- DL manuals

- Walchem

- Water Pump

- ehe series

- Instruction Manual

Walchem ehe series Instruction Manual

Summary of ehe series

Page 1

Ehe series electronic metering pump instruction manual w a l c h e m iwaki america inc. Ehe series metering pumps five boynton road hopping brook park holliston, ma 01746 usa tel: 508-429-1110 fax: 508-429-7433 web: www.Walchem.Com.

Page 2

Notice © 2017 walchem, iwaki america inc. (hereinafter “walchem”) five boynton road, holliston, ma 01746 usa tel (508) 429-1110 all rights reserved printed in usa proprietary material the information and descriptions contained herein are the property of walchem. Such information and descriptions may...

Page 3

Table of contents thank you for choosing a walchem e series metering pump. This instruction manual deals with the correct installation, operation, programming maintenance, and troubleshooting procedures for the ehe series metering pumps. Please read through it carefully to ensure the optimum perform...

Page 4

1 1.0 introduction 1.1 safety and caution notes always wear protective clothing, eye protection and gloves before working on or near a metering pump. Follow all recommendations of the supplier of the solution being pumped. Refer to the msds from the solution supplier for additional precautions. Walc...

Page 5

2 1.3 specifications eh e36 e 1 - pc v 1 2 3 4 5 6 1 pump series ehe electronicmetering pump with external analog and pulse control or manual speed control (adjustable to 360 strokes per minute). Manually adjustable stroke length. (turndown ratio 1800:1) 2 capacity/pressure rating size output capaci...

Page 6

3 adjustment range stroke length adjustment range 20% to 100% stroke length frequency adjustment range 1 to 360 strokes per minute (1 to 240 strokes per minutes for –hv) operating conditions ambient temperature 32 to 122°f (0 to 50°c) relative humidity 30 to 90% non-condensing liquid temperature 32 ...

Page 7

4 fc and hv models model a b c d e f h j l w ehe 31 36 e1 e2 -fc 6.06 1.05 7.76 6.42 0.65 0.67 9.69 3.15 9.53 5.75 ehe 46 e1 e2 -fc 6.06 1.14 7.83 6.42 0.75 0.67 10.00 2.80 9.72 5.75 ehe 56 e1 e2 -fc 6.06 1.42 8.13 6.42 0.85 0.67 10.45 2.38 10.12 5.75 ehe 36/46 e1 e2 -hv 6.06 1.05 7.80 6.42 0.70 0.6...

Page 8

5 2.0 installation 2.1 unpacking open the shipping carton and inspect contents for damage. If any items are missing or damaged contact your local distributor to arrange for replacement. Caution pumps are pre-primed with water at the factory. If the application is not compatible with water, drain and...

Page 9

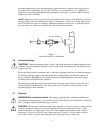

6 figure 1 figure 2 figure 3 flooded suction shelf mount tank mount suction lift suction lift if flooded suction mounting is not possible, a shelf adjacent to (but not directly above) the supply tank often works well (see figure 2). The supply tank or cover can also be used if it has provisions for ...

Page 10

7 the eh-hv series pumps require a flooded suction or pre-primed condition before operation. Flooded suction (mounting the pump below the level of liquid in the supply tank) is recommended for proper operation of high viscosity pumps. (see figure 1) these pumps are not designed to be self-priming. T...

Page 11

8 warning: all fittings and coupling nuts should be tightened by hand. If necessary, small pliers may be used to make it snug. Do not use excessive force or large wrenches. Figure 6 tubing connections 2.4 discharge tubing cut a length of tubing long enough to go from the pump to the application (inj...

Page 12

9 maximum backpressure and, depending upon the application, may be higher if the back-pressure is lower than rated. Additionally, the valve does not act as an anti-siphon valve. If siphoning is a possibility, or if pumping downhill into open atmosphere (open tank), a separate backpressure/anti- siph...

Page 13

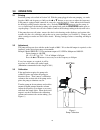

10 3.0 operation 3.1 priming install the pump as described in section 2.0. With the pump plugged in but not pumping, set stroke length at 100% and frequency at 360 (use the or buttons as necessary to adjust the frequency). If the pump is equipped with a manual air vent valve, open the knob ½-1 turn;...

Page 14

11 3.4 control unit operation and programming the ehe series metering pumps can be operated in either manual or external modes. The external mode can be controlled from a digital or analog external signal. An external stop function is available for remotely suspending operation of the pump and funct...

Page 15

12 eh-e program overview not e s : 1. Upo n p o we r u p , d ispl a y wil l s h o w so ftw a re ve rsio n f o r a p p ro xi m a te ly 1 s e co n d a n d t h e n m o ve t o which e ve r m o d e it w a s p o w e re d d o w n i n ( w a it m o d e if p o we re d u p f o r t h e fir s t tim e ). 2. T o o...

Page 16

13 manual operation (1) power on when power is applied to the pump, the green indicator above on lights up, the display momentarily shows the software version (“vx.Xe”), and the controller goes to whatever mode the pump was in when power was disconnected. If being powered for the first time, the str...

Page 17

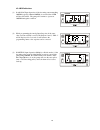

14 external operation analog input operation in analog mode the pump will accept a milliamp signal and produce a pump speed proportional to the signal level received. The input resistance of the analog signal is 250. The pump’s response can be fine-tuned by variable set points to meet system requir...

Page 18

15 (5) setting the input current (ma) of set point 1: use the and keys to set the input current (ma) of set point 1. The value will increase with the key and decrease with the key. The numerical value will change slowly by 0.1ma if the keys are pressed briefly, but will increment rapidly if ...

