- DL manuals

- Walker

- Lawn Mower

- MB

- Detailed Instructions

Walker MB Detailed Instructions

WALKER SERVICE MANUAL

Detailed Instructions for

Servicing Walker Mowers

Model MT, MTL, MTEFI and MTLEFI

Model MD

Model MC

Model MS

Model MW15

Model MB

Decks

Implements

Please Read and Save These Instructions

Effective Date: 07-01-06

For Safety, Read All Safety and Operation

P/N 9000-30

Instructions Prior to Operating Machine

™

Summary of MB

Page 1

Walker service manual detailed instructions for servicing walker mowers model mt, mtl, mtefi and mtlefi model md model mc model ms model mw15 model mb decks implements please read and save these instructions effective date: 07-01-06 for safety, read all safety and operation p/n 9000-30 instructions ...

Page 2: Foreword

Foreword dear walker servicing professional, this manual is provided as a resource for you to not only repair but also maintain walker mowers, decks and implements. Your service capability as a walker dealer is valuable to the strength and vitality of our program—many customers base their purchases ...

Page 3: Service Instructions

Walker manufacturing company july 2006 service instructions section index introduction...................................................................................................Intro set-up .........................................................................................................

Page 4: Service Instructions

Walker manufacturing company july 2006 service instructions.

Page 5: Service Instructions

Walker manufacturing company page: intro-1 july 2006 service instructions introduction contents of this section subject page glossary of terms - all models and implements ..............................Intro-2 general information ..........................................................................

Page 6: Service Instructions

Page: intro-2 walker manufacturing company july 2006 service instructions introduction glossary of terms - all models and implements there are many terms that are either unique to this equipment or that are used as acronyms. The following terms and their definitions will help while using this manual...

Page 7: Service Instructions

Page: intro-3 walker manufacturing company july 2006 service instructions general information identifying number locations model ms, mb, mc, md, mt the tractor serial number plate is affixed to the tractor body just below the left rear corner of the seat. The mower deck serial number plate is affixe...

Page 8: Service Instructions

Page: intro-4 walker manufacturing company july 2006 service instructions engine serial number location model mc, mt, mtl, mtefi, mtlefi refer to the engine manual for the location of the en- gine serial number. For the mower model(s) covered by this manual, an engine manual is available from kohler...

Page 9: Service Instructions

Page: intro-5 walker manufacturing company july 2006 service instructions model mw the kawasaki engine model, type, and code numbers are located on the side of the engine opposite the recoil starter handle (on the aluminum housing). For the mow- er model covered by this manual, an engine manual is a...

Page 10: Service Instructions

Page: intro-6 walker manufacturing company july 2006 service instructions product registration product registration is available online. Go to www.Service.Walkermfg.Com/registration/register.Py to fill out registration information. Product registration link manufacturer information service manuals a...

Page 11: Service Instructions

July 2006 service instructions page: intro-7 walker manufacturing company specifications model engine manufacturer/model mt mtl25 mtefi mtl31 md mc ms mw mb kohler command ch20, 2 cyl., gasoline (air cooled) kohler aegis tm lh685, 2 cyl., gasoline (liquid cooled) kohler command pro ® ch26, 2 cyl., g...

Page 12: Service Instructions

July 2006 service instructions page: intro-8 walker manufacturing company idle rpm mt, mtl, mtefi, mc md ms mw mb 1200 ± 75 1000 ± 50 1300 1500 1750 spark plug type mt, mtefi, mc mtl, mb md ms mw champion ® rc12yc champion ® rc14yc n/a ngk bpr5es champion ® rcj8y spark plug gap mt, mtl, mtefi, mc, m...

Page 13: Service Instructions

July 2006 service instructions page: intro-9 walker manufacturing company electrical system battery mt, mc md, mtl, mtefi ms mw mb 12 volt, 35 ah, 295 cca 12 volt, 41ah, 340 cca (interstate u1-sp40) 12 volt, 230 cca (interstate sp-30) 12-volt, interstate pc1250 12 volt, 220 cca (interstate pc12/80) ...

Page 14: Service Instructions

July 2006 service instructions page: intro-10 walker manufacturing company forward speed control mt, mtl, mtefi, md, mc, ms, mb mw precision friction lock lever, cruise control, with neutral-park position variable speed controlled by rocker switch near rh thumb, with neutral park setting service bra...

Page 15: Service Instructions

Page: intro-11 walker manufacturing company july 2006 service instructions blade drive clutch and brake mt, mtl, mtefi, md, mc, mw ms mb manual belt tightener clutch and band brake (stops blades within five (5) seconds of disengagement) manual belt tightener clutch and scrubber brake (stops blades w...

Page 16: Service Instructions

Page: intro-12 walker manufacturing company july 2006 service instructions tire pressure deck caster wheel all models 20 psi (137 kpa) drive all models 15 psi (103 kpa) rear all models 20 psi (137 kpa) dimensions (tractor and mower) (**mt, mtefi, mtl, md) length mt, mtl, mtefi, md mw mb 91 in. (231 ...

Page 17: Service Instructions

July 2006 service instructions page: intro-13 walker manufacturing company tread width (tractor) standard tires mc, ms 28-1/4 in. (72 cm) tread width (tractor) mt, mtl, mtefi, md, mb mw 29-3/4 in. (76 cm) 29-1/4 in. (74 cm) optional tires mc, ms 29-3/4 in. (76 cm) mower deck width of cut sd/ghs mt, ...

Page 18: Service Instructions

July 2006 service instructions page: intro-14 walker manufacturing company deck suspension all models torsion-flex frame with caster wheels and counterweight springs curb weight (approximate) sd tractor only mt, mtefi mtl md mc ms mw, mb 660 lb (299 kg) 705 lb (320 kg) 760 lb (345 kg) 645 lb (293 kg...

Page 19: Service Instructions

July 2006 service instructions page: intro-15 walker manufacturing company drive belts engine pto mt, mtl, mtefi, mc md ms mw mb walker p/n 8230 walker p/n 7230 walker p/n 5230-2 gates bx30 walker p/n 9230 walker p/n 4230 jackshaft drive mt, mtl, mtefi md mc ms, mw, mb gates 3vx375 (or walker p/n 62...

Page 20: Service Instructions

Page: intro-16 walker manufacturing company july 2006 service instructions full signal (grass-pak ® switch) mt, mtl, mtefi, md, mc, ms mw, mb oscillating vane switch mounted on grass delivery spout triggers horn signal n/a powerfil ® mt, mtl, mtefi, md, mc, ms mw, mb oscillating delivery spout drive...

Page 21: Service Instructions

Walker manufacturing company page:1-1 july 2006 service instructions section 1 set-up contents of this section subject page set-up ..............................................................................................................1-3 tractor set up ...........................................

Page 22: Service Instructions

Walker manufacturing company july 2006 service instructions page:1-2 dozer blade ................................................................................................1-21 dozer blade assembly .....................................................................................1-21 dozer b...

Page 23: Service Instructions

Page: 1-3 walker manufacturing company july 2006 service instructions set-up tractor set up tire installation (tractor) model ms, mc, md, mt, mtl, mtefi • install the drive tires using the eight (8) lug bolts that are supplied with the owner's packet of materials. Bolts are torqued to 75 to 85 ft-lb...

Page 24: Service Instructions

Page:1-4 walker manufacturing company july 2006 service instructions model mw, mb the battery is a completely sealed, non-serviceable battery. Battery location - model mw all models important: make sure battery is securely mounted in the frame. A loose battery may cause damage to the case resulting ...

Page 25: Service Instructions

Page: 1-5 walker manufacturing company july 2006 service instructions battery charging - ms, mc, md, mt, mtl, mtefi important: on mtefi and mtlefi models, al- ways disconnect the negative (-) battery terminal before charging. Failure to do so can result in dam- age to the ecu. 1. Charge the battery ...

Page 26: Service Instructions

Page:1-6 walker manufacturing company july 2006 service instructions battery installation - model mt, mtl, mtefi battery installation - model md battery installation - model mc battery installation - model ms battery installation - model mw battery installation - model mb battery clamp secured by wi...

Page 27: Service Instructions

Page: 1-7 walker manufacturing company july 2006 service instructions mower deck assembly deck caster wheels installation - all models 1. Remove the bolt, nut, axle spacer tube, and spacer washers from each deck caster wheel fork. 2. Fit the axle spacer tube through the wheel hub, po- sition the spa...

Page 28: Service Instructions

Page: 1-8 walker manufacturing company july 2006 service instructions discharge shield installation on side discharge deck pto shaft guard installation - all models position the shaft guard as shown and mount with two 1/4-20 x 1/2 in. Bolts. Pto shaft guard installation tilt-up roller wheel installa...

Page 29: Service Instructions

Page: 1-9 walker manufacturing company july 2006 service instructions mower deck installation on tractor deck installation - model mc, md, mt, mtl, mtefi 1. Lightly grease each deck support arm (2) on the tractor. Refer to mower deck installation photo for location of deck support arm. 2. Engage the...

