® operating manual airless high-pressure spraying unit prospray 30 • 34.

Prospray 30 • 34 g warning! Never put your fingers, hands or any other parts of the body into the spray jet! Never point the spray gun at yourself, other persons or animals. Never use the spray gun without safety guard. Do not treat a spraying injury as a harmless cut. In case of injury to the skin ...

1. Safety regulations for airless spraying all local regulations in force must be observed. For secure handling of airless high-pressure spraying units the following safety regulations are to be ob- served: p flash point only use coating materials with a flash point of 21 °c or above without additio...

P electrostatic charging (formation of sparks or flame) under certain circumstances, electrostat- ic charging can occur on the unit due to the rate of flow of the coating material when spraying. On discharging this can result in the emergence of sparks or fire. It is therefore necessary that the uni...

2. General view of application 2.1 application all painting jobs in the workshop and on the building site, small and large-area dispersion work with the spray gun or internally fed airless roller, corrosion and fire pro- tection. Examples of objects of spraying doors, door frames, balustrades, furni...

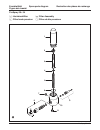

Prospray 30 • 34 g description of unit 3.3 legend for explanatory diagram of prospray 30 • 34 1 spray gun 2 high-pressure hose 3 pressure control knob 4 control panel indicators 5 oil cup for easyglide (easyglide prevents increased wear of the packings) 6 pail hook 7 control system cover 8 return ho...

Prospray 30 • 34 g description of unit starting operation 3.5 technical data prospray 30 • 34 prospray 30 prospray 34 voltage: 220~240 v ac, 50/60 hz or 100~120 v ac, 50/60 hz max. Current consumption: 220~240 v ac 7.5 a 8.7 a 100~120 v ac 12 a 12 a power cord: 3 x 1.5 mm 2 – 6 m acceptance capacity...

Prospray 30 • 34 g 4. Fill in easyglide (fig. 5). Do not fill in too much easyglide, i.E. Ensure that no easyglide drips into the coating material container. 4.2 control panel indicators the following is a description of the control panel indicators. Pressure indicator the pressure indicator shows t...

Prospray 30 • 34 g starting operation 4.4 connection to the mains network before connecting the unit to the mains supply, ensure that the line voltage matches that specified on the unit’s rating plate. 4.5 cleaning preserving agent when starting-up of operation initially 1. Immerse the suction tube ...

Prospray 30 • 34 g service time screen the service time screen allows the user to set a service time interval (in hours). Below the set time, the screens shows the current amount of hours on the sprayer. To select the service timer screen, press the #4 key. The screen will toggle between the service...

Prospray 30 • 34 g 8. Cleaning the unit (shutting down) a clean state is the best method of ensuring operation without problems. After you have finished spraying, clean the unit. Under no circumstances may any remain- ing coating material dry and harden in the unit. The cleaning agent used for clean...

Prospray 30 • 34 g 8.1 cleaning unit from outside wipe down unit externally with a cloth which has been immersed in a suitable cleaning agent. 8.2 suction filter – screw off the filter (fig. 9) from suction pipe. – clean or replace the filter. Carry out cleaning with a hard brush and an appropri- at...

Prospray 30 • 34 g remedy in case of faults 9. Remedy in case of faults unit does not start unit does not suck in unit sucks, but the pressure does not build up coating material exits at the top of the fluid section no voltage applied. Pressure setting too low. On/off switch defective. Relief valve ...

Prospray 30 • 34 g remedy in case of faults increased pulsation at the spray gun poor spray pattern unit loses power incorrect high-pressure hose type. Tip worn or too large. Pressure too high. Tip is too large for the coating material which is to be sprayed. Pressure setting incorrect. Volume too l...

Prospray 30 • 34 g servicing repairs at the unit 10. Servicing 10.1 general servicing servicing of the unit should be carried out once annually by the wagner service. 1. Check high-pressure hoses, device connecting line and plug for damage. 2. Check the inlet valve, outlet valve and filter for wear....

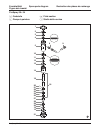

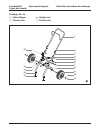

Prospray 30 • 34 g repairs at the unit 6. Swivel the unit 90° to the rear in order to work more easily on the material feed pump. 7. Loosen and unscrew inlet valve housing (2) from the lower housing (3) with light blows from a hammer or unscrew with an adjusting wrench. 8. Remove bearing ring (4), o...

Prospray 30 • 34 g repairs at the unit 11. Remove the transportation devices from the upper and lower packings. (the transportation device from the upper packing is required for installation of the piston.) 12. Lubricate upper packing (8) and lower packing (9) with machine grease. 13. Insert upper p...

Prospray 30 • 34 g repairs at the unit 11.4 prospray 30 • 34 connection diagram potentiometer motor pressure sensor pressure sensor jumper p lu g w h it e white white b l a c k green control panel board surge suppressor electronic pressure control (epc) j16 ac-motor ac-neut ac-line ac-motor j9 j 2 j...

Prospray 30 • 34 g item order no. Description 5 0034 038 double socket for coupling high-pressure hoses 6 0034 950 metex-reuse reuse for pre-filtering of coating material in vessel. Place suction pipe in the reuse. 0034 952 sieve package (5 pcs) for paint 0034 951 sieve package (5 pcs) for dispersio...

