- DL manuals

- Walker

- Lawn Mower

- MDD

- Owner's Manual

Walker MDD Owner's Manual

Summary of MDD

Page 1

Owner’s manual safety, assembly, operating, and maintenance instructions model mdd (20.9 hp diesel) please read and save these instructions effective date: 12-01-03 for safety, read all safety and operation p/n 7000-6 instructions prior to operating machine price $5.00 ™.

Page 2: Foreword

Foreword thank you. . .For purchasing a walker mower. Every effort has been made to provide you with the most reliable mower on the market, and we are sure you will be among our many satisfied custom- ers. If for any reason this product does not perform to your expectations, please contact us at (97...

Page 3: Table Of Contents

Table of contents general information ________________ 1 highlighted information _____________ 1 glossary ____________________________ 1 identifying number locations________ 1 engine serial number location ______ 2 servicing of engine and drivetrain components ______________ 2 specifications _______...

Page 4: Table Of Contents

Table of contents maintenance instructions __________ 46 maintenance schedule chart _______ 46 important tips for care of the kubota engine _______________ 47 fuel system _________________________ 47 starting/stopping _____________________ 47 cooling system ______________________ 47 air cleaner syst...

Page 5: General Information

General information 1 highlighted information walker manufacturing recommends that any ser- vice requiring special training or tools be performed by an authorized walker mower dealer. There are several general practices to be aware of in the area of safety. Most accidents associated with the oper- a...

Page 6: General Information

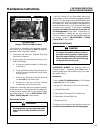

General information 2 tractor serial number location mower deck serial number location engine serial number location refer to the engine manual that accompanies this manual for the location of the engine serial number. For the mower model covered by this manual, an en- gine manual is available cover...

Page 7: Specifications

Specifications 3 model mdd engine manufacturer/model kubota d722, 3 cyl., diesel (liquid cooled) displacement 44.0 cu. In. (722 cc) hp (@ 3600 rpm) 20.9 max. Rpm (no load) 3800 governed rpm 3600 max. Torque [ft-lb (n·m) @ rpm] 34 (46.1) @ 2600 idle rpm 1000 ± 50 spark plug type n/a spark plug gap n/...

Page 8: Specifications

Specifications 4 model mdd transmission (continued) service brake dynamic braking through hydrostatic transmission parking brake mechanical pin lock in transmission gear neutral transmission release by manual dump valve final drive gear drive axle transmission fluid factory service mobil 1 synthetic...

Page 9: Specifications

Specifications 5 model mdd dimensions (tractor and mower)* length 91 in. (231 cm) width 49 in. (124 cm) height 44 in. (112 cm) wheel base (tractor) 42-1/4 in. (107 cm) tread width (tractor) 29-3/4 in. (76 cm) mower deck width of cut sd/ghs 42 or 48 in. (107 or 122 cm) cutting height 1 to 4 in. (3 to...

Page 10: Specifications

Specifications 6 model mdd drive belts engine pto walker p/n 7230 jackshaft drive gates 3vx335 (p/n 6231) ground drive walker p/n 7248 blower (ghs model) gates 3vx280 (p/n 7234-1) ghs system (optional) blower 4 x 10 x 1/4 in. (10 x 25 x 1 cm) three-blade paddle wheel (driven by mower engine) blower ...

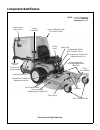

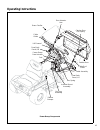

Page 11: Component Identification

Component identification 7 front view and right side view note: control identification shown in operating instructions section. Catcher door safety latch grass handling system 9.5 bushel catcher tilt-up latch counterweight spring and protective cover deck support pins and height adjustment hitch pin...

Page 12: Component Identification

Component identification 8 left hand drive wheel instrument panel box (shock mounted) instrument panel guard catcher lift / dump handle radiator catcher door gas spring removable grass catcher screen (not visible) catcher exhaust deflector catcher door catcher door handle dump plate anti-scuff rolle...

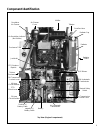

Page 13: Component Identification

Component identification 9 donaldson air cleaner air cleaner cover radiator guard radiator ghs blower rh hydrostatic transmission neutral safety switch battery negative (-) battery cable air restriction indicator (not visible) precleaner tube jackshaft pto gearbox dipstick turbine precleaner rh tran...

Page 14: Component Identification

Component identification 10 exhaust manifold oil fill cap alternator water temperature gauge sender thermostat housing and thermostat radiator screen (removable) radiator fan and shield engine stop lever linkage (fuel shut-off valve) throttle control linkage lever injection pump injectors air intake...