Page 30: Service Instructions

Page: 1-10 walker manufacturing company july 2006 service instructions quick coupler installation tool model mc, md, mt, mtl, mtefi 6. Raise the mower body (instead of lifting the front of deck) and clip the counterweight springs to the re- ceptacle on front of body. Lower the body to ten- sion the ...

Page 31: Service Instructions

Page: 1-11 walker manufacturing company july 2006 service instructions deck counterweight spring installation 5. Raise mower body (instead of lifting the front of deck) and clip the counterweight springs to the re- ceptacle on front of body. Lower the body to ten- sion the springs. (refer to deck co...

Page 32: Service Instructions

Page: 1-12 walker manufacturing company july 2006 service instructions installing pto quick coupler coupler ring “locked” position 5. Pull out counterweight spring receptacle assist handle and lift up on locking finger slightly to unlock the receptacle assembly. Lower this assembly to- ward the deck...

Page 33: Service Instructions

Page: 1-13 walker manufacturing company july 2006 service instructions deck leveling - all models 1. Position mower on a smooth, level surface. Set the cutting height to the highest position - 4 in. (102 mm) - for easy access under the deck to measure blade height. Note: a block of wood cut 4 in. (1...

Page 34: Service Instructions

Page: 1-14 walker manufacturing company july 2006 service instructions preoperating fluid levels tractor fluid levels deck fluid levels use sae e.P. (extreme pressure) 90w oil until the oil level is up to (submerges) the horizontal shaft in the gearbox (shaft parallel to cover plate). Note: in case ...

Page 35: Service Instructions

Page: 1-15 walker manufacturing company july 2006 service instructions implement fluid levels perfaerator rotary broom two-stage snowblower sb36 snowblower gearbox oil level 80w-90 15 oz. (44.36 cl) sae e.P. (extreme pressure) 80w-90 5 fl. Oz. (15 cl).

Page 36: Service Instructions

Page: 1-16 walker manufacturing company july 2006 service instructions implement assembly setup instructions perfaerator the perf aerator™ is shipped partially assembled. After uncrating, initial setup is required. Note: during the process of unpacking, any dam- aged or missing parts should be noted...

Page 37: Service Instructions

Page: 1-17 walker manufacturing company july 2006 service instructions implements walker implements are shipped partially assembled. After uncrating the implement adaptor and/or imple- ment(s), initial setup is required. Note : during the process of unpacking, any dam- aged or missing parts should b...

Page 38: Service Instructions

Page: 1-18 walker manufacturing company july 2006 service instructions implement hitch wiring 1. Drill five (5) 13/64 in. (5 mm) diameter holes in the tractor, two in the fsc lever and three in the body, as shown in the illustration. Drill holes for implement hitch wiring 2. Attach the toggle switch...

Page 39: Service Instructions

Page: 1-19 walker manufacturing company july 2006 service instructions 6. Complete the wiring by connecting the wiring har- ness ends to the toggle switch and to the actuator motor of the implement hitch. Complete implement hitch wiring 7. Move the implement lift switch backward to raise the impleme...

Page 40: Service Instructions

Page: 1-20 walker manufacturing company july 2006 service instructions implement hitch wiring diagram.

Page 41: Service Instructions

Page: 1-21 walker manufacturing company july 2006 service instructions dozer blade dozer blade assembly 1. Insert the female quick hitch into the hitch box on the blade attachment. 2. Align the single hole at the end of the female quick hitch with the single hole in the hitch box and insert the pivo...

Page 42: Service Instructions

Page: 1-22 walker manufacturing company july 2006 service instructions 8. Adjust the skid shoes to allow the required clear- ance under the blade. Install a skid shoe pin in each shoe and lock in place with a 4 mm x 80 mm hairpin. Refer to adjustments of dozer blade skid shoes in the service procedu...

Page 43: Service Instructions

Page: 1-23 walker manufacturing company july 2006 service instructions prepare rotary broom for installation 3. Attach the female broom driveline half (with quick connect yoke) over the male broom driveline half. Set the driveline on its support. Note: driveline sliding surfaces must be greased. Ass...

Page 44: Service Instructions

Page: 1-24 walker manufacturing company july 2006 service instructions 6. Remove the hairpin from the welded sleeve on the right hand side of the broom mounting bracket. Carefully pull out the stopper pin to its most ex- tended position and lock in place with the hairpin. Lock stopper pin in place n...

Page 45: Service Instructions

Page: 1-25 walker manufacturing company july 2006 service instructions optional gauge wheel installation note: gauge wheels are required for lawn work or heavy loads. This adjustment is required for lawn thatching or leaf raking operations. Height is adjusted by removing pin and adjusting broom heig...

Page 46: Service Instructions

Page: 1-26 walker manufacturing company july 2006 service instructions 6. Install the rotation worm assembly through the tube weldment with the attaching plate of the support on the underside of the chute base lip. Install rotation worm assembly 7. Install the chute over the plastic insert and secur...

Page 47: Service Instructions

Page: 1-27 walker manufacturing company july 2006 service instructions attach drive shaft yoke to reduction shaft 4. Install one 1/4 x 7-1/2 in. Bolt through the upper set of holes in the reduction box and secure loosely with a lock washer and nut. Install bolt in reduction box 5. Hook the reduction...

Page 48: Service Instructions

Page: 1-28 walker manufacturing company july 2006 service instructions 9. Attach the driveline quick lock coupler to the tractor pto. Connect driveline coupler to tractor pto 10. Attach the parallel bar to the female hitch and the implement adaptor using the two clevises and spring clips. Attach par...

Page 49: Service Instructions

Page: 1-29 walker manufacturing company july 2006 service instructions debris blower debris blower installation the debris blower is shipped completely assembled ex- cept for the driveline, which must be connected to the input shaft. 1. Remove the belt guard from the debris blower housing by removin...

Page 50: Service Instructions

Page: 1-30 walker manufacturing company july 2006 service instructions sb36 snowblower model ms, mc, md, mt, mtl, mtefi 1. Remove the mower deck from the tractor if neces- sary. Refer to the appropriate tractor owner’s manual. 2. Attach each of the lift brackets to the predrilled holes on the front ...

Page 51: Service Instructions

Page: 1-31 walker manufacturing company july 2006 service instructions model mb 1. Remove the mower deck from the tractor if neces- sary. Refer to the appropriate tractor owner’s manual. 2. Raise tractor body and use prop to hold body up. Install lift plate and backing plates, as showin in parts bre...

Page 52: Service Instructions

Page: 1-32 walker manufacturing company july 2006 service instructions model ms, mb, mc, md, mt, mtl, mtefi 3. Remove the pto cover (between the footrests). Remove the shipping wire from the counterweight springs, place the lift handle in the up (back) position, and hook the counterweight springs on...

Page 53: Service Instructions

Page: 1-33 walker manufacturing company july 2006 service instructions align pto shaft and pto coupler (shown before engaging snowblower mounting tubes with tractor support arms) b. Slide snowblower assembly onto tractor. Reaching under the tractor, pull the ring back on the pto quick coupler, slide...

Page 54: Service Instructions

Page: 1-34 walker manufacturing company july 2006 service instructions 11. Pull the lift handle back to raise the snowblower to the up position. Snowblower in up (raised) position 12. Pull the lift handle back, press the foot trigger, and hold on to the lift handle while letting it move forward to l...

Page 55: Service Instructions

Walker manufacturing company page: 2-1 july 2006 service instructions section 2 lubrication contents of this section subject page lubrication - tractors ........................................................................... 2-3 engine oil - all models ..............................................

Page 56: Service Instructions

Walker manufacturing company page: 2-2 july 2006 service instructions grease fitting and oil point lubrication ...........................................................2-18 grease fitting and oil point lubrication ...........................................................2-18 pto u-joint ...........

Page 57: Service Instructions

Page: 2-3 walker manufacturing company july 2006 service instructions lubrication - tractors proper lubrication is an important maintenance proce- dure. It reduces wear and makes the machine quieter and easier to operate. Engine oil - all models engine break-in oil model mw, mc, mt, mtl, mtefi no sp...

Page 58: Service Instructions

Page: 2-4 walker manufacturing company july 2006 service instructions important: do not overfill the crankcase (oil above “f” mark) as this can result in engine overheating, loss of power, and possible engine damage. Dipstick operating range - model mc, mt, mtl, mtefi dipstick operating range - mode...

Page 59: Service Instructions

Page: 2-5 walker manufacturing company july 2006 service instructions dipstick position for checking oil level dipstick operating range 4. If additional oil is needed, refer to specifications for proper crankcase lubricant. Fill to the full (h) mark. Important: do not overfill crankcase [oil above f...

Page 60: Service Instructions

Page: 2-6 walker manufacturing company july 2006 service instructions oil drain/oil filter location - model mc, mt, mtl, mtefi (model mt shown) oil drain location (view from left side of tractor) - model md oil drain, dipstick (oil fill), and oil filter locations (view from lower left side of tracto...

Page 61: Service Instructions

Page: 2-7 walker manufacturing company july 2006 service instructions all models 4. Before removing the oil filter, clean the area around the filter to keep dirt and debris out of the engine. Oil filter location - model md 5. Remove the old oil filter and wipe off the filter mounting surface on the ...

