Edition 9 / 2014 0558 932j prospray 3.21 gb operating manual prospray 3.21 airless high-pressure spraying unit models: 0558019 0558046 original operating manual.

2 prospray 3.21 gb warning! Attention: danger of injury by injection! Airless units develop extremely high spraying pressures. Be safety conscious! 1 2 3 never put your fingers, hands or any other parts of the body into the spray jet! Never point the spray gun at yourself, other persons or animals. ...

Prospray 3.21 3 gb contents contents page 1. Safety regulations for airless spraying ...................................... 4 1.1 explanation of symbols used .............................................................. 4 1.2 electric safety ............................................................

4 prospray 3.21 gb safety regulations 1. Safety regulations for airless spraying 1.1 explanation of symbols used this manual contains information that must be read and understood before using the equipment. When you come to an area that has one of the following symbols, pay particular attention and ...

Prospray 3.21 5 gb safety regulations • follow material and solvent manufacturer’s warnings and instructions. Be familiar with the coating material’s msds sheet and technical information to ensure safe use. • use lowest possible pressure to flush equipment. • when cleaning the unit with solvents, th...

6 prospray 3.21 gb general view of application description of unit 2. General view of application 2.1 application 2.2 coating materials processible coating materials i pay attention to the airless quality of the coating materials to be processed. Dilutable lacquers and paints or those containing sol...

Prospray 3.21 7 gb description of unit 14 13 12 11 15 16 7 1 3 4 6 5 9 10 2 8 3.3 legend for explanatory diagram prospray 3.21 3 return hose 4 suction hose 5 frame 6 drip cup 7 power cord 8 relief valve lever position vertical – prime ( k circulation) lever position horizontal – spray ( p ) 9 oil bu...

8 prospray 3.21 gb description of unit starting operation 3.5 technical data voltage: 100-120 volt , 50/60 hz max. Current consumption: 9.0 a power cord: 3 x 1.5 mm 2 – 6 m or 2.5 m acceptance capacity: 900 watt max. Operating pressure: 221 bar (22.1 mpa) volume flow at 12 mpa (120 bar) with water: ...

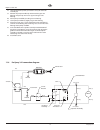

Prospray 3.21 9 gb starting operation 6 4.2 control panel indicators the following is a description of the control panel indicators. Pressure indicator service indicator pressure indicator the pressure indicator shows the current operating pressure of the sprayer. It has three different indications:...

10 prospray 3.21 gb starting operation spraying technique 4.5 cleaning preserving agent when starting-up of operation initially 1. Immerse the suction tube (fig. 6, item 1) and return hose (2) into a container with a suitable cleaning agent. 2. Turn the pressure control knob counterclockwise (3) to ...

Prospray 3.21 11 gb handling the high-pressure hose cleaning the unit (shutting down) 6. Handling the high-pressure hose the unit is equipped with a high-pressure hose specially suited for piston pumps. Danger of injury through leaking high-pressure hose. Replace any damaged high-pressure hose immed...

12 prospray 3.21 gb cleaning the unit (shutting down) 8.2 suction filter i a clean suction filter always guarantees maximum feed quantity, constant spraying pressure and problem-free functioning of the unit. 1. Screw off the filter (fig. 7) from suction pipe. 2. Clean or replace the filter. Carry ou...

Prospray 3.21 13 gb remedy in case of faults type of malfunction a. Unit does not start b. Unit does not draw in material c. Unit draws in material, but the pressure does not build up d. Coating material exits at the top of the fluid section e. Increased pulsation at the spray gun f. Poor spray patt...

14 prospray 3.21 gb servicing repairs at the unit 10. Servicing 10.1 general servicing servicing of the unit should be carried out once annually by the wagner service. 1. Check high-pressure hoses, device connecting line and plug for damage. 2. Check the inlet valve, outlet valve and filter for wear...

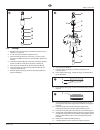

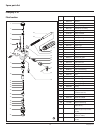

Prospray 3.21 15 gb repairs at the unit 11 10 12 13 9 8 11.3 packings 1. Remove inlet valve housing in accordance with the steps in chapter 11.2, page 14. 2. It is not necessary to remove the outlet valve. 3. Unscrew both cylinder head screws (fig. 13, item 1) from the pump manifold (2) with a 3/8 i...

16 prospray 3.21 gb repairs at the unit 18. Slide the top of the piston (3) into the t-slot (9) on the slider assembly (4). 19. Position the pump manifold (2) underneath the gear unit housing and push up until it rests against the gear unit housing. 20. Attach pump manifold (2) to the gear unit hous...

