- DL manuals

- Walchem

- Recording Equipment

- WCT400

- Instruction Manual

Walchem WCT400 Instruction Manual

Summary of WCT400

Page 1

Wct400/410 series cooling tower conductivity controller instruction manual five boynton road hopping brook park holliston, ma 01746 usa tel: 508-429-1110 fax: 508-429-7433 web: www.Walchem.Com wct400/410 controllers w a l c h e m iwaki america inc..

Page 2

Notice © 2014 walchem, iwaki america inc. (hereinafter “walchem”) 5 boynton road, holliston, ma 01746 usa (508) 429-1110 all rights reserved printed in usa proprietary material the information and descriptions contained herein are the property of walchem. Such information and descriptions may not be...

Page 3

Table of contents 1.0 introduction ........................................................................................................................ 1 2.0 specifications ..................................................................................................................... 2 2.1...

Page 4

1 1.0 introduction the walchem wct400 series controllers offer conductivity and watermeter-based control of cooling tower water, control of corrosion/scale inhibitor feed, and with the wct410 models, control of two biocide pumps. The inhibitor pump may be selected to operate in one of the following ...

Page 5

2 2.0 specifications 2.1 measurement performance conductivity range 0 - 10,000 µs/cm (microsiemens/centimeter) conductivity resolution 1 µs/cm conductivity accuracy 10 - 10,000 µs/cm ±1% of reading 0 - 10 µs/cm ±20% of reading temperature range 32 - 158°f (0 - 70°c) temperature resolution 0.1°c temp...

Page 6

3 2.4 wct variables and their limits low limit high limit conductivity menu ppm conversion factor 0.200 ppm/µs/cm 1.000 ppm/µs/cm interval time (sampling) 5 minutes 24:00 hours duration time (sampling) 1 minute 59 min: 59 sec % calibration range -50 +50 temperature menu no variables bleed menu set p...

Page 7

4 3.0 unpacking & installation 3.1 unpacking the unit inspect the contents of the carton. Please notify the carrier immediately if there are any signs of damage to the controller or its parts. Contact your distributor if any of the parts are missing. The carton should contain: a wct400 series contro...

Page 8

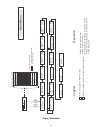

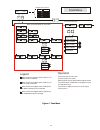

5 figure 1 typical installation metering pumps heat exchanger circulating pump solenoid valve cooling tower water meter cooling tower controller www.Walchem.Com prev next enter exit flow flow flow switch electrode sample valve 10.0" (254 mm) 1/4” polypro panel 17" (43 2 mm) cooling tower controller ...

Page 9

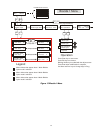

6 figure 1a typical installation intermittent sampling to electrode to solenoid to constant 110 volts pe discharge tubing chemical pump to sanitary server spray tower spray pump city water makeup shutoff valve (a) (d) (a) (b) (f) (c) (e) (a) unions; installed for replacement of solenoid, strainer or...

Page 10

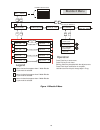

7 figure 1b typical installation submersion electrode to 110 volt ac outlet to sanitary server cooling tower open sump circulation pump (x) unions; installed for replacement of solenoid or strainer (y) ½" y-strainer (z) ½"solenoid typical installation submersion electrode (option "a") valve x y z x ...

Page 11: Caution

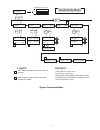

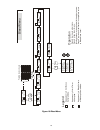

8 3.5 electrical installation the various standard wiring options are shown in figure 2. Your wct series controller will arrive from the factory prewired or ready for hardwiring. Depending on your configuration of controller options, you may be required to hardwire some or all of the input/output de...

Page 12

9 figure 3 inputs conductivity electrode power supply (115 vac or 230 vac) contact closure: polarity not critical reed switch flow meter polarity not critical in- flow mtr 1 flow mtr 2 in+ in- flow sw 1 in+ in- in+ +5v blk red cond t- t+ bleed n.C. Feed n.O. N.C. N.O. L2 l2 l1 l2/n hall effect flow ...

Page 13

10 figure 4a wct400 outputs bleed solenoid/ motorized ball valve bleed n.C. Feed n.O. N.C. N.O. Pump bleed n.C. Feed n.O. N.C. N.O. L2 l2 l1 l2/n ground stud blk 120v brn 240v wht 120v blu 240v grn 120v grn/yel 240v if motorized ball valve blk 120 brn 240v w h t 1 20 v bl u 2 40 v g r n 1 2 0 v g r ...