Page 62: Service Instructions

Page: 2-8 walker manufacturing company july 2006 service instructions model mw 9. Fill the crankcase with new, clean oil. Use only crankcase lubricants recommended by the engine manufacturer. Refer to specifications in this man- ual or the engine owner’s manual. Use the recom- mended oil viscosity f...

Page 63: Service Instructions

Page: 2-9 walker manufacturing company july 2006 service instructions note: in case the gearboxes are completely drained of oil, approximately 5 fl. Oz. (15 cl) of oil per gearbox is required to refill the gear drive assembly. Note: since the gearboxes are connected as a unit by connector tubes, it ...

Page 64: Service Instructions

Page: 2-10 walker manufacturing company july 2006 service instructions tractor pto gearbox lubrication - model mc, md, mt, mtl, mtefi checking gearbox oil level check the gearbox oil level every 25 hours, and if nec- essary, add oil [sae e.P. (extreme pressure) 80w-90 gear lube] to maintain oil leve...

Page 65: Service Instructions

Page: 2-11 walker manufacturing company july 2006 service instructions tractor pto gearbox lubrication - model ms the tractor pto gearbox is permanently lubricated (oil filled) and sealed requiring no scheduled lubrication. However, the gearbox oil seals should be checked ev- ery 25 hours for indica...

Page 66: Service Instructions

Page: 2-12 walker manufacturing company july 2006 service instructions transaxle lubrication - model mb • the transaxle oil lubrication is sae 20w-50 engine oil. • inspect both transaxle cases and hoses after every 100 hours of operation for visible leaks. • the fluid levels for each transaxle can b...

Page 67: Service Instructions

Page: 2-13 walker manufacturing company july 2006 service instructions oil filter access steering linkage and pto linkage lubrication - model mw the steering and pto linkage are located at the rear of the tractor below the body. The grease and oil points should be lubricated every 25 hours. Steering...

Page 68: Service Instructions

Page: 2-14 walker manufacturing company july 2006 service instructions 3. If the fluid is below the cold mark (or the trans- mission is not performing properly), loosen the air bleed plug (located on the top of transmission case next to the plastic reservoir). A. If a small amount of fluid leaks fro...

Page 69: Service Instructions

Page: 2-15 walker manufacturing company july 2006 service instructions grease fitting and oil point lubrication - all models lubricate the grease fittings and oil points after every 25 hours of operation. Lubricate more often when op- erating in dusty or dirty conditions. Use sae general purpose lit...

Page 70: Service Instructions

Page: 2-16 walker manufacturing company july 2006 service instructions lifting mechanism lubricate the grease fittings (4) across the lifting mech- anism attached to the frame every 25 hours. Use sae general purpose lithium or molybdenum base grease. Lubricating lift mechanism and camshaft drive cam...

Page 71: Service Instructions

Page: 2-17 walker manufacturing company july 2006 service instructions rotary broom drive chain lubricate the drive chain every 25 hours. A light penetrating oil or special purpose chain oil is recom- mended. Lubricate the drive chain as follows: 1. Remove the two (2) bolts fastening the chain guard...

Page 72: Service Instructions

Page: 2-18 walker manufacturing company july 2006 service instructions two-stage snowblower reduction chain lubricate the reduction chain every 25 hours. A light penetrating oil or special purpose chain oil is recom- mended. Lubricate the reduction chain as follows: 1. Remove the bolt fastening the ...

Page 73: Service Instructions

Page: 2-19 walker manufacturing company july 2006 service instructions 2. Clean the area around the gearbox cover plate to prevent contaminants from entering the gearcase. 3. Remove the screws securing the cover plate on the gearbox. 4. Check the level of lubricant in the gearbox. If the lubricant i...

Page 74: Service Instructions

Page: 2-20 walker manufacturing company july 2006 service instructions ident lubrication no. No. Location type places ident lubrication no. No. Location type places 1 deck caster wheel fork pivot grease 2 2 deck caster wheel bearing grease 2 3 tee gearbox, deck oil * 1 4 blade drive gearbox oil * 2 ...

Page 75: Service Instructions

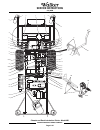

Page: 2-21 walker manufacturing company july 2006 service instructions 2 2 3 1 1 5 4 4 7 7 8 8 6 6 6 6 10 11 9 13 13 12 15 16 14 14 18 19 19 17 21 & 36 22 22 21 24 25 23 27 27 26 29 30 30 & 35 28 32 33 31 34 34 20 chassis and deck lubrication points - model mt.

Page 76: Service Instructions

Page: 2-22 walker manufacturing company july 2006 service instructions ident lubrication no. No. Location type places ident lubrication no. No. Location type places 1 deck caster wheel fork pivot grease 2 2 blade drive gearbox oil * 2 3 tee gearbox, deck oil * 1 4 deck caster wheel bearing grease 2 ...

Page 77: Service Instructions

Page: 2-23 walker manufacturing company july 2006 service instructions 2 2 3 4 4 13 13 12 12 9 10 11 15 16 14 18 18 20 21 22 19 17 23 24 23 & 32 25 25 26 28 27 30 30 29 31 1 1 5 7 7 8 8 6 6 6 6 chassis and deck lubrication points - model md.

Page 78: Service Instructions

Page: 2-24 walker manufacturing company july 2006 service instructions ident lubrication no. No. Location type places ident lubrication no. No. Location type places 1 deck caster wheel fork pivot grease 2 2 deck caster wheel bearing grease 2 3 tee gearbox, deck oil* 1 4 blade drive gearbox oil* 2 5 ...

Page 79: Service Instructions

Page: 2-25 walker manufacturing company july 2006 service instructions 2 2 1 1 4 7 6 6 26 26 29 28 27 27 & 34 30 19 20 28 & 35 32 33 31 8 13 14 19 3 4 5 6 6 7 8 13 15 16 17 18 14 21 21 23 24 22 25 10 11 9 12 chassis and deck lubrication points - model mc.

Page 80: Service Instructions

Page: 2-26 walker manufacturing company july 2006 service instructions ident lubrication no. No. Location type places ident lubrication no. No. Location type places 1 deck caster wheel fork pivot grease 2 2 blade drive gearbox oil * 2 3 tee gearbox, deck oil * 1 4 deck caster wheel bearing grease 2 ...

Page 81: Service Instructions

Page: 2-27 walker manufacturing company july 2006 service instructions 2 3 1 4 10 6 7 6 8 31 13 32 28 & 33 27 & 34 15 31 9 27 28 25 29 30 26 26 20 21 9 14 15 11 12 18 16 6 7 6 8 4 2 1 10 11 12 13 22 22 23 23 22 22 24 24 23 24 25 18 19 17 19 5 chassis and deck lubrication points - model ms.

Page 82: Service Instructions

Page: 2-28 walker manufacturing company july 2006 service instructions ident lubrication no. No. Location type places ident lubrication no. No. Location type places 1 deck caster wheel fork pivot grease 2 2 deck caster wheel bearing grease 2 3 tee gearbox, deck oil * 1 4 blade drive gearbox oil * 2 ...

Page 83: Service Instructions

Page: 2-29 walker manufacturing company july 2006 service instructions chassis and deck lubrication points - model mw 3 4 5 6 6 12 14 8 7 1 2 4 6 7 6 10 9 11 13 11 14 16 11 15 1 17 17 10 2.

Page 84: Service Instructions

Page: 2-30 walker manufacturing company july 2006 service instructions ident lubrication no. No. Location type places ident lubrication no. No. Location type places lubrication points - mb (start s/n 2004-68441) 1 deck caster wheel fork pivot grease 2 2 deck caster wheel bearing grease 2 3 tee gearb...

Page 85: Service Instructions

Page: 2-31 walker manufacturing company july 2006 service instructions chassis and deck lubrication points - model mb (start s/n 2004-68441) 3 4 5 7 7 8 9 10 13 16 17 18 6 1 2 4 7 6 7 9 12 18 & 23 21 & 24 22 20 19 15 1 2 11 12 14 21 20

Page 86: Service Instructions

Page: 2-32 walker manufacturing company july 2006 service instructions ident lubrication no. No. Location type places ident lubrication no. No. Location type places lubrication points - mb (start s/n 2007-85248) 1 deck caster wheel fork pivot grease 2 2 deck caster wheel bearing grease 2 3 tee gearb...

Page 87: Service Instructions

Page: 2-33 walker manufacturing company july 2006 service instructions 3 4 5 7 7 8 11 9 13 16 17 18 6 1 2 4 7 6 7 11 12 22 & 23 20 & 24 21 20 19 15 1 2 10 12 14 22 chassis and deck lubrication points - model mb (start s/n 2007-85248).

Page 88: Service Instructions

Page: 2-34 walker manufacturing company july 2006 service instructions ident lubrication no. No. Location type places ident lubrication no. No. Location type places lubrication points - perfaerator 1 deck caster wheel fork pivot grease 2 2 deck caster wheel bearing grease 2 3 rod bearing bushing gre...

