- DL manuals

- WAGNER

- Paint Sprayer

- PEA-C4XL-S

- Translation Of The Original Operating Manual

WAGNER PEA-C4XL-S Translation Of The Original Operating Manual

Summary of PEA-C4XL-S

Page 1

0102 ii 2 d eex 2mj 85 °c p_02330 automatic powder spray gun pea-c4xl-s version 03 / 2014 translation of the original operating manual.

Page 3: Pea-C4Xl-S

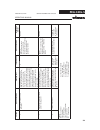

3 pea-c4xl-s operating manual version 03/2014 order number doc2345334 table of contents 1 general information 6 1.1 preface 6 1.2 warnings, notices, and symbols in this operating manual 6 1.3 languages 7 1.4 abbreviations 7 2 correct use 8 2.1 device type 8 2.2 type of use 8 2.3 use in potentially e...

Page 4: Pea-C4Xl-S

4 pea-c4xl-s operating manual version 03/2014 order number doc2345334 6.7 grounding 28 6.7.1 grounding the powder coating system 29 7 operation 30 7.1 training the operating staff 30 7.2 safety instructions 30 7.3 switching on the spray gun 31 7.4 switching off the spray gun 31 7.5 switching off the...

Page 5: Pea-C4Xl-S

5 pea-c4xl-s operating manual version 03/2014 order number doc2345334 13 spare parts 65 13.1 how can spare parts be ordered? 65 13.2 pea-c4xl-s corona automatic gun 66 13.3 c4 r electrode holder with nozzles 67 13.4 wa90 c4 angle adapter 68 13.5 wa60 c4 angle adapter 69 13.6 wa30 c4 angle adapter 70...

Page 6: Pea-C4Xl-S

6 pea-c4xl-s operating manual version 03/2014 order number doc2345334 1 general information the operating manual contains information about safely operating, maintaining, cleaning and repairing the device. The operating manual is part of the device and must be available to operating and service staf...

Page 7: Pea-C4Xl-S

7 pea-c4xl-s operating manual version 03/2014 order number doc2345334 1.3 languages the operating manual is available in the following languages: language: order no. Language: order no. German 2345333 english 2345334 italian 2345335 1.4 abbreviations number of pieces position marking in the spare pa...

Page 8: Pea-C4Xl-S

8 pea-c4xl-s operating manual version 03/2014 order number doc2345334 2 correct use 2.1 device type automatic spray gun for automatic coating 2.2 type of use the pea-c4xl-s spray gun serves as stationary equipment for industrial electrostatic coating with fl ammable powder in automatic systems. It c...

Page 9: Pea-C4Xl-S

9 pea-c4xl-s operating manual version 03/2014 order number doc2345334 2.6 reasonably foreseeable misuse the following is prohibited: coating work pieces which are not grounded, unauthorized conversions and modifi cations to the spray gun, processing liquid or similar coating products, and using defe...

Page 10: Pea-C4Xl-S

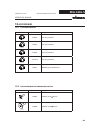

10 pea-c4xl-s 0102 operating manual version 03/2014 order number doc2345334 3 identification 3.1 explosion protection identification 3.2 permissible device combinations the pea-c4xl-s powder spray gun may only be connected to the control devices listed below: epg-s2 epg-sprint x gun type: pea-c4xl-s...

Page 11: Pea-C4Xl-S

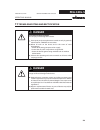

11 pea-c4xl-s operating manual version 03/2014 order number doc2345334 3.3 safety feature identification plates bearing information for the user have been attached to the work openings of the powder coating booth. The plate size corresponds to the standard category Ø 100 mm; 3.94 inches. The label p...

Page 12: Pea-C4Xl-S

12 pea-c4xl-s operating manual version 03/2014 order number doc2345334 4 general safety instructions 4.1 safety instructions for the operator 4.1.1 electrical devices and equipment 4.1.2 staff qualifications 4.1.3 safe work environment keep this operating manual at hand near the device at all times....

Page 13: Pea-C4Xl-S

13 pea-c4xl-s operating manual version 03/2014 order number doc2345334 4.2.1 safe handling of wagner powder spray devices 4.2.2 grounding the device 4.2.3 accessories and spare parts 4.2 safety instructions for staff always follow the information in this manual, particularly the general safety instr...

