- DL manuals

- Waldorf

- Ranges

- RN8510GE

- Installation And Operation Manual

Waldorf RN8510GE Installation And Operation Manual

Summary of RN8510GE

Page 1

I n s t a l l a t i o n a n d o p e r a t i o n m a n u a l rn8510ge/gec rn8610ge/gec rn8810ge/gec gas ranges electric static/convection oven date purchased serial number dealer service provider 230562-14 rnl8510ge/gec rnl8610ge/gec rnl8810ge/gec for use in gb, ie & dk.

Page 2

Manufactured by moffat limited christchurch new zealand international contacts australia moffat pty limited web: www.Moffat.Com.Au e.Mail: vsales@moffat.Com.Au main office: (tel) +61 (03) 9518 3888 (fax) +61 (03) 9518 3833 service: (tel): 1800 622 216 spares: (tel): 1800 337 963 customer service: (t...

Page 3

Contents list waldorf gas range electric static/convection ovens rn(l)8510ge gas range electric static oven four open burner. Rn(l)8610ge gas range electric static oven six open burner. Rn(l)8810ge gas range electric static oven eight open burner. Rn(l)8510gec gas range electric convection oven four...

Page 4

2 introduction we are confident that you will be delighted with your waldorf gas ranges electrical static / convection oven and it will become a most valued appliance in your commercial kitchen. To ensure you receive the utmost benefit from your new waldorf appliance, there are two important things ...

Page 5

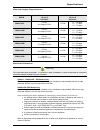

3 specifications model numbers covered in this specification rn[1]8510ge [2] 4 open burners + electric static oven. Rn[1]8513ge [2] 2 open burners + 300mm griddle + electric static oven. Rn[1]8610ge [2] 6 open burners + electric static oven. Rn[1]8613ge [2] 4 open burners + 300mm griddle + electric ...

Page 6

4 specifications gas supply requirements - non ce only (australia / new zealand): - ce only: appliance classification category: ii 2h3p (20, 30 / 37). Flue type: a 1. * - measure burner operating pressure at manifold test point with two burners operating at full setting. Operating pressure is ex-fac...

Page 7

5 specifications electrical supply requirements electrical connection rn8510 / rn8610ge / gec models only. Electrical supply connection point is located at rear of appliance, approximately 80mm from right hand side, 466mm from rear and 150mm from floor. Rn8810ge/gec models only. Electrical supply co...

Page 8

6 dimensions rn(l)8510ge / gec refer to page 8 for cook top options rn(l)8610ge / gec.

Page 9

7 dimensions rn(l)8810ge / gec refer to page 8 for cook top options.

Page 10

8 dimensions rn(l)8610ge/gec rn(l)8613ge/gec rn(l)8616ge/gec rn(l)8619ge/gec rn(l)8810ge/gec rn(l)8813ge/gec rn(l)8816ge/gec rn(l)8819ge/gec cook top options rn(l)8510ge/gec rn(l)8513ge/gec.

Page 11

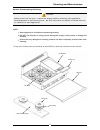

9 installation installation requirements note: it is most important that this appliance is installed correctly and that operation is correct before use. Installation shall comply with local electrical, gas, health and safety requirements. This appliance shall be installed with sufficient ventilation...

Page 12

10 installation clearances note: only non-combustible materials can be used in close proximity to this appliance. * side clearances can be 50mm when adjacent surface is at least 100mm below cooking surface. Assembly this model is delivered completely assembled. Ensure legs are securely attached. Not...

Page 13

11 installation gas connection note: all gas fitting must only be carried out by a qualified service person. 1. It is essential that gas supply is correct for appliance to be installed and that adequate supply pressure and volume are available. The following checks should be made before installation...

Page 14

12 installation electrical connection note: all electrical connections must only be carried out by a qualified person. Each appliance should be connected to an adequately protected power supply and an isolation switch mounted adjacent to, but not behind appliance. This switch must be clearly marked ...

Page 15

13 installation commissioning 1. Before leaving the new installation; a. Check the following functions in accordance with the operating instructions specified in the 'operation' section of this manual. Light the griddle. Light the open burners. (f - flame failure option). Light the open burners. (pf...

Page 16

14 operation operation guide 1. Waldorf appliances have been designed to provide simplicity of operation and 100% safety protection. 2. Improper operation is almost impossible, however bad operation practices can reduce the life of the appliance and produce a poor quality product. To use this applia...