Page 89: Service Instructions

Page: 2-35 walker manufacturing company july 2006 service instructions 2 3 1 3 7 6 6 5 8 7 6 11 3 1 2 3 4 9 10 chassis and deck lubrication points - perfaerator.

Page 90: Service Instructions

Page: 2-36 walker manufacturing company july 2006 service instructions ident lubrication no. No. Location type places ident lubrication no. No. Location type places 1 pto shield hinge oil 1 2 hitch locking lever pivot oil 1 3 mounting tube sockets grease 2 4 hitch lift crank grease 1 5 hitch pivot s...

Page 91: Service Instructions

Page: 2-37 walker manufacturing company july 2006 service instructions lubrication points - implement hitch.

Page 92: Service Instructions

Page: 2-38 walker manufacturing company july 2006 service instructions ident lubrication no. No. Location type places ident lubrication no. No. Location type places lubrication points - dozer blade 1 cutting edge oil 1 2 skid shoe brackets grease 2 (grease slide area) 3 hitch box pin oil 1 4 trip sp...

Page 93: Service Instructions

Page: 2-39 walker manufacturing company july 2006 service instructions lubrication points - dozer blade.

Page 94: Service Instructions

Page: 2-40 walker manufacturing company july 2006 service instructions ident lubrication no. No. Location type places ident lubrication no. No. Location type places lubrication points - rotary broom 1 chain drive sprocket oil 1 2 chain drive shaft grease 1 3 gearbox oil * 1 4 wheel brackets grease 2...

Page 95: Service Instructions

Page: 2-41 walker manufacturing company july 2006 service instructions lubrication points - rotary broom.

Page 96: Service Instructions

Page: 2-42 walker manufacturing company july 2006 service instructions ident lubrication no. No. Location type places ident lubrication no. No. Location type places lubrication points - two-stage snowblower 1 auger sections grease 2 2 gearbox oil * 1 3 cutting edge oil 1 4 skid shoes grease 2 5 gear...

Page 97: Service Instructions

Page: 2-43 walker manufacturing company july 2006 service instructions lubrication points - two-stage snowblower.

Page 98: Service Instructions

Page: 2-44 walker manufacturing company july 2006 service instructions ident lubrication no. No. Location type places ident lubrication no. No. Location type places lubrication points - debris blower 1 front gauge wheel grease 1 2 plastic anti-friction insert grease 1 3 air blast nozzle oil 1 4 spro...

Page 99: Service Instructions

Page: 2-45 walker manufacturing company july 2006 service instructions lubrication points - debris blower.

Page 100: Service Instructions

Page: 2-46 walker manufacturing company july 2006 service instructions ident lubrication no. No. Location type places ident lubrication no. No. Location type places lubrication points - sb36 snowblower 1 spout deflector pivot oil 2 2 rotation worm oil 1 handle pivot 3 foot trigger latch grease 1 (gr...

Page 101: Service Instructions

Page: 2-47 walker manufacturing company july 2006 service instructions 3 1 4 4 9 6 6 2 7 10 rear view bottom view lubrication points - sb36 snowblower 8 6 5 5 6.

Page 102: Service Instructions

Page: 2-48 walker manufacturing company july 2006 service instructions.

Page 103: Service Instructions

Walker manufacturing company page: 3-1 july 2006 service instructions section 3 maintenance instructions contents of this section subject page maintenance schedule chart ...............................................................3-3 checking/servicing - all models ..................................

Page 104: Service Instructions

Walker manufacturing company page: 3-2 july 2006 service instructions cylinder head cooling fins - model ms ..................................................3-25 engine cooling system - model md, mtl .......................................................3-25 radiator screen and cooling fins .........

Page 105: Service Instructions

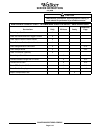

Page: 3-3 walker manufacturing company july 2006 service instructions maintenance schedule chart recommended service intervals - model mt, mtl, mtefi, mtlefi service item daily 25 hours 100 hours 200 hours yearly every 2years ref. Page check engine crankcase oil level x 2-3 check/clean engine air co...

Page 106: Service Instructions

Page: 3-4 walker manufacturing company july 2006 service instructions maintenance schedule chart - recommended service intervals - model md service item daily 25 hours 100 hours 200 hours yearly every 2years ref. Page check engine crankcase oil level x 2-3 check coolant level in radiator and overflo...

Page 107: Service Instructions

Page: 3-5 walker manufacturing company july 2006 service instructions maintenance schedule chart - recommended service intervals - model mc service item daily 25 hours 100 hours 200 hours yearly every 2years ref. Page check engine crankcase oil level x 2-3 check/clean engine air cooling system* x 3-...

Page 108: Service Instructions

Page: 3-6 walker manufacturing company july 2006 service instructions maintenance schedule chart - recommended service intervals - model ms service item daily 25 hours 50 hours 100 hours yearly every 2years ref. Page check engine crankcase oil level x 2-4 check/clean engine air cooling system* x 3-2...

Page 109: Service Instructions

Page: 3-7 walker manufacturing company july 2006 service instructions maintenance schedule chart - recommended service intervals - model mw service item daily 25 hours 50 hours 100 hours 200 hours ref. Page check engine crankcase oil level x 2-3 check/clean engine air intake screen* x 3-27 check for...

Page 110: Service Instructions

Page: 3-8 walker manufacturing company july 2006 service instructions maintenance schedule chart - recommended service intervals - model mb service item daily 25 hours 50 hours 100 hours yearly ref. Page check engine crankcase oil level x 2-3 check/clean engine air cooling system* x 3-27 clean grass...

Page 111: Service Instructions

Page: 3-9 walker manufacturing company july 2006 service instructions maintenance schedule chart - recommended service intervals - implements model service item daily 25 hours yearly reference page all models: check tire chains (optional) x check gauge wheels or skid shoes x check tractor tailweight...

Page 112: Service Instructions

Page: 3-10 walker manufacturing company july 2006 service instructions maintenance schedule chart - recommended service intervals - sb36 snowblower service item daily 25 hours yearly reference page check auger condition x check lift handle and foot trigger function x check spout position control han...

Page 113: Service Instructions

Page: 3-11 walker manufacturing company july 2006 service instructions checking/servicing - all models model ms, mw, mb, mc, mt model md engine cooling system - model md, mtl coolant level overflow tank - model mtl check the coolant level in the coolant recovery tank and maintain the coolant level b...

Page 114: Service Instructions

Page: 3-12 walker manufacturing company july 2006 service instructions security of air filtration components - model ms, mc, md, mt note: the following inspection is only an external inspection and should be done without “disturbing” the filtration components. On a daily basis, visually inspect the ...

Page 115: Service Instructions

Page: 3-13 walker manufacturing company july 2006 service instructions wheel nuts torque - model mw, mb check every 100 hours the eight (8) drive tire mount- ing nuts. They should each be torqued to 75-85 ft-lbs. (101.7-115.2 n ⋅ m). Sharpen mower blades - all models check mower blade(s) for straigh...

Page 116: Service Instructions

Page: 3-14 walker manufacturing company july 2006 service instructions blade balanced on magnetic wall-mounted balancer 7. Mount the blade with wing tips pointing up into the housing. Reinstall the blade, washer, lock washer, and nut. Tighten the nut to 60 ft-lb (81.3 n ⋅ m). Model ms, mc, md, mt, m...

Page 117: Service Instructions

Page: 3-15 walker manufacturing company july 2006 service instructions mower deck gearbox oil seals - all decks the mower deck gearbox seals should be inspected every 25 hours for evidence of oil leaking; particularly the lower oil seal on the blade drive gearbox. This seal is protected by the trash...

Page 118: Service Instructions

Page: 3-16 walker manufacturing company july 2006 service instructions fuel valve solenoid - model md the starting and stopping of the diesel engine is con- trolled by the fuel shut-off valve. If the engine cranks, but does not start or the engine does not stop when the ignition switch is turned off...

Page 119: Service Instructions

Page: 3-17 walker manufacturing company july 2006 service instructions blade brake action - all models model ms, mw, mc, md, mt check the function of the cutter blade brake (and blow- er brake on ghs models) by engaging the blade clutch (pto), operating the engine at full throttle, then disen- gagin...

Page 120: Service Instructions

Page: 3-18 walker manufacturing company july 2006 service instructions cleaning engine air cleaner system - model ms, mc, md, mt model mc, md, mt there are two main components in the engine air clean- er system: a turbine precleaner and a donaldson radi- alseal™ air cleaner. Each component is checke...

Page 121: Service Instructions

Page: 3-19 walker manufacturing company july 2006 service instructions donaldson air cleaner donaldson air cleaner cover hose clamp precleaner tube turbine precleaner air restriction gauge hose clamp air intake hose hose clamp engine safety filter air cleaner cartridge vacuator™ valve engine air cle...

Page 122: Service Instructions

Page: 3-20 walker manufacturing company july 2006 service instructions donaldson air cleaner vacuator™ valve donaldson air cleaner cover air intake hose turbine precleaner precleaner tube engine air cleaner cartridge hose clamp safety filter air restriction gauge brass elbow engine air cleaner syste...