Page 14: Pea-C4Xl-S

14 pea-c4xl-s operating manual version 03/2014 order number doc2345334 4.2.5 handling powder lacquers 4.2.4 cleaning and maintenance before starting cleaning or any other manual work, the high-voltage in the spray area must be shut down and locked to prevent it from being switched back on. Lock the ...

Page 15: Pea-C4Xl-S

15 pea-c4xl-s p_01091 operating manual version 03/2014 order number doc2345334 4.3 note on safe discharges with the high-voltage switched on, a luminous or corona discharge occurs at the electrode tip; this can only be seen in the dark. This physical eff ect can be seen when the electrode is brought...

Page 16: Pea-C4Xl-S

16 pea-c4xl-s operating manual version 03/2014 order number doc2345334 4.4 protective and monitoring equipment 4.4.1 release guns (high-voltage/pneumatic system) enabling high-voltage depends on: exhaust air is ok fire extinguishing system/fi re detection system is ok (external signal) no emergency ...

Page 17: Pea-C4Xl-S

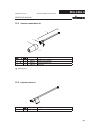

17 pea-c4xl-s b c a f g h x x p_02331 g k i l d e a operating manual version 03/2014 order number doc2345334 5 description 5.1 spray gun design designation a fan spray nozzle or round spray nozzle b defl ector cone for round spray nozzle c round spray nozzle electrode d union nut e interlocking f sp...

Page 18: Pea-C4Xl-S

18 pea-c4xl-s operating manual version 03/2014 order number doc2345334 dimensions: length/width/height see chapter 5.3.1 weight electrical: input voltage maximum 22 vpp input current maximum 0.9 a frequency 19 - 30 khz output voltage maximum 100 kv dc polarity negative construction type in accordanc...

Page 19: Pea-C4Xl-S

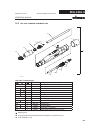

19 pea-c4xl-s e d x x a* p_02332 b c operating manual version 03/2014 order number doc2345334 5.3.1 dimensions measurement mm inch a* 30 1.18 b 400 15.75 c 1,100 43.31 d 60 2.36 e 72 2.83 measurement for installation dimension c calculation when utilizing a round spray nozzle with defl ector cone.

Page 20: Pea-C4Xl-S

20 pea-c4xl-s operating manual version 03/2014 order number doc2345334 quantity order no. Designation 1 2344249 pea-c4xl-s automatic gun 1 --- nozzle set the standard equipment includes: 1 2347535 conformity certifi cate 1 2345333 operating manual, german 1 see chapter 1.3 operating manual in local ...

Page 21: Pea-C4Xl-S

21 pea-c4xl-s operating manual version 03/2014 order number doc2345334 6 assembly and commissioning 6.1 training assembly/commissioning staff 6.2 storage conditions until the point of assembly, the powder spray gun must be stored in a dry location, free from vibrations and with a minimum of dust. Th...

Page 22: Pea-C4Xl-S

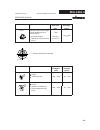

22 pea-c4xl-s p_00694 p_00694 p_00694 p_00694 p_00935 p_00694 operating manual version 03/2014 order number doc2345334 6.4 preparing the spray gun 6.4.1 selection of the suitable nozzle system nozzle application distance to work piece powder discharge (mm) (g/min) f1¹ universal application (slow pow...

Page 23: Pea-C4Xl-S

23 pea-c4xl-s p_00935 p_00695 p_00694 f1 p_01107 operating manual version 03/2014 order number doc2345334 nozzle application distance to work piece powder discharge (mm) (g/min) hpo-1¹ wide fl at spray nozzle for high powder application (slow powder cloud) > 200 (total air > 4.5 nm³/h) 150 400 good ...

Page 24: Pea-C4Xl-S

24 pea-c4xl-s operating manual version 03/2014 order number doc2345334.

Page 25: Pea-C4Xl-S

25 pea-c4xl-s 3 2 p_02335 1 4 operating manual version 03/2014 order number doc2345334 6.5 handling of the hose coupling loosening the hose coupling: 1. Lift the o-ring 1 out of the groove and slide it towards spray gun. 2. Turning the locking nut 2 in a clockwise direction up to the stop and pull t...

