- DL manuals

- Walker

- Lawn Mower

- MBK23

- Operator's Manual

Walker MBK23 Operator's Manual

Summary of MBK23

Page 1

Operator’s manual safety, assembly, operating, and maintenance instructions model mbk23 please read and save these instructions beginning s/n: 116942 for safety, read all safety and operation effective date: 04-20-12 instructions prior to operating machine p/n 4000-5.

Page 2: Foreword

Foreword thank you. . . For purchasing a walker mower. Every effort has been made to provide you with the most reliable mower on the market, and we are sure you will be among our many satisfied custom- ers. If for any reason this product does not perform to your expectations, please contact your loc...

Page 3: Table Of Contents

Table of contents general information ________________ 1 highlighted information _____________ 1 glossary ____________________________ 1 identifying number locations ________ 1 engine serial number location _______ 2 servicing of engine and drivetrain components ______________ 2 specifications _____...

Page 4: Table Of Contents

Table of contents cleaning ____________________________ 46 engine air cooling system _____________ 46 cylinder head cooling fins ____________ 47 engine air cleaner system _____________ 48 cummins/fleetguard optiair™ air cleaner _________________________ 48 grass buildup in mower housing ________ 50 ...

Page 5: General Information

General information 1 highlighted information walker manufacturing recommends that any service requiring special training or tools be performed by an authorized walker mower dealer. There are sev- eral general practices to be aware of in the area of safety. Most accidents associated with the opera- ...

Page 6: General Information

General information 2 serial number mower deck serial number location engine serial number location refer to the engine manual that accompanies this manual or the photo below for the location of the engine serial number. Serial number engine serial number location servicing of engine and drivetrain ...

Page 7: Specifications

Specifications 3 model mbk23 engine manufacturer/model kohler command pro ech680, 2 cyl. (air-cooled), electronic fuel injection (efi) displacement cu. In. (cc) 42 (694) max. Power hp (kw) 23.0 (17.2) @ 3600 rpm governed rpm 3600 max. Torque lb·ft (n·m) 36.1 (48.9) idle rpm 1200 ± 75 spark plug type...

Page 8: Specifications

Specifications 4 model mbk23 transmission (continued) neutral transmission release by manual dump valve final drive transaxle direct to drive wheel transmission fluid factory service 20w-50 multi-viscosity motor oil (minimum sl grade oil) transmission capacity 79 fl oz (2336 ml) transmission cooling...

Page 9: Specifications

Specifications 5 model mbk23 dimensions length in. (cm) tractor only 58-1/4 (148) tail wheels forward - muffler is most rear point tractor wheel base 40 (102) tractor with tilted deck (approximate) 72 (183) with dsd36 85-1/2 (217) with dsd42 90-1/4 (229) with dsd42bd 94-3/4 (241) with dsd48 90-1/2 (...

Page 10: Specifications

Specifications 6 model mbk23 with dsd56 857 (389) with dml36 771 (350) with dml42a 798 (362) with dml42b 803 (364) with dml48 800 (363) side discharge decks model dsd36 dsd42 dsd42bd dsd48 dsd52 dsd56 cutting width in. (cm) 36 (91) 42 (107) 48 (122) 52 (132) 56 (142) drive type gear belt gear belt g...

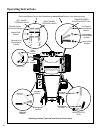

Page 11: Component Identification

Component identification 7 front view and right side view note: control identification shown in operating instructions section. Negative (-) battery cable tilt-up hook (not visible) deck discharge shield deck caster wheels counterweight springs and protective covers positive (+) battery cable deck l...

Page 12: Component Identification

Component identification 8 rear view and left side view left hand drive wheel fuel tank and cap muffler tailwheel fork and wheel tailpipe footrests fuel pickup line cylinder head cooling fins spread axle tail wheel dipstick oil fill.

Page 13: Component Identification

Component identification 9 top view (engine compartment) rh transaxle rh transaxle lockout rod pto clutch lever parking brake fuel pickup line fuel tank dipstick rubber bumpers (body support) rh transmission control arm lh transmission control arm steering lever dampening springs lh transaxle lh tra...

Page 14

Safety instructions - before operating 10 pay particular attention to any information labeled danger, warning, caution, important, and note in this manual. When you see the safety alert symbol ( ), read, understand, and follow the instructions. Fail ure to comply with safety instructions may result ...

