- DL manuals

- WAGNER

- Water Pump

- ZIP52 Finishing

- Operating manual

WAGNER ZIP52 Finishing Operating manual - Contents

4

OPERATING MANUAL

VERSION 12 / 2012

ORDER NUMBER DOC 2332848

Contents

5.3 Data

17

5.3.1

Materials of the Fluid Transporting Parts

17

5.3.2 Technical

Data

18

5.3.3

Dimensions and Connections

20

5.3.4 Performance

Diagrams

22

5.4

Mode of Operation

24

6

ASSEMBLY AND COMMISSIONING

25

6.1 Transportation

25

6.2 Storage

25

6.3 Assembly

25

6.4 Grounding

27

6.5 Commissioning

29

6.5.1 Safety

Regulations

29

6.5.2 Preliminary

Operations

30

6.5.3

Unit Pressure Tightness Test

31

7 OPERATION

32

7.1 Operation

32

7.2

Ending or Interrupting Work

33

7.3 Ending

Work:

Cleaning

34

7.4

Storage Over Longer Periods of Time

34

8

TROUBLE SHOOTING AND RECTIFICATION

35

9

CLEANING AND MAINTENANCE

36

9.1 Safety

Instructions

37

9.2 Filter

Cleaning

37

9.3

Diaphragm Replacement (Preventive Maintenance)

39

9.4

Diaphragm Replacement (Due to Breakage)

41

9.5

Cleaning / Replacement of the Suction and Delivery Ball Valves

42

9.6

Replacement of the Reversing Valve

42

9.7 Material

Hoses

42

9.8 Decommisioning

43

10 ACCESSORIES

44

11 SPARE

PARTS

46

11.1

How can Spare Parts be Ordered?

46

11.2 ZIP52

Finishing

47

11.3

ZIP52 PF Eco-Finishing – Aluminium

50

11.4

ZIP52 Pump – Metal

52

11.5

ZIP52 Pump - Conductive Acetal

54

11.6 ZIP

Motor

56

11.7

Trolley, Stand Set, and Wheel Set

58

11.8

Fine Flow Controller

60

11.9 Material

Filter

62

11.10 Service

Sets

63

12

GUARANTEE AND CONFORMITY DECLARATIONS

64

12.1

Important Notes Regarding Product Liability

64

12.2 Guarantee

Claim

64

12.3

CE Declaration of Conformity

65

Summary of ZIP52 Finishing

Page 1

B_04044 b_04043 b_04045 pneumatic double diaphragm pump spray pack version 12 / 2012 translation of the original operating manual.

Page 3: Contents

3 operating manual version 12 / 2012 order number doc 2332848 contents 1 about these instructions 5 1.1 preface 5 1.2 warnings, notes and symbols in these instructions 5 1.3 languages 6 1.4 abbreviations in the text 6 2 correct use 7 2.1 device types 7 2.2 type of use 7 2.3 use in potentially explos...

Page 4: Contents

4 operating manual version 12 / 2012 order number doc 2332848 contents 5.3 data 17 5.3.1 materials of the fluid transporting parts 17 5.3.2 technical data 18 5.3.3 dimensions and connections 20 5.3.4 performance diagrams 22 5.4 mode of operation 24 6 assembly and commissioning 25 6.1 transportation ...

Page 5

5 operating manual version 12 / 2012 order number doc 2332848 1.2 warnings, notes and symbols in these instructions 1 about these instructions warning instructions in this operating manual highlight particular dangers to users and device and state measures for avoiding the hazard. These warning inst...

Page 6

6 operating manual version 12 / 2012 order number doc 2332848 1.3 languages 1.4 abbreviations in the text number of pieces position labeling in the spare parts lists order no. Order number double stroke fine-flow controller (precisely adjustable fi lter fl ow controller with fi lter and integrated p...

Page 7

7 operating manual version 12 / 2012 order number doc 2332848 2 correct use 2.1 device types 2.2 type of use 2.3 use in potentially explosive areas a) metallic versions (aluminium and stainless steel): pneumatic double diaphragm pumps with order number aluminum stainless steel aluminum u760.00 u765....