Prospray 3.21 17 gb appendix 12. Appendix 12.1 selection of tip to achieve faultless and rational working, the selection of the tip is of the greatest importance. In many cases the correct tip can only be determined by means of a spraying test. Some rules for this: the spray jet must be even. If str...

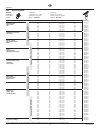

18 prospray 3.21 gb appendix application tip marking spray angle bore (inch / mm) spraying width mm 1) order no. Natural paints clear paints oils spray gun filter “red” 407 40° 0.007 / 0.18 160 0552 407 507 50° 0.007 / 0.18 190 ––––––– 209 20° 0.009 / 0.23 145 0552 209 309 30° 0.009 / 0.23 160 0552 ...

Prospray 3.21 19 gb appendix 12.5 pump-runner (order no. 2306987) universal accessories for cleaning, clean transportation and preservation of the pump unit. Features: • simpler cleaning – the cleaning liquid circulates constantly through the pump making thorough cleaning of the interior • no cleani...

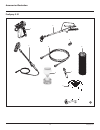

20 prospray 3.21 accessories illustration prospray 3.21 3 1 5 7 9 2 4 6 8.

Prospray 3.21 21 item part no. Description 1 0296 388 spray gun ag 08, f-thread 0296 386 spray gun ag 08, g-thread 0502 166 spray gun ag 14, f-thread 0502 119 spray gun ag 14, g-thread 2 0296 441 pole gun 120 cm, g-thread 7/8” 0296 443 pole gun 120 cm, f-thread 11/16” 0296 442 pole gun 200 cm, g-thr...

22 prospray 3.21 spare parts list prospray 3.21 28 30 29 31 32 33 34 35 1 19 18 25 49 6 26 43 21 22 23 24 20 45 46 47 48 7 5 9 10 11 8 27 44 2 3 4 37 36 40 38 39 41 42 14 15 16 17 12 13 main assembly 0558 466 ~110v 6 m 0290 281 ~120v 2.5 m bs4343 nema 5-15p.

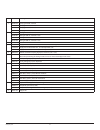

Prospray 3.21 23 item part no. Description 1 0290 230 motor shroud 2 9805 403 set screw 3 9810 103 nut 4 0524 353 nut 5 9800 319 screw (2) 6 9822 627 washer (2) 7 0558 332a belly pan assembly (includes items 28-34) 8 9802 266 screw (2) 9 0558 408 dust cover 10 0509 218 screw (2) 11 0290 222 door 12 ...

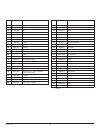

24 prospray 3.21 spare parts list prospray 3.21 24 23 25 26 27 28 29 30 31 32 33 34 1 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 2 3 4 5 7 6 fluid section item part no. Description 1 0509 594 retainer 2 0509 584 piston guide 3 ------- upper packing 4 0551 756 transducer assembly 5 0507 517 pipe plug...

Prospray 3.21 25 spare parts list prospray 3.21 3 4 2 1 5 6 7 8 9 10 11 8 12 drive assembly item part no. Description 1 0524 637a housing assembly 2 0509 121 2nd stage gear 3 0558 373 motor assembly, 120v (includes items 5-7) 4 9800 319 screw (4) 5 0522 018 capacitor assembly 6 0290 217 baffle assem...

26 prospray 3.21 1 3 2 4 5 prospray 3.21 1 4 5 6 7 8 9 2 3 10 stand spare parts list item part no. Description 1 9805 367 screw (3) 2 0290 215 drip cup 3 0290 211 leg, right 4 0294 635 plug 5 0290 214 foot 6 0508 660 screw (2) 7 0294 635 plug 8 0290 219 cord holder 9 0290 214 foot 10 0290 210 leg, l...

Prospray 3.21 27 gb important notes on product liability as a result of an ec regulation being effective as from january 1, 1990, the manufacturer shall only be liable for his product if all parts come from him or are released by him, and if the devices are properly mounted and operated. If the user...

28 prospray 3.21 www.Wagner-group.Com a j. Wagner ges.M.B.H. Ottogasse 2/20 2333 leopoldsdorf Österreich tel. +43/ 2235 / 44 158 telefax +43/ 2235 / 44 163 office@wagner-group.At dk wagner spraytech scandinavia a/s helgeshøj allé 28 2630 taastrup denmark tel. +45/43/ 27 18 18 telefax +45/43/ 43 05 2...