Page 26: Pea-C4Xl-S

26 pea-c4xl-s x x 1 2 4 5 g k i l p_02333 6 3 operating manual version 03/2014 order number doc2345334 6.6 assembling the spray gun unintentional putting into operation! Risk of injury. Before any work on the device, in the event of work interruptions and malfunctions: switch off the energy/compress...

Page 27: Pea-C4Xl-S

27 pea-c4xl-s operating manual version 03/2014 order number doc2345334 procedure: 1. Switch off the high-voltage generation on the control unit. 2. Press locking button 1 and move supporting tube 2 away backwards. 3. Connect electrical cable 3 to connection i on the spray gun and to the control unit...

Page 28: Pea-C4Xl-S

28 pea-c4xl-s operating manual version 03/2014 order number doc2345334 6.7 grounding for safety reasons, the spray gun and the work piece must be properly grounded. For the spray gun, this is done via the grounding connection. Perfect grounding of the work piece is also necessary to achieve an optim...

Page 29: Pea-C4Xl-S

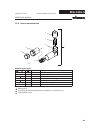

29 pea-c4xl-s 1 2 4 3 5 6 p_02338 operating manual version 03/2014 order number doc2345334 6.7.1 grounding the powder coating system 1 only use mains cables with grounding strand! 2 connect grounding cable with signal ground! 3 remove all paint from hooks and other hanger parts! 4 do not wear non-co...

Page 30: Pea-C4Xl-S

30 pea-c4xl-s operating manual version 03/2014 order number doc2345334 7 operation 7.1 training the operating staff 7.2 safety instructions incorrect operation! Risk of injury and damage to the device. The operating staff must be qualifi ed to operate the entire system. Before work commences, the op...

Page 31: Pea-C4Xl-S

31 pea-c4xl-s operating manual version 03/2014 order number doc2345334 7.3 switching on the spray gun the spray gun is switched on via the superordinated control unit of the system. At the same time, the high-voltage and the powder feed are activated. 7.4 switching off the spray gun the gun is switc...

Page 32: Pea-C4Xl-S

32 pea-c4xl-s operating manual version 03/2014 order number doc2345334 procedure: 1. Switch on the high-voltage generation and the powder feed. Note: to minimize the wear on the wearing parts, the total feed air and dosing air should be under 5 nm³/h! The atomizing air should be adjusted for the: fa...

Page 33: Pea-C4Xl-S

33 pea-c4xl-s operating manual version 03/2014 order number doc2345334 7.7 performing a paint change in the case of a paint change, powder residues must be thoroughly removed from all powder-conveying parts. In the following, only the procedure for the powder spray gun is described. Note: during a p...

Page 34: Pea-C4Xl-S

34 pea-c4xl-s operating manual version 03/2014 order number doc2345334 7.7.1 impulse flushing if the gun is supplied with coating powder from a powder center, you can initiate an impulse fl ushing from there. Further details are contained in the powder center's operating manual. Note: during a paint...

Page 35: Pea-C4Xl-S

35 pea-c4xl-s 30° 15° 0° x x p_01095 p_01096 operating manual version 03/2014 order number doc2345334 7.8 reproducible setting of the nozzle position for a horizontal powder cloud, the fl at spray nozzle is set where the protective wedge is in the 0° position. When attaching a round spray nozzle, we...

Page 36: Pea-C4Xl-S

36 pea-c4xl-s operating manual version 03/2014 order number doc2345334 8 cleaning and maintenance cleaning work should be undertaken regularly and carefully by qualifi ed and trained staff . The staff must be familiar with the din en 50177 provisions. They should be informed of specifi c hazards dur...

Page 37: Pea-C4Xl-S

37 pea-c4xl-s operating manual version 03/2014 order number doc2345334 the cleaning intervals should be adapted by the operator depending on the level of use and if necessary the level of soiling. If in doubt, we recommend contacting j. Wagner ag's specialist personnel. The valid health and safety s...

Page 38: Pea-C4Xl-S

38 pea-c4xl-s operating manual version 03/2014 order number doc2345334 8.2 maintenance maintenance work should be undertaken regularly and carefully by qualifi ed and trained staff . They should be informed of specifi c hazards during their training. The following hazards may arise during maintenanc...

