WAGNER Super Finish 27 Operating Manual - 12.

Super Finish 27 • 31

41

GB

Accessories and spare parts

12.

acceSSorIeS and Spare partS

12.1

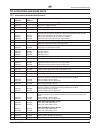

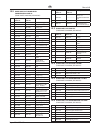

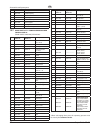

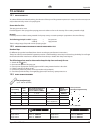

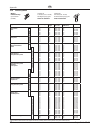

acceSSorIeS For Super FInISh 27 and 31

Item SuperFinish 27

Order no.

SuperFinish 31

Order no.

Description

accessories illustration, see page 42

1

0341 705

--------------------- Inlet valve – trigger housing

2

0341 713

--------------------- Tool box

3

0341 910

0341 910

Hose drum (without high-pressure hose) for 30 m high-pressure hose DN 6 mm

4

0070 212

0070 317

0070 344

0070 326

0070 212

0070 317

0070 344

0070 326

High-pressure filter 200 meshes, 0.085 mm mesh width

The high-pressure filter is suitable as a fine filter, each tuned to the tip used.

Filter insert 200 meshes (tip size under 011/0.28 mm)

Filter insert 100 meshes (tip size over 011/0.28 mm)

Filter insert 70 meshes (tip size over 015/0.38 mm)

accessories illustration, see page 95

Spray gun accessories and tips, see page 45/46

5

0257 001

0335 002

0257 001

0335 002

Spray gun AG-09 S (stainless steel model)

Spray gun G 12 (aluminium model)

6

0096 004

0096 019

0096 005

0096 006

0096 004

0096 019

0096 005

0096 006

Pole gun 30 cm

Pole gun 100 cm

Pole gun 150 cm

Pole gun 270 cm

7

0097 057

0097 057

Injection lance for regeneration of concrete

8

0345 010

0345 010

Inline Roller IR-100

9

9984 510

9984 507

9984 562

9984 510

9984 507

9984 562

High-pressure hose DN 4 mm, 7.5 m with stainless steel nipple

High-pressure hose DN 6 mm, 15 m for dispersion

High-pressure hose DN 6 mm, 30 m for dispersion

10

0034 030

0034 030

Double socket for coupling high-pressure hoses

11

0341 263

0341 263

Suction system QuickClean, filter mesh width 1 mm

12

0097 531

0097 531

Filter bag, mesh width 0.3 mm

13

0341 265

0341 265

Upper hopper fittings, 5 litres

14

0097 258

0097 259

0097 258

0097 259

Hopper filling sieve for upper hopper 5 litres. Prevents filling of rough particles

from the container. Through this suction problems are avoided.

Sieve package (5 pcs) for paint

Sieve package (5 pcs) for dispersion

15

0341 266

0341 266

Upper hopper fittings, 20 litres

16

0097 260

0097 261

0097 260

0097 261

Hopper filling sieve for upper hopper 20 litres. Prevents filling of rough particles

from the container. Through this suction problems are avoided.

Sieve package (5 pcs) for paint

Sieve package (5 pcs) for dispersion

17

0034 950

0034 952

0034 951

0034 950

0034 952

0034 951

Metex-Reuse

Reuse for pre-filtering of coating material in vessel. Place suction pipe in the

reuse.

Sieve package (5 pcs) for paint

Sieve package (5 pcs) for dispersion

18

0037 607

0003 756

0097 521

0017 408

0037 607

0003 756

0097 521

0017 408

Filter disks upper hopper, 5 litres

Filter disk, mesh width 0.8 mm

Filter disk, mesh width 0.4 mm

Filter disksupper hopper, 20 litres

Filter disk, mesh width 0.8 mm

Filter disk, mesh width 0.4 mm

19

0034 660

0034 660

Suction system (flexible) for paint

20

0034 630

0034 630

Suction system (flexible) for dispersion

0340 720

0340 720

Concrete regeneration set (without diagram)