- DL manuals

- Waldorf

- Cooktop

- RN8510GC

- Installation And Operation Manual

Waldorf RN8510GC Installation And Operation Manual

Summary of RN8510GC

Page 1

I n s t a l l a t i o n a n d o p e r a t i o n m a n u a l rn8510gc rn8610gc rn8810gc gas range convection oven date purchased serial number dealer service provider 228680-19 rnl8510gc rnl8610gc rnl8810gc for use in gb, ie & dk.

Page 2

Manufactured by moffat limited christchurch new zealand international contacts australia moffat pty limited e.Mail: vsales@moffat.Com.Au main office: (tel) +61 (03) 9518 3888 (fax) +61 (03 9518 3833 service: (tel): 1800 622 216 spares: (tel): 1800 337 963 customer service: (tel): 1800 335 315 (fax):...

Page 3

1 waldorf gas convection oven range rn(l)8510gc gas range convection oven - 750 mm wide. Rn(l)8610gc gas range convection oven - 900 mm wide. Rn(l)8810gc gas range convection oven - 1200 mm wide. Introduction ..............................................................................................

Page 4

2 introduction we are confident that you will be delighted with your waldorf gas range convection oven, and it will become a most valued appliance in your commercial kitchen. To ensure you receive the utmost benefit from your new waldorf appliance, there are two important things you can do. Firstly:...

Page 5

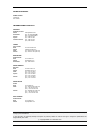

3 specifications model numbers covered in this specification rn[1]8510gc [2] gas range convection oven + 4 open burners. Rn[1]8513gc [2] gas range convection oven + 2 open burners + 300 mm griddle. Rn[1]8610gc [2] gas range convection oven + 6 open burners. Rn[1]8613gc [2] gas range convection oven ...

Page 6

4 gas supply requirements - non ce only (australia / new zealand): - ce only: appliance classification category: ii 2h3p (20, 30 / 37). Flue type: a 1. * the burner operating pressure is to be measured at the manifold test point with two burners operating at full setting. The operating pressure is e...

Page 7

5 dimensions rn(l)8510gc rn(l)8510gc rn(l)8513gc cooktop options.

Page 8

6 dimensions rn(l)8610gc rn(l)8610gc rn(l)8613gc rn(l)8616gc rn(l)8619gc cooktop options.

Page 9

7 dimensions rn(l)8810gc rn(l)8810gc rn(l)8813gc rn(l)8816gc rn(l)8819gc cooktop options.

Page 10

8 installation requirements note: • it is most important that this appliance is installed correctly and that operation is correct before use. Installation shall comply with local gas, electrical and health and safety requirements. • this appliance shall be installed with sufficient ventilation to pr...

Page 11

9 clearances note: only non-combustible materials can be used in close proximity to this appliance. * side clearances can be 50 mm when the adjacent surface is at least 100 mm below the cooking surface. Assembly all models are delivered completely assembled. No further assembly is required. Refer to...

Page 12

10 the regulator connections are 3 / 4 " bsp female. The connection to the appliance is 3 / 4 " bsp male. (refer to the “specifications” section for the gas supply location dimensions). Note: a manual isolation valve must be fitted to the individual appliance supply line. 3. Correctly locate the app...

Page 13

11 operation guide 1. Waldorf appliances have been designed to provide simplicity of operation and 100% safety protection. 2. Improper operation is therefore almost impossible, however bad operation practices can reduce the life of the appliance and produce a poor quality product. To use this applia...

Page 14

12 operation open burners note: only cooking pans from size Ø 150 mm to Ø 420 mm are suitable fo use on these open burners. Flame failure option (f-models) lighting the open burners flame failure protection is incorporated for each burner by way of a thermo-electric system which will shut off the ga...

Page 15

13 operation griddle these griddles are fitted with a pilot as a standard option and flame failure protection, which is incorporated by way of a thermo-electric system for each main burner. Flame failure protection will shut off the gas supply to that burner in the event that the pilot for that burn...

Page 16

14 oven - main burner / thermostat 1. Ensure that the oven door is closed. 2. Turn ‘on’ electrical power at the mains supply, the (green) power indicator light will illuminate on the oven control panel. 3. With the pilot burner alight, depress and rotate the oven gas control knob to the 'main flame'...

Page 17

15 cleaning and maintenance general clean the range regularly. A clean range looks better, will last longer and will perform better. Carbonised grease on the surface or between the trivets, griddle plates will hinder the transfer of heat from the cooking surface to the food. This will result in loss...