Page 14

11 figure 4b wct410 outputs pump(s) bleed solenoid/ motorized ball valve alarm l1 l2/n l2 l2 l2 l2 l2 l2 bleed n.C. N.O. N.C. Boi 1 n.O. N.C. Feed n.C. Bio 2 n.O. N.C. N.O. N.O. Alarm n.C. N.O. L2/n l2/n l2/n l2/n l2/n l2/n bleed n.C. N.O. N.C. Bio 1 n.O. N.C. Feed n.C. Bio 2 n.O. N.C. N.O. N.O. Ala...

Page 15: Cooling Tower Controller

12 4.0 function overview 4.1 front panel figure 5 front panel 4.2 display a summary screen is displayed while the wct controller is on. This display shows a bar graph of the conductivity relative to the set point, the actual conductivity value, and current operating conditions. The center of the bar...

Page 16

13 4.3 keypad the keypad consists of 4 directional arrow keys and 4 function keys. The arrows are used to move the adjustment cursor and change settings, while the function keys are used to enter values, and navigate the various menu screens. The function keys are enter, exit, next, and prev (previo...

Page 17

14 5.0 operation these units control continuously while power is applied. Programming is accomplished via the local keypad and display. To view the top level menu, press any key. The menu structure is grouped by inputs and outputs. Each input has its own menu for calibration and unit selection as ne...

Page 18

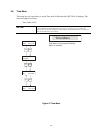

15 figure 7 main menu 20 0 0 s 67° f condu ctivi ty 2 000 s 6 7 °f t e mperature 20 0 0 s 6 7 °f bleed o f f 2000 s 6 7 °f feed off 2 000 s 67° f wm1 0 g a l main menu pos s ible statu s scree n s pr ess enter key to enter m e nu. Pre s s ex it k e y t o e x it m e nu. Blin k ing fie lds ma y b e ed...

Page 19

16 5.2 conductivity menu the conductivity menu provides the following settings: calibration, self test, unit selection, and sampling mode setup. Additional settings are also discussed below. Refer to figure 8, conductivity menu chart. Calibrate to calibrate the conductivity, use either a hand held m...

Page 20

17 figure 8 conductivity menu calibrate s 2000 self test cond 1000 s self test cond 666 ppm units s/cm s units ppm ppm sample mode c continuous sample mode i intermittent . . . . Warning . . . . Adjust set point cond 1000µs calibrate 2000 s 68° f conductivity cond 1000µs self test cond 1000µs units ...

Page 21

18 5.3 temperature menu the temperature menu contains the following settings: calibration and units (if the temp element is detected when the unit is powered on) or manual temp and units (if no temp sensor is detected at power up). Refer to the temperature menu chart, figure 9. If a "temp error" mes...

Page 22

19 5.4 bleed menu the bleed menu provides the following settings: set point, dead band, bleed mode, bleed vol, makeup vol, hoa. The bleed menu will be indicated on the display by one of the following: (the 'a' indicates that the output is being controlled automatically.) hint: for easiest programmin...

Page 23

20 figure 10 bleed menu 20 00 s 6 8 ° f ble ed 1:0 1 :1 5 bl ee d 1: 01: 15 se t p o int 2 0 0 0 bl ee d 1: 01: 15 dea d b and 20 0 bl ee d 1: 01: 15 b le ed mo de h ble ed mod e h hig h s e t poin t bl e ed mo de l l o w set po in t bl ee d 1:0 1 :1 5 hand off > aut o ble ed off b leed l o c ko ut ...

Page 24

21 5.5 feed menu the feed menu adapts to the selected feed output mode. Hint: for easiest programming, program feed mode first, then step through the rest of the feed parameters. The modes are defined as follows: a bleed and feed with optional lockout bleed and feed mode turns the feed output on and...

Page 25

22 feed based on water contactor mode time/cont. (time per contact.) this determines the length of time that the feed pump should be on for each contact that is received. ÷ contacts by this setting allows a divider to be entered. The divider will count actual contacts from the meter until the settin...

Page 26

23 figure 11 feed menu 2 1 1 2 feed chem feed mode timeout feed timeout hand off >auto 2000 s/cm 68° f feed 21:05 a feed off feed 21:05 feed lockout feed no flow feed menu possible status screens press enter key to enter menu. Press exit key to exit menu. Blinking fields may be edited with the adjus...

Page 27

24 5.6 wm1 and wm2 menus the water meter 1 and 2 menus are used to set up the type of meter and how to convert the water meter signal into volume. The water meter menus will be indicated on the display as follows: wm1 100 gal or liters reset total this allows you to restart the totalizer display. Pr...

