- DL manuals

- WAGNER

- Paint Sprayer

- PEM-X1

- Original Operating Manual

WAGNER PEM-X1 Original Operating Manual

Summary of PEM-X1

Page 1

0102 ii 2d 2mj p_01660 manual powder spray gun pem-x1 version 09/2012 translation of the original operating manual.

Page 3: Pem-X1

3 pem-x1 operating manual version 09/2012 order number doc 2326020 contents 1 general information 6 1.1 preface 6 1.2 warnings, notes and symbols in these instructions 6 1.3 languages 7 1.4 abbreviations 7 2 correct use 8 2.1 device type 8 2.2 correct use 8 2.3 for use in potentially explosive areas...

Page 4: Pem-X1

4 pem-x1 operating manual version 09/2012 order number doc 2326020 7 operation 27 7.1 qualifi cation of the operating staff 27 7.2 safety instructions 27 7.3 optimizing the powder cloud for coating 28 7.3.1 recommended settings for total air volume 28 7.4 switching off the spray gun 29 7.5 adjustmen...

Page 5: Pem-X1

5 pem-x1 operating manual version 09/2012 order number doc 2326020 13 spare parts 60 13.1 how to order spare parts? 60 13.2 pem-x1 corona manual spray gun 61 13.3 electrode holder x1 r 62 14 declaration of warranty and conformity 63 14.1 important notes on product liability 63 14.2 warranty claim 63...

Page 6: Pem-X1

6 pem-x1 operating manual version 09/2012 order number doc 2326020 1 general information the operating manual contains information about safely operating, maintaining, cleaning and repairing the device. The operating manual is part of the device and must be available to the operating and service sta...

Page 7: Pem-X1

7 pem-x1 operating manual version 09/2012 order number doc 2326020 1.3 languages 1.4 abbreviations the this operating manual is available in the following languages: german 2326019 english 2326020 french 2326021 italian 2326022 spanish 2326023 piece item marking in the spare parts lists number spare...

Page 8: Pem-X1

8 pem-x1 operating manual version 09/2012 order number doc 2326020 2 correct use 2.1 device type powder spray guns for manual coating of grounded work pieces 2.2 correct use the pem-x1 manual powder spray gun is designed for the electrostatic coating of work pieces with organic powders. Any other fo...

Page 9: Pem-X1

9 pem-x1 operating manual version 09/2012 order number doc 2326020 2.5 processing materials types of powder which can be charged electrostatically metallic powder 2.6 reasonably foreseeable misuse 2.7 residual risks residual risks are risks which cannot be excluded even in the event of correct use. ...

Page 10: Pem-X1

10 pem-x1 0102 operating manual version 09/2012 order number doc 2326020 3 identification 3.1 explosion protection identification the ec type examination certifi cate ptb 12 atex 5002 can be found in chapter 14.4. 3.2 permissible device combinations gun type: pem-x1 manufacturer: j. Wagner ag ch - 9...

Page 11: Pem-X1

11 pem-x1 operating manual version 09/2012 order number doc 2326020 4 general safety instructions 4.1 safety instructions for the operator 4.1.1 electrical devices and operating equipment 4.1.2 personnel qualifications 4.1.3 a safe work environment keep this operating manual to hand near the unit at...

Page 12: Pem-X1

12 pem-x1 operating manual version 09/2012 order number doc 2326020 4.2.1 safe handling of wagner powder spray devices 4.2.2 grounding the device 4.2.3 material hoses 4.2 safety instructions for staff only use original wagner powder hose. Always follow the information in these instructions, particul...

Page 13: Pem-X1

13 pem-x1 operating manual version 09/2012 order number doc 2326020 4.2.5 handling powder paints 4.2.4 cleaning before starting cleaning or any other manual work, the high-voltage in the spray area must be shut down and locked to prevent it from being switched back on! Lock the supply of compressed ...

Page 14: Pem-X1

14 pem-x1 p_01698 operating manual version 09/2012 order number doc 2326020 4.3 information about harmless discharges with the high-voltage switched on, a luminous or corona discharge occurs at the electrode tip; this can only be seen in the dark. This physical eff ect can be seen when the electrode...

Page 15: Pem-X1

15 pem-x1 operating manual version 09/2012 order number doc 2326020 4.4 protective and monitoring equipment to prevent electrostatic fl ashover, the cup nut for securing the nozzles is designed in a certain geometric shape. This shape, together with the shape of the fl at spray nozzle or defl ector ...