Page 15

Safety instructions - before operating 11 6. Do not wear loose fitting clothing that could get caught in moving parts. Do not operate this ma- chine while wearing shorts; always wear ade- quate protective clothing, including long pants. Wearing safety glasses, safety shoes, and a helmet is advisable...

Page 16

Safety instructions - operating 12 1. Operate the mower only in daylight or in good artificial light with good visibility of the area being mowed. 2. Sit on the seat when starting the engine and operating the machine. Keep feet on the deck footrests at all times when the tractor is moving and/or mow...

Page 17

Safety instructions - operating 13 14. Never adjust cutting height with the engine running. Before adjusting cutting height or servicing, disengage the blade clutch (pto), stop the engine, and remove the ignition key. Wait for all movement to stop before getting off the seat. Note: the blade/pto bra...

Page 18

Safety instructions - maintenance 14 1. To prevent accidental starting of the engine when servicing or adjusting the machine, re- move the key from the ignition switch and dis- connect the spark plug wires. 2. To reduce fire hazards, keep the engine free of grass, leaves, excessive grease, and dirt....

Page 19: Safety Instructions

Safety instructions 15 safety, control, and instruction decals safety, control, and instruction decals are installed on the machine; if any are missing, illegible, or damaged, a replacement should be ordered and installed before putting the machine into operation. The decal part number is listed bel...

Page 20: Safety Instructions

Safety instructions 16 safety, control, and instruction decals safety, control, and instruction decals are installed on the machine; if any are missing, illegible, or damaged, a replacement should be ordered and installed before putting the machine into operation. The decal part number is listed bel...

Page 21: Safety Instructions

Safety instructions 17 safety, control, and instruction decals safety, control, and instruction decals are installed on the machine; if any are missing, illegible, or damaged, a replacement should be ordered and installed before putting the machine into operation. The decal part number is listed bel...

Page 22: Assembly Instructions

Assembly instructions 18 setup instructions walker mowers are shipped partially assembled to our distribution network, and are typically assem- bled by the selling dealer. For any additional as- sembly besides the following, contact your walker dealer. Battery service check the battery for electroly...

Page 23: Assembly Instructions

Assembly instructions 19 battery charging danger batteries produce explosive gases • charge the battery in a well-ventilated area, so that gases produced while charg- ing can dissipate. • keep sparks, flames, and smoking mate- rials away from the battery at all times. • make sure the battery cap ven...

Page 24: Assembly Instructions

Assembly instructions 20 attach shield deck discharge shield installation pto shaft guard installation position the shaft guard as shown and mount with two (2) 1/4-20 x 1/2 in. Bolts. Carrier frame tube sockets attach guard pto shaft guard installation tilt-up roller wheel installation mount the two...

Page 25: Assembly Instructions

Assembly instructions 21 5. Remove installation tool from quick disconnect ring and make sure the ring has “snapped” se- curely on the spline shaft. Important: do not operate tractor with coupler installation tool installed. Important: to prevent damage to the mow- er, make sure the pto quick discon...

Page 26: Assembly Instructions

Assembly instructions 22 deck leveling 1. Position mower on a smooth, level surface. Set the cutting height to the highest position - 4 in. (102 mm) - for easy access under the deck to measure blade height. Refer to adjusting cutting height in operating instructions . Note: a block of wood cut 4 in....

Page 27: Assembly Instructions

Assembly instructions 23 preoperating checklist before operating the mower for the first time, and as a routine before daily operations, it is important to make sure the mower is properly prepared and ready for operation. The following is a list of items to be checked. (for a mower with frequent ope...

Page 28: Assembly Instructions

Assembly instructions 24 check engine cooling system check that the engine cooling air intake screen is free of obstruction by grass clippings or debris and clean if required. Also, cylinder head cooling fins should be inspected and cleaned if any build-up of debris is noted. Refer to cleaning the c...

Page 29: Assembly Instructions

Assembly instructions 25 check mower blade condition, sharpness, balance, and security of mounting the blade mounting nuts on gear driven decks should be torqued to 60 lb·ft (81 n·m), and the blade mount- ing bolts on belt driven decks torqued to 70 lb·ft (95 n·m). If blade sharpening is required, r...

Page 30: Operating Instructions

Operating instructions 26 control identification, location, and function caution before operating the mower, become famil- iar with the location and function of all op- erator controls. Knowing the location, function, and operation of these controls is important for safe and efficient operation of t...