Page 8: Notice

8 operating manual version 12 / 2012 order number doc 2332848 2.4 safety parameters wagner accepts no liability for any damage arising from incorrect use. Use the unit only to work with the materials recommended by wagner. Operate only the entire unit. Do not deactivate safety fi xtures. Use only wa...

Page 9

9 operating manual version 12 / 2012 order number doc 2332848 2.6 reasonably foreseeable misuse 2.7 residual risks residual risks are risks which cannot be excluded even in the event of correct use. If necessary, warning and prohibition signs at the relevant points of risk indicate residual risks. R...

Page 10

10 operating manual version 12 / 2012 order number doc 2332848 3 identification 3.1 explosion protection identification 3.2 maximum surface temperature metallic (aluminium and stainless steel) and conductive acetal versions: pneumatic double diaphragm pumps with order number as defi ned in the direc...

Page 11

11 operating manual version 12 / 2012 order number doc 2332848 4 general safety instructions 4.1 safety instructions for the operator 4.1.1 electrical equipment 4.1.2 personnel qualifications 4.1.3 safe work environment keep this operating manual at hand near the device at all times. Always follow l...

Page 12

12 operating manual version 12 / 2012 order number doc 2332848 4.2.1 safe handling of wagner spray units 4.2.2 earthing the unit the spray jet is under pressure and can cause dangerous injuries. Avoid injection of paint or cleaning agents: never point the spray gun at people. Never reach into the sp...

Page 13

13 operating manual version 12 / 2012 order number doc 2332848 4.2.4 cleaning 4.2.5 handling hazardous liquids, varnishes and paints de-energize the unit electrically. Disconnect the pneumatic supply line. Relieve the pressure from the unit. Ensure that the flash point of the cleaning agent is at lea...

Page 14

14 operating manual version 12 / 2012 order number doc 2332848 4.2.8 noise risk 4.2.9 material chemical compatibility 4.2.10 emergency stop in some working conditions, the pump can be particularly noisy: for example when the air feeding pressure is high and when there is no pressure or a very low pr...

Page 15

15 operating manual version 12 / 2012 order number doc 2332848 4.3.1 safety regulations 4.3 use in areas subject to explosion hazards only the pneumatic double diaphragm metallic pumps (aluminium and stainless steel) and conductive acetal versions can be used in explosion hazard zones. The following...

Page 16

16 operating manual version 12 / 2012 order number doc 2332848 4.3.2 operation without fluid 4.3.3 maximum surface temperature 4.3.4 maximum surface temperature - exothermic reactions 4.3.5 connection pipes 4.3.6 pump protection avoid running the pump sucking air, without fl uid inside. The air, com...

Page 17: Notice

17 operating manual version 12 / 2012 order number doc 2332848 5 description 5.1 areas of application 5.2 scope of delivery 5.3 data abrasive materials and pigments! Greater wear of the material transporting parts. Use the application-oriented model (fl ow rate/cycle, material, valves, etc.) as indi...

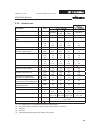

Page 18

18 operating manual version 12 / 2012 order number doc 2332848 description unit u760.00 u765.00 u773.00 u731.00 wetted parts materials aluminum stainless steel conductive acetal aluminum transmission ratio 1:1 1:1 1:1 1:1 flow volume per double stroke (dh) cm³ 108 108 108 62 cc maximum operating pre...

Page 19: Warning

19 operating manual version 12 / 2012 order number doc 2332848 outgoing air containing oil! Risk of poisoning if inhaled. Air motor switching problems. Provide compressed air free from oil and water (quality standard 5.5.4 according to iso 8573.1) 5.5.4 = 40 μm / +7 / 5 mg/m³. Warning.

Page 20

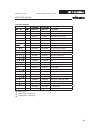

20 b_04046 b c a e f g g d (x4) h b_04047 b a c d e operating manual version 12 / 2012 order number doc 2332848 5.3.3 dimensions and connections zip52 finishing on the trolley.