Page 39: Pea-C4Xl-S

39 pea-c4xl-s operating manual version 03/2014 order number doc2345334 the maintenance intervals should be adapted by the operator depending on the level of use and if necessary the level of soiling. If in doubt, we recommend contacting j. Wagner ag's specialist personnel. The valid health and safet...

Page 40: Pea-C4Xl-S

40 pea-c4xl-s x x 1 2 4 5 g k i l p_02333 6 3 operating manual version 03/2014 order number doc2345334 8.2.4 replacing the spray gun unintentional putting into operation! Risk of injury. Before any work on the device, in the event of work interruptions and malfunctions: switch off the energy/compres...

Page 41: Pea-C4Xl-S

41 pea-c4xl-s operating manual version 03/2014 order number doc2345334 before replacing the spray gun, any powder residue must be thoroughly removed. The wearing parts in the spray gun, marked in the spare parts list with " ", must be regularly checked and, if necessary replaced. Procedure: 1. Switc...

Page 42: Pea-C4Xl-S

42 pea-c4xl-s 1 2 3 5 p_00591 p_00592 p_00593 operating manual version 03/2014 order number doc2345334 8.3 cleaning the gun and dismantling the flat spray nozzle procedure: 1. Unscrew union nut 1 from gun housing 5. 2. Pull fl at spray nozzle 2 off electrode holder 3. 3. Carefully remove electrode h...

Page 43: Pea-C4Xl-S

43 pea-c4xl-s 2 3 1 p_00594 3 2 1 p_00595 3 1 2 p_00596 operating manual version 03/2014 order number doc2345334 8.4 replacing the protective wedge 1 wedge tool 2 protective wedge (when positioned) 3 electrode holder (shown with a cut- away view to improve comprehension) procedure: 1. Guide wedge to...

Page 44: Pea-C4Xl-S

44 pea-c4xl-s 3 2 1 p_00597 3 1 2 y x p_00598 y x p_00599 operating manual version 03/2014 order number doc2345334 procedure: 1. Guide protective wedge 2 into wedge tool 1. 2. Insert both parts into opening on electrode holder up to stop. 3. If it is not possible to push the wedge tool in as far as ...

Page 45: Pea-C4Xl-S

45 pea-c4xl-s 5 3 2 1 p_00700 1 2 3 5 p_00591 operating manual version 03/2014 order number doc2345334 8.5 fitting the round spray nozzle the standard corona spray gun is delivered with a fl at spray nozzle. The nozzle can be changed easily, as described below. Note: if changing from the fl at spray...

Page 46: Pea-C4Xl-S

46 pea-c4xl-s 7 6 5 7 1 8 y x p_00701 operating manual version 03/2014 order number doc2345334 5. Carefully fi t the new c4 r electrode holder 6 into spray gun housing 5. 6. Slide defl ector cone sleeve 7 onto electrode holder 6. 7. Align the x and y marks. 8. Fasten union nut 1. 9. Slide defl ector...

Page 47: Pea-C4Xl-S

47 pea-c4xl-s 1 2 3 5 p_00591 operating manual version 03/2014 order number doc2345334 8.6 assembling the angle adapter the standard corona spray gun is delivered with a fl at spray nozzle. The nozzle can be changed easily, as described below. Note: if changing from the fl at spray nozzle to the rou...

Page 48: Pea-C4Xl-S

48 pea-c4xl-s 6 5 p_01616 4 2 1 4 5 6 4 6 5 7 3 2 1 p_01617 operating manual version 03/2014 order number doc2345334 8.6.2 fitting the angle adapter procedure: 1. Install electrode holder 1 together with nozzle 2 in nozzle insert 3 and tighten union nut 4. 2. Push angle adapter 5 onto the gun body a...

Page 49: Pea-C4Xl-S

49 pea-c4xl-s 7 12 11 10 8, 9 p_01618 a2 x a1 b1 y1 y2 z b2 operating manual version 03/2014 order number doc2345334 4. Unscrew threaded sleeve 8 and locking sleeve 9 with mounting tool 10. 5. Pull connecting element 11 out of elbow fi tting 12. 6. Insert screwdriver into recess x and turn it until ...

Page 50: Pea-C4Xl-S

50 pea-c4xl-s b 1 a c 2 3 g e f d p_02337 h operating manual version 03/2014 order number doc2345334 8.7 assembling the corona-star the corona-star is a retrofi t set for the spray gun, which helps to achieve a better surface quality (reduction of "orange peel"). Procedure: 1. Switch off the high-vo...