Page 16: Pem-X1

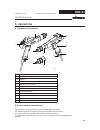

16 pem-x1 a b c k i f p_01663 e d g f l h operating manual version 09/2012 order number doc 2326020 5 description 5.1 design of the spray gun designation a suspension hook b handle c electrical connection cable d powder hose connection e trigger lever f cap nut g round spray nozzle h atomizer air co...

Page 17: Pem-X1

17 pem-x1 operating manual version 09/2012 order number doc 2326020 dimensions: length/width/height see chapter 5.3.1 weight 490 g; 1.08 lbs electrical: input voltage maximum of 22 vpp input current maximum of 0.9 a frequency 19 - 30 khz output voltage maximum of 100 kv dc max. Corona current 120 μa...

Page 18: Pem-X1

18 pem-x1 a p_01662 b c operating manual version 09/2012 order number doc 2326020 5.3.1 dimensions measurement mm inch a* 335/349 13.19/13.74 b 248 9.76 c 45 1.77 * with fl at spray nozzle/with defl ector cone.

Page 19: Pem-X1

19 pem-x1 operating manual version 09/2012 order number doc 2326020 stk order no. Designation 1 2322587 pem-x1 manual spray gun 1 --- nozzle set the standard equipment includes: 1 2326024 declaration of conformity 1 2326019 operating manual german 1 see chapter 1.5 operating manual in the local lang...

Page 20: Pem-X1

20 pem-x1 operating manual version 09/2012 order number doc 2326020 6 assembly and commissioning 6.1 qualification of the assembly/commissioning staff incorrect installation/operation! Risk of injury and damage to the equipment. The commissioning staff must have the technical skills to safely undert...

Page 21: Pem-X1

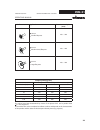

21 pem-x1 p_01664 p_01664 p_01665 operating manual version 09/2012 order number doc 2326020 6.4 preparing the spray gun 6.4.1 selection of the suitable nozzle system nozzle application distance to work piece powder discharge (mm) (g/min) universal 120 … 300 50 … 300 deep and complex shapes extensive...

Page 22: Pem-X1

22 pem-x1 p_01665 p_01666 p_01667 operating manual version 09/2012 order number doc 2326020 defl ector cone application distance to work piece (mm) r18 100 … 300 18 mm smaller fl at parts r25 100 … 300 25 mm medium sized, fl at parts r34 100 … 300 34 mm large fl at parts output quantity [g/min] over...

Page 23: Pem-X1

23 pem-x1 operating manual version 09/2012 order number doc 2326020 procedure: 1. Switch off the high-voltage generation on the control unit. 2. Before connecting the spray gun, check that all components (such as the nozzle system and cap nut) are correctly fi tted. 3. Connect electrical cable of sp...

Page 24: Pem-X1

24 pem-x1 p_01668 i o operating manual version 09/2012 order number doc 2326020 to the electrical connection on the control unit powder feed from the powder injector atomizing air from the control unit powder spray gun control unit powder injector red blue transparent.

Page 25: Pem-X1

25 pem-x1 operating manual version 09/2012 order number doc 2326020 6.6 grounding no grounding! Risk of explosion and risk of electric shock. Electrostatic control units and the associated spray equipment may only be connected to mains supplies with a protective conductor connection (pe conductor)! ...

Page 26: Pem-X1

26 pem-x1 p_01120 1 2 3 6 7 5 4 operating manual version 09/2012 order number doc 2326020 6.6.1 grounding the powder coating system the footwear worn by the operators must comply with the requirements of en iso 20344. The measured insulation resistance must not exceed 100 mΩ (megaohms). The protecti...

Page 27: Pem-X1

27 pem-x1 operating manual version 09/2012 order number doc 2326020 7 operation 7.1 qualification of the operating staff 7.2 safety instructions incorrect operation! Risk of injury and damage to the equipment. The operating staff must be qualifi ed to operate the entire system. Before work commences...

Page 28: Pem-X1

28 pem-x1 operating manual version 09/2012 order number doc 2326020 procedure: 1. Switch on the high-voltage generation and the powder feed. Note: to minimize wear on the wearing parts, the total air volume should be below 5 nm³/h! The atomizing air should be adjusted for the fl at spray nozzle to 0...

Page 29: Pem-X1

29 pem-x1 operating manual version 09/2012 order number doc 2326020 7.4 switching off the spray gun by releasing the trigger the powder supply is stopped and the high-voltage switched off . To safely switch off the spray gun, e.G. For maintenance work, the control unit must be switched off ..

