- DL manuals

- Walker

- Lawn Mower

- DB6660

- Owner's Manual

Walker DB6660 Owner's Manual - Component Identification

Summary of DB6660

Page 1

Owner’s manual safety, assembly, operating, and maintenance instructions and illustrated parts manual ih6620 implement hitch, rb6650 rotary broom, db6660 dozer blade, sb6670 two-stage snowblower and db6680 debris blower please read and save these instructions effective date 06-01-01 for safety, read...

Page 2: Foreword

Foreword thank you. . .For purchasing a walker implement. Every effort has been made to provide you with the most reliable product on the market, and we are sure you will be among our many satisfied cus- tomers. If for any reason this product does not perform to your expectations, please contact us ...

Page 3: Table Of Contents

Table of contents owner’s manual general information ________________ 1 highlighted information _____________ 1 glossary ____________________________ 1 identifying number locations ________ 1 servicing of drivetrain gearbox ____ 3 unit descriptions ____________________ 3 implement hitch ____________...

Page 4: Table Of Contents

Table of contents maintenance instructions __________ 43 maintenance schedule chart _______ 43 lubrication _________________________ 44 rotary broom gearbox ________________ 44 rotary broom drive chain _____________ 44 two-stage snowblower gearbox ________ 45 two-stage snowblower reduction chain____...

Page 5: General Information

General information 1 highlighted information walker manufacturing recommends that any ser- vice requiring special training or tools be performed by an authorized walker mower dealer. There are several general practices to be aware of in the area of safety. Most accidents associated with the oper- a...

Page 6: General Information

General information 2 implement hitch serial number location (top view) dozer blade serial number location (rear view) rotary broom serial number location (rear view) two-stage snowblower serial number location (rear view and rh view) debris blower serial number location (rear view and rh view) seri...

Page 7: General Information

General information 3 servicing of drivetrain gearbox detailed servicing and repair of the gearbox used on the implement attachments is not covered in this manual. Only routine maintenance and general service instructions are provided. For the service of the gearbox during the limited warranty perio...

Page 8: Specifications

Specifications 4 model implements implement hitch height 10 in. (25 cm) width 33-1/2 in. (85 cm) length 30 in. (76 cm) overall length installed on tractor 69-3/4 in. (177 cm) weight 70 lb (32 kg) lift 12 volt dc electric ram linear actuator, operated by toggle switch mounted on fsc lever dozer blade...

Page 9: Specifications

Specifications 5 model implements rotary broom (continued) hitch system patented quick hitch system type brush 18 in. (46 cm) diameter polypropylene or steel, clockwise rotation brush drive pto shaft driving center mounted gearbox primary reduction gearbox, 2.78:1 ratio secondary reduction #40 chain...

Page 10: Specifications

Specifications 6 model implements debris blower height 28-1/2 in. (72 cm) width 26 in. (66 cm) length 34-3/4 in. (88 cm) overall length installed on tractor 102-1/2 in. (260 cm) weight (with female hitch) 130 lb (59 kg) lift 12 volt dc electric ram linear actuator, operated by toggle switch mounted ...

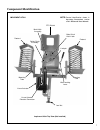

Page 11: Component Identification

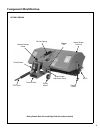

Component identification 7 implement hitch top view (not installed) male hitch assembly note: control identification shown in operating instructions section and in illustrated parts manual. Implement hitch male quick hitch latch footrest linchpin mounting tube hitch locking lever jam nut footrest sa...

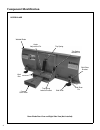

Page 12: Component Identification

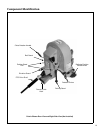

Component identification 8 dozer blade rear view and right side view (not installed) skid shoe pin skid shoe trip spring lockout bracket skid shoe bracket trip spring lockout pin female quick hitch hitch box angle adjustment pin trip spring welded blade dozer blade.

Page 13: Component Identification

Component identification 9 rotary broom rear view and right side view (not installed) rotary broom brush rotary broom housing ground contact knob tension spring stopper pin pivot bracket parking stand broom angle adjustment lever plastic wheel female hitch pto shaft.