Page 123: Service Instructions

Page: 3-21 walker manufacturing company july 2006 service instructions engine air cleaner cartridge hose clamp vacuator™ valve donaldson air cleaner cover safety filter donaldson air cleaner hose clamp air intake hose air restriction gauge engine air cleaner system components - model ms.

Page 124: Service Instructions

Page: 3-22 walker manufacturing company july 2006 service instructions donaldson radialseal™ air cleaner - model ms, mc, md, mt, mtl a remote mounted donaldson radialseal™ air cleaner provides the air filtering function. The paper filter ele- ment slides over an outlet tube inside the air cleaner ca...

Page 125: Service Instructions

Page: 3-23 walker manufacturing company july 2006 service instructions 7. Use a clean, damp cloth and wipe the interior of the air cleaner canister clean. Use special care to clean both the inside and outside surfaces of the outlet tube. Important: any dust left on the inside of the out- let tube wi...

Page 126: Service Instructions

Page: 3-24 walker manufacturing company july 2006 service instructions 1. Close the fuel shut-off valve. 2. Loosen sediment bowl and remove filter screen and gasket. Replace filter screen, if damaged (use only kawasaki replacement filter #49019-2095). 3. Remove any sediment, wipe clean and reinstall...

Page 127: Service Instructions

Page: 3-25 walker manufacturing company july 2006 service instructions cooling system airflow cylinder head cooling fins - model ms it is essential for performance and longevity of the air- cooled engine to keep the cylinder head cooling fins clean and free of obstruction. After every 8 hours of ope...

Page 128: Service Instructions

Page: 3-26 walker manufacturing company july 2006 service instructions note: directing pressurized air or water from the fan side of the radiator outward is recommended to dislodge material packed on the outside of the cool- ing fins. Do not use cold water on a hot radiator. Flushing radiator and ch...

Page 129: Service Instructions

Page: 3-27 walker manufacturing company july 2006 service instructions engine cooling system - model mw air intake screen before each use , check that the air intake (rotary) screen is free from grass and debris and clean if nec- essary. Engine cooling fins every 100 hours , check and clean the cool...

Page 130: Service Instructions

Page: 3-28 walker manufacturing company july 2006 service instructions air cleaner components grass buildup in mower housing - all models model ms, mw, mb, mc, mt model md all models 1. Raise the deck lock lever handle on each side of the carrier frame and pull out to release carrier frame for tilti...

Page 131: Service Instructions

Page: 3-29 walker manufacturing company july 2006 service instructions ghs blower - model ms, mc, md, mt normally, the ghs blower operates with no mainte- nance or cleaning. However, when mowing grass that is dirty and damp (especially springtime mowing), a deposit of dirt may accumulate inside the ...

Page 132: Service Instructions

Page: 3-30 walker manufacturing company july 2006 service instructions model ms pto drive belt removal for cleaning ghs blower - model ms 3. Reinstall the pto drive belt by reversing the re- moval procedure. Ghs exhaust screen - model ms, mc, md, mt refer to cleaning the ghs exhaust screen in this s...

Page 133: Service Instructions

Page: 3-31 walker manufacturing company july 2006 service instructions transaxle cooling fins - model mb keeping the cooling fins on the transaxles clean and free of obstruction is essential to avoid overheating the transmission fluid and shortening transmission life. The cooling fins should be chec...

Page 134: Service Instructions

Page: 3-32 walker manufacturing company july 2006 service instructions.

Page 135: Service Instructions

Walker manufacturing company page: 4-1 july 2006 service instructions section 4 service procedures contents of this section subject page replacing/repairing - all models ........................................................4-4 drive belts - model mc, mt, mtl .........................................

Page 136: Service Instructions

Walker manufacturing company page: 4-2 july 2006 service instructions ghs blower assembly installation - model ms, mc, md, mt ...................4-30 10.5” blower wheel removal - model mc, md, mt ..................................4-31 replacing fuel valve solenoid - model md ...........................

Page 137: Service Instructions

Walker manufacturing company page: 4-3 july 2006 service instructions handlebar height adjustment - mw .................................................................4-58 forward speed control friction lock - model ms, mc, md, mt .....................4-59 tilt-up deck adjustable stop - all decks ....

Page 138: Service Instructions

Page: 4-4 walker manufacturing company july 2006 service instructions replacing/repairing - all models model ms, mw, mb, mc, mt model md all models important: always use genuine factory replace- ment parts. Substitute parts can result in product mal- function and possible injury to the operator and/...

Page 139: Service Instructions

Page: 4-5 walker manufacturing company july 2006 service instructions jackshaft drive belt engine pto belt ghs blower belt (ghs model only) hydrostatic ground drive belt belt locations - model mc, mt, mtl.

Page 140: Service Instructions

Page: 4-6 walker manufacturing company july 2006 service instructions jackshaft drive belt engine pto belt engine fan belt ghs blower belt (ghs model only) hydrostatic ground drive belt belt locations - model md.

Page 141: Service Instructions

Page: 4-7 walker manufacturing company july 2006 service instructions pto drive belt ground drive belt engine belt belt locations - model ms engine/pto belt matched set ground drive belt belt locations - model mb s/n 2004-68441.

Page 142: Service Instructions

Page: 4-8 walker manufacturing company july 2006 service instructions pto belts ground drive belt belt locations - model mb s/n 2007-85248.

Page 143: Service Instructions

Page: 4-9 walker manufacturing company july 2006 service instructions engine pto drive belt (3 groove power band) - model mc, mt, mtl 1. To remove the engine pto drive belt: a. Remove the jackshaft drive belt from its idler pulley (by pushing down on idler pulley) and let the belt drop down out of t...

Page 144: Service Instructions

Page: 4-10 walker manufacturing company july 2006 service instructions engine pto drive belt (3 groove power band) - model md 1. To remove the engine pto drive belt: a. Remove the jackshaft drive belt from its idler pulley (by pushing down on cold start lever) and let the belt drop down out of the w...

Page 145: Service Instructions

Page: 4-11 walker manufacturing company july 2006 service instructions engine belt - model ms 1. To remove the engine belt: a. Relax the belt by depressing the spring- loaded idler arm. B. Roll the belt off the compound pulley and remove the belt. Engine belt (engaged) compound pulley idler pulley b...

Page 146: Service Instructions

Page: 4-12 walker manufacturing company july 2006 service instructions pto drive belt - model ms 1. To remove the pto drive belt: a. Remove the engine belt, as described in pre- vious section. B. Remove 1/4-20 x 3/4 bolt locating belt guide on gearbox pulley and rotate guide to clear belt. C. Move b...

Page 147: Service Instructions

Page: 4-13 walker manufacturing company july 2006 service instructions pto drive belt - model mw 1. Remove the two mounting bolts holding the pto belt guide in place and loosen the front mounting bolts of pto actuator assembly (as shown). Re- move belt guide. Remove nuts on the front of brake band a...

Page 148: Service Instructions

Page: 4-14 walker manufacturing company july 2006 service instructions engine/pto belt - model mb 1. To remove the engine/pto belts: a. Remove belt guard from underneath muffler. Refer to remove belt guard photo. B. Relax the belt by depressing the spring- loaded idler arm. C. Roll the belts off the...

Page 149: Service Instructions

Page: 4-15 walker manufacturing company july 2006 service instructions engine/pto belt 1. To remove the engine/pto belt: a. Loosen and remove idler tension bolt and jam nut. B. Relax belt by depressing idler arm. C. Roll the belt off the pulley and remove the belt. Idler arm engine/pto belts idler t...

Page 150: Service Instructions

Page: 4-16 walker manufacturing company july 2006 service instructions jackshaft drive belt - model mc, mt, mtl 1. To remove the jackshaft drive belt: a. Remove the engine pto drive belt, as described in previous section. Jackshaft drive belt (engaged) 2. Reverse the removal procedure to replace the...

Page 151: Service Instructions

Page: 4-17 walker manufacturing company july 2006 service instructions jackshaft drive belt - model md 1. To remove the jackshaft drive belt: a. Relax the belt by releasing spring tension from the jackshaft drive idler arm using the cold start lever. Cold start lever (released) spring tension (relea...

Page 152: Service Instructions

Page: 4-18 walker manufacturing company july 2006 service instructions ghs blower drive belt - model mc, md, mt, mtl 1. Remove the ghs blower drive belt tension by de- pressing the idler pulley on the tightener arm. Roll the belt off the blower pulley. The belt should be clear of the blower pulley, ...

Page 153: Service Instructions

Page: 4-19 walker manufacturing company july 2006 service instructions b. Slide belt off pulleys, then release the idler. Hydrostatic ground drive belt - model mc, mt, mtl 1. To remove the hydrostatic ground drive belt: a. Raise the spring-loaded belt tightener arm and idler pulley to relax belt. Hy...

Page 154: Service Instructions

Page: 4-20 walker manufacturing company july 2006 service instructions hydrostatic ground drive belt - model md 1. To remove the hydrostatic ground drive belt: a. Raise the spring-loaded belt tightener arm and idler pulley to relax belt. Transmission drive pulley spring idler pulley jackshaft belt t...