Page 30: Pem-X1

30 pem-x1 p_01669 operating manual version 09/2012 order number doc 2326020 7.5 adjustment of powder quantity led display green reduce powder quantity increase powder quantity led display control mode flashing normal operation of gun constant blinking activated recipe has been changed using the "+" ...

Page 31: Pem-X1

31 pem-x1 2x p_01701 2x 2x kv 80 60 40 20 100 tri cor 5 4 3 2 1 120 80 40 20 10 µa 2x 2x kv 80 60 40 20 100 tri cor 5 4 3 2 1 120 80 40 20 10 µa 2x 2x kv 80 60 40 20 100 tri cor 5 4 3 2 1 120 80 40 20 10 µa operating manual version 09/2012 order number doc 2326020 7.6 "double click" recipe (high dyn...

Page 32: Pem-X1

32 pem-x1 p_01671 operating manual version 09/2012 order number doc 2326020 7.7 reproducible setting of the nozzle position an adjustment tool is provided for the fl at spray nozzle. This allows all fl at spray nozzles to be turned without damaging the electrodes and without removing the cap nut. Th...

Page 33: Pem-X1

33 pem-x1 operating manual version 09/2012 order number doc 2326020 8 cleaning and maintenance cleaning work should be undertaken regularly and carefully by qualifi ed and trained staff . The staff must be familiar with the din en 50050-2 and din en 50177 provisions. They should be informed of speci...

Page 34: Pem-X1

34 pem-x1 operating manual version 09/2012 order number doc 2326020 the cleaning intervals should be adapted by the operator depending on the level of use and if necessary the level of soiling. In doubt, we recommend to contact j. Wagner ag's specialist personnel. The valid health and safety specifi...

Page 35: Pem-X1

35 pem-x1 operating manual version 09/2012 order number doc 2326020 8.2 maintenance maintenance work should be undertaken regularly and carefully by qualifi ed and trained staff . They should be informed of specifi c hazards during their training. The following hazards may arise during maintenance w...

Page 36: Pem-X1

36 pem-x1 operating manual version 09/2012 order number doc 2326020 the maintenance intervals should be adapted by the operator depending on the level of use and if necessary the level of soiling. In doubt, we recommend to contact j. Wagner ag's specialist personnel. The valid health and safety spec...

Page 37: Pem-X1

37 pem-x1 5 4 3 2 1 p_01672 operating manual version 09/2012 order number doc 2326020 8.2.4 replacing the spray gun before replacing the spray gun any powder residue must be thoroughly removed. The wear parts in the spray gun, marked in the spare parts list with " ", must be regularly checked and, i...

Page 38: Pem-X1

38 pem-x1 1. 2. P_01673 3. Operating manual version 09/2012 order number doc 2326020 8.3 removing the flat spray nozzle 3. The parts can be separated by gently pressing the sliding ring on the fl at spray nozzle. 4. Remove powder residue from the parts removed and from the spray gun. Note: never pla...

Page 39: Pem-X1

39 pem-x1 2. 4. 3. P_01674 operating manual version 09/2012 order number doc 2326020 8.4 fitting the flat spray nozzle 4. Screw cap nut onto gun housing until fl at spray nozzle can no longer be turned by hand. Procedure: note: 1. Before inserting the electrode holder, the spring contact of the gun ...

Page 40: Pem-X1

40 pem-x1 1. 3. P_01677 2. 4. Operating manual version 09/2012 order number doc 2326020 8.5 removing the round spray nozzle procedure: 1. Pull off defl ector cone. 2. Unscrew cap nut from the gun housing. 3. Take cap nut with nozzle system off gun body. The nozzle system remains inserted in the cap ...

Page 41: Pem-X1

41 pem-x1 2. P_01678 3. 4. 5. 6. Operating manual version 09/2012 order number doc 2326020 8.6 fitting the round spray nozzle procedure: note: 1. Before inserting the electrode holder, the spring contact of the gun body and contact surface of the electrode holder should be checked. The spring contac...

Page 42: Pem-X1

42 pem-x1 p_01675 2. 1. 3. 2 3 1 e a operating manual version 09/2012 order number doc 2326020 8.7 replacing the protective wedge 1 wedge tool 2 electrode holder (shown with a cut-away view to improve comprehension) 3 protective wedge (when positioned) procedure: 1. Guide wedge tool 1 into electrode...

