- DL manuals

- Walchem

- Controller

- WDT400 Series

- Instruction manual

Walchem WDT400 Series Instruction manual

Summary of WDT400 Series

Page 1

Wdt400 controllers w a l c h e m iw aki america inc. Wdt400 series dual cooling tower conductivity controller instruction manual five boynton road hopping brook park holliston, ma 01746 usa tel: 508-429-1110 fax: 508-429-7433 web: www.Walchem.Com.

Page 2

Notice © 2014 walchem, iwaki america inc.(hereinafter “walchem”) five boynton road, holliston, ma 01746 usa (508) 429-1110 all rights reserved printed in usa proprietary material the information and descriptions contained herein are the property of walchem. Such information and descriptions may not ...

Page 3

Table of contents 1.0 introduction..................................................................................................................... 1 2.0 specifications .................................................................................................................. 2 2.1 measur...

Page 4

1.0 introduction the walchem wdt400 series controllers offer conductivity control of cooling tower water and control of corrosion/scale inhibitor feed. The inhibitor pump may be selected to operate in one of the following modes: feed and bleed feed and bleed with lockout feed as a percent of bleed f...

Page 5

2.0 specifications 2.1 measurement performance conductivity range 0 - 10,000 µs/cm (microsiemens/centimeter) conductivity resolution 1 µs/cm conductivity accuracy 10 - 10,000 µs/cm ± 1% of reading 0 - 10 µs/cm ± 20% of reading temperature range 32 – 158°f (0 – 70°c) temperature resolution 0.1°c temp...

Page 6

2.4 wdt variables and their limits low limit high limit conductivity menu ppm conversion factor 0.200 ppm/µs/cm 1.000 ppm/µs/cm interval time (sampling) 5 minutes 24:00 hours duration time (sampling) 1 minute 59 min: 59 sec % calibration range -50 +50 temperature menu no variables bleed menu set poi...

Page 7

3.0 unpacking & installation 3.1 unpacking the unit inspect the contents of the carton. Please notify the carrier immediately if there are any signs of damage to the controller or its parts. Contact your distributor if any of the parts are missing. The carton should contain: a wdt400 series controll...

Page 8

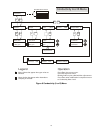

Cooling tower bleed metering valve pump heat exchanger system a cooling tower controller www.Wal chem.Com pre v n ext enter ex t cooling tower bleed valve metering pump heat exchanger system b figure 1 typical installation 5.

Page 9: Caution

3.4 icon definitions symbol publication description iec 417, no.5019 protective conductor terminal iec 417, no. 5007 on (supply) iec 417, no. 5008 off (supply) iso 3864, no. B.3.6 caution, risk of electric shock iso 3864, no. B.3.1 caution 3.5 electrical installation the various standard wiring opti...

Page 10

Bleed b feed b spares 4-20 ma (2) (optional) conductivity electrode b conductivity electrode a flow switch a (optional) power bleed a alarm 4-20 ma (1) (optional) flow meter b (optional) flow switch b (optional) flow meter a (optional) feed a figure 2 conduit/wiring configuration 7.

Page 11

G r e e n w h it e gr n 1 20 v gr n /y e l 2 40 v b lk 120v b r n 2 40 v g r e e n w h it e r- r+ r- r+ l2 l2 bleed n.C. N.O. Feed n.C. N.O. F1 l1 l2/n f2 ground stud co nd t+ t - re d bl k +5 v fl o w s w 1 f l o w sw 2 fl o w m tr 2 fl o w m tr 1 in + in in+ in in+ in in+ cond red bl k +5 v t+ t...

Page 12

System a system b chart chart recorder recorder bleed feed boi 1 bio 2 alarm l2 l2 l2 l2 l2 l2 n.C. N.O. N.C. N.O. N.C. N.O. N.C. N.O. N.C. N.O. N.C. N.O. Co nd t+ t re d bl k +5 v fl o w sw 1 fl o w sw 2 fl o w m t r 1 fl o w m t r 2 in + in in + in in + in + in co n d t+ t re d bl k +5 v l1 l2/n...

Page 13

4.0 function overview 4.1 front panel on/off power switch backlit lcd display output leds setting adjustment keys menu/function keys usb connector usb led figure 5 front panel 4.2 display a summary screen is displayed while the wdt controller is on. This display shows the conductivity of tower a on ...

Page 14

4.3 keypad the keypad consists of 4 directional arrow keys and 4 function keys. The arrows are used to move the adjustment cursor and change settings, while the function keys are used to enter values, and navigate the various menu screens. The function keys are enter, exit, next, and prev (previous)...

Page 15

5.0 operation these units control continuously while power is applied. Programming is accomplished via the local keypad and display. To view the top level menu, press any key. The menu structure is grouped by inputs and outputs. Each input has its own menu for calibration and unit selection as neede...

Page 16

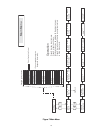

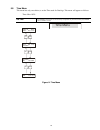

Possible st at us sc reens main menu figure 7 main menu 13 a 100 0 b 1000 no rma l exi t en t e r to w e r a a 1000 b 1000 exi t en t e r a 1000 s 7 7 °f co nductivity *t em p e rr a *t em p e rr b *c o nd e rr a *c ond er r b *n o fl ow a *no f low b *bl e ed t ime out a *b leed t ime o u t b *fee ...