Page 14: Component Identification

Component identification 10 two-stage snowblower front view and right side view (not installed) two-stage snowblower hand guard gearbox support bracket deflector position control knob chute chute rotation handle fan frame auger auger gearbox deflector.

Page 15: Component Identification

Component identification 11 two-stage snowblower rear view (not installed) deflector chute chute rotation handle reduction box cover skid shoe parallel bar pto drive shaft female quick hitch skid shoe snowblower housing deflector position control knob.

Page 16: Component Identification

Component identification 12 debris blower front view and left side view (not installed) debris blower parking stand female quick hitch pto drive shaft pivot wheel belt guard blower motor housing chute rotation handle linchpin.

Page 17: Component Identification

Component identification 13 chute rotation handle belt guard parking stand pins driveline guard pto drive shaft female quick hitch parking stand rotation pinions deflector position control knob debris blower rear view and right side view (not installed).

Page 18: Safety Instructions

Safety instructions 14 pay particular attention to any information labeled danger, warning, caution, important, and note in this manual. When you see the safety alert symbol ( ), read, understand, and follow the instructions. Fail- ure to comply with safety instructions may result in personal injury...

Page 19: Safety Instructions

Safety instructions 15 7. Do not wear loose fitting clothing that could get caught in moving parts. Always wear ade- quate protective clothing including long pants. Wearing safety glasses, safety shoes, and a helmet is advisable and required by some local ordinances and insurance regulations. 8. Pro...

Page 20: Safety Instructions

Safety instructions 16 12. Disengage the pto clutch when transporting the machine. 13. Do not operate across the face of slopes. Use extreme caution when changing direction on slopes. Do not attempt to clear steep slopes. 14. Never adjust gauge wheels or skid shoes with the engine running. Before ad...

Page 21: Safety Instructions

Safety instructions 17 safety, control, and instruction decals safety, control, and instruction decals are installed on the machine. If any are missing, illegible, or damaged, a replacement should be ordered and installed before putting the machine into operation. The decal part number is listed bel...

Page 22: Safety Instructions

Safety instructions 18 safety, control, and instruction decals safety, control, and instruction decals are installed on the machine. If any are missing, illegible, or damaged, a replacement should be ordered and installed before putting the machine into operation. The decal part number is listed bel...

Page 23: Assembly Instructions

Assembly instructions 19 setup instructions walker implements are shipped partially assem- bled. After uncrating the implement adaptor and/or implement(s), initial setup is required. Note: during the process of unpacking, any dam- aged or missing parts should be noted and reported to the delivering ...

Page 24: Assembly Instructions

Assembly instructions 20 implement hitch wiring 1. Drill five (5) 13/64 in. (5 mm) diameter holes in the tractor, two in the fsc lever and three in the body, as shown in the illustration. Drill holes for implement hitch wiring 2. Attach the toggle switch mounting bracket on the fsc lever using two (...

Page 25: Assembly Instructions

Assembly instructions 21 6. Complete the wiring by connecting the wiring harness ends to the toggle switch and to the ac- tuator motor of the implement hitch. Complete implement hitch wiring 7. Move the implement lift switch backward to raise the implement hitch to the up position. 8. Move the imple...

Page 26: Assembly Instructions

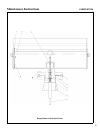

Assembly instructions 22 implement hitch wiring diagram.

Page 27: Assembly Instructions

Assembly instructions 23 dozer blade dozer blade assembly 1. Insert the female quick hitch into the hitch box on the blade attachment. 2. Align the single hole at the end of the female quick hitch with the single hole in the hitch box and insert the pivot pin through both holes. Se- cure the pivot p...

Page 28: Assembly Instructions

Assembly instructions 24 8. Adjust the skid shoes to allow the required clearance under the blade. Install a skid shoe pin in each shoe and lock in place with a 4 mm x 80 mm hairpin. Refer to adjustments of dozer blade skid shoes in maintenance in- structions. Install skid shoes 9. Install the trip ...

