- DL manuals

- Walchem

- Controller

- WDP340

- Instruction Manual

Walchem WDP340 Instruction Manual

Summary of WDP340

Page 1

Wph/wdp series ph & orp controllers instruction manual walchem corporation five boynton road hopping brook park holliston, ma 01746 usa tel: 508-429-1110 fax: 508-429-7433 web: www.Walchem.Com w a l c h e m wph/wdp controllers.

Page 2

Notice © 2008 walchem corporation 5 boynton road, holliston, ma 01746 usa (508) 429-1110 all rights reserved printed in usa proprietary material the information and descriptions contained herein are the property of walchem corporation. Such information and descriptions may not be copied or reproduce...

Page 3

Table of contents 1.0 introduction........................................................................................................................ 1 2.0 specifications ..................................................................................................................... 2 2.1 ...

Page 4

1 1.0 introduction the walchem wph series single sensor input and wdp series dual sensor input controllers are wall mount ph/orp controllers that are available in on/off or modulated pulse proportional versions. They are available with four on/off control relays (wph410 or wdp410) with two modulated...

Page 5

2 2.0 specifications 2.1 measurement performance ph range -2 to 16 ph units ph resolution 0.0015 ph units (0.01 ph displayed) ph accuracy (calibrated): ± .01 ph orp range -1500 to 1500 mv orp resolution 92 µv (1mv displayed) orp accuracy ±1 mv temp comp (optional): 100 or 1000 ohm platinum rtd tempe...

Page 6

3 2.3 mechanical enclosure material polycarbonate nema rating nema 4x dimensions 8.5" x 6.5" x 5.5" display 2 x 16 character backlit liquid crystal operating ambient temp 32 – 122°f (0 – 50°c) storage temperature -20 – 180°f (-29 – 80°c) flow switch manifold temperature rating 140°f (60°c) max flow ...

Page 7

4 3.0 unpacking & installation 3.1 unpacking the unit inspect the contents of the carton. Please notify the carrier immediately if there are any signs of damage to the controller or its parts. Contact your distributor if any of the parts are missing. The carton should contain: a wph/wdp series contr...

Page 8

5 for submersion applications, mount the electrode below the minimum solution level. If the tank will be completely emptied, plan on removing the electrode and storing it in tap water (not di water) or ph 4 buffer solution while the tank is empty. If this is not desirable, a recirculation loop may b...

Page 9

6 acid base submersion electrode ph probe ac power flow out flow in ph/orp controller w a l c h e m circulating pump solenoid valve cooling tower water meter ph electrode flow switch ph/orp controller w a l c h e m ph electrode flow switch figure 1 typical installation installation with submersion e...

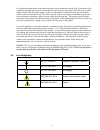

Page 10: Caution

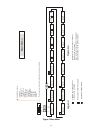

7 3.5 electrical installation the various standard wiring options are shown in figure 2. Your wph series controller will arrive from the factory prewired or ready for hardwiring. Depending on your configuration of controller options, you may be required to hardwire some or all of the input/output de...

Page 11

8 power ctrl 2 ctrl 1 ph/orp 2 flow switch 2 alarm ctrl 4 ctrl 3 ph/orp 1 flow switch 1 4-20ma 1 4-20ma 2 power ctrl 2 ctrl 1 ph/orp 2 flow switch 2 alarm ctrl 4 ctrl 3 ph/orp 1 flow switch 1 4-20ma 1 4-20ma 2 plug figure 2b wph420 conduit wiring power ctrl 4 ctrl 3 flow switch (optional) ctrl 1 ctr...

Page 12

9 power ctrl 2 ctrl 1 ph/orp 2 flow switch 2 alarm ctrl 4 ctrl 3 ph/orp 1 flow switch 1 4-20ma 1 4-20ma 2 plug figure 2e wdp440 conduit wiring.

Page 13

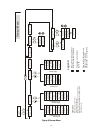

10 power supply (115 vac or 230 vac) contact closure: polarity not critical interlock function +5v t- t+ g r e e n w h it e /g r n ground stud shield l1 l2/n g r n 1 20 v g r n /y e l 2 40 v wht 120v blu 240v b l k 1 2 0 v b r n 2 4 0 v in+ in- +5 v -5 v -5v in+ in- o r n w h it e /o r n b l u w h i...