Page 43: Pem-X1

43 pem-x1 y x p_01676 3. 1. 2. Operating manual version 09/2012 order number doc 2326020 procedure: 1. Guide protective wedge 2 into wedge tool 1. 2. Insert both parts into opening on electrode holder until they stop. If it is not possible to push the wedge tool in as far as the mark x, rotate the w...

Page 44: Pem-X1

44 pem-x1 1. 4. 2. 3. P_01679 operating manual version 09/2012 order number doc 2326020 the standard corona spray gun is delivered with a fl at spray nozzle. The nozzle can be changed easily, as described below. The x1 r electrode holder is necessary to perform the change. 8.8 changing from flat spr...

Page 45: Pem-X1

45 pem-x1 p_01690 8. 7. 9. 6. Operating manual version 09/2012 order number doc 2326020 procedure: 5. Before inserting the electrode holder, the spring contact of the gun body and contact surface of the electrode holder should be checked. The spring contact must be clean and smooth-running, the gun ...

Page 46: Pem-X1

46 pem-x1 1 2 b ±90° p_01703 operating manual version 09/2012 order number doc 2326020 8.9 mounting the corona-star the corona-star is a retrofi t set for the spray gun, which helps to achieve a better surface quality (e.G. Reduction of "orange peel"). Procedure: 1. Guide plug-in contact 1 of corona...

Page 47: Pem-X1

47 pem-x1 p_01717 1. 2. 3. 4. Operating manual version 09/2012 order number doc 2326020 8.10 replacing the suspension hook procedure: 1. Loosen retaining bolts on rear of hook and unscrew. 2. Slide hook in direction indicated by arrow and remove from gun housing. 3. Fit new hook on receiver and slid...

Page 48: Pem-X1

48 pem-x1 operating manual version 09/2012 order number doc 2326020 9 inspections in accordance with din en 50177: 2010 if the system is used for electrostatic coating with fl ammable coating powders, testing should be undertaken in accordance with din en 50177: 2010-04 as per table 3 and table 4..

Page 49: Pem-X1

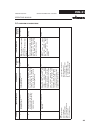

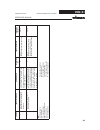

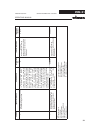

49 pem-x1 operating manual version 09/2012 order number doc 2326020 9.1 overview of inspections s e c tion t y pe of inspec tion requir emen ts inspec tion by t y pe of inspec tion inspec tion in ter v al 1 eff ec tiv eness of t echnical v e ntilation check eff ec tiv eness of t echnical v e ntilati...

Page 50: Pem-X1

50 pem-x1 operating manual version 09/2012 order number doc 2326020 s e c tion t y pe of inspec tion requir emen ts inspec tion by t y pe of inspec tion inspec tion in ter v al 4 m easur es t o take if c onduc tiv e components ar e insuffi ciently g rounded if suffi cient g rounding of c onduc tiv e...

Page 51: Pem-X1

51 pem-x1 operating manual version 09/2012 order number doc 2326020 s e c tion t y pe of inspec tion requir emen ts inspec tion by t y pe of inspec tion inspec tion in ter v al 6 m easur es t o take if the w o rk piec es ar e insuffi ciently g rounded if suffi cient w o rk piec e g rounding in ac co...

Page 52: Pem-X1

52 pem-x1 operating manual version 09/2012 order number doc 2326020 do not dispose of waste electrical equipment with household refuse! In accordance with european directive 2002/96/ec on the disposal of waste electrical equipment and its implementation in national law, this product may not be dispo...

Page 53: Pem-X1

53 pem-x1 operating manual version 09/2012 order number doc 2326020 11 troubleshooting and rectification incorrect maintenance/repair! Risk of injury and damage to the equipment. Have repairs and part replacements be carried out by specially trained staff or a wagner service center. Before all work ...

Page 54: Pem-X1

54 pem-x1 operating manual version 09/2012 order number doc 2326020 malfunction cause remedy no electrostatics (e.G. No wrap around or powder adhesion) fault in the high-voltage generator. Contact wagner service center. Electrical cable from spray gun to control unit faulty. Contact wagner service c...

Page 55: Pem-X1

55 pem-x1 p_01664 p_01665 p_01666 p_01667 p_01691 p_01692 operating manual version 09/2012 order number doc 2326020 12 accessories 12.1 flat spray nozzle order no. Designation 2321976 x1 fl at spray nozzle, complete 12.2 deflector cone order no. Designation 2321981 d18 defl ector cone, complete 2321...