Page 18

16 cleaning and maintenance daily cleaning 1. The grease tray(s) should be checked and emptied frequently to prevent overflow and spillage. Remove the grease tray(s) while still warm so that the grease is in a liquid state. Empty any grease from the trays and wash thoroughly in the same manner as an...

Page 19

17 fig 11 fig 12 fig 13 cleaning and maintenance e. Clean with hot water, a mild detergent solution and a scrubbing brush. Dry all components thoroughly with a dry cloth. F. The griddle should be switched on briefly to ensure that the griddle plate becomes dry. A thin smear of cooking oil should be ...

Page 20

18 cleaning and maintenance re-fitting the components to the range a. Refit the trivet supports to the range, ensuring that the trivet supports are correctly fitted. Note: it is imperative that the trivet supports are correctly re-fitted to the appliance to ensure that the trivets locate correctly a...

Page 21

19 fault finding this section provides an easy reference guide to the more common problems that may occur during the operation of your appliance. The fault finding guide in this section is intended to help you correct, or at least accurately diagnose problems with your equipment. Although this secti...

Page 22

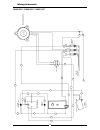

20 wiring schematic rn8510gc / rn8610gc / rn8810gc gre e n 11987 therm o stat 2 p5 1 5 e bro w n bl ue cor d set p n 7 blu e 8 10 heat orange/clear mi croswit ch 0030 04 com n.O. 13 12 e bloc k te r m in a l e 12 gree n 11 cap a cito r blac k brow n blue bla ck br own gree n mo tor w h en vi ew e d ...

Page 23

21 conversion procedure note: • these conversions should only be carried out by qualified persons. All connections must be checked for leaks before re-commissioning the appliance. • for all relevant gas specifications refer to the table at the end of this section. Open burners ('f' - flame failure o...

Page 24

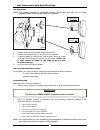

22 12. Refit all the trivet supports to the top of the appliance. Note the orientation of the trivet support when re-fitting. The trivet support front end side rail profiles are different from the rear end side rail profiles. (see fig 14). 13. Refit the trivets to the top of the appliance taking not...

Page 25

23 pilot injectors a. Unscrew and remove the pilot injector plug from the fitting at the end of the pilot injector tube using a 11 mm a/f spanner. (see fig 23). B. Using a flat bladed screwdriver, unscrew and remove the pilot injector from the pilot injector housing. Note take care not to lose the s...

Page 26

24 gas griddle pilot burner a. With the gas supply turned off at the main supply, remove the griddle plate section by lifting it straight off the cooktop. B. Remove the gas control heat shield from around the griddle burner, this is just a push in fit. C. Disconnect the thermocouple and the piezo ig...

Page 27

25 gas conversion and specifications oven main injector a. With the gas supply turned off at the main supply, unscrew and remove the 6 screws securing the lower lintel to the front of the oven. B. Remove the lintel from the oven. C. Open the oven door and remove the cast sole plate from inside the o...

Page 28

26 gas regulator note: the regulator supplied is convertible between natural gas and lpg, but it’s outlet pressure is fixed ex-factory and is not to be adjusted. 1. Ensure that the gas and electrical supply are turned off. 2. Unscrew the hexagonal cap (23 mm a/f) from the regulator. 3. Un-clip the p...

Page 29

27 gas specifications - non ce only (australia / new zealand): - ce only appliance classification category: ii 2h3p (20, 30 / 37). Flue type: a 1. * the burner operating pressure is to be measured at the manifold test point with two burners operating at the ‘high’ setting. The operating pressure is ...

Page 30

28 replacement parts list when ordering replacement parts, please quote the part number and the description as listed below. If the part required is not listed below, request the part by description and quote model number and serial number which is shown on the rating plate. Cooktop open burners 227...

Page 31

29 oven 232233 knob thermostat (80-300°c). 227933 oven burner. 018691k oven pilot burner kit. 020253 oven thermocouple (1200 mm). 018743 thermocouple spacer. 032260 oven burner injector (nat gas) 2.60 mm. 032160 oven burner injector (lpg) 1.60 mm. 026488 pilot injector (nat. Gas) 0.35 mm. 019217 pil...

Page 32

30 'pf' model s 'f' models gas conversion kits replacement parts list models gas type to convert to australia / new zealand only nat. Gas (g20) lpg (propane) (g31) nat. Gas lpg rn8510gc 231885 231884 231909 231908 rn8610gc 231889 231888 231911 231910 rn8810gc 231893 231892 231913 231912 rn8510gc 231...

Page 33

31.

Page 34

32.