Page 155: Service Instructions

Page: 4-21 walker manufacturing company july 2006 service instructions ground drive belt - model ms 1. To remove the ground drive belt: a. Raise the spring-loaded idler to relax belt. B. Slide belt off pulleys, then release the idler. Raise idler pulley to relax belt transmission drive pulley ground...

Page 156: Service Instructions

Page: 4-22 walker manufacturing company july 2006 service instructions ground drive belt - model mb 1. To remove the ground drive belt: a. Raise the spring-loaded idler to relax belt. B. Slide belt off pulleys, then release the idler. Raise idler pulley to relax belt lh hydro-gear ground drive belt ...

Page 157: Service Instructions

Page: 4-23 walker manufacturing company july 2006 service instructions engine fan belt - model md 1. To remove the fan belt: a. Loosen the alternator mounting pivot bolt and the alternator bracket tensioner bolt. B. Pivot the alternator as shown to relax and remove belt. Engine fan belt (tight) engi...

Page 158: Service Instructions

Page: 4-24 walker manufacturing company july 2006 service instructions fuel filter - model mb, mc, mt, mt25 models mt, mtl, mc and mb are equipped with an in- line fuel filter. Visually inspect the filter periodically, and replace the filter yearly. Fuel filter location important: replace the fuel f...

Page 159: Service Instructions

Page: 4-25 walker manufacturing company july 2006 service instructions fuel filter - model md model md has two (2) fuel filters. Replace both the in-line filter and the kubota filter element every 400 hours of operation. Fuel filter location important: replace fuel filters only in a clean area where...

Page 160: Service Instructions

Page: 4-26 walker manufacturing company july 2006 service instructions pto shear pin - all models the pto drive shaft connection to the deck gearbox has a shear pin to provide shock load protection to the mower deck drive. This system provides primary shock protection in case of blade impact and wil...

Page 161: Service Instructions

Page: 4-27 walker manufacturing company july 2006 service instructions • check the blades for straightness by marking blade tip position inside the deck housing and then rotating the opposite end of the blade to the same position and comparing or using a blade balancer with straightness indicator. I...

Page 162: Service Instructions

Page: 4-28 walker manufacturing company july 2006 service instructions blade drive gearbox timing 8. Reinstall the four (4) bolts mounting the gearbox to the connector tube but do not tighten them at this time; leave connector tube bolts finger-tight. 9. Position the gear drive assembly on the deck ...

Page 163: Service Instructions

Page: 4-29 walker manufacturing company july 2006 service instructions 4. Remove the blower assembly from the chassis as follows: a. Remove the blower skid bar by removing front and rear mounting bolts from the skid bar (underneath the blower) and removing the bolt connecting the blower housing to t...

Page 164: Service Instructions

Page: 4-30 walker manufacturing company july 2006 service instructions pressing blower wheel out of housing blower wheel installation - model ms, mc, md, mt 1. To install the blower wheel, reverse the removal procedures. The front bearing is mounted on the blower wheel shaft, secured by a locking co...

Page 165: Service Instructions

Page: 4-31 walker manufacturing company july 2006 service instructions 10.5” blower wheel removal - model mc, md, mt with blower assembly removed and when required, replace the 10.5 blower wheel using the following procedure: 1. Remove intake tube by removing three (3) 1/4-20 x 1/2 bolts. 2. Remove ...

Page 166: Service Instructions

Page: 4-32 walker manufacturing company july 2006 service instructions replacing fuel valve solenoid - model md for checking operation of the solenoid, refer to checking/servicing the fuel valve solenoid in the maintenance instructions section. To replace the solenoid: 1. Remove the engine air intak...

Page 167: Service Instructions

Page: 4-33 walker manufacturing company july 2006 service instructions implements dozer blade cutting edge note: the cutting edge of the dozer blade is revers- ible and needs to be replaced only when both the top and bottom edges have worn. Replace the dozer blade cutting edge as follows: 1. Remove ...

Page 168: Service Instructions

Page: 4-34 walker manufacturing company july 2006 service instructions loosen chain idler and set screws 7. Remove the three bolts on the bearing flanges on each side of the broom and loosen the bearing set screws. Push the bearings and flanges towards the brush. 8. Remove the bearing, brush support...

Page 169: Service Instructions

Page: 4-35 walker manufacturing company july 2006 service instructions remove chain guard and loosen chain tension 3. Turn the brush drive shaft until the master link for the chain is accessible. 4. Remove the master link from the chain and remove the chain from the sprocket. 5. Place the new chain ...

Page 170: Service Instructions

Page: 4-36 walker manufacturing company july 2006 service instructions remove and replace sprocket align sprockets 7. Position the sprocket on the drive shaft so it is aligned with the chain drive shaft sprocket. 8. When the sprockets are aligned properly, tighten the set screw in the drive shaft sp...

Page 171: Service Instructions

Page: 4-37 walker manufacturing company july 2006 service instructions snowblower cutting edge replacement two-stage snowblower gearbox remove and replace the gearbox as follows: 1. Stop the tractor engine, set the parking brake, and remove the ignition key. Replace snowblower gearbox 2. Remove the ...

Page 172: Service Instructions

Page: 4-38 walker manufacturing company july 2006 service instructions replace reduction chain 6. Adjust the chain tension. Refer to adjust- ments of two-stage snowblower reduction chain tension in this section. 7. Reinstall the reduction box cover by reversing the removal procedures. Two-stage snow...

Page 173: Service Instructions

Page: 4-39 walker manufacturing company july 2006 service instructions debris blower drive belt 1. Remove the belt guard from the debris blower housing by removing the two (2) cover pins and hairpins securing it to the housing. 2. Loosen the three (3) nuts and three (3) bolts on lower pulley bearing...

Page 174: Service Instructions

Page: 4-40 walker manufacturing company july 2006 service instructions sb36 snowblower ending s/n 2001-1216 gearbox replacement remove and replace the gearbox as follows: 1. Remove the gearbox cover. Two (2) bolts (one on each side) fasten the cover to mounting tabs on the frame. 2. Loosen the set s...

Page 175: Service Instructions

Page: 4-41 walker manufacturing company july 2006 service instructions drive chain the drive chain should be replaced if, when adjusted properly, it can be pulled away from the front of the au- ger sprocket more than 1/2 of the height of a tooth on the sprocket. Running the snowblower with a worn ch...

Page 176: Service Instructions

Page: 4-42 walker manufacturing company july 2006 service instructions sprockets a sprocket should be replaced when the teeth be- come asymmetric (when the front side of a tooth is a different shape than the back side of the tooth). Note: generally; a small sprocket wears faster than a large sprocke...

Page 177: Service Instructions

Page: 4-43 walker manufacturing company july 2006 service instructions 10. Recheck the sprocket alignment with the chain in- stalled. Check sprocket alignment with chain installed 11. Lubricate the drive chain. Refer to lubrication of drive chain in the lubrication section. 12. Reinstall the auger g...

Page 178: Service Instructions

Page: 4-44 walker manufacturing company july 2006 service instructions 19. Lubricate the drive chain. Refer to lubrication of drive chain in the lubrication section. 20. Reinstall the auger guards and the chain guard cover by reversing the removal procedures. Snowblower housing auger shaft bolt auge...

Page 179: Service Instructions

Page: 4-45 walker manufacturing company july 2006 service instructions scraper blade inspect the scraper blade for wear or damage before each use. The blade is hardened and if the gauge wheels (or skid shoes) are properly adjusted, the blade should give a reasonable amount of service before re- plac...

Page 180: Service Instructions

Page: 4-46 walker manufacturing company july 2006 service instructions adjustments - all models safety switches - model mc, md, mt, mtl there are three (3) safety interlock switches on the tractor; seat switch, fsc neutral - park switch, and pto switch. If any of the following conditions occur durin...

Page 181: Service Instructions

Page: 4-47 walker manufacturing company july 2006 service instructions pto clutch engaged blade clutch (pto) - model mc, mt, mtl clutch engagement/belt tension the clutch engagement and pto belt tension are ad- justed using the clutch actuator rod. Initially, after in- stalling a new pto belt, after...

Page 182: Service Instructions

Page: 4-48 walker manufacturing company july 2006 service instructions clutch disengagement/brake action - model mc, mt, mtl the declutched or disengaged position of the blade clutch idler pulley is adjustable and is set to give belt re- lease without excessive slack and to apply the blade brake. Th...

Page 183: Service Instructions

Page: 4-49 walker manufacturing company july 2006 service instructions spring overall length 2 in. (51 mm) knuckle joint adjustment nut spring uncompressed blade clutch idler pulley blade clutch lever disengaged pto clutch disengaged - model mc.

Page 184: Service Instructions

Page: 4-50 walker manufacturing company july 2006 service instructions use the following procedures to check and adjust clutch disengagement and brake action: stop block eccentric adjustment - step 1 use the stop block attached to pto belt tightener arm to set the bottom position of the clutch idler...

Page 185: Service Instructions

Page: 4-51 walker manufacturing company july 2006 service instructions blade brake band adjustment note: the length of the actuator rod is adjusted by disconnecting the bottom clevis and shortening or lengthening accordingly. The standard pre-set length of the actuator rod is set at the factory at 8...