Page 56: Pem-X1

56 pem-x1 p_01693 p_01694 p_01695 1 operating manual version 09/2012 order number doc 2326020 12.4 hose take-up order no. Designation 2322761 d10-d12 hose take-up, complete 2322768 d8-d10 hose take-up, complete 12.5 retrofit set corona-star pos order no. Designation 2322868 pem-x1 corona-star, compl...

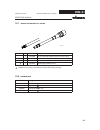

Page 57: Pem-X1

57 pem-x1 p_01697 operating manual version 09/2012 order number doc 2326020 12.7 nozzle extension x1 vl 150/300 12.8 powder hose order no. Designation 351794 powder hose 9 mm 2310699 powder hose 10 mm 2307502 powder hose 11 mm 2310700 powder hose 12 mm pos k stk order no. Designation 1 2323366 x1 vl...

Page 58: Pem-X1

58 pem-x1 operating manual version 09/2012 order number doc 2326020 p_01861 12.9 wall mount order no. Designation 2330223 wall mount with bracket.

Page 59: Pem-X1

59 pem-x1 p_01716 operating manual version 09/2012 order number doc 2326020 12.10 powder measuring adapter order no. Designation 2325320 x1 powder measuring adapter with bag, complete for measuring powder quantities for the pem-x1 spray gun the powder measuring adapter is slid onto the nozzle. Risk ...

Page 60: Pem-X1

60 pem-x1 operating manual version 09/2012 order number doc 2326020 13 spare parts 13.1 how to order spare parts? To ensure proper spare parts delivery, the following information is necessary: order number, designation and quantity the quantity does not have to be identical to the numbers in the "st...

Page 61: Pem-X1

61 pem-x1 1 3 4 5 6 7 10 p_01699 2 8 9 operating manual version 09/2012 order number doc 2326020 13.2 pem-x1 corona manual spray gun pem-x1 manual spray gun pos k stk order no. Designation 1 1 2322587 pem-x1 corona manual spray gun 2 1 2322761 hose take-up d10-12, complete 3 2 9971364 o-ring 4 1 232...

Page 62: Pem-X1

62 pem-x1 4 3 5 6 7 p_01700 2 1 operating manual version 09/2012 order number doc 2326020 electrode holder x1 r with nozzles pos k stk order no. Designation 1 1 2322493 electrode holder x1 r with nozzle 2 1 2322490 electrode holder x1 r et 3 1 2320488 replacement protective wedge x1 4 1 2320503 defl...

Page 63: Pem-X1

63 pem-x1 operating manual version 09/2012 order number doc 2326020 14 declaration of warranty and conformity 14.1 important notes on product liability 14.2 warranty claim as a result of an ec regulation eff ective from january 1, 1990, the manufacturer shall only be liable for his product if all pa...

Page 64: Pem-X1

64 pem-x1 operating manual version 09/2012 order number doc 2326020 14.3 declaration of conformity pem-x1 manual spray gun 2326024 herewith we declare that the supplied version of - pem-x1 manual spray gun, order no. 2322587 complies with the following provisions applying to it: - 94/9/ec (atex dire...

Page 65: Pem-X1

65 pem-x1 operating manual version 09/2012 order number doc 2326020 14.4 ec type examination certificate.

Page 66: Pem-X1

66 pem-x1 operating manual version 09/2012 order number doc 2326020

Page 67: Pem-X1

67 pem-x1 operating manual version 09/2012 order number doc 2326020

Page 68: Pem-X1

68 pem-x1 operating manual version 09/2012 order number doc 2326020 14.5 fm approval in submission.

Page 69: Pem-X1

69 pem-x1 operating manual version 09/2012 order number doc 2326020

Page 70: Pem-X1

70 pem-x1 operating manual version 09/2012 order number doc 2326020 germany j. Wagner gmbh otto-lilienthal-str. 18 postfach 1120 d- 88677 markdorf phone: +49/ 7544/ 505-0 fax: +49/ 7544/ 505-200 e-mail: service.Standard@wagner-group.Com switzerland j. Wagner ag industriestrasse 22 postfach 663 ch- 9...

Page 72: Cert

Cert if ie d order no. 2326020 germany j. Wagner gmbh otto-lilienthal-str. 18 postfach 1120 d- 88677 markdorf tel. +49/ (0)7544 / 5050 fax +49/ (0)7544 / 505200 e-mail: service.Standard@wagner-group.Com switzerland j. Wagner ag industriestrasse 22 postfach 663 ch- 9450 altstätten tel. +41/ (0)71 / 7...