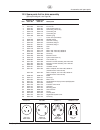

Prospray 30 • 34 g accessories and spare parts as-3112 0551 726 220v~240v 0508 775 110v~120v 0508 776 220v~240v 0551 727 100v bs-546 cee 7/7 nema 5-15p 12.3 spare parts list for drive assembly (spare parts diagram, see page 98) prospray 30 prospray 34 item order no. Order no. Description 1 0507 772 ...

Prospray 30 • 34 g accessories and spare parts item order no. Description 9 0509 390 wheel (2) 10 0295 687 washer (2) 11 0508 722 hub cap (2) 12 0507 784 grommet (2) 13 0508 719 spacer sleeve (2) 14 0551 550 sealing stopper (2) 15 0508 720 base frame 16 0295 617 sealing stopper (2) 12.6 spare parts ...

Prospray 30 • 34 g tip extension length 15 cm order no. 0999 320 length 30 cm order no. 0999 321 length 45 cm order no. 0999 322 length 60 cm order no. 0999 323 13. Appendix 13.1 selection of tip to achieve faultless and rational working, the selection of the tip is of the greatest importance. In ma...

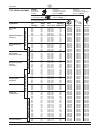

Application tip spray bore spraying marking angle inch / mm width mm 1) order no. Order no. Order no. Natural paints 407 40° 0.007 / 0.18 160 0090 407 1088 407 0552 407 clear paints 507 50° 0.007 / 0.18 190 0090 507 ––––––– ––––––– oils 209 20° 0.009 / 0.23 145 0090 209 1088 209 0552 209 309 30° 0.0...

Prospray 30 • 34 g j. Wagner gmbh otto-lilienthal str. 18 88677 markdorf germany phone 07544 / 5050 fax 07544 / 505-200 germany j. Wagner ag industriestr. 22 9450 altstätten switzerland phone 071 / 7 57 22 11 fax 071 / 7 57 22 22 switzerland wagner spraytech corp. P.O. Box 9362 minneapolis / minn. 5...

Prospray 30 • 34 d zubehörbild g accessories illustration f illustration des accessoires i figura degli accessori 3 1 5 2 4 6 prospray 30 • 34.

1 2 3 4 6 5 7 8 9 11 10 12 13 14 prospray 30 • 34 d hauptbaugruppe g main assembly f ensemble principal i gruppo principale ersatzteilbild spare parts diagram illustration des pièces de rechange figura dei ricambi prospray 30 • 34.

Ersatzteilbild spare parts diagram illustration des pièces de rechange figura dei ricambi prospray 30 • 34 2 6 2 5 3 5 1 2 3 4 5 9 6 7 1 0 8 1 2 1 3 1 4 1 5 1 6 1 7 1 9 1 8 2 1 2 2 2 4 2 0 2 3 1 1 3 1 3 4 3 3 3 6 3 2 3 0 2 7 2 8 2 9 prospray 30 • 34 d baugruppe antrieb g drive assembly f ensemble mo...

Ersatzteilbild spare parts diagram illustration des pièces de rechange figura dei ricambi prospray 30 • 34 1 2 3 4 5 10 11 12 13 14 19 20 21 22 23 24 25 27 28 29 30 12 13 31 8 9 18 prospray 30 • 34 d farbstufe g fluid section f pompe à peinture i stadio della vernice.

Prospray 30 • 34 prospray 30 • 34 d hochdruckfilter g filter assembly f filtre haute pression i filtro ad alta pressione 11 1 3 5 4 6 2 7 9 8 10 ersatzteilbild spare parts diagram illustration des pièces de rechange figura dei ricambi.

Ersatzteilbild spare parts diagram illustration des pièces de rechange figura dei ricambi prospray 30 • 34 prospray 30 • 34 d hoher wagen g upright cart f chariot haut i carrello alto 1 2 3 4 5 6 7 8 10 11 16 14 13 9 12 15.

Prospray 30 • 34 d g pr fung des ger tes nach den richtlinien f r fl ssigkeitsstrahler (spritzger te) der berufsgenossenschaften. Das gerät ist bei bedarf, jedoch mindestens alle 12 monate, durch sachkundige daraufhin zu prüfen, ob ein sicherer betrieb weiterhin gewährleistet ist. Bei stillgelegtem ...

Prospray 30 • 34 f i note importante sur la responsabilit de produit suite aux nouvelles directives européennes entrées en vigueur au 01.01.1990, le fabricant n'engage sa responsabilité produit que lorsque l'ensemble des pièces constitutives proviennent bien du fabri- cant, ou ont été homologuées pa...

Prospray 30 • 34 d f konformit tserkl rung hiermit erklären wir, dass die bauart von wagner prospray 30 ¥ 34 folgenden einschlägigen bestimmungen entspricht: 73/23 ewg, 89/336 ewg, 92/31 ewg, 93/68 ewg, 98/37 ewg. Angewendete harmonisierte normen, insbesondere: en 292-1/-2, en 1953, en 55014, en 603...