Page 29: Assembly Instructions

Assembly instructions 25 prepare rotary broom for installation 3. Attach the female broom driveline half (with quick connect yoke) over the male broom driv- eline half. Set the driveline on its support. Note: driveline sliding surfaces must be greased. Assemble rotary broom driveline 4. Insert the m...

Page 30: Assembly Instructions

Assembly instructions 26 6. Remove the hairpin from the welded sleeve on the right hand side of the broom mounting bracket. Carefully pull out the stopper pin to its most extended position and lock in place with the hairpin. Lock stopper pin in place note: the pin in the innermost position is used t...

Page 31: Assembly Instructions

Assembly instructions 27 1. Remove the pin and hairpin from each gauge wheel. Select the required number of spacer sleeves to remain on the bottom portion of the gauge wheels. Refer to adjustments of rotary broom gauge wheelsin maintenance instructions. 2. Remove the parking stands and replace them ...

Page 32: Assembly Instructions

Assembly instructions 28 5. Insert the 1-11/16 in. (43 mm) plastic bushing in- to the bushing support and place this over the shaft on the rotation worm. 6. Install the rotation worm assembly through the tube weldment with the attaching plate of the support on the underside of the chute base lip. In...

Page 33: Assembly Instructions

Assembly instructions 29 attach drive shaft yoke to reduction shaft 4. Install one 1/4 x 7-1/2 in. Bolt through the upper set of holes in the reduction box and secure loosely with a lock washer and nut. Install bolt in reduction box 5. Hook the reduction box cover over the bolt and secure the cover ...

Page 34: Assembly Instructions

Assembly instructions 30 attach snowblower to implement hitch 9. Attach the driveline quick lock coupler to the tractor pto. Connect driveline coupler to tractor pto 10. Attach the parallel bar to the female hitch and the implement adaptor using the two clevises and spring clips. Attach parallel bar...

Page 35: Assembly Instructions

Assembly instructions 31 14. For ghs (grass handling system) equipped walker tractors, install a blower intake cover in the blower intake tube. The cover “unloads” the blower and seals the intake to effectively elimi- nate power loss and noise when the blower is not being used. Refer to ghs blower i...

Page 36: Assembly Instructions

Assembly instructions 32 9. For stability of the tractor when transporting with the debris blower in raised position, approxi- mately 80 lb (36 kg) of counterweight should be installed on the tail of the tractor. Optional tail weights for the various tractor models are avail- able from your walker d...

Page 37: Assembly Instructions

Assembly instructions 33 check broom angle adjustment refer to angle adjustment lever in operating in- structions. Check drive chain refer to lubrication for rotary broom drive chain in maintenance instructions . Refer to adjustments of rotary broom drive chain tension in maintenance instructions . ...

Page 38: Operating Instructions

Operating instructions 38 snow removal 1. The rotary broom works best on snow depths of 4 in. (10 cm) or less. Larger amounts of snow can be moved if the ground speed is reduced. 2. To avoid snow being blown back onto the tractor and operator, sweep with the wind blowing in the direction of broom di...

Page 39: Operating Instructions

Operating instructions 39 engaging the snowblower 1. Make sure that the snowblower is clear of snow and/or ice before engaging the snowblower. 2. Make sure that the auger and fan operate freely. 3. Check the oil level in the worm gearbox and if necessary, add sae 90 e.P. (extreme pres- sure) oil. Ma...

Page 40: Operating Instructions

Operating instructions 40 • when operating on a slope, reduce speed and use caution to start, stop, and maneuver. Avoid sharp turns or sudden changes in direction. • when blowing through deep snow drifts, let the snowblower work its way through the drifts. For best results, raise the snowblower and ...

Page 41: Operating Instructions

Operating instructions 41 the following list of items should be checked if a pat- tern of clogging begins to develop. All of these items are capable of causing clogging. • check that the inside of the snowblower housing is clean and free of snow and/or ice buildup. • check that the auger is in good ...

Page 42: Operating Instructions

Operating instructions 42 engaging the debris blower 1. Set the engine throttle at about 1/3 speed. Do not attempt to engage the pto clutch at high engine speeds. This will drastically short- en drive belt life. Use only moderate engine speed when engaging the pto clutch. 2. Pull the pto clutch leve...