Page 28

25 5.7 bio1 and bio2 menus these menus are only available on the wct410 controller. The bio 1 and bio 2 menus are separate from each other but operate in exactly the same way. Each menu provides the following independent settings: prog bio adds, bio pre-bleed, bio lockout time, set bio mode, hoa. Bi...

Page 29

26 prog bio 1 add press enter here to see a list of all of the biocide adds presently scheduled. The first screen displayed is for today's biocide add. Use the next key to see tomorrow's add or the prev key to see yesterday's add. Use the arrow keys to edit the starting time or length of the add. Th...

Page 30

27 figure 13 biocide 1 menu bio 1 add mode 1 week cycle bio 1 add mode daily adds bio 1 add mode 2 week cycle bio 1 add mode 4 week cycle bio 1 pre bld hand off >auto 2000 s 68° f bio 1 pre bld bio 1 prog bio 1 adds pre bld bio 1 pre bleed (µs) 1800 pre bld bio 1 lockout (h) 2:00 pre bld bio 1 bio 1...

Page 31

28 figure 14 biocide 2 menu bio 2 add mode 1 week cycle bio 2 add mode 2 week cycle bio 2 add mode 4 week cycle bio 2 pre bld hand off >auto 2000 s 68° f bio 2 pre bld bio 2 prog bio 2 adds pre bld bio 2 pre bleed (µs) 1800 pre bld bio 2 lockout (h) 2:00 pre bld bio 2 bio 2 add mode pre bld bio 2 10...

Page 32

29 5.8 time menu this menu has only one choice, to set the time used for biocide adds (wct410) or datalogs. This menu will appear as follows: time: 2mon 10:20 set time press enter to set the time. Use the arrow keys to adjust the day and time and then press enter to store or exit to discard. If eith...

Page 33

30 5.9 conductivity alarm menu this menu is available for both wct400 and wct410 series controllers, however, only the wct410 has a relay output for the alarm. On both units the settings here determine when the (l) and (h) indicators appear on the summary screen. The alarm menu screen will appear as...

Page 34

31 5.10 4-20ma menu this menu is only available if the 4-20ma output is installed in the controller. The 4-20ma output is available for either the wct400 or wct410 series controllers. This menu provides for scaling and calibrating the output. The 4-20ma menu screen appears as follows: 4-20ma 9.20ma ...

Page 35

32 5.11 access code menu this menu determines whether the access code feature of the controller is enabled or disabled and allows you to customize the access code to your own value. The access code controls whether or not you are allowed to change the parameters in the controller. With the access co...

Page 36

33 5.12 datalog menu this menu is available on both the wct400 and wct410, if the data logging option has been purchased. This is indicated in the model code by the letter u at the end of the model code. This menu allows you to save data from the controller to a usb flash drive. The controller has f...

Page 37

34 5.13 config menu this menu is available on both the wct400 and wct410 models. It allows you to export a file that contains all of the set points in the controller to a usb flash disk drive, and then later import the set points into another controller. Export config place a usb flash drive with at...

Page 38

35 5.14 upgrade menu this menu is available in both wct400 and wct410 models. It is used to upgrade the software to a newer version. If a new version of the software is available, an upgrade file will be posted on our web site. Save this file to a usb flash disk drive. It needs to be the only execut...

Page 39

36 6.0 maintenance the wct controller itself requires very little maintenance. Wipe with a damp cloth. Do not spray down the controller unless the enclosure door is closed and latched. 6.1 electrode cleaning note: the controller must be recalibrated after cleaning the electrode. Frequency the electr...

Page 40

37 6.2 replacing the fuses caution: disconnect power to the controller before opening front panel! Locate the fuses on the circuit board at the back of the controller enclosure. (see figure 3.) gently remove the old fuse from its retaining clip and discard. Press the new fuse into the clip, secure t...

Page 41

38 bleed timeout this error condition will stop conductivity control. It is caused by the bleed output being activated for longer than the programmed bleed time limit. Possible cause corrective action programmed value too low for normal conditions. Increase bleed time limit. Bleed flow rate too low....

Page 42

39 7.3 procedure for evaluation of conductivity electrode can be used for troubleshooting low conductivity, high conductivity, conductivity stuck at 0, and/or conductivity stuck at a number other than 0. Try cleaning the electrode first (refer to sect. 6.1). To find out if the electrode or the contr...

Page 43

40 wct400 wct410 voltage 1 = 120 vac, prewired 5 = 100-240 vac, conduit output n = no data output 4 = single 4-20 ma output 2 = dual 4-20 ma output (wdt) sensor n = no electrode wct400/410 1 = pp/graphite electrode & tee, 20ft. (6.1m) cable (for in-line or submersion mounting) 2 = pp/graphite electr...