Page 21

21 b_04048 a b c d operating manual version 12 / 2012 order number doc 2332848 finishing on the trolley eco-finishing mm; inch mm; inch mm; inch a 280.0; 11.02 520.0; 20.47 405.0; 15.94 b 189.0; 7.44 481.0; 18.94 335.0; 13.19 c 15.0; 0.59 1015.0; 39.96 940.0; 37.01 d ø9.0; ø0.35 930.0; 36.61 602.0; ...

Page 22

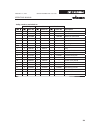

22 operating manual version 12 / 2012 order number doc 2332848 8.0 (0.8) 4.0 (0.4) 2.0 (0.2) 0 0 60 50 40 30 20 10 0 bar (mpa) nl/min l/min 10 (1.0) 750 600 450 300 150 6.0 (0.6) a a b b c c bar bar bar bar bar bar "? 5.3.4 performance diagrams example m a te rial pr essur e bar (mp a) material fl o...

Page 23

23 operating manual version 12 / 2012 order number doc 2332848 8.0 (0.8) 4.0 (0.4) 2.0 (0.2) 0 0 30 25 20 15 10 5 0 bar (mpa) nl/min l/min 10 (1.0) 250 200 150 100 50 6.0 (0.6) a a b b c c diagram zip52 pf m a te rial pr essur e material fl ow volume - water a = 8 bar; 0.8 mpa; 116 psi air pressure ...

Page 24: Warning

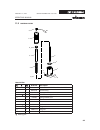

24 a b p p m m a c c c c b_04006 operating manual version 12 / 2012 order number doc 2332848 5.4 mode of operation double diaphragm pump - operating principle the double diaphragm pump is driven with compressed air. Two diaphragms (a) are mechanically connected to each other by means of a shaft (b)....

Page 25: Warning

25 operating manual version 12 / 2012 order number doc 2332848 6 assembly and commissioning 6.3 assembly 6.2 storage install the unit on a fl at and horizontal surface. Ensure that all fi xing screws (diaphragm covers, manifold, etc.) are correctly tightened. Tighten the fi xing screws regularly dep...

Page 26

26 operating manual version 12 / 2012 order number doc 2332848 material connection: connect the suction hose (on the underside) and the paint/air double hose to the corresponding connections. Note: make sure that the color hose does not get mixed up with the air hose, as the connections are the same...

Page 27: Warning

27 b_00304 r max Ω operating manual version 12 / 2012 order number doc 2332848 6.4 grounding grounding schema (example) paint container electrostatically conductive fl ooring conveyor work piece spraying stand heavy paint mist if grounding is insuffi cient! Danger of poisoning. Insuffi cient paint a...

Page 28

28 b_04049 operating manual version 12 / 2012 order number doc 2332848 procedure: 1. Remove the crimp connection delivered with the pump. 2. Crimp the grounding cable on the terminal and screw it back onto the pump’s foot. 3. Ground the material/paint container to a local ground connection. 4. Groun...

Page 29: Warning

29 operating manual version 12 / 2012 order number doc 2332848 6.5 commissioning before carrying out any work, the following points must be observed in accordance with the operating instructions: - observe all safety regulations in accordance with chapter 4. - carry out commissioning properly. 6.5.1...

Page 30

30 4 3 1 2 5 6 b_04050 b_04051 4 3 1 2 5 operating manual version 12 / 2012 order number doc 2332848 6.5.2 preliminary operations preliminary fl ushing the pump was tested with oil or other fl uids, depending on the model. Before use, it is necessary to fl ush the pump once using an adequate solvent...

Page 31

31 operating manual version 12 / 2012 order number doc 2332848 6.5.3 unit pressure tightness test close the spray gun and the material return valve, when the pump is fi lled. Gradually increase the pressure of the material pressure regulator (if available - zip52 finishing), until the maximum allowe...