Page 14

11 power supply (115 vac or 230 vac) contact closure: polarity not critical interlock function +5v t- t+ ground stud l1 l2/n g r n 1 20 v g r n /y e l 2 40 v wht 120v blu 240v b l k 1 2 0 v b r n 2 4 0 v in + in - +5 v -5 v -5v in+ in- in- dig in 2 dig in 3 in+ in- dig in 1 in+ in- in+ dig in 4 in+ ...

Page 15

12 power supply (115 vac or 230 vac) ground stud l1 l2/n g r n 1 20 v g r n /y e l 2 40 v wht 120v blu 240v b l k 1 2 0 v b r n 2 4 0 v +5v t- t+ g r e e n w h it e /g r n shield -5v in+ in- o r n w h it e /o r n b l u w h it e /b l u wel electrode diffamp housing (102581, 102606, 102582,102607, 102...

Page 16

13 power supply (115 vac or 230 vac) contact closure: polarity not critical interlock function ground stud l1 l2/n g r n 1 20 v g r n /y el 2 40 v wht 120v blu 240v b l k 1 2 0 v b r n 2 4 0 v in + in - +5v -5 v in- dig in 2 dig in 3 in+ in- dig in 1 in+ in- in+ dig in 4 in+ in- dig in 5 in+ in- in-...

Page 17

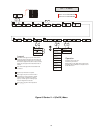

14 pump solenoid/ motorized ball valve alarm l1 l2/n l2 l2 l2 l2 l2 l2 bleed n.C. N.O. N.C. Boi 1 n.O. N.C. Feed n.C. Bio 2 n.O. N.C. N.O. N.O. Alarm n.C. N.O. L2/n l2/n l2/n l2/n l2/n l2/n ctrl 1 n.C. N.O. Com. Ctrl 3 n.O. N.C. Ctrl 2 com ctrl 4 n.O. Com n.O. N.O. Alarm com n.O. Ground stud w h t 1...

Page 18

15 pump(s) alarm l1 l2/n l2 l2 l2 l2 l2 l2 bleed n.C. N.O. N.C. Boi 1 n.O. N.C. Feed n.C. Bio 2 n.O. N.C. N.O. N.O. Alarm n.C. N.O. L2/n l2/n l2/n l2/n l2/n l2/n ctrl 1 + - n.C. Ctrl 3 - + ctrl 2 n.C. Ctrl 4 n.O. N.C. N.O. N.O. Alarm n.C. N.O. Ground stud chart recorder in+ in - +5v -5 v in - di g i...

Page 19

16 pump alarm blowdown solenoid/ motorized ball valve l1 l2/n l2 l2 l2 l2 l2 l2 bleed n.C. N.O. N.C. Boi 1 n.O. N.C. Feed n.C. Bio 2 n.O. N.C. N.O. N.O. Alarm n.C. N.O. L2/n l2/n l2/n l2/n l2/n l2/n ctrl 1 n.C. N.O. Ctrl 3 n.O. N.C. Ctrl 2 n.C. Ctrl 4 n.O. N.C. N.O. Alarm n.C. N.O. Ground stud wht 1...

Page 20

17 pump(s) alarm l1 l2/n l2 l2 l2 l2 l2 l2 bleed n.C. N.O. N.C. Boi 1 n.O. N.C. Feed n.C. Bio 2 n.O. N.C. N.O. N.O. Alarm n.C. N.O. L2/n l2/n l2/n l2/n l2/n l2/n ctrl 1 + - n.C. Ctrl 3 - + ctrl 2 n.C. Ctrl 4 n.O. N.C. N.O. N.O. Alarm n.C. N.O. Ground stud f1 grn 120v grn/yel 240v w h t 120v bl u 24 ...

Page 21

18 4.0 function overview 4.1 front panel figure 5 front panel 4.2 display a summary screen is displayed while the wph/wdp controller is on. If you have a single sensor (wph), this display will show a bar graph of the ph/orp relative to the set point, the numeric sensor reading, and current operating...

