- DL manuals

- WAGNER

- Paint Sprayer

- ProSpray 3.39

- Operating Manual

WAGNER ProSpray 3.39 Operating Manual

Summary of ProSpray 3.39

Page 1

Edition 5 / 2014 0558 977l prospray 3.39 gb operating manual prospray 3.39 airless high-pressure spraying unit model: 0558054 0558079 original operating manual.

Page 2: Warning!

Gb warning! Attention: danger of injury by injection! Airless units develop extremely high spraying pressures. Be safety conscious! 1 2 3 never put your fingers, hands or any other parts of the body into the spray jet! Never point the spray gun at yourself, other persons or animals. Never use the sp...

Page 3

Prospray 3.39 3 gb contents contents page 1. Safety regulations for airless spraying ...................................... 4 1.1 explanation of symbols used .............................................................. 4 1.2 electric safety ............................................................

Page 4

4 prospray 3.39 gb safety regulations 1. Safety regulations for airless spraying 1.1 explanation of symbols used this manual contains information that must be read and understood before using the equipment. When you come to an area that has one of the following symbols, pay particular attention and ...

Page 5

Prospray 3.39 5 gb safety regulations • followmaterialandsolventmanufacturer’swarningsand instructions.Befamiliarwiththecoatingmaterial’smsds sheet and technical information to ensure safe use. • uselowestpossiblepressuretoflushequipment. • whencleaningtheunitwithsolvents,thesolventshould never be s...

Page 6

6 prospray 3.39 gb general view of application description of unit 2. General view of application 2.1 application 2.2 coating materials processible coating materials i pay attention to the airless quality of the coating materials to be processed. Dilutable lacquers and paints or those containing sol...

Page 7

Prospray 3.39 7 gb description of unit 7 8 2 1 3 5 6 4 9 10 13 12 11 14 3.3 legend for explanatory diagram prospray 3.39 1 spray gun 2 high-pressure hose 3 oil cup for easyglide (easyglide prevents increased wear of the packings) 4 oil level gauge 5 pail hook 6 oil button 7 suction tube 8 return hos...

Page 8

8 prospray 3.39 gb description of unit 3.5 technical data voltage: 100-110voltac,50hz max. Current consumption: 15 a / 20 a power cord: 3 x 1.5 mm 2 – 6 m or 4.6 m acceptance capacity: 2000 watt max. Operating pressure: 221 bar (22,1 mpa) volume flow at 12 mpa (120 bar) with water: 5.0 l/min max tip...

Page 9

Prospray 3.39 9 gb starting operation 4. Starting operation 4.1 high-pressure hose, spray gun and separating oil 1. Screw the high-pressure hose (2) to the coating material outlet (fig. 4, item 1). 2. Screw the spray gun (3) with the selected tip onto the high- pressure hose. 3. Tighten the union nu...

Page 10

10 prospray 3.39 gb starting operation solid green when the pressure indicator is solid green, the sprayer is operating between 12 mpa (120 bar) and 23 mpa (230 bar). A solid green pressureindicatormeans: • thesprayerisattheproperpressuresettingforsprayingoil- based and latex house paints • thespray...

Page 11

Prospray 3.39 11 gb starting operation 4.7 digital electronic spray control (desc) the digital electronic spray control (desc) increases the functionality of the sprayer. It is installed directly below the pressure control knob on the control panel. It consists of a display and four function keys. T...

Page 12

12 prospray 3.39 gb starting operation spraying technique security code screen security code change-2 menu-1 the security code screen allows the user to set a four digit security code to prevent unauthorizeduseofthesprayer.Ifasecuritycodehasbeenset,the control system display will ask for the code at...

Page 13

Prospray 3.39 13 gb handling the high-pressure hose cleaning the unit (shutting down) 6. Handling the high-pressure hose the unit is equipped with a high-pressure hose specially suited for piston pumps. Danger of injury through leaking high-pressure hose. Replace any damaged high-pressure hose immed...

Page 14

8.2 cleaning the high-pressure filter clean the filter cartridge regularly. A soiled or clogged high-pressure filter can cause a poor spray pattern or a clogged tip. 1. Turnthepressureregulatorknobintotheblackzoneuntilit stops (no pressure). 2. Open the relief valve, valve position prime (k circulat...

Page 15

Prospray 3.39 15 gb remedy in case of faults digital electronic spray control (desc) error messages the following error message screens appear whenever the digital electronic spray control (desc) detects a problem with the sprayer. Once a problem occurs and the error message appears, the sprayer wil...

Page 16

16 prospray 3.39 gb servicing repairs at the unit 10. Servicing 10.1 general servicing servicing of the unit should be carried out once annually by the wagner service. 1. Check high-pressure hoses, device connecting line and plug for damage. 2. Check the inlet valve, outlet valve and filter for wear...

Page 17

Prospray 3.39 17 gb repairs at the unit 15. Clean all the parts with the corresponding cleaning agent. Check outlet valve housing (9), outlet valve seat (15), outlet valve ball (13) and upper ball guide (12) for wear and replace parts if necessary. If the worn outlet valve seat (15) is unused on one...

Page 18

18 prospray 3.39 gb repairs at the unit 19. Insert upper packing (fig. 17) with o-ring (1) and protruding lip (2) downward. 1 2 20. Insert upper support ring (9) on top of the upper packing (10) 21. Thread the upper seal retainer (8) into the upper housing (2). 22. Rotate the upper housing in the vi...