Page 186: Service Instructions

Page: 4-52 walker manufacturing company july 2006 service instructions clutch linkage adjustment - engaged clutch disengagement/brake action the declutched or disengaged position of the blade clutch idler pulley is adjustable and is set to give belt re- lease without excessive slack and to apply the...

Page 187: Service Instructions

Page: 4-53 walker manufacturing company july 2006 service instructions blade brake - model ms the mower blade drive (and blower on ghs models) is equipped with a brake system to stop blades within five (5) seconds after disengaging the clutch. A belt scrub- ber brake acting on the pto drive belt pro...

Page 188: Service Instructions

Page: 4-54 walker manufacturing company july 2006 service instructions blade clutch (pto) - model mw clutch disengagement/brake action the blade brake is activated by linkage to the clutch pulley mechanism. The brake is designed to stop the blades within five (5) seconds after disengaging the clutch...

Page 189: Service Instructions

Page: 4-55 walker manufacturing company july 2006 service instructions forward speed control stop and steering lever adjustment - model mt forward speed control stop and steering lever adjustment - model mc steering lever end play adjustment - step 2 1. Position the fsc lever to the most forward po-...

Page 190: Service Instructions

Page: 4-56 walker manufacturing company july 2006 service instructions model mc, md, mt, mtl 4. Check and adjust the neutral safety switch for closure and function with the fsc in neutral (the engine will not start when the switch is open). Slight adjustments can be made by careful- ly bending the l...

Page 191: Service Instructions

Page: 4-57 walker manufacturing company july 2006 service instructions fsc actuator stop adjustment - step 1 1. Loosen jam nut and back off the adjustment bolt lo- cated in the steering pivot rod (as shown). 2. Turn the ignition key to the on position and toggle the fsc switch to the neutral positio...

Page 192: Service Instructions

Page: 4-58 walker manufacturing company july 2006 service instructions speed control actuator adjustment (lh) tracking adjustment - step 4 1. Start engine and set the fsc switch to a normal walking speed. Check for equal drive speed for both wheels. 2. If one wheel is moving too fast, bring the mowe...

Page 193: Service Instructions

Page: 4-59 walker manufacturing company july 2006 service instructions forward speed control friction lock - model ms, mc, md, mt the fsc friction lock is adjusted to hold the selected forward speed when the steering levers are moved and yet the friction is not too heavy to make moving the control d...

Page 194: Service Instructions

Page: 4-60 walker manufacturing company july 2006 service instructions fuel valve solenoid linkage adjustment (shown with air intake hose removed for clarity) 2. If the gap is incorrect, adjust the linkage by loos- ening the jam nut at the solenoid, removing the cotter pin and washer from the connec...

Page 195: Service Instructions

Page: 4-61 walker manufacturing company july 2006 service instructions 3. Start the engine and allow it to warm up by running at 1/2 throttle for approximately five (5) minutes. The engine must be warm before making final set- tings. 4. Move the throttle to the idle position. Adjust idle speed for 1...

Page 196: Service Instructions

Page: 4-62 walker manufacturing company july 2006 service instructions throttle body/intake manifold assembly - model mtefi upper intake manifold general the efi engines have no carburetor, so the throttle function (regulate incoming combustion airflow) is in- corporated in the intake manifold assem...

Page 197: Service Instructions

Page: 4-63 walker manufacturing company july 2006 service instructions the idle speed adjustment procedure remains the same for engines with or without a dampening spring. Typi- cally, no periodic servicing is necessary in this area. If however, removal/replacement of the dampening spring is require...

Page 198: Service Instructions

Page: 4-64 walker manufacturing company july 2006 service instructions inserting feeler gauge (engines without stop screw) b. On engines with a stop screw, pivot the throt- tle shaft and plate into the “full throttle” posi- tion, so the tang of the throttle shaft plate is against the end of the high...

Page 199: Service Instructions

Page: 4-65 walker manufacturing company july 2006 service instructions 5. Reconnect the dampening spring into its governor lever hole from the bottom. Reinstall the bushing and reattach the throttle linkage. Refer to throttle linkage/governor lever connection photo. Reattach the governor spring in t...

Page 200: Service Instructions

Page: 4-66 walker manufacturing company july 2006 service instructions initial governor adjustment - model mtlefi the initial governor adjustment is especially critical on efi engines because of the accuracy and sensitivity of the electronic control system. Incorrect adjustment can result in overspe...

Page 201: Service Instructions

Page: 4-67 walker manufacturing company july 2006 service instructions checking ‘‘split’’ of clamp 2. Follow the instructions in step 2 of checking the initial adjustment , then reattach the throttle linkage to the governor lever with the bushing clip. It is not necessary to reattach the damper or g...

Page 202: Service Instructions

Page: 4-68 walker manufacturing company july 2006 service instructions to adjust the carburetor for engine idle, use the follow- ing procedure: 1. Gently close the idle mixture needle valve by turn- ing it clockwise until it bottoms lightly. Important: the needle valve and carburetor seat may be dam...

Page 203: Service Instructions

Page: 4-69 walker manufacturing company july 2006 service instructions idle mixture screw adjustment if engine is equipped with a secondary governor spring as shown in secondary governor spring illustration, check governor lever adjustment procedure before starting engine. Secondary governor spring ...

Page 204: Service Instructions

Page: 4-70 walker manufacturing company july 2006 service instructions adjust idle mixture 6. Hold throttle lever against idle speed adjustment screw and readjust idle to rpm shown below: a. 1200 rpm - governed idle spring part #805453 (red). B. 900 rpm - governed idle spring part #805454 (white). 7...

Page 205: Service Instructions

Page: 4-71 walker manufacturing company july 2006 service instructions ghs “full” signal horn with grass-pak ® switch - model ms, mc, md, mt model mc, md, mt if the ghs “full” signal horn is not sounding when the catcher is full, the following troubleshooting instructions apply: model ms if the ghs ...

Page 206: Service Instructions

Page: 4-72 walker manufacturing company july 2006 service instructions ghs signal horn adjustment (when horn sounds at wrong time) - model ms, md, mt the vertical position of the grass-pak ® switch is critical to make sure the catcher box does not overfill causing the delivery chute to clog. The ver...

Page 207: Service Instructions

Page: 4-73 walker manufacturing company july 2006 service instructions adjustments - implements perfaerator drive chain tension the drive chain should have 1/4 to 1/2 in. (6 to 13 mm) of slack at midspan. Remove the chain guard cover to check slack. Adjust the drive chain as follows: 1. Remove the t...

Page 208: Service Instructions

Page: 4-74 walker manufacturing company july 2006 service instructions implements dozer blade skid shoes adjust the skid shoes to allow the required clearance under the blade. On level, paved surfaces, adjust the skid shoes to allow approximately 1/4 in. (6 mm) clear- ance between the cutting edge a...

Page 209: Service Instructions

Page: 4-75 walker manufacturing company july 2006 service instructions loosen chain idler nut 2. Position the chain idler so the chain has 1/4 to 1/2 in. (6 to 13 mm) of slack. 3. Retighten the chain idler nut. 4. Recheck the drive chain tension. Proper drive chain tension two-stage snowblower skid ...

Page 210: Service Instructions

Page: 4-76 walker manufacturing company july 2006 service instructions debris blower front gauge wheel adjust the gauge wheel height according to surface condition. Important: the air blast nozzle must clear the ground at all times. 1. Remove the linchpin from the wheel pivot shaft. 2. Adjust wheel ...

Page 211: Service Instructions

Page: 4-77 walker manufacturing company july 2006 service instructions debris blower rotation pinions the two (2) rotation pinions should slightly contact each other without any resistance. 1. Loosen the set screw of each stop ring on the ro- tation handle. 2. Keeping the two (2) pinions slightly in...

Page 212: Service Instructions

Page: 4-78 walker manufacturing company july 2006 service instructions sb36 snowblower gauge wheels or skid shoes inspect for paper adjustment of the gauge wheels or skid shoes before each use. Important: failure to maintain proper adjustment of the gauge wheels or skid shoes can result in accelerat...

Page 213: Service Instructions

Walker manufacturing company page: 5-1 july 2006 service instructions section 5 electrical systems contents of this section subject page electrical system - model mt, mtl, mtefi ........................................ 5-2 circuit breakers ...............................................................

Page 214: Service Instructions

Page: 5-2 walker manufacturing company july 2006 service instructions electrical system - model mt, mtl, mtefi for troubleshooting, refer to wiring diagram. Important: for model mtefi, an illuminated en- gine service light on the control panel means that a fault has been detected in the electrical/f...

Page 215: Service Instructions

Page: 5-3 walker manufacturing company july 2006 service instructions electrical system - model md for troubleshooting, refer to wiring diagram. Important: disconnect both battery cables before unplugging any wiring connectors or making repairs on the electrical system. Important: disconnect the bat...

Page 216: Service Instructions

Page: 5-4 walker manufacturing company july 2006 service instructions electrical system - model mc for troubleshooting, refer to wiring diagram. Important: disconnect both battery cables before unplugging any wiring connectors or making repairs on the electrical system. Circuit breakers a master cir...