Page 22: Normal

19 figure 6 summary screens 4.3 keypad the keypad consists of 4 directional arrow keys and 4 function keys. The arrows are used to move the adjustment cursor and change settings, while the function keys are used to enter values, and navigate the various menu screens. The function keys are enter, exi...

Page 23

20 normal startup startup is a simple process once your set points are in memory. Simply check your supply of chemicals, turn on the controller, calibrate it if necessary and it will start controlling. 4.6 shut down to shut the controller down, simply turn off the power. Programming remains in memor...

Page 24

21 10 .2 0 ph 68° f sensor a 10 .20 ph 6 8 °f c trl 1 a 1 1 :40 pos s ib le st a tus screens * pr ob e erro r * t e mp sensor err probe w a sh probe w a sh hol d * interlock * o u tp u t t im e ou t * c a lib ra tio n t im e range ala rm in r a ng e ou tp u t hi gh/low al arm out p ut 1 o n out p ut...

Page 25

22 5.2 sensor menu the sensor menu provides the following settings: calibration history (informational only), 2 point calibration, 1 point calibration, ph/orp selection, and other calibration menus. Each is discussed in detail below. Refer to the sensor menu chart on the next page. Note: if you are ...

Page 26

23 continue y the controller will hold this display until you have replaced the electrode in the process, and press enter. Control will not begin until enter is pressed, or 10 minutes go by. If calibration failed, control will begin using old calibration setpoints. If using manual temperature compen...

Page 27

24 second buffer this is a prompt to place the electrode in the second buffer. Again, in a few seconds the controller will automatically go to the next step. Input xxx mv the display will show the mv reading from the electrode. The entire number will blink until the reading is stable, then the displ...

Page 28

25 if using manual temperature compensation, the first display will be: cal temp °f/c 68 use the arrow keys to enter the actual temperature of the buffer solutions. Press enter to go on to the next step. If using automatic temperature compensation, this display will not appear. Rinse electrode remov...

Page 29

26 sensor mv this menu displays the mv from the electrode. It is useful for troubleshooting. Self test press enter to perform a self-test. If it says "fail" in the upper right hand corner, this indicates a problem with the controller which should be returned for repair. If it passes, and you have a ...

Page 30

27 . . . . W a r n in g . . . . Chec k set p o in ts s e ns or 1 0 .00ph c a l'd mar/1 0 /9 6 se ns or 10. 00 ph 2 pt ca lib ra tio n 2 p t cal ib rat ion r ins e el ec tr o d e 2 p t cal ib rat ion sec ond bu ff er % d if fere n c e -1 .3 % 2 p t cal ib rat ion 2 p t cal ib rat ion f irst bu ff er ...

Page 31

28 5.3 temperature menu (this menu does not appear if an orp sensor has been selected) the temperature menu contains the following settings: calibrate and units (if the pt100 or pt1000 sensor is detected when the unit is powered on) or manual temp and units (if no pt100 or pt1000 sensor is detected ...

Page 32

29 5.4 control 1 - 4 menus (for on/off controllers) the description of the menus for relay outputs will apply to control 1 2, 3, and 4 for wph410 and wdp410 models, and to control 3 and 4 for wph420 and wdp420 models. The control 1 - 4 menus are separate from each other but operate in exactly the sa...

Page 33

30 time prop hi press enter when this is displayed to use time proportional control with a high set point. In time proportional mode, the farther away from the set point the system is, the longer the on time. Refer to the drawings below for an illustration of time proportional mode. A time limit men...

Page 34

31 this menu only appears if time proportional control mode is selected. The proportional band menu sets the deviation from set point at which the control output will be on for the entire sampling period. The volume added at the worst case deviation can be calculated by multiplying the pump flow rat...

Page 35

32 reset timer this menu only appears if the output mode has been selected as a low set point, or a high set point and the time limit has expired. Determine the reason that the output stayed on too long, and once the problem has been solved, press enter to reset the timer. Probe wash sched this menu...