Page 43: Maintenance Instructions

Maintenance instructions 43 maintenance schedule chart - recommended service intervals - implements model service item daily 25 hours yearly reference page all models: check tire chains (optional) x 32 check gauge wheels or skid shoes x 32 check tractor tailweight x 32 lubricate grease fittings and ...

Page 44: Maintenance Instructions

Maintenance instructions lubrication 44 lubrication proper lubrication is an important maintenance pro- cedure. It reduces wear and makes the machine quieter and easier to operate. Rotary broom gearbox the gearbox is permanently lubricated (oil filled) and sealed requiring no scheduled lubrication. ...

Page 45: Maintenance Instructions

Maintenance instructions lubrication 45 two-stage snowblower gearbox the gearbox is permanently lubricated (oil filled) and sealed requiring no scheduled lubrication. However, the gearbox oil seal(s) should be checked every 25 hours for indication of an oil leak. If an oil leak is noted, replace the...

Page 46: Maintenance Instructions

Maintenance instructions lubrication 46 ident lubrication no. No. Location type places ident lubrication no. No. Location type places implement hitch 1 pto shield hinge oil 1 2 hitch locking lever pivot oil 1 3 mounting tube sockets grease 2 4 hitch lift crank grease 1 5 hitch pivot shaft oil 1 6 qu...

Page 47: Maintenance Instructions

Maintenance instructions lubrication 47 implement hitch lubrication points.

Page 48: Maintenance Instructions

Maintenance instructions lubrication 48 ident lubrication no. No. Location type places ident lubrication no. No. Location type places dozer blade 1 cutting edge oil 1 2 skid shoe brackets grease 2 (grease slide area) 3 hitch box pin oil 1 4 trip spring lockout bracket pivot pin oil 1 5 angle adjustm...

Page 49: Maintenance Instructions

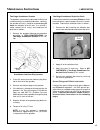

Maintenance instructions lubrication 49 dozer blade lubrication points.

Page 50: Maintenance Instructions

Maintenance instructions lubrication 50 ident lubrication no. No. Location type places ident lubrication no. No. Location type places rotary broom 1 chain drive sprocket oil 1 2 chain drive shaft grease 1 3 gearbox oil * 1 4 wheel brackets grease 2 5 angle adjustment lever pivot oil 1 6 driveline gr...

Page 51: Maintenance Instructions

Maintenance instructions lubrication 51 rotary broom lubrication points.

Page 52: Maintenance Instructions

Maintenance instructions lubrication 52 ident lubrication no. No. Location type places ident lubrication no. No. Location type places two-stage snowblower 1 auger sections grease 2 2 gearbox oil * 1 3 cutting edge oil 1 4 skid shoes grease 2 5 gearbox shaft oil 1 6 rotation worm grease 1 7 reduction...

Page 53: Maintenance Instructions

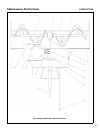

Maintenance instructions lubrication 53 two-stage snowblower lubrication points.

Page 54: Maintenance Instructions

Maintenance instructions lubrication 54 ident lubrication no. No. Location type places ident lubrication no. No. Location type places debris blower 1 front gauge wheel grease 1 2 plastic anti-friction insert grease 1 3 air blast nozzle oil 1 4 sprockets oil 2 5 rotation handle grease * 2 6 universal...

Page 55: Maintenance Instructions

Maintenance instructions lubrication 55 debris blower lubrication points.

Page 56: Maintenance Instructions

Maintenance instructions replacing/repairing 56 replacing/repairing dozer blade cutting edge note: the cutting edge of the dozer blade is re- versible and needs to be replaced only when both the top and bottom edges have worn. Replace the dozer blade cutting edge as follows: 1. Remove the six (6) 5/...

Page 57: Maintenance Instructions

Maintenance instructions replacing/repairing 57 6. Loosen the two sprocket set screws and push sprocket towards the brush. Loosen chain idler and set screws 7. Remove the three bolts on the bearing flanges on each side of the broom and loosen the bear- ing set screws. Push the bearings and flanges t...

