- DL manuals

- WAGNER

- Paint Sprayer

- W 867 E

- Operating Instructions Manual

WAGNER W 867 E Operating Instructions Manual

Summary of W 867 E

Page 1

2 ans de garantie 2 jaar garantie 2 years guarantee 2 jahre garantie w 867 e d/gb/f/nl.

Page 2: 24/25

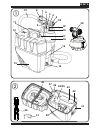

W 867 e 10 24/25 26 9 12 11 18 23 22 27 21 29 28 7 8 6 4 5 3 19 1/2 13 14 17 16 15 20 30 31.

Page 3

W 867 e f e a b d c.

Page 4

W 867 e h j g i 2 2 1 1 3 a c a b c 20-30 cm b.

Page 5: 11B

6 19 11b 8 9 7 17 13 14 15 11a 1 18 4 3 2 12 c 11b 11a 11 10 5 20 21 22 w 867 e k.

Page 6: ........

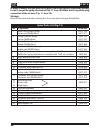

W 867 e l d ..........................................................................1 - 15 ........ ........................................................................16 - 30 ........................................................................31 - 45 .........................................

Page 7: Operating Instruction

Gb 16 w 867 e operating instruction congratulations on purchasing your wagner spray guns. You have purchased a proprietary device that requires careful cleaning and care to ensure trouble-free functioning. Read the operating instructions carefully beforeusing the tool and observe the safety instruct...

Page 8: 2. Electrical Safety

Gb 17 w 867 e never use the tool in hazardous areas that contain flammable liquids, gases b) or dusts. Power tools generate sparks that can ignite the dust or vapors. Keep children and other persons away when using the power tool. C) you can lose control of the tool if you are distracted. 2. Electri...

Page 9: 5. Service

Gb 18 w 867 e this appliance is not intended for use by persons (including children) with g) reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their...

Page 10: •

Gb 19 w 867 e caution! • wear breathing equipment: paint mist and solvent vapors are damaging to health. Always wear breathing equipment and only work in well ventilated rooms or using supplementary ventilating equipment. It is advisable to wear working clothing, safty glasses, ear protection and gl...

Page 11: Technical Data

Gb 20 w 867 e technical data sound pressure level 80 db (a) oscillation level air hose length 3.5 m weight approx. 6.3 kg description (figs. 1+2) air cap 1) tip 2) union nut 3) perfect spray spray attachment 4) trigger guard 5) material volume regulation 6) gun handle 7) air volume control 8) on/off...

Page 12: Thinning Recommendation

Gb 21 w 867 e coating materials not suitable for use materials that contain highly abrasive components, facade paint, caustic solutions and acidic coating substances. Materials with a flash point below 21°c. Preparation of the workplace (for interior wall paint) cover all surfaces and objects that s...

Page 13: Thinning Recommendation

Gb 22 w 867 e thinning recommendation sprayed material interior wall paint (dispersions and latex paint) dilute by 10 % if the feed rate is too low even at maximum flow setting, dilute in steps of 5 - 10 % until 2. The feed rate meets your requirements. Start-up before connecting to the mains supply...

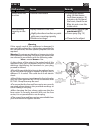

Page 14: Selecting The Spray Setting

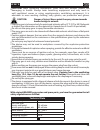

Gb 23 w 867 e three different spray jet settings can be chosen on the spray gun, depending on the application and target object. Selecting the spray setting fig. 8 a = horizontal flat jet for horizontal surfaces fig. 8 b = vertical flat jet for vertical surfaces fig. 8 c = circular jet for corne...

Page 15

Gb 24 w 867 e fig. 10 a: correct: even distance to the object. Fig. 10 c: incorrect: uneven distance causes uneven coating. Move the spray gun evenly cross-wise or up-and-down, depending on the spray pattern • setting. An even movement of the spray gun results in an even surface quality. • when coat...

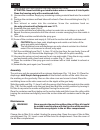

Page 16: Assembly

Gb 25 w 867 e turn the gun front part and gun rear part against each other. Attention: never hold the gun handle under water or immerse it into liquids. Clean the housing only with a moistened cloth. Unscrew the container. Empty any remaining coating material back into the material 3) tin. Preclean ...

Page 17: Storage

Gb 26 w 867 e in order to mount the gun more easily apply lubricating grease (enclosed) liberally to the o-ring at the spray attachment (fig. 11, item 18) and to the o-ring of the plug connection of the air hose (fig. 11, item 19). Storage remove the hose and when storing it in the cover put in the ...

Page 18: Environmental Protection

Gb 27 w 867 e the new click&paint system with additional spray attachments and accessories off ers the richt tool for each work. Accessories (not included in the delivery) name order no. Hvlp handle extension for easier coating of ceilings and horizontal objects. 2307 678 container with cover 800 ml...

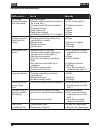

Page 19: Correction of Malfunctions

Gb 28 w 867 e correction of malfunctions malfunction cause remedy no coating material emerges from the nozzle nozzle clogged • material volume setting turned too • far to the left (-) no pressure build-up in container • container empty • feed tube loose • feed tube clogged • ventilating bore (fig.12...

Page 20: Malfunction

Gb 29 w 867 e malfunction cause remedy device does not function device overheated • unplug the power ➞ plug, let the device cool down approx. 30 minutes, do not bend the hose, check the air filter, do not cover the intake slots poor covering capacity on the wall spray material is too cold • highly a...

Page 21

Gb 30 w 867 e 2 years guarantee the guarantee runs for two years, counting from the date of sale (sales slip). It covers and is restricted to free-of-charge rectification of faults which are demonstrably attributable to the use of faulty materials in manufacture, or assembly errors; or free- of-char...

Page 22: Ce Konformitätserklärung

61 w 867 e ce konformitätserklärung wir erklären in alleiniger verantwortung, dass dieses produkt den folgenden einschlägigen bestimmungen entspricht: 73/23/ewg, 89/336 ewg; 2002/95/eg; 2002/96/eg angewandte harmonisierte normen: en 55014-1: 2002, en 55014-2: 2001, en 61000-3-2/2005, en 61000-3-3:20...

Page 23

62 w 867 e part. No. 2308 351 11/2009_rs © copyright by j.Wagner gmbh nl wagner spraytech benelux b.V. Zoonebaan 10 3542 ec utrecht +31/30/2 41 41 55 +31/30/2 41 17 87 aus wagner spraytech australia pty. Ltd., 14-16 kevlar close, braeside, vic 3195/australia +61/3/95 87 20 00 +61/3/95 80 91 20 h...