Page 32

32 operating manual version 12 / 2012 order number doc 2332848 7 operation 7.1 operation priming: make sure that the air pressure regulator knob is turned fully counterclockwise (0 bar pressure). Open the air cut-off valve and the spray gun. Increase the air pressure until the pump starts. Don't let...

Page 33

33 operating manual version 12 / 2012 order number doc 2332848 the atomizing air pressure should be set to 1-2.5 bar, depending on the paint characteristics. To obtain perfect atomization and to avoid spray mist, the lowest possible atomizing air pressure should be used. In very few cases, the gun m...

Page 34

34 operating manual version 12 / 2012 order number doc 2332848 when storing the device for longer periods of time, it is necessary to thoroughly clean it and protect it from corrosion. Use a suitable preserving fl uid, according to the material of the wetted parts of the pump. 7.4 storage over longe...

Page 35

35 operating manual version 12 / 2012 order number doc 2332848 8 trouble shooting and rectification problem cause remedy the unit does not work. The unit has no compressed air. Check the compressed air supply line and the air cut-off valve. Check the compressed air maintenance unit (if available). T...

Page 36: Warning

36 operating manual version 12 / 2012 order number doc 2332848 9 cleaning and maintenance 1. Check and clean the material and suction fi lters daily or as necessary. 2. Carry out every decommissioning as explained in paragraph 7.2. 3. As necessary, check and replace hoses, pipes, and connections dai...

Page 37

37 b_04059 b_04060 operating manual version 12 / 2012 order number doc 2332848 9.1 safety instructions prior to maintenance and cleaning measures note: wear protective clothing and use specifi c protection devices with regard to the nature of the fl uids involved. Close the compressed air supply and...

Page 38

38 4 3 1 2 b_04052 3 4 5 6 1 2 b_04053 operating manual version 12 / 2012 order number doc 2332848 fine flow controller (zip52 finishing) to clean the fi lter of the fine-flow controller, unscrew the plastic ring nut (1) from the metal body, lift the cup (2) paying attention to the ptfe gasket on th...

Page 39

39 b_04015 operating manual version 12 / 2012 order number doc 2332848 mark the coupled parts (diaphragm covers, distributor, covers) with a felt-tip pen so as to make subsequent reassembly easier. A) remove the suction and delivery manifolds. 9.3 diaphragm replacement (preventive maintenance) b) di...

Page 40

40 b_04067 12 nm 8.8 lbft operating manual version 12 / 2012 order number doc 2332848 c) hold the end nut of the one outer diaphragm disc with a wrench. Loosen the end nut of the other diaphragm disc and dismantle it. D) remove the released diaphragm with its corresponding internal disc, and remove ...

Page 41

41 b_04018 1 2 3 4 5 6 3.5 nm 2.6 lbft 2 nm; 1.5 lbft 2 nm 1.5 lbft operating manual version 12 / 2012 order number doc 2332848 9.4 diaphragm replacement (due to breakage) if the diaphragms are replaced as a result of breakage, all the internal parts of the motor must be cleaned and the condition of...

Page 42: Warning

42 operating manual version 12 / 2012 order number doc 2332848 9.6 replacement of the reversing valve a) disassemble the pressure side cover and remove the reversing valve. B) to clean it, blow the housing cavity of the reversing valve out with a jet of compressed air (wear safety goggles). C) put t...

Page 43

43 operating manual version 12 / 2012 order number doc 2332848 9.8 decommisioning when the equipment must be scrapped, please diff erentiate the disposal of the waste materials. The following materials have been used: steel aluminium elastomerics plastics carbide the consumable materials (paints, ad...

Page 44

44 4 6 12 12 14 15 8 3 1 2 11 11 9 16 13 10 5 7 b_04054 operating manual version 12 / 2012 order number doc 2332848 10 accessories.

Page 45

45 operating manual version 12 / 2012 order number doc 2332848 order no. Description 1 u760.00 zip52 finishing, aluminium 1 u765.00 zip52 finishing, stainless steel 1 u773.00 zip52 finishing, (pom) acetal 2 u731.00 zip52 pf eco-finishing 3 s419.00g low pressure double hose 3 s419.00gi low pressure d...

