01/2013 order number doc 2333538.

Page 90

90 90 nm; 66 lbft 140 nm 103 lbft 12 21 11 10 1 4 7 13 20 33 2 3 5 b_03934 23 34 36 35 36 34 34 20 34 operating manual version 01/2013 order number doc 2333538 11.9 high-pressure filter (up to 530 bar; 7687 psi) identifi cation of the fi lter tighten pos. 3 by hand stainless steel carbon steel.

Page 91: Warning

91 operating manual version 01/2013 order number doc 2333538 incorrect maintenance/repair! Danger to life and equipment damage. Only a wagner service center or a suitably trained person may carry out repairs and replace parts. Only repair and replace parts that are listed in the chapter "spare parts...

Page 92

92 90 nm; 66 lbft 140 nm; 103 lbft 12 21 11 10 1 4 7 13 2 3 5 b_04069 23 34 35 34 36 36 37 8 operating manual version 01/2013 order number doc 2333538 11.10 high-pressure filter (up to 270 bar; 3,916 psi) identifi cation of the fi lter tighten pos. 3 by hand.

Page 93: Warning

93 operating manual version 01/2013 order number doc 2333538 incorrect maintenance/repair! Danger to life and equipment damage. Only a wagner service center or a suitably trained person may carry out repairs and replace parts. Only repair and replace parts that are listed in the chapter "spare parts...

Page 94

94 4 1 2 17 15 10 6 5 9 7 8 5 13 11 12 b_03932 3 14 16 a b operating manual version 01/2013 order number doc 2333538 11.11 trolley distance designation order no. For wildcat order no. For puma order no. For leopard 1 1 trolley, complete 2325901 2325916 2 1 stand left 4"-6" (welded) -- 3 1 stand righ...

Page 95

95 b_00363 8 1 2 3 4 5 6 7 operating manual version 01/2013 order number doc 2333538 11.12 "heavy duty" trolley designation order no. For leopard order no. For jaguar 1 1 trolley, heavy duty 369024 2 4 washer, din125, a6.4 or a8.4 9920103 9920102 3 2 wheel 9998892 4 2 fixed washer 9998894 5 2 quick ...

Page 96

96 operating manual version 01/2013 order number doc 2333538 12.1 important notes regarding product liability 12.2 guarantee claim 12 guarantee and conformity declarations as a result of an ec regulation eff ective from january 1, 1990, the manufacturer shall only be liable for his product if all pa...

Page 97

97 operating manual version 01/2013 order number doc 2333538 12.3 ce declaration of conformity herewith we declare that the supplied version of pneumatic pumps and their spraypacks: comply with the following guidelines: 2006/42/ec 94/9/ec applied standards, in particular: din en iso 12100: 2011 din ...

Page 98

98 operating manual version 01/2013 order number doc 2333538 germany j. Wagner gmbh otto-lilienthal-str. 18 postfach 1120 d- 88677 markdorf telephone: +49 7544 5050 telefax: +49 7544 505200 e-mail: service.Standard@wagner-group.Com switzerland j. Wagner ag industriestrasse 22 postfach 663 ch- 9450 a...

Page 100: Cert

Cert if ie d order no. 2333538 germany tel. Fax e-mail switzerland tel. Fax.