Page 217: Service Instructions

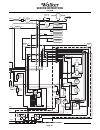

Page: 5-5 walker manufacturing company july 2006 service instructions schematics wiring diagram - model mt s1 = start circuit s2 = start/accessory circuit m = magneto ground circuit b = battery circuit a = accessory circuit g = ground circuit ignition switch circuits off start run run g + m b + a / ...

Page 218: Service Instructions

Page: 5-6 walker manufacturing company july 2006 service instructions relay - a relay - b only dept. Service test plug diagnostic 86 85 to j12/j13 to j1/j2 to j1 to j11 to j10 to j3/j4 to j3 to j3 to j8 to j20 to j20 to j20 to j2 to j4 to j5 j21 time delay module for tail wheel lock j17 j14 = igniti...

Page 219: Service Instructions

Page: 5-7 walker manufacturing company july 2006 service instructions optional light optional light red/wht red/ wht red/ wht wht pur red relay - d relay - c 20 amp fuse 10 amp fuse pump fuel horn switch grass pak starter solenoid starter oil pressure switch oil temp switch temp switch cylinder head...

Page 220: Service Instructions

Page: 5-8 walker manufacturing company july 2006 service instructions only dept. Service test plug diagnostic j14 = ignition coil ground j20 = speed pick-up sensor j13 = #2 ignition coil j12 = #1 ignition coil j11 = #2 ignition coil j10 = #1 ignition coil j8 = engine ground j5 = oxygen sensor j6 = r...

Page 221: Service Instructions

Page: 5-9 walker manufacturing company july 2006 service instructions _ + - 30 85 87 87a 30 85 85 blk to j12/j13 to j1/j2 red red/wht red/yel red/yel red gra 10 amp fuse f2 pump fuel 20 amp fuse 30 amp fuse j17 j16 red/ wht red/ wht blk blk blk 85 f1 30 87 red/yel battery blk blk chassis ground red ...

Page 222: Service Instructions

Page: 5-10 walker manufacturing company july 2006 service instructions _ + - 30 85 87 87a 30 85 30 85 87a ignition switch circuits start run start pto on off g + m b + a b + a / s1 + s2 s1 = start circuit m = magneto ground circuit relay - a pto relay off 30 + 87a open 30 + 87a start run relay - b s...

Page 223: Service Instructions

Page: 5-11 walker manufacturing company july 2006 service instructions ignition switch circuits off glow plug start run off off off off start glow plug run run start glow plug run run (low) run (high) glow plug start all open 30 + 19 + ac 30 + 17 + 50 + ac 30 + ac 30 + 87 30 + 87a 30 + 87a 30 + 87a ...

Page 224: Service Instructions

Page: 5-12 walker manufacturing company july 2006 service instructions b a m s1 s2 g 87 30 85 86 30 86 85 85 86 87a 87a 30 starter solenoid starter rectifier/regulator magneto oil pressure switch engine case ground to motor mount powerfil motor grass pak switch r r horn optional light optional light...

Page 225: Service Instructions

Page: 5-13 walker manufacturing company july 2006 service instructions g m s b starter solenoid starter fuel solenoid voltage regulator alternator magneto 20 amp fuse engine powerfil motor grass pak switch r r horn optional light chassis ground battery optional lights pto interlock switches hour met...

Page 226: Service Instructions

Page: 5-14 walker manufacturing company july 2006 service instructions b a m s1 s2 g 10 amp circuit breaker battery walker model mw beginning s/n 2004-68081 s1 = start circuit s2 = start/accessory circuit m = magneto ground circuit b = battery circuit a = accessory circuit g = ground circuit fsc act...

Page 227: Service Instructions

Page: 5-15 walker manufacturing company july 2006 service instructions hour meter b a m s1 s2 g 15 amp circuit breaker ba tter y walker model mb beginning s/n 2005-68441 thru 2006-85007 s1 = start circuit s2 = start/accessory circuit m = magneto ground circuit b = battery circuit a = accessory circu...

Page 228: Service Instructions

Page: 5-16 walker manufacturing company july 2006 service instructions optional lights optional lights optional lights hour meter b a m s1 s2 g 15 amp circuit breaker ba tter y walker model mb beginning s/n 2007-85248 s1 = start circuit s2 = start/accessory circuit m = magneto ground circuit b = bat...

Page 229: Service Instructions

Page: 5-17 walker manufacturing company july 2006 service instructions ba tter y walker hd8400 electrical schematic relay - a relay - b 40 amp circuit breaker red red red red red red red red red blk blk blk blk blk blk blk hydraulic valve block coil hydraulic pump lift switch dump switch blu/ wht bl...

Page 230: Service Instructions

Page: 5-18 walker manufacturing company july 2006 service instructions.

Page 231: Service Instructions

Walker manufacturing company page: 6-1 july 2006 service instructions section 6 decks contents of this section subject page aluminum gear drives ............................................................................. 6-2 aluminum peerless gearbox 1000-053a (walker p/n 5053-1) ....... 6-3 alumi...

Page 232: Service Instructions

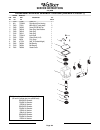

Page: 6-2 walker manufacturing company july 2006 service instructions 063 aluminum gear drives 5053-1 5051-16 5052-1 dsd42 5704-51 5051-16 5053-1 5052-1 dsd36 5704-43 5053-1 5051-16 5052-1 dsd48 5704-60 5704-51 5053-1 5051-16 5052-1 dml42 (ending serial # 2006-98651) 5052-1 5051-16 5052-1 dghs36 570...

Page 233: Service Instructions

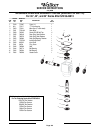

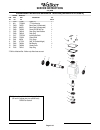

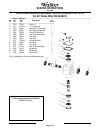

Page: 6-3 walker manufacturing company july 2006 service instructions 063 aluminum peerless gearbox 1000-053a (walker p/n 5053-1) 10 4 1 14 5 3 12 2 9 12 7 6 11 13 5 3 8 12 1 p018 772067 cover, lh 1 2 n/a 770092a right angle drive housing 1 3 p003 778101 miter gear (17 teeth-steel) 2 4 p008 792025 s...

Page 234: Service Instructions

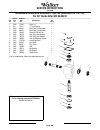

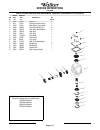

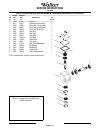

Page: 6-4 walker manufacturing company july 2006 service instructions 13 12 9 7 6 11 2 12 3 5 14 1 4 10 3 8 12 075 aluminum peerless gearbox 1000-054a (walker p/n 5052-1) 1 p018 772067 cover, lh 1 2 n/a 770092a right angle drive housing 1 3 p003 778101 miter gear (17 teeth-steel) 2 4 p008 792025 scr...

Page 235: Service Instructions

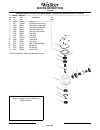

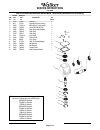

Page: 6-5 walker manufacturing company july 2006 service instructions 3 15 1 5 14 4 11 6 13 9 14 2 10 13 7 12 8 054 aluminum peerless gearbox 1000-099 (walker p/n 5051-16) for 36", 42", and 54" decks after s/n 99-46813 1 p018 772067 cover, lh 1 2 n/a 770117 “t” drive housing 1 3 p003 778101 miter ge...

Page 236: Service Instructions

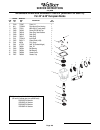

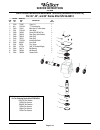

Page: 6-6 walker manufacturing company july 2006 service instructions 1 5 11 15 6 3 13 10 13 7 12 8 14 4 9 14 2 aluminum peerless gearbox 1000-100 (walker p/n 7751-16) for 48" decks after s/n 99-46813 1 p018 772067 cover, lh 1 2 n/a 770117 “t” drive housing 1 3 p047* 6064p1 bevel gear (15 teeth-stee...

Page 237: Service Instructions

Page: 6-7 walker manufacturing company july 2006 service instructions 11 5 1 15 6 3 2 10 13 8 7 12 14 6 9 13 4 13 aluminum peerless gearbox 1000-094 (walker p/n 5053-2) 1 p018 772067 cover, lh 1 2 n/a 770092a right angle drive housing 1 3 p057* 7062p1 bevel gear (15 teeth-steel) 1 4 p057* 6496p1 bev...

Page 238: Service Instructions

Page: 6-8 walker manufacturing company july 2006 service instructions 13 15 1 5 11 6 3 13 10 2 13 13 8 7 12 9 4 14 aluminum peerless gearbox 1000-095 (walker p/n 5052-2) 1 p018 772067 cover, lh 1 2 n/a 770092a right angle drive housing 1 3 p060* 7062p1 bevel gear (15 teeth-steel) 1 4 p060* 6064p1 be...

Page 239: Service Instructions

Page: 6-9 walker manufacturing company july 2006 service instructions 12 1 14 4 10 15 5 3 13 2 9 13 6 7 11 3 8 13 16 aluminum peerless gearbox 1000-074 (walker p/n 5052-10) for 42" & 48" european decks 1 p018 772067 cover, lh 1 2 n/a 770092a right angle drive housing 1 3 p003 778101 miter gear (17 t...

Page 240: Service Instructions