- DL manuals

- Walchem

- Water Pump

- EZ Series

- Instruction Manual

Walchem EZ Series Instruction Manual

Summary of EZ Series

Page 1

Ez series electronic metering pump instruction manual five boynton road hopping brook park holliston, ma 01746 usa tel: 508-429-1110 fax: 508-429-7433 web: www.Walchem.Com w a l c h e m iwaki america inc. Ez series metering pumps.

Page 2

Notice © 2014 walchem, iwaki america inc. (hereinafter “walchem”) five boynton road, holliston, ma 01746 usa tel (508) 429-1110 fax (508) 429-7433 all rights reserved printed in usa proprietary material the information and descriptions contained herein are the property of walchem. Such information a...

Page 3

Table of contents thank you for choosing a walchem ez series metering pump. This instruction manual deals with the correct installation, operation, maintenance and troubleshooting procedures for the ez metering pumps. Please read through it carefully to ensure the optimum performance, safety and ser...

Page 4

1 1.0 introduction 1.1 safety and caution notes always wear protective clothing, eye protection and gloves before working on or near a metering pump. Follow all recommendations of the supplier of the solution being pumped. Refer to the msds from the solution supplier for additional precautions. Walc...

Page 5

2 1.3 model code ez b16 d 1 - vc a 1 2 3 4 5 6 1 pump series ez electronic metering pump with manual speed control (adjustable to 360 strokes per minute) 2 capacity/pressure rating (see section 1.4 for detailed chart.) 3 control module d for use on all ez models, features digitally adjustable speed ...

Page 6

3 1.4 specifications electrical 50/60 hz, single phase ezb 115 vac±10% 0.9 amp max. 16 watt avg. 230 vac±10% 0.4 amp max. 16 watt avg. Ezc 115 vac±10% 1.4 amp max. 24 watt avg. 230 vac±10% 0.6 amp max. 24 watt avg. Operating conditions ambient temperature 32°f to 122°f (0°c to 50°c) relative humidit...

Page 7

4 1.5 dimensions ez models with thermoplastic liquid end materials ezb model shown for reference all dimensions in inches model a b c d e f g h j l p & q tubing w ezb 11 16 21 d1 d2 -vc -pc -tc -ve -pe -vf 3.21 0.87 0.08 3.54 1.46 (3.03) 1 [1.83] 2 0.20 5.91 [6.11] 2 7.24 [8.39] 2 1.02 7.44 (9.53) 1...

Page 8

5 2.0 installation 2.1 unpacking open the shipping carton and inspect contents for damage. If any items are missing or damaged contact your local distributor. Pumps are pre-primed with water at the factory. If the application is not compatible with water, drain and dry before use. Be sure to remove ...

Page 9

6 figure 4 tubing connections 2.3 supply tubing the supply tubing run should be as short as possible. For flooded suction mounting, install a shut-off valve with an appropriate tubing connector at the tank outlet. Cut a length of tubing from the coil supplied and install between the shut-off valve a...

Page 10

7 2.4 discharge tubing cut a length of tubing long enough to go from the pump to the application (injection) point. Additional tubing can be ordered from your distributor. Avoid sharp turns or bends and hot surfaces. Routing tubing through rigid pipe such as pvc pipe is recommended for long runs and...

Page 11

8 in addition to preventing backflow from pressurized lines, the injection valve acts as a back pressure valve when pumping into atmosphere or low pressure applications. However, the back pressure by the injection valve can vary and the valve does not act as an anti-siphon valve. If siphoning is a p...

Page 12

9 3.0 operation 3.1 priming install the pump as described above. With the pump turned on, set frequency at 100%. If the pump is equipped with an air vent valve, open the knob 1/2 turn. Liquid should move through the suction tubing and into the pump head. When liquid starts running through the vent s...

Page 13: P 3 6 0

10 b. Ez pumps using the ‘t’ control module the ezb-timer series is able to operate in daily, weekly and 2-week modes. An external stop input and 12vdc output are also available. Display/keypad overview figure 8 alpha/numeric display. Indicates wait mode, stroke frequency, time or pump on-time. Mode...

Page 14

11 ez-t quick reference guide from: press: to: mode key select key wait menu + + move to manual menu changes pump frequency (1 to 360 spm) starts and stops manual operation or sets the hour (incrementing only) (hold for 3 seconds) mode sel mode sel sel sel min hour move to time / date setting menu m...

Page 15

12 programming and timer use caution! Before use, check the time and date. Set to the local time and date before programming. Incorrect time/date can result in incorrect operation. 1. Manual operation from the wait menu, pressing the mode key will enter the manual mode. Pressing sel will toggle the ...

Page 16

13 pressing mode again will display the current time and date. The pump is now operating in the timer mode and will come on at the next programmed timer operation. 3.3 calibration if exact output calibration is required, first prime and adjust the pump as above. Then connect a calibration column to ...

Page 17

14 3.6 auto air vent valve operation the auto air vent valve is an option on select ez pumps and replaces the standard manual air vent valve when ordered. It is used primarily in applications where gassing is a problem and pumps can lose prime. Unlike the manual air vent valve, the auto air vent val...

