- DL manuals

- WAGNER

- Paint Sprayer

- ProSpray 3.29

- Operating Manual

WAGNER ProSpray 3.29 Operating Manual

Summary of ProSpray 3.29

Page 1

® edition 3 / 2010 0558 938a prospray 3.29 • 3.31 gb operating manual prospray 3.29 • 3.31 airless high-pressure spraying unit models: 0558014 0558015 0558016 0558029 0558299 0558387 0558388 original operating manual.

Page 2: Warning!

2 prospray 3.29 • 3.31 gb warning! Never put your fingers, hands or any other parts of the body into the spray jet! Never point the spray gun at yourself, other persons or animals. Never use the spray gun without safety guard. Do not treat a spraying injury as a harmless cut. In case of injury to th...

Page 3

Prospray 3.29 • 3.31 3 gb contents contents page 1. Safety regulations for airless spraying .......................4 1.1 earthing instructions.........................................................5 2. General view of application ...........................................6 2.1 application...........

Page 4

4 prospray 3.29 • 3.31 gb safety regulations 1. Safety regulations for airless spraying this manual contains information that must be read and understood before using the equipment. When you come to an area that has one of the following symbols, pay particular attention and make certain to heed the ...

Page 5

Prospray 3.29 • 3.31 5 gb safety regulations general view of application hazard: explosion hazard due to incompatible materials will cause severe injury or property damage. Prevention : • do not use materials containing bleach or chlorine. • do not use halogenated hydrocarbon solvents such as methyl...

Page 6

6 prospray 3.29 • 3.31 gb general view of application description of unit 2. General view of application 2.1 application 2.2 coating materials processible coating materials i pay attention to the airless quality of the coating materials to be processed. Dilutable lacquers and paints or those contain...

Page 7

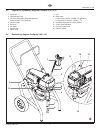

Prospray 3.29 • 3.31 7 gb description of unit 7 8 2 1 3 5 6 4 9 10 13 12 11 14 3.3 legend for explanatory diagram prospray 3.29 / 3.31 1 spray gun 2 high-pressure hose 3 oil cup for easyglide (easyglide prevents increased wear of the packings) 4 oil level gauge 5 pail hook 6 oil button 7 suction tub...

Page 8

8 prospray 3.29 • 3.31 gb description of unit starting operation 3.5 technical data prospray 3.29 prospray 3.31 voltage: 220~240 volt, 50/60 hz max. Current consumption: 7.5 a 8 a power cord: 3 x 1.5 mm 2 – 6 m acceptance capacity: 1725 watt 1840 watt max. Operating pressure: 221 bar (22.1 mpa) volu...

Page 9

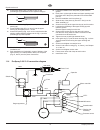

Prospray 3.29 • 3.31 9 gb starting operation 4 4.2 control panel indicators the following is a description of the control panel indicators. Pressure indicator service indicator pressure indicator the pressure indicator shows the current operating pressure of the sprayer. It has three different indic...

Page 10

10 prospray 3.29 • 3.31 gb starting operation 4.5 cleaning preserving agent when starting- up of operation initially 1. Immerse the suction tube (fig. 7, item 1) and return hose (2) into a container with a suitable cleaning agent. 2. Turn the pressure control knob counterclockwise (3) to minimum pre...

Page 11

Prospray 3.29 • 3.31 11 gb starting operation volume pumped screen volume pumped select-4 menu-1 the volume pumped screen shows the total number of gallons or liters sprayed by the sprayer. Gallons x menu-1 litres x menu-1 litres-2 gallons-2 to select the volume pumped screen, press the #4 key. Job ...

Page 12

12 prospray 3.29 • 3.31 gb spraying technique handling the high-pressure hose 5. Spraying technique injection hazard. Do not spray without the tip guard in place. Never trigger the gun unless the tip is completely turned to either the spray or the unclog position. Always engage the gun trigger lock ...

Page 13

Prospray 3.29 • 3.31 13 gb cleaning the unit (shutting down) 8. Cleaning the unit (shutting down) a clean state is the best method of ensuring operation without problems. After you have finished spraying, clean the unit. Under no circumstances may any remaining coating material dry and harden in the...