Page 36

33 10.00 ph 68° f ctrl 1 1:01:15 a ctrl 1 off loalarmpt 2.00 a ctrl 1 1:01:15 mode lowsetpoint a ctrl 1 1:01:15 dead band 0.10 a ctrl 1 1:01:15 interlock n a ctrl 1 1:01:15 time limit 0:00 a ctrl 1 off ctrl 1 intrlck ctrl 1 timeout ctrl 1 - 4 menu possible status screens press enter key to enter men...

Page 37

34 5.5 control 1-4 menu (for proportional controllers) the description of the menus for pulse outputs will apply to control 1 2, 3, and 4 for wdp440 models, and to control 1 and 2 for wph420 and wdp420 models. The control menus are separate from each other but operate in exactly the same way. Each m...

Page 38

35 reset timer this menu only appears if the output mode has been selected as a low set point, or a high set point and the time limit has expired. Determine the reason that the output stayed on too long, and once the problem has been solved, press enter to reset the timer. Assign input press enter t...

Page 39

36 5.6 interlock a menu this menu only appears in wdp models. The interlock a menu is used to assign an interlock device to the appropriate sensor. An interlock device is an external monitoring sensor like a flow or level switch that serves to deactivate control outputs when activated. For example, ...

Page 40

37 5.7 4-20 ma 1 and 2 menus (optional) these menus will only appear if the optional 4-20 ma output board(s) is installed. They are used to set the scale of the 4-20 ma output. It contains the following menu selections: assign inputs, 4 ma point, 20 ma point, and calibrate. Note: when programming th...

Page 41

38 5.8 time menu the time menu is used to set the date and time that the controller uses to schedule probe washing and calibration prompts. There is only one menu selection: set clock. Set clock press enter to set the clock. Use the arrow keys to change the year, date, and month, then press enter. U...

Page 42

39 5.9 access code menu this menu determines whether the access code feature of the controller is enabled or disabled and allows you to customize the access code to your own value. The access code controls whether or not you are allowed to change the parameters in the controller. With the access cod...

Page 43

40 5.10 datalog menu this menu is available if the data logging option has been purchased. This is indicated in the model code by the letter u at the end of the model code. This menu allows you to save data from the controller to a usb flash drive. The controller has four logs, the current datalog, ...

Page 44

41 datalog current datalog datalog copy event log datalog menu enter exit 67° f datalog 7.00 ph datalog transfer success next prev datalog copy reset log next prev enter exit enter exit enter exit datalog transfer success datalog transfer success possible status screens transfer success transfer fai...

Page 45

42 5.11 config menu this menu allows you to export a file that contains all of the set points in the controller to a usb flash disk drive, and then later import the set points into another controller. Place a usb flash drive with at least 10 mb capacity into the usb port on the front panel of the co...

Page 46

43 config export config config import config config menu enter exit 67° f config 7.00 ph config transfer success config entr selects cfg next prev config import success any key to reboot entr selects cfg ucf.Ini enter exit enter exit enter exit enter exit possible status screens transfer success tra...

Page 47

44 5.12 upgrade menu this menu is used to upgrade the software to a newer version. If a new version of the software is available, an upgrade file will be posted on our web site. Save this file to a usb flash disk drive. It needs to be the only upgrade file stored on the root directory of the stick. ...

Page 48

45 6.0 maintenance the wph/wdp control module itself needs very little maintenance. Clean the outside of the controller enclosure with a damp cloth. Do not spray down the controller unless the enclosure door is closed and latched. "pigtails" should be protected from spray or wash-down. Check the cor...

Page 49

46 6.2 replacing the fuses caution: disconnect power to the controller before opening front panel! Locate the fuses on the circuit board at the back of the controller enclosure. (see figure 4.) gently remove the old fuse from its retaining clip and discard. Press the new fuse into the clip, secure t...

Page 50

47 high alarm this error message appears if the ph/orp reading exceeds the set point for one of the control outputs that has been configured as a high alarm output. There are a number of possible causes for this condition: possible cause corrective action the process went further out of control than...

Page 51

48 out range alarm this error message appears if the ph/orp reading is outside of the range selected for one of the control outputs that has been programmed as an "out of range alarm". Refer to the possible causes and corrective actions listed above for the "high alarm" error message. In range outpu...