Page 51: Pea-C4Xl-S

51 pea-c4xl-s p_02334 1 2 3 operating manual version 03/2014 order number doc2345334 8.8 corona-star for angle adapter 8.8.1 assembling the corona-star procedure: 1. Switch off the high-voltage and the powder feed and secure them against being inadvertently switched on. 2. Detach the corona-star 1 f...

Page 52: Pea-C4Xl-S

52 pea-c4xl-s operating manual version 03/2014 order number doc2345334 9 inspections in accordance with din en 50177: 2010-04 if the system is used for electrostatic coating with fl ammable coating powders, testing should be undertaken in accordance with din en 50177: 2010-04 as per table 3 and tabl...

Page 53: Pea-C4Xl-S

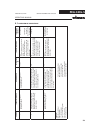

53 pea-c4xl-s operating manual version 03/2014 order number doc2345334 s e c tion t y pe of inspec tion requir emen ts inspec tion by t y pe of inspec tion inspec tion in ter v al 1e ff ec tiv eness of t echnical v e ntilation check eff ec tiv eness of t echnical v e ntilation check tp/sp me e .G . ...

Page 54: Pea-C4Xl-S

54 pea-c4xl-s operating manual version 03/2014 order number doc2345334 s e c tion t y pe of inspec tion requir emen ts inspec tion b y t y pe of inspec tion inspec tion in ter v al 4e ff ec tiv eness of g rounding measur es all the sy st em 's c onduc tiv e elements , such as fl oors , walls , ceili...

Page 55: Pea-C4Xl-S

55 pea-c4xl-s operating manual version 03/2014 order number doc2345334.

Page 56: Pea-C4Xl-S

56 pea-c4xl-s x x 1 2 4 5 g k i l p_02333 6 3 operating manual version 03/2014 order number doc2345334 10 disassembly and disposal 10.1 disassembly warning incorrect disassembly! Risk of injury and damage to the device. Before starting disassembly: - switch off the energy/compressed air supply. - en...

Page 57: Pea-C4Xl-S

57 pea-c4xl-s operating manual version 03/2014 order number doc2345334 10.2 disposal do not dispose of used electrical equipment with household refuse! In accordance with european directive 2002/96/ec on the disposal of used electrical equipment and its implementation in national law, this product m...

Page 58: Pea-C4Xl-S

58 pea-c4xl-s operating manual version 03/2014 order number doc2345334 11 troubleshooting and rectification incorrect maintenance/repair! Risk of injury and damage to the device. Have repairs and part replacements carried out only by specially trained staff or a wagner service center. Before all wor...

Page 59: Pea-C4Xl-S

59 pea-c4xl-s operating manual version 03/2014 order number doc2345334 fault cause remedy no electrostatics (e.G. No wrap around or powder adhesion) fault in the high-voltage generator contact a wagner service center electrical cable from spray gun to control unit faulty replace the electric cable c...

Page 60: Pea-C4Xl-S

60 pea-c4xl-s p_00935 p_00695 p_00694 p_00694 p_00694 p_00694 p_00694 operating manual version 03/2014 order number doc2345334 12 accessories 12.1 flat spray nozzles order no. Designation 390324 flat spray nozzle f1 390325 flat spray nozzle f2 390326 fan spray nozzle f3 2311889 flat spray nozzle f4 ...

Page 61: Pea-C4Xl-S

61 pea-c4xl-s 1 2 3 p_01104 p_01168 operating manual version 03/2014 order number doc2345334 order no. Designation 1 1 390918 corona-star, complete 2 1 260296 corona-star electrode 3 1 390319 union nut wearing parts 12.3 corona-star retrofit set 12.4 corona-star wa c4 pos k order no. Designation 1 1...

Page 62: Pea-C4Xl-S

62 pea-c4xl-s p_00714 operating manual version 03/2014 order number doc2345334 12.5 wedge tool order no. Designation 1 390900 wedge tool including 20 protective wedges only available as a set 12.6 electric cables and hoses order no. Designation application 351216 electrical cable 5 m for connecting ...