Page 46: Warning

46 operating manual version 12 / 2012 order number doc 2332848 11 spare parts 11.1 how can spare parts be ordered? Incorrect maintenance/repair! Risk of injury and damage to the device. Have repairs and part replacements carried out by specially trained staff or a wagner service center. Before all w...

Page 47: Warning

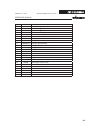

47 operating manual version 12 / 2012 order number doc 2332848 zip52 finishing u773.00 order no. Order no. Order no. Description 1 u760.00 u765.00 u773.00 zip52 finishing 1 1 u550.Ahss0-a u550.Shss0-b u552.Ghss1 ddp zip52 2 1 t0180.00a t0180.00ai t0180.L0ai ffc 14/0,5-8 bar pneum., aluminium 3 1 e31...

Page 48

48 4 6 42 27 41 23 22 24 14 15 8 8 3 1 11 17 9 36 9 15 16 18 13 12 10 10 2 5 7 20 21 8 37 38 (u765.00) (u765.00) 31 32 29 30 35 25 26 28 34 40 39 19 21 33 43 * * * * * * * * * * * * * * * * * * b_04055 * * * operating manual version 12 / 2012 order number doc 2332848.

Page 49

49 operating manual version 12 / 2012 order number doc 2332848 zip52 finishing u773.00 order no. Order no. Order no. Description 21 8 9920103 9920103 9920103 washer, a6.4, din 125 22 1 t139.01 t139.01 t139.01 air manifold 23 3 m404.00 m404.00 m404.00 hollow screw 24 1 m250.00 m250.00 m250.00 mf redu...

Page 50

50 4 6 26 26 27 28 14 25 12 21 22 23 15 8 3 1 11 17 9 16 18 13 10 2 24 24 23 5 7 7 7 20 19 b_04056 * * * * * * * * * * * * 29 * operating manual version 12 / 2012 order number doc 2332848 11.3 zip52 pf eco-finishing – aluminium.

Page 51

51 operating manual version 12 / 2012 order number doc 2332848 zip52 pf eco-finishing order no. Description 1 u731.00 zip52 pf eco-finishing 1 1 u551.Ahss1 ddp zip52 pf ahss1 2 1 e3112.92 mounting plate for zip52 3 2 e111.92b leg zip52 eco 4 4 r211.07 closure cap d20 5 2 p123.00e compressed air regu...

Page 52

52 b_04058 4 6 8 3 1 12 16 9 17 13 11 2 5 7 19 18 20 21 5 nm; 3.7 lbft 12 nm; 8.8 lbft 5 nm; 3.7 lbft 10 14 22 23 24 25 5 nm; 3.7 lbft 11 11 operating manual version 12 / 2012 order number doc 2332848 11.4 zip52 pump – metal.

Page 53

53 operating manual version 12 / 2012 order number doc 2332848 zip52 pump aluminium stainless steel aluminium order no. Order no. Order no. Description 1 u550.Ahss0-a u550.Shss0-b u551.Ahss1 zip52 pump 1 1 f184.01 f188.03 f184.01 suction manifold - left 2 1 f185.01 f189.03 f185.01 delivery manifold ...

Page 54

54 b_04063 2 1 3 4 5 7 8 9 11 10 13 14 16 19 20 (21*) 17 22 23 24 4.5 nm; 3.3 lbft 12 nm; 8.8 lbft 7 nm; 5.2 lbft 25 2 4.5 nm; 3.3 lbft 11 12 18 27 operating manual version 12 / 2012 order number doc 2332848 11.5 zip52 pump - conductive acetal.

Page 55

55 operating manual version 12 / 2012 order number doc 2332848 zip52 conductive acetal u552.Ghss1 order no. Description 1 u552.Ghss1 ddp zip52 1 1 f833.07g-a suction manifold - left 2 1 f859.07g delivery manifold - left 3 2 f834.07d external diaphragm disc 4 2 f831.07g-a conductive diaphragm cover 5...

