- DL manuals

- Walchem

- Controller

- WDIS Series

- Instruction Manual

Walchem WDIS Series Instruction Manual

Summary of WDIS Series

Page 1

Wdis series disinfection controller instruction manual walchem corporation five boynton road hopping brook park holliston, ma 01746 usa tel: 508-429-1110 fax: 508-429-7433 web: www.Walchem.Com w a l c h e m wdis controllers.

Page 2

Notice ©2008 walchem corporation 5 boynton road, holliston, ma 01746 usa (508) 429-1110 all rights reserved printed in usa proprietary material the information and descriptions contained herein are the property of walchem corporation. Such information and descriptions may not be copied or reproduced...

Page 3

Table of contents 1.0 introduction ..................................................................................................................................... 1 2.0 specifications..................................................................................................................

Page 4

New access code.......................................................................................................................................... 26 6.0 maintenance ..................................................................................................................................

Page 5

1 1.0 introduction the walchem wdis series controllers are wall mount disinfection controllers that provide two relays used to perform on/off control of chlorine, chlorine dioxide, ozone or peracetic acid. Two additional relays are available for use as alarms or probe washing. A fifth output is used...

Page 6

2 2.2 electrical: input/output input power (controller) 110-120vac or 220-240vac 50/60 hz, 10a or 50/60 hz, 5a input signal controller sensor input ±1400 mv interlock (optional) isolated dry contact closure required (i.E., flow, level, etc.) output control 1/2 (on/off) internally powered relays @ 12...

Page 7

3 3.0 unpacking and installation 3.1 unpacking the unit inspect the contents of the carton. Please notify the carrier immediately if there are any signs of damage to the controller or its parts. Contact your distributor if any of the parts are missing. The carton should contain a wdis controller and...

Page 8

4 6. Push the cable onto the end of the sensor, aligning the pins with the holes. Turn the connector until hand tight to seal the cable connection. Flow cell placement instructions for mounting the sensor into the process can vary greatly with the circumstances that are encountered in your applicati...

Page 9

5 3.4 icon definitions symbol publication description iec 417, no.5019 protective conductor terminal iec 417, no. 5007 on (supply) iec 417, no. 5008 off (supply) iso 3864, no. B.3.6 caution, risk of electric shock iso 3864, no. B.3.1 caution nut, p/n 102586 body, p/n 191279-r o-ring, p/n 102594 sens...

Page 10

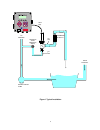

6 isolation valve (normally open) 1 2 3 4 5 6 7 8 9 10 1/4" npt rotameter 30-100 lph recirculation pump from process 20 ft (6m) 3/4" npt to process figure 1 typical installation.

Page 11

7 typical installation using walchem manifold sample valve flow control valve water in water out to open atmosphere rotameter flow cell flow switch sensor.

Page 12: Caution

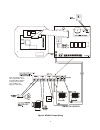

8 3.5 electrical installation based on the model number, the following voltages are required: wdis3xx-1xx 120 vac, 50/60 hz, prewired wdis3xx-4xx 120 vac, 50/60 hz, hardwired wdis3xx-5xx 240 vac, 50/60 hz, hardwired the various standard wiring options are shown below. Your wdis series controller wil...

Page 13

9 figure 2 conduit/wiring options power ctrl 2 ctrl 1 supply alarm aux 1 aux 2 inputs outputs optional input 4-20 ma (optional) side view bottom view optional input sensor input wdis prewired option bottom view 4-20 ma output optional optional sensor (optional) input input input strain reliefs (230 ...

Page 14

10 neu neutral hot f2 tb3 tb2 f1 (grounding stud) inputs + _ 4-20ma (optional 4-20 ma board) com ph+ flow switch fm to grounding stud -5 wfcb wcdb wozb wpab front panel power supply wh t re d bl a c k figure 3 wiring to sensor.

Page 15

11 figure 4 wdis310 output wiring note: the alarm relay is non-programmable. Refer to the main menu diagram on page 14 for the list of error conditions that trigger the alarm relay..

Page 16

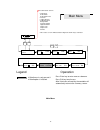

12 4.0 function overview 4.1 front panel 4.2 display a summary screen is displayed while the wdis controller is on. This display shows a bar graph of the oxidizer process value relative to the set points, a digital display of the process value, and the current operating conditions. Towards the cente...

Page 17

13 4.3 keypad the keypad consists of 4 directional arrows and 4 function keys. The arrow keys are used to move the adjustment cursor and change settings, while the function keys are used to enter values, and navigate the various menu screens. The function keys are enter, exit, next and prev (previou...

Page 18

14 normal startup startup is a simple process once your set points are in memory. Simply check your supply of chemicals, turn on the controller, calibrate the sensor if necessary and it will start controlling. 4.6 shutdown to shut the wdis controller down, simply turn off the power switch. Programmi...

Page 19

15 cl2 1.00ppm sensor cl2 1.00ppm ctrl 1 a 11:40 possible status screens * probe error probe wash probe wash hold * interlock * output timeout * calibration time range alarm in range output high/low alarm output 1 on output 2 on normal * these status screens indicate that the diagnostic alarm relay ...