Page 63: Pea-C4Xl-S

63 pea-c4xl-s p_01621 p_01626 operating manual version 03/2014 order number doc2345334 12.7 angle adapter order no. Designation 390927 angle adapter wa30 c4 390930 angle adapter wa60 c4 390931 angle adapter wa 90 c4 order no. Designation 390939 mounting tool wa c4.

Page 64: Pea-C4Xl-S

64 pea-c4xl-s p_01105 p_01106 operating manual version 03/2014 order number doc2345334 12.8 powder measuring bag order no. Designation 390940 powder measuring bag, complete for measuring powder quantities for the c4 gun generation the powder measuring bag is slid onto the nozzle. Risk of explosion d...

Page 65: Pea-C4Xl-S

65 pea-c4xl-s operating manual version 03/2014 order number doc2345334 13 spare parts 13.1 how can spare parts be ordered? To ensure proper spare parts delivery, the following information is necessary: order number, designation, and quantity the quantity need not be the same as the number given in t...

Page 66: Pea-C4Xl-S

66 pea-c4xl-s 2 13 3 p_02336 4 5 1 9 6 7 10 11 12 8 operating manual version 03/2014 order number doc2345334 13.2 pea-c4xl-s corona automatic gun pea-c4xl-s automatic gun order no. Designation 1 1 2344249 pea-c4xl-s corona automatic gun 2 1 390311 union nut 3 1 390324 flat spray nozzle f1 4 1 390915...

Page 67: Pea-C4Xl-S

67 pea-c4xl-s 3 4 5 6 p_01103 2 1 operating manual version 03/2014 order number doc2345334 c4 r electrode holder with nozzles order no. Designation 1 1 390917 c4 r electrode holder, complete 2 1 390916 c4 r electrode holder 3 1 390310 wedge 4 1 390313 defl ector cone sleeve 5 1 390207 r20 defl ector...

Page 68: Pea-C4Xl-S

68 pea-c4xl-s 5 6 7 p_01623 1 2 3 4 operating manual version 03/2014 order number doc2345334 wa90 c4 angle adapter order no. Designation 1 1 390931 wa90 c4 angle adapter 2 1 390947 wa c4 et union nut 3 1 390933 wa90 c4 et nozzle insert 4 1 390942 wa90 c4 et elbow fi tting 5 1 390932 wa c4 et connect...

Page 69: Pea-C4Xl-S

69 pea-c4xl-s p_01624 1 2 3 4 5 6 7 operating manual version 03/2014 order number doc2345334 wa60 c4 angle adapter order no. Designation 1 1 390930 wa60 c4 angle adapter 2 1 390947 wa c4 et union nut 3 1 390934 wa60 c4 et nozzle insert 4 1 390943 wa60 c4 et elbow fi tting 5 1 390932 wa c4 et connect...

Page 70: Pea-C4Xl-S

70 pea-c4xl-s p_01625 1 2 3 4 5 6 7 operating manual version 03/2014 order number doc2345334 wa60 c4 angle adapter order no. Designation 1 1 390927 wa30 c4 angle adapter 2 1 390947 wa c4 et union nut 3 1 390935 wa30 c4 et nozzle insert 4 1 390944 wa30 c4 et elbow fi tting 5 1 390932 wa c4 et connect...

Page 71: Pea-C4Xl-S

71 pea-c4xl-s operating manual version 03/2014 order number doc2345334 14 declaration of warranty and conformity 14.1 important notes regarding product liability 14.2 warranty claim as a result of an ec regulation eff ective from january 1, 1990, the manufacturer shall only be liable for his product...

Page 72: Pea-C4Xl-S

72 pea-c4xl-s operating manual version 03/2014 order number doc2345334 14.3 declaration of conformity pea-c4xl-s automatic gun 2347535 herewith we declare that the supplied version of - pea-c4xl-s automatic gun, order no. 2344249 complies with the following provisions: - 94/9/ec (atex directive) - 2...

Page 73: Pea-C4Xl-S

73 pea-c4xl-s operating manual version 03/2014 order number doc2345334.

Page 74: Pea-C4Xl-S

74 pea-c4xl-s operating manual version 03/2014 order number doc2345334.

Page 76: Cert

Cert if ie d dokument-nr . 1 1 160384 v ersion - order no. 2345334 edition 03/2014 germany phone fax e-mail switzerland phone fax more contact addresses on the internet at: company/locations/wagner worldwide subject to changes without notice.