Page 31: Operating Instructions

Operating instructions 27 engine throttle the throttle control lever (red knob) is located on the left side of the seat and is used to control engine speed. Moving the lever forward toward the fast position increases engine speed; moving it back- ward toward the idle position decreases engine speed....

Page 32: Operating Instructions

Operating instructions 28 parking brake the parking brake functions by locking a detent arm internally into the transaxle. Moving the lever for- ward engages the parking brake; moving the le- ver backward releases the brake. Important: stop the tractor completely before engaging the parking brake. T...

Page 33: Operating Instructions

Operating instructions 29 body latch the tractor body hinges forward for maintenance ac- cess and is latched down in the operating posi- tion. To raise the body, pull back on body latch and lift body from the rear of the machine. Use the body support rod to secure the body in the raised position as ...

Page 34: Operating Instructions

Operating instructions 30 n 1. 2. Operating controls (top view from drivers point of view) blade clutch (pto) forward position (no control change) right wheel steering lever parking brake throttle the forward speed control also establishes the neutral-park position of the steering levers full forwar...

Page 35: Operating Instructions

Operating instructions 31 starting the engine caution before operating the mower, read and un- derstand all safety instructions and operat- ing instructions . Warning never run the engine in an enclosed or poorly ventilated area. Engine exhaust contains carbon monoxide, an odorless and deadly gas. 1...

Page 36: Operating Instructions

Operating instructions 32 1. Move the fsc out of neutral-park position to the desired forward speed. Do not hold for ward on steering levers. It is not necessary to hold the fsc lever in position since a friction lock maintains the selected lever position (and forward travel speed). Warning in case ...

Page 37: Operating Instructions

Operating instructions 33 note: smooth action on the steering levers will produce smooth mower operation. Remem- ber to keep the engine and ground speed slow until learning the control response. 4. The fsc may be adjusted forward for faster ground speed and backward for slower ground speed. When mow...

Page 38: Operating Instructions

Operating instructions 34 caution if the cutting blades strike a stationary ob- ject while mowing, stop the mower imme- diately, disconnect the spark plug wires, lift the deck, and inspect the deck and blades thoroughly for damage. Make sure that the blade timing has not been dis turbed (the blades ...

Page 39: Operating Instructions

Operating instructions 35 lift handle deck support pin hitch pin cutting height adjustment transaxle lockouts important: do not tow this mower faster than 2 mph (3.2 km/h) with the transmission lockout en- gaged. Towing can produce excessive internal pressure and damage the transaxle(s). To move the...

Page 40: Operating Instructions

Operating instructions 36 recommendations for mowing danger do not mow around overhanging tree branches or bushes at the same height as the operator’s torso and head where inad- vertent contact may cause injury. Avoid low hanging branches important: operate the engine at full throttle when mowing, t...

Page 41: Operating Instructions

Operating instructions 37 • when operating on a slope, reduce speed and use caution to start, stop, and maneuver. Avoid sharp turns or sudden changes in direction. The maximum recommended side slope operating angle is 15 degrees or 26% grade. 16 in. 15° 52 in. Maximum recommended side slope - do not...

Page 42: Maintenance Instructions

Maintenance instructions 38 maintenance schedule chart - recommended service intervals - model mbk23 service item daily 25 hours 100 hours 200 hours 400 hours yearly every 2 years ref. Page check engine crankcase oil level x 40 check/clean engine air cooling system* x 46 clean grass buildup under de...

Page 43: Maintenance Instructions

39 maintenance instructions kohler tips important tips for care of the kohler engine fuel system • fuel must be clean - free from water, dirt, and or- ganic material. • change fuel filter on a regular basis and when con- tamination is suspected or found in the fuel. • the fuel pump module is a seale...

Page 44: Maintenance Instructions

Maintenance instructions lubrication 40 lubrication warning do not attempt to lubricate the machine with the engine running. Disengage the pto clutch, shut off the machine, and re- move the ignition key. Proper lubrication is an important maintenance pro- cedure. It reduces wear and makes the machin...

Page 45: Maintenance Instructions

Maintenance instructions lubrication 41 3. Remove the dipstick and open oil drain valve and drain the oil into a suitable container. Be sure to allow ample time for complete drainage. Dipstick oil fill dipstick and oil fill (view from above right side of tractor) oil filter oil filter location (view...

Page 46: Maintenance Instructions

Maintenance instructions lubrication 42 mower deck gearbox lubrication on gear driven decks, the mower deck gearboxes (tee gearbox and blade drive gearboxes) are con- nected as a unitized assembly, and oil flows freely between them. The gearboxes are permanently lu- bricated (oil filled) and sealed ...