Page 17

15 operation open burners ('f' - flame failure option) lighting the open burners flame failure protection is incorporated for each burner by way of a thermo-electric system which will shut off gas supply to that burner in the event that burner goes out, so that un-burnt gas is not expelled. A. Selec...

Page 18

16 operation griddle lighting the griddle a. Depress gas control knob and rotate anti-clockwise to ‘pilot’ position. B. Hold gas control knob depressed, press piezo ignition button to ignite pilot burner. Repeat items 1 to 2 until pilot is lit. C. Release gas control knob approximately 10-20 seconds...

Page 19

17 cleaning and maintenance before commencing cleaning note: allow appliance to cool before commencing cleaning. Do not use abrasive or strong caustic detergents as they could corrode or damage the cooktop. Ensure that any detergent or cleaning material has been completely removed after each cleanin...

Page 20

18 cleaning and maintenance open burner cleaning 1. Remove pot stands, burner caps, burner bowls and pot stand supports from top of cooktop. Wash with hot soapy water, using a soft bristled brush. Dry thoroughly with a dry cloth. Any baked-on deposits can be scraped off using a scraper tool. Note: p...

Page 21

19 cleaning and maintenance oven interior cleaning 1. Do not use wire brushes, steel wool or other abrasive materials to clean oven interior. 2. Clean oven regularly with a good quality domestic oven cleaner. 3. Weekly - remove and clean any built up of grease etc. From oven racks and bottom spill c...

Page 22

20 fault finding this section provides an easy reference guide to more common problems that may occur during operation of your appliance. The fault finding guide in this section is intended to help you correct, or at least accurately diagnose problems with your equipment. Although this section cover...

Page 23

21 fault finding fault possible cause remedy element does not work when turned ‘on’. Check individual fuses located behind control panel. Check for electrical short by checking that there is no continuity between any 'phase in' line and metal appliance body itself. Check for item failing (element, c...

Page 24

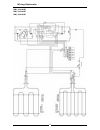

22 wiring schematic rn(l)8510ge rn(l)8610ge rn(l)8810ge.

Page 25

23 wiring schematic wiring diagram for rn(l)8510ge rn(l)8610ge rn(l)8810ge.

Page 26

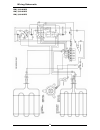

24 wiring schematic rn(l)8510gec rn(l)8610gec rn(l)8810gec.

Page 27

25 wiring schematic wiring diagram rn(l)8510gec rn(l)8610gec rn(l)8810gec.

Page 28

26 gas conversion and specifications conversion procedure note: these conversions should only be carried out by qualified persons. All connections must be checked for leaks before re-commissioning the appliance. Adjustment of components that have adjustments / settings sealed (e.G. Paint sealed) can...

Page 29

27 gas conversion and specifications griddle 1. Carry out the following:- remove griddle plate section and heat shield. Remove main burner. Disconnect piezo igniter from mounting bracket. (for access purposes). Disconnect pilot supply tube from pilot burner to access pilot injector. 2. With main bur...

Page 30

28 gas conversion and specifications gas regulator - nat gas / lpg / butane only. Note: the gas regulator supplied is convertible between natural gas and lp gas, but it’s outlet pressure is fixed ex-factory and is not to be adjusted. Gas type identification label on completion of gas conversion, rep...

Page 31

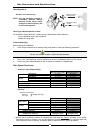

29 replacement parts list replacement parts list when ordering replacement parts, please quote part number and description as listed below. If part required is not listed below, request part by description and quote model number and serial number which is shown on rating plate. Cook top open burners...

Page 32

30 replacement parts list oven 228691 oven top element 1.75kw (750 ovens). 228690 oven bottom element 3.75kw (750 ovens). 228082 oven top element 2kw (900 - 1200 ovens). 228059 oven bottom element 4.5kw (900 - 1200 ovens). 228704 door spring kit. 229021 terminal block mains. 227399 control knob ther...

Page 33

31 replacement parts list gas conversion kits - australia / new zealand only: - uk only: note: each gas conversion kit is universal for all hob open burners and griddle variations possible within the model specified. Models gas type to convert to nat. Gas lpg butane town gas rn8510ge / gec 231841 23...