Page 14

14 prospray 3.29 • 3.31 gb cleaning the unit (shutting down) remedy in case of faults type of malfunction a. Unit does not start b. Unit does not draw in material c. Unit draws in material, but the pressure does not build up possible cause 1. No voltage applied. 2. Pressure setting too low. 3. On/of...

Page 15

Prospray 3.29 • 3.31 15 gb remedy in case of faults type of malfunction d. Coating material exits at the top of the fluid section e. Increased pulsation at the spray gun f. Poor spray pattern g. Unit loses power possible cause 1. Upper packing is worn. 2. Piston is worn. 1. Incorrect high-pressure h...

Page 16

16 prospray 3.29 • 3.31 gb servicing repairs at the unit 10. Servicing 10.1 general servicing servicing of the unit should be carried out once annually by the wagner service. 1. Check high-pressure hoses, device connecting line and plug for damage. 2. Check the inlet valve, outlet valve and filter f...

Page 17

Prospray 3.29 • 3.31 17 gb repairs at the unit 14. Unscrew lower housing (fig. 13, item 10) with adjusting wrench while holding the upper housing (11) securely with a second adjusting wrench. 15. Remove bearing ring (13) and o-ring (12). 16. Screw out outlet valve housing (14) from the piston (15) w...

Page 18

18 prospray 3.29 • 3.31 gb repairs at the unit 12. Insert upper packing (fig. 15) with o-ring (1) and protruding lip (2) downward into the upper housing (6). 1 2 13. Place intermediate ring (fig. 14, item 10) on the upper packing (8). 14. Screw threaded joint (fig. 14, item 7) into the upper housing...

Page 19

Prospray 3.29 • 3.31 19 gb appendix 12. Appendix 12.1 selection of tip to achieve faultless and rational working, the selection of the tip is of the greatest importance. In many cases the correct tip can only be determined by means of a spraying test. Some rules for this: the spray jet must be even....

Page 20

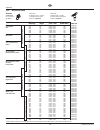

20 prospray 3.29 • 3.31 gb appendix application tip spray bore spraying marking angle inch / mm width mm 1) order no. Natural paints 407 40° 0.007 / 0.18 160 0552 407 clear paints 507 50° 0.007 / 0.18 190 ––––––– oils 209 20° 0.009 / 0.23 145 0552 209 309 30° 0.009 / 0.23 160 0552 309 409 40° 0.009 ...

Page 21

Prospray 3.29 • 3.31 21 gb appendix 12.5 tempspray the paint material is heated to the required temperature uniformly by an electric heating element, which is located inside the hose (regulated from 20°c to 60°c). Advantages: • constant paint temperature even at low outside temperatures • considerab...

Page 22

22 prospray 3.29 • 3.31 gb appendix 12.6 pump-runner (order no. 2306987) universal accessories for cleaning, clean transportation and preservation of the pump unit. Features: • simpler cleaning – the cleaning liquid circulates constantly through the pump making thorough cleaning of the interior • no...

Page 23

Prospray 3.29 • 3.31 23 deutschland j. W agner gmbh • otto-lilienthal-straße 18 • 88677 markdor f t el. 0043/07544/5050 • fax: 0043/07544/505/200 • info@wagner-group.Co m t el. 0043/2235/44 158 • fax: 0043/2235/44 163 • office@wagner-group.A t Österreic h j. W agner ges.M.B.H • ottogasse 2/20 • 2333...

Page 24

24 prospray 3.29 • 3.31 accessories illustration prospray 3.29 / 3.31 3 1 5 7 2 4 6 8.

Page 25

Prospray 3.29 • 3.31 25 item part no. Description 1 0296 388 spray gun ag 08, f-thread 0296 386 spray gun ag 08, g-thread 0502 166 spray gun ag 14, f-thread 0502 119 spray gun ag 14, g-thread 2 0296 441 pole gun 120 cm, g-thread 7/8” 0296 443 pole gun 120 cm, f-thread 11/16” 0296 442 pole gun 200 cm...