Page 47: Maintenance Instructions

Maintenance instructions lubrication 43 3. Reinstall drain plugs. 4. Remove the oil reservoir hose attached to the elbow on top of the transaxles and remove the elbows to access the oil fill openings. 5. Fill the transaxles with 20w-50 (api service class sl or higher) oil through the opening where t...

Page 48: Maintenance Instructions

Maintenance instructions lubrication 44 ident lubrication no. No. Location type places ident lubrication no. No. Location type places 1 deck caster wheel fork pivot grease 2 2 deck caster wheel bearing grease 2 3 blade spindle grease Δ 3 4 pivot assembly, tilt-up deck grease 4 5 deck support arm soc...

Page 49: Maintenance Instructions

Maintenance instructions lubrication 45 chassis and deck lubrication points (dsd42 shown) 1 11 12 7 4 4 13 14 15 29 30 29 5 1 2 12 4 5 4 16 27 & 31 21 2 22 18 20 16 19 28 27 26 17 23 24 23 25.

Page 50: Maintenance Instructions

Maintenance instructions lubrication/cleaning 46 mower deck spindle lubrication for belt driven decks, lubricate each deck spindle grease fitting every 25 hours. Use sae general purpose lithium or molybdenum base grease for grease fittings. Transaxle lubrication • the transaxle oil lubrication is sa...

Page 51: Maintenance Instructions

Maintenance instructions cleaning 47 cylinder head cooling fins it is essential for performance and longevity of the air-cooled engine to keep the cylinder head cooling fins clean and free of obstruction. After every 8 hours of operation, check the performance of the cooling system by starting the e...

Page 52: Maintenance Instructions

48 maintenance instructions cleaning engine air cleaner system cummins/fleetguard optiair™ air cleaner a remote mounted cummins/fleetguard optiair™ air cleaner provides the air filtering function. The paper filter element slides over an outlet tube inside the air cleaner canister with radial sealing...

Page 53: Maintenance Instructions

Maintenance instructions cleaning 49 inspect the paper element after every 100 hours of service and replace the element and safety filter ev- ery 400 hours (or when dirty or damaged). More frequent replacement may be required when operat- ing in extremely dusty conditions as indicated by the air fil...

Page 54: Maintenance Instructions

Maintenance instructions cleaning 50 optiair™ filter element radial sealing surface canister safety filter air filter element replacement 10. Install the cover with the word “down” prop- erly oriented to the bottom of the canister. Twist the optiair™ cover to the right and put into the “closed” posi...

Page 55: Maintenance Instructions

Maintenance instructions cleaning 51 3. Clean grass buildup underneath the deck using a pressure washer (and scraper if required). Note: if the buildup is severe, it may be easi- er to clean the deck by removing the deck as- sembly from the tractor and standing the deck assembly on its “nose”. Note:...

Page 56: Maintenance Instructions

52 maintenance instructions checking/servicing checking/servicing danger to prevent accidental starting of the en- gine when servicing or adjusting the ma- chine, remove the key from the ignition switch and disconnect the spark plug wires. Security of air cleaner system note: the following inspectio...

Page 57: Maintenance Instructions

53 maintenance instructions checking/servicing cleaning the terminals if battery terminals are corroded, remove battery from the mower. Using a wire brush, remove corro- sion with a solution of one part baking soda and four parts water. Rinse with clean water. Coat the terminals with petroleum jelly...

Page 58: Maintenance Instructions

54 maintenance instructions checking/servicing warning do not try to straighten a blade that is bent. Never weld a broken or cracked blade. Always replace with a new blade to assure safety. 4. If the blade cutting edge is dull or nicked, it should be sharpened. Remove blades for sharpening by graspi...

Page 59: Maintenance Instructions

55 maintenance instructions checking/servicing spark plugs every 100 hours, remove the spark plugs, inspect, clean, and reset the gap (or replace with a new plug). Clean spark plug with a wire brush. If the electrodes are burned short or pitted, replace the plug (refer to specifications for the prop...

Page 60: Maintenance Instructions

56 maintenance instructions checking/servicing/ replacing/repairing forward speed control friction lock the fsc friction lock is designed to hold the se- lected forward travel speed when the steering le- vers are moved and yet the friction is not too heavy to make moving the fsc control difficult (t...