Page 58: Maintenance Instructions

Maintenance instructions replacing/repairing 58 2. Loosen the bearing flange mounting nuts and bolts. Position the chain tension block so that the chain has as much slack as possible. Tight- en the bearing flange mounting nuts and bolts slightly to hold the bearing flange in this posi- tion. Remove ...

Page 59: Maintenance Instructions

Maintenance instructions replacing/repairing 59 6. Align the slot in the new sprocket with the square key and slide the sprocket onto the drive shaft. Make sure the key is in place between the drive shaft and sprocket. Remove and replace sprocket align sprockets 7. Position the sprocket on the drive...

Page 60: Maintenance Instructions

Maintenance instructions replacing/repairing 60 snowblower cutting edge replacement two-stage snowblower gearbox remove and replace the gearbox as follows: 1. Stop the tractor engine, set the parking brake, and remove the ignition key. Replace snowblower gearbox 2. Remove the three (3) 5/16 nuts and...

Page 61: Maintenance Instructions

Maintenance instructions replacing/repairing 61 replace reduction chain 6. Adjust the chain tension. Refer to adjust- ments of two-stage snowblower reduc- tion chain tensionin this section. 7. Reinstall the reduction box cover by reversing the removal procedures. Two-stage snowblower reduction sproc...

Page 62: Maintenance Instructions

Maintenance instructions 62 replacing/repairing/ adjustments 2. Loosen the three (3) nuts and three (3) bolts on lower pulley bearing support and the adjust- ment nut on the lower end of each (2) eyebolts to release belt tension. 3. Loosen the two (2) set screws securing the up- per pulley bearing t...

Page 63: Maintenance Instructions

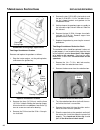

63 maintenance instructions adjustments skid shoe height adjustment rotary broom brush leveling important: the proper level adjustment of the broom is essential for efficient operation and life of the bristles. The broom should regu- larly be adjusted to prevent uneven brush wear. 1. Extend the park...

Page 64: Maintenance Instructions

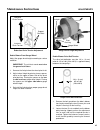

64 maintenance instructions adjustments rotary broom drive chain tension the drive chain should have 1/4 to 1/2 in. (6 to 13 mm) of slack at midspan. Remove the chain guard cover to check slack. Adjust the drive chain as follows: 1. Loosen the chain idler nut. Loosen chain idler nut 2. Position the ...

Page 65: Maintenance Instructions

65 maintenance instructions adjustments reduction chain tension adjustment debris blower front gauge wheel adjust the gauge wheel height according to surface condition. Important: the air blast nozzle must clear the ground at all times. 1. Remove the linchpin from the wheel pivot shaft. 2. Adjust wh...

Page 66: Maintenance Instructions

66 maintenance instructions adjustments drive belt tension adjustment debris blower rotation pinions the two (2) rotation pinions should slightly contact each other without any resistance. 1. Loosen the set screw of each stop ring on the rotation handle. 2. Keeping the two (2) pinions slightly in co...

Page 67: Maintenance Instructions

Maintenance instructions torque specifications 67 torque specifications.

Page 68

Removal and storage instructions 68 removal removing attachments from implement hitch dozer blade 1. Park the tractor on a level surface and lower the dozer blade. 2. Remove the linchpin from the quick hitch latch and place the hitch locking lever in the un- locked position. 3. Start the tractor eng...

Page 69

Removal and storage instructions 69 detach rotary broom from implement hitch two-stage snowblower 1. Park the tractor on a level surface and lower the snowblower. 2. Remove the hairpin from the parallel bar at the adaptor end, and remove the parallel bar from the implement adaptor. 3. Disconnect the...

Page 70

Removal and storage instructions 70 detach debris blower from implement hitch removing implement hitch from tractor important: detach any attached implement from the hitch before detaching the hitch from the tractor. Refer to the instructions for removal of dozer blade, rotary broom, two-stage snowb...

Page 71

Removal and storage instructions 71 note: rustproofing or painting every year will prolong the life of the blade components and moving parts. 3. When the dozer blade is dry, lubricate all mov- ing parts with sae 30 engine oil. Apply oil lib- erally to all exposed surfaces to protect against rust. 4....