Page 17

5.2 conductivity (a or b) menu the conductivity menu provides the following settings: calibration, self test, unit selection, and sampling mode setup. Additional settings are also discussed below. Refer to figure 8, conductivity menu chart. Calibrate to calibrate the conductivity, use either a hand ...

Page 18

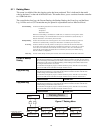

Possible status screens conductivity a or b menu calibrate cond 2000 s/cm cond self test 1000 s/cm cond self test 1000 ppm units s/cm s/cm units ppm ppm sample mode c continuous sample mode i intermittent . . . . Warning . . . . Adjust set point cond 2000 calibrate s a: 2000 s 68° f conductivity co...

Page 19

5.3 temperature (a or b) menu the temperature menu contains the following settings: calibration and unit selection . The temperature menu will be indicated on the display by one of the following: temperature normal operation temp 70°f normal operation temp error indicates that there is a problem wit...

Page 20

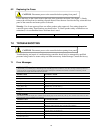

5.4 bleed (a or b) menu the bleed menu provides the following settings: set point, dead band, control direction, hoa. The bleed menu will be indicated on the display by one of the following: (the 'a' indicates that the output is being controlled automatically.) bleed a off indicates that the bleed o...

Page 21

5.5 feed (a or b) menu the feed menu adapts to the selected feed output mode. Hint: for easiest programming, program feed mode first, then step through the rest of the feed parameters. The modes are defined as follows: a bleed and feed with optional lockout b feed % of bleed c feed % of time d feed ...

Page 22

Time limit this setting puts a limit on the amount of time that can be accumulated by the water meter input. Once this setting has been reached, all contacts will be ignored until the accumulated feed time expires. By setting time limit = time/cont., the accumulation of contacts can be disabled. Fee...

Page 23

5.6 wm1 and wm2 menu the water meter 1 and 2 menus are used to set up the type of meter and how to convert the water meter signal into volume. The water meter menus will be indicated on the display as follows: wm1 100 gal or liters reset total this allows you to restart the totalizer display. Press ...

Page 24

5.7 alarm (a or b) menu the alarm menu screen will appear as follows: alarm off alarm low alrm alarm hi alrm this is the % below the bleed set point that the low alarm will activate. If the set point is 1000 set % low and the % low setting is 20 then the low alarm will activate at 800. This is the %...

Page 25

5.8 time menu this menu has only one choice, to set the time used for datalogs. This menu will appear as follows: time: mon 10:20 set time press enter to set the time. Use the arrow keys to adjust the day and time and then press enter to store or exit to discard. 2000 s 68° f time sat 12:15 time sat...

Page 26

5.9 4-20ma (a or b) menu this menu is only available if the 4-20ma output is installed in the controller. Installing this option board in the left hand position in the controller will assign it to tower a. Installing a 4-20ma option board in the right hand position assigns the output to tower b. See...

Page 27

5.10 access code menu this menu determines whether the access code feature of the controller is enabled or disabled and allows you to customize the access code to your own value. The access code controls whether or not you are allowed to change the parameters in the controller. With the access code ...

Page 28

5.11 datalog menu this menu is available if the data logging option has been purchased. This is indicated in the model code by the letter u at the end of the model code. This menu allows you to save data from the controller to a usb flash drive. The controller has four logs, the current datalog, the...

Page 29

5.12 config menu this menu allows you to export a file that contains all of the set points in the controller to a usb flash disk drive, and then later import the set points into another controller. Export config place a usb flash drive with at least 10 mb capacity into the usb port on the front pane...

Page 30

5.13 upgrade menu this menu is used to upgrade the software to a newer version. If a new version of the software is available, an upgrade file will be posted on our web site. Save this file to a usb flash disk drive. It needs to be the only executable (.Exe file extension) file stored on the root di...

Page 31

6.0 maintenance the wdt controller itself requires very little maintenance. Wipe with a damp cloth. Do not spray down the controller unless the enclosure door is closed and latched. 6.1 electrode cleaning note: the controller must be recalibrated after cleaning the electrodes. Frequency the electrod...

Page 32

6.2 replacing the fuses caution: disconnect power to the controller before opening front panel! Locate the fuses on the circuit board at the back of the controller enclosure. (see figure 3.) gently remove the old fuse from its retaining clip and discard. Press the new fuse into the clip, secure the ...

Page 33

Temp error it indicates that the temperature signal from the conductivity electrode is no longer valid. The controller reverts to manual temperature compensation. Possible cause corrective action green or white electrode wire disconnected. Reconnect. Faulty electrode replace electrode. Cond error th...

Page 34

Cond low alarm this error message indicates that the conductivity is below the programmed percentage below set point. The conductivity will continue to be monitored, and the feed output will be allowed to be activated. Possible cause corrective action fouled conductivity electrode see conductivity e...

Page 35

7.4 procedure for checking relay outputs if any prewired output is not activating the device (pump, valve, etc.) attached to it: verify that the pump or valve is not faulty by plugging it directly into a wall socket. In some controllers, certain relays are not internally powered. Check the instructi...

Page 36

Model code wdt400 voltage output sensor u (usb) - voltage 1 = 120 vac, prewired 5 = 100-240 vac, conduit output n = no data output 4 = single 4-20 ma output 2 = dual 4-20 ma output (wdt) sensor n = no electrode wdt400 1 = two graphite electrodes & tees, (inline or submersion) 20ft. (6.1m) cable 2 = ...

Page 37

Five boynton road hopping brook park holliston, ma 01746 usa tel: 508-429-1110 fax: 508-429-7433 web: www.Walchem.Com.