Page 19

16 (11) setting the stroke rate of set point 2: set the stroke rate corresponding to the current setting of set point 2 using the and keys. The allowable range is 0-360 spm and the default setting from the factory is 360 spm. (12) press the stop/start key to confirm the pump speed value of set p...

Page 20

17 digital input operation in digital mode, the pump can accept a non-powered (dry contact) pulse signal from a flowmeter or other similar instrument. The pump can be set to divide pulses by a factor of 1 to 999; or in multiply mode, 1 input pulse can produce 1 to 999 pump strokes. The minimum pulse...

Page 21

18 (6) press the ext key to enter the memory selections and return to the “dig” set menu. (7) press the start/stop key to confirm the digital operation selection and return to the wait mode. The set backlight will go out and the wait light will illuminate. (8) digital input selection: (note: pump is...

Page 22

19 (11) press the start/stop key to confirm the operation mode and value settings. This will also return to the wait mode. The wait light will illuminate and the backlight behind set will go out. (12) important: changing the pump speed in the wait (or man) mode using the and keys sets the max op...

Page 23

20 alarm indications (1) in analog input operation, if the incoming current matching 360spm (typically, 20ma=360spm) is exceeded, the over will become backlit. The pump will continue to operate at 360spm during this condition. (2) while programming the analog input setpoints, if the same value (curr...

Page 24

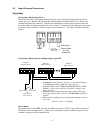

21 3.5 input wiring and connections digital mode connecting a digital input device disconnect ac power to the pump. Remove the four screws from the terminal block cover and remove the cover. Remove the cord nut and bushing from the terminal block cover. Remove the terminal block from the connector. ...

Page 25

22 analog mode caution: open loop signal voltage must not exceed 25 vdc. If the signal voltage is greater than 25 vdc, power down the signal source prior to connection. Connecting an analog signal device disconnect ac power to the pump. Remove the four screws from the terminal block cover and remove...

Page 26

23 4.0 maintenance caution: before working on the pump, disconnect the power cord, depressurize the discharge tubing and drain or flush any residual liquid from the pump head and valves. Always wear protective gear when working around chemicals. 4.1 diaphragm replacement disconnect ac power to the p...

Page 27

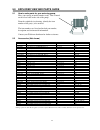

24 5.0 exploded view and parts guide 5.1 how to order parts for your metering pump. Have your catalog or model number ready. This is found on the silver label on the side of the pump. From the exploded view drawing, identify the item number of the part(s) to be ordered. The item numbers are listed a...

Page 28

25 5.3 ehe31, 36, 46 liquid end exploded view 17 1 19 21 20 17 14 11 13 12 11 13 12 4 6 5 15 3 14 14 (ehe46 & fc models only) 14 zz 11 13 12 3 15 5 6 4 14 (fc models only) 14 (ehe46 & fc models only) 25 22 23 26 24 27 28 4 6 5 8 9 e d d (fc models only) (ehe31/36) (ehe46) 11 13 12 (ehe31/36) (ehe46)...

Page 29

26 ehe31, 36, 46 liquid end parts list it em part no description qt y size liquid end mtl it em part no description qt y size liquid end mtl 1 eh2101 head, e31 pvc 1 31 vc, ve, vf *13 eh0646 ball, valve, 0.500, ce 2 46 vc, ve, pc, pe, fc eh2102 head, e31 gfrpp 1 31 pc, pe e00072 ball, valve, 0.500, ...

Page 30

27 5.4 ehe 56 liquid end exploded view c head assembly ehe 56 c head assembly d valve cartridge e manual air vent valve see page 31 for the assembly part numbers 3 15 5 6 4 3 15 5 6 4 14 13 11 zz 17 14 11 13 12 19 21 20 17 12 (fc only) (fc only) 14 14 25 22 23 26 24 27 28 29 30 31 32 8 9 10 d d.

Page 31

28 ehe 56 liquid end parts list item part no description qty size liquid end mtl 1 eh2114 head, e56 pvc 1 56 vc, ve, vf eh2115 head, e56 gfrpp 1 56 pc, pe eh2118 head, e56 pvc machined 1 56 vm eh2116 head, e56 pvdf 1 56 fc 3 eh0656 housing, valve, e56, pvc 2 56 vc, ve, vm, vf eh0685 housing, valve, ...

Page 32

29 5.5 ehe-hv liquid end parts list 17 1 19 21 20 17 11 13 12 4 6 5 2 3 14 14 zz 3 8 9 15 17 11 13 12 14 14 15 3 3 item part no description qty size liquid end 1 eh2392 head, hv, gfrpp 1 36 all eh2110 head, hv, gfrpp 1 46 all * 2 eh0028 o-ring, p12, fkm 1 36,46 hv, hvv 3 eh1244 housing, valve, ½” np...

Page 33

30 33 32 34 37 38 36 39 35 40 43 41 42 31 b control module a drive unit 44 45 46 47 48 49 5.6 drive control components item part no. Description qty 31 eh1746 base, pump, ehe 1 32 eh0697 cover, control panel 1 33 eh1658 gasket, ehe pump base 1 34 eh1071 screw, m5 x 12, ss, ph 4 35 eh0696 gasket, con...

Page 34

31 5.7 assembly part numbers key letter from exploded view drawing, previous pages a drive unit b control module c head assembly d valve cartridge e manual air vent valve assembly e h e 36 e 1 – v c series size control voltage liquid end pump model drive unit use p/n: control module use p/n: head as...

Page 35

32 6.0 troubleshooting caution: before working on the pump disconnect the power cord, depressurize the discharge tubing and drain or flush any residual liquid from the pump head and valves. Problem possible cause corrective action pump does not start faulty wiring correct wiring improper voltage con...

Page 36

Five boynton road hopping brook park holliston, ma 01746 usa tel: 508-429-1110 web: www.Walchem.Com.