- DL manuals

- Waldorf

- Kitchen Appliances

- PC8140G

- Installation And Operation Manual

Waldorf PC8140G Installation And Operation Manual

Summary of PC8140G

Page 1

I n s t a l l a t i o n a n d o p e r a t i o n m a n u a l gas pasta cooker pc8140g pcl8140g date purchased serial number dealer service provider 230008-10 for use in gb & ie.

Page 2

The reproduction or copying of any part of this manual by any means whatsoever is strictly forbidden unless authorized previously in writing by the manufacturer. In line with policy to continually develop and improve its products, moffat ltd. Reserves the right to change the specifications and desig...

Page 3

1 contents pc (l) 8140g gas pasta cooker (single tank - 40 ltr) introduction ............................................................................................. 2 specifications ........................................................................................... 3 model numbers cove...

Page 4

Introduction we are confident that you will be delighted with your waldorf gas pasta cooker and it will become a most valued appliance in your commercial kitchen. To ensure you receive the utmost benefit from your new waldorf appliance, there are two important things you can do. Firstly: please read...

Page 5

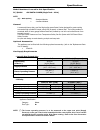

3 specifications model numbers covered in this specification pc [1] 8140g gas pasta cooker (single tank - 40 ltr) note: [1]: - back options; - - standard models. L - low back models. General a commercial heavy duty, gas fired high performance pasta cooker designed for pasta cooking commercial high p...

Page 6

4 specifications gas connection gas supply connection point is located 190 mm from the right hand side, 36 mm from the rear of the appliance and 124 mm from the floor and is entered from beneath the appliance. An optional rear connection is available. Connection is 3 / 4 ” bsp male. Water supply req...

Page 7

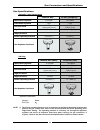

5 dimensions pc (l) 8140g.

Page 8

6 installation installation requirements note: • it is most important that this appliance is installed correctly and that operation is correct before use. Installation shall comply with local, gas, health and safety requirements. • this appliance shall be installed with sufficient ventilation to pre...

Page 9

7 installation 4. All air for burner combustion is supplied from underneath the appliance. The legs must always be fitted and no obstructions placed on the underside or around the base of the appliance, as obstructions will cause incorrect operation and / or failure of the appliance. 5. Components h...

Page 10

8 installation gas connection note: all gas fitting must only be carried out by a qualified service person. 1. Waldorf pasta cookers do not require an electrical connection, they function totally on the gas supply only. 2. It is essential that the gas supply is correct for the appliance to be instal...

Page 11

9 8. Turn ‘off’ the mains gas supply and bleed the gas out of the appliance gas lines. 9. Turn ‘on’ the gas supply and the appliance. 10. Verify the operating pressure remains correct 11. Check the pilot flame size. (re-adjust if required by changing the pilot injector. Refer to the gas conversion s...

Page 12

10 operation operation guide 1. Waldorf 'pasta cookers have been designed to provide simplicity of operation and 100% safety protection. 2. Improper operation is therefore almost impossible, however bad operation practices can produce a poor quality product. To use this pasta cooker correctly please...

Page 13

11 operation before use 1. Check that the gas supply is turned on. 2. Check that no foreign articles are in the tank. Filling the tank note: tank capacity - 40 ltrs of water. 1. Before filling the tank, always check that the drain valve behind the door is closed. A locking slide is provided on the v...

Page 14

12 lighting the pilot burner 1. With the pasta cooker tank full of water, the pilot burner can be lit. 2. Check that the gas supply is turned on at the mains supply. 3. Depress and rotate the gas control knob to the position marked ‘pilot’ and hold the knob depressed. 4. Open the front access door o...

Page 15

13 general clean the pasta cooker regularly. A clean pasta cooker looks better, will last longer and will perform better. A dirty pasta cooker will hinder the transfer of heat from the cooking surface to the food. This will result in loss of cooking efficiency. Note: • do not clean the appliance usi...

Page 16

14 after each use 1. Clean the interior of the pan regularly after each use. Do not use wire brushes on the pan. Clean using a mild detergent and a hot water solution using soft cloth or a soft bristled brush. Dry the appliance thoroughly using a dry clean cloth. Daily cleaning 1. The water should b...

Page 17

15 weekly cleaning note: • if the pasta cooker usage is very high, we recommend that the weekly cleaning procedure is carried out on a more frequent basis. • ensure that protective gloves are worn during the cleaning process. • do not use harsh abrasive detergents, strong solvents, sharp scrapers or...

Page 18

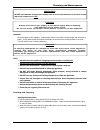

16 fault finding fault possible cause remedy pilot burners will not ignite or ignites with difficulty and will not stay alight. Check gas supply is turned on. Turn on gas supply. Check gas supply is low or empty. Replenish gas supply. Thermocouple connection loose. Tighten thermocouple connection. R...

Page 19

17 wiring schematics pc8140g pasta cooker.

Page 20

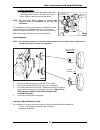

18 gas conversion and specifications conversion procedure note: • these conversions should only be carried out by qualified service persons. All connections must be checked for leaks before re-commissioning the appliance. • for all relevant information and specifications refer to the table at the en...

Page 21

19 gas conversion and specifications low fire adjustment a. To adjust the burner low fire adjustment, adjust the low fire adjustment screw on the open burner gas control valves to obtain the desired flame size. Note: the ‘low fire screw’ should be sealed with coloured paint on completion of the low ...

Page 22

20 gas conversion and specifications commissioning before leaving the converted installation; 1. Check all gas connections for leakages using soapy water or other gas detecting equipment. 2. Check the following functions in accordance with the operating instructions specified in the ‘operation’ sect...

Page 23

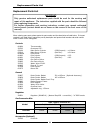

21 gas conversion and specifications gas specifications - australia / new zealand only: - uk only: appliance classification category: ii 2h3p. Flue type: a 1. Note: (*) the burner operating pressure is to be measured at the burner operating pressure test point on the gas control valve, this is to be...

Page 24

22 replacement parts list replacement parts list when ordering spare parts, please quote the part number and the description as listed below. If the part required is not listed below, request the part by description and quote model number and serial number which is shown on the rating plate. Control...

Page 25

23.