Page 19

Prospray 3.39 19 gb appendix 12. Appendix 12.1 selection of tip to achieve faultless and rational working, the selection of the tip is of the greatest importance. In many cases the correct tip can only be determined by means of a spraying test. Some rules for this: the spray jet must be even. If str...

Page 20

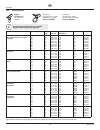

20 prospray 3.39 gb appendix 12.4 airless tip table wagner tradetip 3 tip up to 270 bar (27 mpa) without tip fthread(11/16-16un) for wagner spray guns order no. 0289391 without tip gthread(7/8-14un) for graco/titan spray guns order no. 0289390 i all of the tips in the table below are supplied togeth...

Page 21

Prospray 3.39 21 gb appendix application tip marking spray angle bore inch / mm spraying width mm 1) gun filter order no. Roof coatings 223 323 423 523 623 723 823 20° 30° 40° 50° 60° 70° 80° 0.023 / 0.58 0.023 / 0.58 0.023 / 0.58 0.023 / 0.58 0.023 / 0.58 0.023 / 0.58 0.023 / 0.58 120 150 190 225 2...

Page 22

22 prospray 3.39 gb appendix 12.5 pump-runner (order no. 2306987) universalaccessoriesforcleaning,cleantransportationandpreservationofthepumpunit. Features: • simplercleaning–thecleaningliquidcirculatesconstantlythroughthepumpmakingthoroughcleaningoftheinterior • nocleaningnecessaryduringworkstoppag...

Page 23

Prospray 3.39 23 www.Wagner-group.Com a j. Wagner ges.M.B.H. Ottogasse 2/20 2333 leopoldsdorf Österreich tel. +43/ 2235 / 44 158 telefax +43/ 2235 / 44 163 office@wagner-group.At dk wagner spraytech scandinavia a/s helgeshøj allé 28 2630 taastrup denmark tel. +45/43/ 27 18 18 telefax +45/43/ 43 05 2...

Page 24

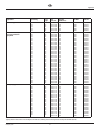

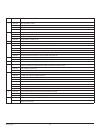

24 prospray 3.39 accessories illustration prospray 3.39 3 1 5 8 2 4 7 9 10 6.

Page 25

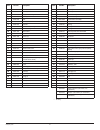

Prospray 3.39 25 item part no. Description 1 0296 388 spray gun ag 08, f-thread 0296 386 spray gun ag 08, g-thread 0502 166 spray gun ag 14, f-thread 0502 119 spray gun ag 14, g-thread 2 0296 441 polegun120cm,g-thread7/8” 0296 443 polegun120cm,f-thread11/16” 0296 442 pole gun 200cm,g-thread7/8” 0296...

Page 26

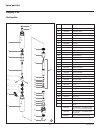

26 prospray 3.39 spare parts list prospray 3.39 59 60 61 1 3 4 38 5 6 9 8 35 2 36 7 2 10 11 12 13 17 16 14 15 18 19 20 21 22 23 24 26 27 28 30 31 32 33 29 25 37 39 41 34 40 43 42 46 44 45 47 48 49 main assembly 52 53 54 57 58 51 50 55 56 62 63 64 0558 599 120v 6 m 0290 299 120v 4.6 m bs4343 nema 5-1...

Page 27

Prospray 3.39 27 item part no. Description 1 0290 271 motor shroud 2 0508 559 screw (2) 3 0558 500 belly pan assembly 4 9802 266 screw (2) 5 0290 228 door 6 0509 218 screw (2) 7 0290 253 grommit 8 0551 778 transducer assembly 9 0558 710 filter assembly 10 0507 785 return tube 11 0290 248 hose 12 050...

Page 28

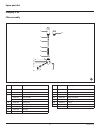

28 prospray 3.39 spare parts list prospray 3.39 1 10 9 8 7 6 2 3 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 4 5 11 32 30 31 fluid section item part no. Description 1 0558 419 cylinder 2 0524 905 stopping spacer 3 0524 906 extension bushing 4 0558 570a piston extension 5 0558 422 extension...

Page 29

Prospray 3.39 29 spare parts list prospray 3.39 7 16 17 4 5 6 8 9 13 12 14 15 10 11 1 2 3 18 19 20 drive assembly item part no. Description 1 0558 572a slider assembly 2 0507 767 screw (4) 3 0290 272 slider housing 4 0558 342a housing assembly 5 0558 362 3rd stage gear 6 0558 363 2nd stage gear 7 98...

Page 30

30 prospray 3.39 filter assembly spare parts list prospray 3.39 1 15 2 3 4 5 6 7 8 9 10 11 12 13 14 item part no. Description 1 0524 918 filter housing 2 14058 conical spring 3 0508 748 filter, 60 mesh (standard) 0508 451 filter, 30 mesh 0508 452 filter, 100 mesh 4 0508 603 bearing ring 5 0508 749 b...

Page 31

Prospray 3.39 31 spare parts list prospray 3.39 15 1 2 3 4 5 7 6 8 9 17 16 18 13 14 15 12 11 10 19 20 upright cart assembly item part no. Description 1 805-206a handle assembly (includes items 8-9) 2 9805 352 screw (2) 3 0290 257 bushing 4 805-200 cart weldment 5 9894 275 spring 6 0290 294 sleeve 7 ...

Page 32

32 prospray 3.39 gb important notes on product liability as a result of an ec regulation being effective as from january 1, 1990, the manufacturer shall only be liable for his product if all parts come from him or are released by him, and if the devices are properly mounted and operated. If the user...