Page 20

16 5.2 sensor menu the sensor menu provides the following settings: calibration history (informational only), 1 point calibration, zero calibration, sensor type selection, and other sensor setup menus. Each is discussed in detail below. Refer to the sensor menu chart on the next page. Note : if you ...

Page 21

17 . . . . Warning . . . . Check set points sensor cal'd mar/10/96 1.00 ppm sensor calibrate 1.00 ppm sensor zero calibration 1.00 ppm zero readn -5.0 mv enter when stable sensor days btwn cal 7 1.00 ppm sensor type cl2 cl2 sensor type cl2 clo2 sensor type cl2 ozone buffer set din din 6.75, 9.23 . ....

Page 22

18 input this menu displays the mv from the sensor. It is useful for troubleshooting. The sensor should be around 0 mv at 0 ppm and –100 mv per ppm (if chlorine, chlorine dioxide or ozone) or –10 mv per ppm (if peracetic acid). Self test press enter to perform a self-test. If it says "fail" in the u...

Page 23

19 is insufficient may be installed in the line, so that if flow past the sensor stops, the controller will not pump in chemicals based on a stagnant sample. Similarly, a level switch may be attached to prevent control of an empty batch tank. Control dir press enter to change the direction of contro...

Page 24

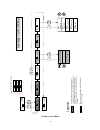

20 c l2 1. 00p pm c trl 1 1: 01 :1 5 ctrl 1 1 :0 1 :15 hi se t point 8 .00 ctrl 1 1 :01: 15 in terlo c k n ctrl 1 1:01 :1 5 lo set point 6 .00 c trl 1 1 :0 1 :1 5 c o n tro l dir h c trl 1 1 :01 :15 t im e limit 0 :00 c trl 1 1 :0 1 :1 5 ha nd off > a ut o c o ntrol d ir h h igh se t p o in t c ont ...

Page 25

21 5.4 auxiliary 1 and 2 menu the aux 1 and 2 relays may be configured to operate in a number of ways. They may be a low alarm, high alarm, an out-of-range alarm, an in-range output, or a probe wash. The aux 1 and 2 menus provides the following settings, which only appear if the appropriate output m...

Page 26

22 probe wash sched only appears if the probe wash mode has been selected. Press enter to program the probe wash schedule. The display may read "event a 12:00 20" which indicates that the probe wash will start at noon and the pump will run for 20 seconds. Use the arrow keys to change the time of day...

Page 27

23 cl2 1.0 0 p p m a u x 1 o f f a aux 1 o f f lo al arm pt 2. 0 0 a u x 1 off ho ld t im e 1:0 0 aux 1 o f f hi ala rm pt 1 0 .00 a u x 1 off m o de a u x 1 off p rob e w a s h s c h e d p rob e w a sh sc he d ev ent a 1 2 :00 99 p rob e w a sh sc he d ev ent j 12 :00 9 9 mod e lo w al ar m mod e o...

Page 28

24 5.5 4-20 ma menu (optional) this menu will only appear if the optional 4-20 ma output board is installed. It is used to set the scale of the 4-20 ma output. It contains the following menu selections: 4 ma point, 20 ma point, and calibrate. 4 ma pt use the arrow keys to enter the process value, in...

Page 29

25 5.6 clock menu the clock menu is used to set the date and time that the controller uses to schedule probe washing and calibration prompts. There is only one menu selection: set clock. Set clock press enter to set the clock. Use the arrow keys to change the year, date, and month, then press enter ...

Page 30

26 5.7 access code menu this menu determines whether the access code feature of the controller is enabled or disabled and allows you to customize the access code to your own value. The access code controls whether or not you are allowed to change the parameters in the controller. With the access cod...

Page 31

27 cl2 1.00ppm access code dis any top display access code 0000 access code dis enable n access code dis enable y access code dis new access code 0 access code dis value 1234 access code req access code ok access code menu possible status screens the access code prompt may appear at any screen in th...

Page 32

28 6.0 maintenance the wdis control module itself needs very little maintenance. Clean the outside of the controller enclosure with a damp cloth. Do not spray down the controller unless the enclosure door is closed and latched. "pigtails" should be protected from spray or wash-down. Check the cords ...

Page 33

29 6.2 replacing the fuses caution : disconnect power to the controller before opening front panel! Locate the fuses on the circuit board at the back of the controller enclosure. (see figure 3.) gently remove the old fuse from its retaining clip and discard. Press the new fuse into the clip, secure ...

Page 34

30 bad zero cal fail the zero calibration will fail if the mv reading from the sensor is outside of the range –100 to 100 mv. If the actual concentration is actually zero, refer to the sensor’s instruction manual for troubleshooting. Output timeout this error message appears if one of the control ou...

Page 35

31 probe error this error message appears if the sensor input signal is outside of the normal range. This usually indicates that the sensor has been disconnected or is faulty. It could appear under normal conditions if the cl2, clo2 or ozone is outside of the operating range of 0 to 10 ppm, or if th...