Page 61: Maintenance Instructions

57 maintenance instructions replacing/repairing engine/pto belt 1. To remove an engine/pto belt: a. Remove wire lock pins (4), open belt guards. B. Relax belt by depressing idler arm. C. Roll the belt off the pulley and remove the belt. Engine/pto belt (belt guards open) (engine hidden for clarity) ...

Page 62: Maintenance Instructions

58 maintenance instructions replacing/repairing ground drive belt 1. To remove the ground drive belt: a. Depress the spring-loaded idler to relax belt. B. Slide belt off pulleys, then release the idler. Ground drive belt assembly (disengaged) 2. Reverse the procedure to install the ground drive belt...

Page 63: Maintenance Instructions

59 maintenance instructions replacing/repairing fuel filter danger gasoline is extremely flammable and can be highly explosive. To minimize danger: • before servicing the fuel system: 1) disconnect the spark plug leads. 2) disconnect the negative (-) battery ca- ble from battery. • use only an appro...

Page 64: Maintenance Instructions

60 maintenance instructions replacing/repairing blade overload shear bolts on gear driven decks each cutting blade is keyed to a blade hub by two (2) shear bolts (10-24 x 5/8 in. Stainless steel machine screws). These bolts are designed to shear and protect the blade drive gear- box from damage if t...

Page 65: Maintenance Instructions

61 maintenance instructions replacing/repairing mower blades mower blades are removed and remounted as de- scribed in sharpen mower blades instructions. During the course of sharpening and inspecting mower blades, if there are any of the following conditions of wear or damage, blades should be repla...

Page 66: Maintenance Instructions

62 maintenance instructions adjustments adjustments transmission control important: the proper adjustment of the transaxle control stops is essential for efficient operation and life of the transaxle. These stops are properly adjusted at the factory and should only require read justment if the trans...

Page 67: Maintenance Instructions

63 maintenance instructions adjustments step 2 - steering handles adjustment 1. An adjustment range of approximately 3 in. (76.2 mm) is available on the steering handles - the han dles can be adjusted forward or aft depending on the arm length of the operator. The handles can be adjusted by loosenin...

Page 68: Maintenance Instructions

64 maintenance instructions adjustments 2. Securely block the tractor up so the drive tires are off the ground. 3. Adjust the elastic stop nuts at the front of both control rods so that 2 or 3 threads are visible, then loosen the jam nuts on the ball joints at the back of the control rods. Control r...

Page 69: Maintenance Instructions

65 maintenance instructions adjustments step 4 - full forward speed adjustment 1. Move the fsc to the full forward speed position. 2. Raise the body. The set screws in the left and right transmission control arms should not be contacting the locating stud in the transaxle. If they are, back the set ...

Page 70: Maintenance Instructions

66 maintenance instructions adjustments fsc switch fsc neutral switch location deck support arm (ref) top locknut bottom locknut front of mower switch closed in neutral fsc switch actuator arm note: adjust the switch downward for quicker activation. Fsc neutral switch adjustment (side view through c...

Page 71: Maintenance Instructions

67 maintenance instructions adjustments blade clutch (pto) clutch engagement/belt tension the clutch engagement and pto belt tension are ad- justed using the clutch actuator link. After installing new pto belts, after 10 hours and every 100 hours thereafter, check and adjust for the clutch spring as...

Page 72: Maintenance Instructions

68 maintenance instructions adjustments clutch spring assembly (spring uncompressed) knuckle joint *note: factory preset dimensions. Reset to these dimensions prior to adjustment if compo- nents have been disassembled. Clutch actuator link 2-1/8 in. * (53.98 mm) 6 in. * (152.4 mm) 6-1/2 in. * (165.1...

Page 73: Maintenance Instructions

69 maintenance instructions adjustments step 2 - blade brake band adjustment after the maximum pulley travel is set, adjust the working travel of the clutch idler pulley by adjusting the brake band nut and make the following adjust- ment as needed: 1. Adjust the blade brake band, using the adjust- m...

Page 74: Operator’S Notes

70 operator’s notes.

Page 75

71 limited warranty for walker model mbk23 rider mowers 1. What this warranty covers, and for how long: walker manufacturing company will, at its option, repair or replace, without charge, any part covered by this warranty which is found to be defective in material and/or workmanship within one (1) ...

Page 76

Walker mfg. Co. • 5925 e. Harmony road, fort collins, co 80528 • (970) 221-5614 form no. 042012 printed in usa www.Walkermowers.Com ©2012 walker mfg. Co tm.