Page 18

15 3.7 multifunction valve operation the multifunction valve is optional on select ez pumps and replaces the standard manual air vent valve when ordered. It integrates the air venting/bleeding functions with a back pressure and anti-siphon valve. Air vent / bleed function 1. Open the air vent by tur...

Page 19

16 4.0 maintenance 4.1 diaphragm replacement disconnect ac power to the pump and disconnect the suction tubing, discharge tubing, and air vent tubing. Remove the four head bolts with a 4mm hex wrench. Unscrew the diaphragm and remove its retainer (small disk behind the diaphragm). Caution: there may...

Page 20

17 5.0 exploded view & parts guide pvc/gfrpp liquid end exploded view #1 for ez pump model sizes 11, 16, and 21 4 23 26 25 14 11 13 12 11 13 12 19 17 8 1 17 14 11 13 12 11 13 12 3 4 zz 30 31 12 32 10 27 5 6 35 4 28 33 29 4 34 13 4 10 23 26 25 21 22 10 e d 9 d c entire head assembly d valve cartridge...

Page 21

18 pvc/gfrpp liquid end exploded view #1 components item part no description qty size liquid end mtl 3 eh0400 housing, valve, 3/8 pvc 1 11, 16, 21 vc, ve, vf, vca eh0418 housing, valve, 3/8 gfrpp 1 11, 16, 21 pc, pe 4 eh0401 nut, coupling, 3/8 pvc 3 11, 16, 21 vc, ve, vf, vca eh0419 nut, coupling, 3...

Page 22

19 pvc/gfrpp liquid end exploded view #2 for ez pump model sizes 31 and 36 c entire head assembly d valve cartridge e air vent valve part numbers for these assemblies are on page 26 14 11 13 12 11 13 12 17 19 1 17 14 11 13 12 11 13 12 3 4 zz 6 5 27 23 16 15 10 4 4 18 e d 8 9 d.

Page 23

20 pvc/gfrpp liquid end exploded view #2 components item part no description qty size liquid end mtl 1 eh1952 head, zb31, pvc 1 31 vc, ve, vf eh1960 head, zc31, pvc 1 31 vc, ve, vf eh1953 head, zc36, pvc 1 36 vc, ve, vf eh1959 head, zb31, gfrpp 1 31 pc, pe eh1961 head, zc31, gfrpp 1 31 pc, pe eh1962...

Page 24

21 pvdf liquid end exploded view #3 for all pvdf ez pump models c entire head assembly d valve cartridge e air vent valve part numbers for these assemblies are on page 26 tc only 31 and 36 tc only 11, 16, and 21 fc only all sizes 14 11 13 12 11 13 12 17 19 1 17 14 11 13 12 11 14 (fc only) 14 (fc onl...

Page 25

22 pvdf liquid end exploded view #3 components item part no description qty size liquid end mtl 1 eh1963 head, zb11, pvdf 1 11 fc, tc eh1968 head, zb16, pvdf 1 16 fc, tc eh1964 head, zb21, pvdf 1 21 fc, tc eh1969 head, zb31, pvdf 1 31 fc, tc eh1970 head, zc16, pvdf 1 16 fc, tc eh1965 head, zc21, pvd...

Page 26

23 accessories (not shown) part no. Description size liquid end mtl e90001 valve, injection 3/8 11, 16, 21 vc e90002 valve, injection 3/8 11, 16, 21 ve, vf e90003 valve, injection, 3/8 11, 16, 21 pc e90004 valve, injection, 3/8 11, 16, 21 pe e90007 valve, injection, 1/2 31, 36 vc e90008 valve, injec...

Page 27

24 drive and control module exploded view rive and control components item part no. Description series 35 e00152 cover, keypad ez-d e00153 membrane keypad ez-d 36 eh1036 gasket, terminal box ez-t 38 eh0261 gasket, m3 x 35 bolt ez-d, ez-t 39 eh0202 grommet, cord ez-d, ez-t 40 eh0204 cap, strain relie...

Page 28

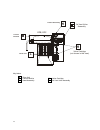

25 a air vent valve assembly valve cartridge (not shown in this view) head assembly control module drive unit ezb, ezc key letters: a drive unit b control module d valve cartridge c head assembly e air vent valve assembly.

Page 29

26 a b pump model drive unit control module head assembly * (spare parts kit) pc pe vc ve vf tc fc ezb11d1- zb11-d1 ezbd1 zb11pc (x11pc-pk) zb11pe (x11pe-pk) zb11vc (x11vc-pk) zb11ve (x11ve-pk) zb11vf (x11vf-pk) zb11tc (z11tc-pk) zb11fc (z11fc-pk) ezb11d2- zb11-d2 ezbd2 ezb16d1- zb16-d1 ezbd1 zb16pc...

Page 30

27 6.0 troubleshooting problem possible cause corrective action pump does not start faulty wiring correct wiring improper voltage connect to proper voltage source electronic control unit is damaged replace control unit (contact distributor or factory) pump does not prime air in suction tubing rerout...

Page 31

Five boynton road hopping brook park holliston, ma 01746 usa tel 508-429-1110 fax 508-429-7433 website: www.Walchem.Com.