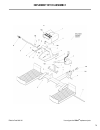

Page 72: Implement Hitch Assembly

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 06-01-01 72 implement hitch assembly implement hitch 1 6627 pto shield 1 2 i392 safety chain assembly 1 i015 chain 1 o/l 5/16 linchpin 1 o/l 5/32 x 1 cotter pin...

Page 73: Implement Hitch Assembly

Effective date 06-01-01 use only genuine walker ® replacement parts. 7 3 implement hitch assembly.

Page 74

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 06-01-01 74 implement hitch electrical components implement hitch electrical components 1 6623-1 switch boot (fits p/n 6623) 1 2 6628 switch mount bracket 1 3 6...

Page 75

Effective date 06-01-01 use only genuine walker ® replacement parts. 75 implement hitch electrical components.

Page 76: Dozer Blade Assembly

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 06-01-01 76 dozer blade assembly dozer blade assembly 1 i061 spring (1-7/8 x 9) 1 2 i064 pivot pin 1 3 i060 1/4 x 1 roll pin 2 4 i065 adjustment pin 1 5 i063 fe...

Page 77: Dozer Blade Assembly

Effective date 06-01-01 use only genuine walker ® replacement parts. 77 dozer blade assembly.

Page 78: Rotary Broom Assembly

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 06-01-01 78 rotary broom assembly rotary broom assembly 1 i385 stand support bracket 2 2 i366 parking stand 2 3 ns housing (rad 661579) 1 4 663827 clevis 1 5 o/...

Page 79: Rotary Broom Assembly

Effective date 06-01-01 use only genuine walker ® replacement parts. 79 rotary broom assembly.

Page 80

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 06-01-01 80 rotary broom drive components gearbox assembly 1 ns dipstick plug (rad 661741) 1 2 o/l m8 x 45 bolt 8 3 ns casing (rad 661740) 1 4 ns oil seal (rad ...

Page 81

Effective date 06-01-01 use only genuine walker ® replacement parts. 81 rotary broom drive components.

Page 82

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 06-01-01 82 snowblower housing components chute rotation assembly 1 ns chute, base and knobs (with decals) 1 (rad 661168) 2 i396 decal, keep hands out 1 3 i172 ...

Page 83

Effective date 06-01-01 use only genuine walker ® replacement parts. 83 snowblower housing components.

Page 84: Snowblower Drive Components

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 06-01-01 84 snowblower drive components gearbox assembly 1 i193 double lip seal 2 2 ns breather, 3/8 npt & o-ring (comer) 1 (rad 661185) ns pressure plug, 1/8 n...

Page 85: Snowblower Drive Components

Effective date 06-01-01 use only genuine walker ® replacement parts. 85 snowblower drive components.

Page 86: Debris Blower Components

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 06-01-01 86 debris blower components debris blower components 1 i402 impeller housing 1 2 ns impeller (rad 662644) 1 3 ns 1-14 castel nut (rad 654988) 1 4 o/l 3...

Page 87: Debris Blower Components

Effective date 06-01-01 use only genuine walker ® replacement parts. 87 debris blower components.

Page 88

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 06-01-01 88 debris blower manual rotation components debris blower manual rotation components 1 7860 handle grip 1 2 ns rotation handle (rad 663509) 1 3 5830 gr...

Page 89

Effective date 06-01-01 use only genuine walker ® replacement parts. 89 debris blower manual rotation components.

Page 90

Use only genuine walker ® replacement parts. Effective date 06-01-01 90 key to abbreviations used in illustrated parts manual º (dimension) .................................................................................................................... Degrees (angle) " (dimension) ................

Page 91

91 limited warranty for walker commercial rider mower 1. What this warranty covers, and for how long: walker manufacturing company will, at its option, repair or replace, without charge, any part covered by this warranty which is found to be defective in material and/or workmanship within one (1) ye...

Page 92

Walker mfg. Co. • 5925 e. Harmony road, fort collins, co 80528 • (970) 221-5614 form no. 060101 printed in usa © 2001 walker mfg. Co www.Walkermowers.Com.