Page 56

56 4 6 12 14 15 8 3 1 11 17 9 16 18 13 10 2 5 7 20 19 2 nm; 1.5 lbft 2 nm; 1.5 lbft 3.5 nm; 2.6 lbft b_04027 21 21 3 3 1 1 21 21 operating manual version 12 / 2012 order number doc 2332848 11.6 zip motor.

Page 57: Warning

57 operating manual version 12 / 2012 order number doc 2332848 zip motor order no. Order no. Description 1 t6103.00 t6103.00s motor 1 2 b0146.04 b0146.04 feeler pin 2 2 b0147.71 b0147.71 inner diaphragm disc 3 1 b0150.03 b0150.03s shaft 4 1 f194.91 f194.91 cover (pressure side) 5 2 f829.07 f829.07 s...

Page 58

58 operating manual version 12 / 2012 order number doc 2332848 11.7 trolley, stand set, and wheel set 4 6 15 3 9 16 13 10 2 5 8 4 6 12 14 15 8 3 1 11 9 16 13 10 2 b_04035 5 7 8 8 16 13.

Page 59

59 operating manual version 12 / 2012 order number doc 2332848 trolley, stand set, and wheel set trolley stand set wheel set order no. Order no. Order no. Description 1 t760.00sr -- -- trolley 1 t760.00s t760.00s -- stand set 1 t760.00r -- t760.00r wheel set with handle 1 1 e3108.92 -- -- 1 e3108.92...

Page 60

60 operating manual version 12 / 2012 order number doc 2332848 11.8 fine flow controller 8 13 18 7 20 3 b_04036 19 4 5 1 9 12 16 10 11 2 14 6 15 17 6 nm 5 nm 40 nm.

Page 61

61 operating manual version 12 / 2012 order number doc 2332848 fine flow controller order no. Order no. Description 1 t0180.00a t0180.00ai fine flow controller, 14/0.5-8 bar 1 1 a588.03 a588.03 diaphragm disc - material side 2 1 a590.03 a590.03 diaphragm disc - air side 3 1 b0172.03 b0172.03 ball gu...

Page 62

62 4 6 8 3 1 9 2 5 7 10 10 b_04057 operating manual version 12 / 2012 order number doc 2332848 11.9 material filter material fi lter order no. Description 1 t4005.00als material fi lter: lp-zip-filter-pn15-g1/4"-cs 1 1 b0259.01 filter housing 2 1 b0127.01 filter cap 3 11 t454.00 aps-filter cartridge...

Page 63: Warning

63 operating manual version 12 / 2012 order number doc 2332848 incorrect maintenance/repair! Risk of injury and damage to the device. Have repairs and part replacements carried out only by specially trained staff or a wagner service center. Before all work on the unit and in the event of work interr...

Page 64

64 operating manual version 12 / 2012 order number doc 2332848 12 guarantee and conformity declarations 12.1 important notes regarding product liability 12.2 guarantee claim as a result of an ec regulation eff ective from january 1, 1990, the manufacturer shall only be liable for his product if all ...

Page 65

65 operating manual version 12 / 2012 order number doc 2332848 12.3 ce declaration of conformity ce certifi cate of conformity the ce certifi cate of conformity is enclosed with this product. If needed, further copies can be ordered through your wagner dealer by specifying the product name and seria...

Page 66

66 operating manual version 12 / 2012 order number doc 2332848 germany j. Wagner gmbh otto-lilienthal-str. 18 postfach 1120 d- 88677 markdorf telephone: +49 7544 5050 telefax: +49 7544 505200 e-mail: service.Standard@wagner-group.Com switzerland j. Wagner ag industriestrasse 22 postfach 663 ch- 9450...

Page 68

Order no. 2332848 people‘s republic of china tel. +86 / (0)21 6652 / 1858 fax +86 / (0)21 6630 / 8085 germany tel. Fax e-mail.