Page 26

26 prospray 3.29 • 3.31 1 18 24 25 26 27 28 29 30 23 13 12 11 14 15 16 17 19 20 21 22 3 4 7 8 9 10 5 6 2 31 32 33 2 42 43 39 40 41 35 34 38 36 37 52 45 46 47 50 51 44 48 49 spare parts list prospray 3.29 / 3.31 main assembly.

Page 27

Prospray 3.29 • 3.31 27 item part no. Description 1 0290 270 motor shroud 2 0508 559 screw (2) 3 0290 269 belly pan 4 9802 266 screw (2) 5 0290 228 door 6 0509 218 screw (2) 7 0552 240a filter assembly 8 0290 262 fitting 9 0508 293 retun tube 10 0507 387 hose 11 9802 266 screw (2) 12 0290 225 electr...

Page 28

28 prospray 3.29 • 3.31 spare parts list prospray 3.29 / 3.31 1 2 5 6 3 4 12 13 14 15 16 17 18 7 8 9 10 19 20 21 22 11 9 10 23 24 fluid section.

Page 29

Prospray 3.29 • 3.31 29 item part no. Description 1 0290 263 retainer 2 0290 255 jam nut 3 0290 276 spacer 4 ------- upper packing 5 0290 249 upper housing 6 0508 343 fitting 7 ------- lower packing 8 0508 712 guide ring 9 0507 730 o-ring (2) 10 0507 731 o-ring (2) 11 0290 250 lower housing 12 0290 ...

Page 30

30 prospray 3.29 • 3.31 spare parts list prospray 3.29 / 3.31 1 2 3 4 5 6 8 9 10 11 7 12 13 drive assembly item part no. Description 1 0558 323a housing assembly 2 0290 241 slider assembly 3 0290 254 thrust washer 4 0290 239 gear/crankshaft assembly 5 0290 240 1st stage gear 6 0558 324a motor assemb...

Page 31

Prospray 3.29 • 3.31 31 prospray 3.29 / 3.31 1 2 3 4 5 6 7 8 9 10 11 12 13 14 filter assembly spare parts list item part no. Description 1 0508 723 filter housing 2 14058 conical spring 3 0507 748 filter, 60 mesh (standard) 0508 451 filter, 30 mesh 0508 452 filter, 100 mesh 4 0508 603 bearing ring 5...

Page 32

32 prospray 3.29 • 3.31 spare parts list prospray 3.29 / 3.31 upright cart assembly 1 13 11 12 11 14 10 9 2 3 4 5 6 7 8 item part no. Description 1 0290 207 handle assembly (includes items 7-8) 2 9805 352 screw (2) 3 0290 257 bushing 4 0290 235 cart weldment 5 9894 275 spring 6 0290 244 carriage ass...

Page 33

Prospray 3.29 • 3.31 33 spare parts list prospray 3.29 10 11 12 15 13 14 1 2 3 4 5 6 9 7 8 low boy cart assembly item part no. Description 1 0290 290 cart 2 0508 381 drip cup 3 0290 291 wheel 4 0294 534 wheel spacer 5 9890 104 axle cap 6 9805 230 drip cup screw 7 0509 386 washer 8 0295 608 screw 9 9...

Page 34

34 prospray 3.29 • 3.31 spare parts list prospray 3.29 1 2 3 4 5 suction system for low boy cart item part no. Description 1 0507 964 return hose 2 0507 965 siphon tube 3 5006 536 inlet screen 4 0507 783 clamp 5 0507 967 siphon tube adapter ------- tie wrap (not shown).

Page 35

Prospray 3.29 • 3.31 35 gb important notes on product liability as a result of an ec regulation being effective as from january 1, 1990, the manufacturer shall only be liable for his product if all parts come from him or are released by him, and if the devices are properly mounted and operated. If t...

Page 36

36 prospray 3.29 • 3.31 declaration of conformity herewith we declare that the supplied version of wagner prospray 3.29 • 3.31 complies with the following provisons applying to it: 2004/108, 92/31 ewg, 93/68 ewg, 2006/42. Applied harmonized standards, in particular: en 292-1/-2, en 1953, en 55014, e...