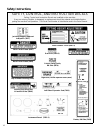

Page 15: Safety Instructions

Safety instructions 11 pay particular attention to any information labeled danger, warning, caution, important, and note in this manual. When you see the safety alert symbol ( ), read, understand, and follow the instructions. Fail- ure to comply with safety instructions may result in personal injury...

Page 16: Safety Instructions

Safety instructions 12 6. Do not wear loose fitting clothing that could get caught in moving parts. Do not operate this machine while wearing shorts; always wear adequate protective clothing, including long pants. Wearing safety glasses, safety shoes, and a helmet is advisable and required by some l...

Page 17: Safety Instructions

Safety instructions 13 9. Watch for holes, rocks, and roots in the terrain and for other hidden hazards. When mowing tall grass, mow higher than desired to expose any hidden obstacles. Then, clean the area and mow to the desired height. 10. Avoid sudden starts or stops. Before backing the machine up...

Page 18: Safety Instructions

Safety instructions 14 maintenance 1. To prevent accidental starting of the engine when servicing or adjusting the machine, re- move the key from the ignition switch and dis- connect the electrical plug on the fuel shut-off solenoid. 2. To reduce fire hazards, keep the engine free of grass, leaves, ...

Page 19: Safety Instructions

Safety instructions 15 adjacent to blower discharge chute through body (5804) sd deck discharge shield (5848) front body adjacent to rh steering lever (7818) hydrostat oil reservoir (5810-2) on body adjacent to clutch control lever (5806) right side of front body, below front body latch release (782...

Page 20: Safety Instructions

Safety instructions 16 instrument panel: (7823-2) fender, rh side (7802) catcher door hinge bar, lh and rh sides (5868) left side of operator seat (7819) right side, below operator seat (7809) top of blower housing (5819) deck carrier frame (8653) jackshaft support adjacent to dipstick (7827) gear a...

Page 21: Assembly Instructions

Assembly instructions 17 setup instructions walker mowers are shipped partially assembled. After uncrating the tractor and mower deck, initial setup is required. Note: during the process of unpacking, any dam- aged or missing parts should be noted and reported to the delivering carrier immediately (...

Page 22: Assembly Instructions

Assembly instructions 18 battery charging 1. Charge the battery at 15 amps for 10 minutes. Do not exceed 20 amps maximum recom- mended charging rate. Charge until specific gravity is at least 1.250. Total charging time should not exceed one (1) hour. 2. After charging the battery, adjust the electro...

Page 23: Assembly Instructions

Assembly instructions 19 deck caster wheel installation note: if semi-pneumatic wheels are installed, make sure the spacer washers fit over the spacer tube and are not caught between the fork and the end of the tube. The washers should move freely on the axle spacer tube. 5. Grease the caster wheel ...

Page 24: Assembly Instructions

Assembly instructions 20 tilt-up spring and roller wheel installation on rear discharge deck mower deck lnstallation on tractor deck installation 1. Lightly grease each deck support arm (2) on the tractor. Refer to mower deck installation photo on next page for location of deck support arm. 2. Engag...

Page 25: Assembly Instructions

Assembly instructions 21 6. Raise the front mower body (instead of lifting the front of deck) and clip the counterweight springs to the receptacle on front of body. Lower the front body to tension the springs. (refer to deck counterweight spring instal- lation photo.) mower deck installation (pto sh...

Page 26: Assembly Instructions

Assembly instructions 22 deck leveling 1. Position mower on a smooth, level surface. Set the cutting height to the highest position - 4 in. (102 mm) - for easy access under the deck to measure blade height. Refer to adjusting cutting height in operating instructions . Note: a block of wood cut 4 in....

Page 27: Assembly Instructions

Assembly instructions 23 preoperating checklist before operating the mower for the first time, and as a routine before daily operations, it is important to make sure the mower is properly prepared and ready for operation. The following is a list of items to be checked. (for a mower with frequent ope...

Page 28: Assembly Instructions

Assembly instructions 24 check hydrostatic transmission oil level refer to lubrication for checking hydrostatic transmission fluid level in maintenance instruc- tions . Check battery electrolyte level refer to checking/servicing the battery in maintenance instructions . Check functions of instrument...

Page 29: Operating Instructions

Operating instructions 25 control identification, location, and function operating controls engine throttle the throttle control lever (red knob) is located on the left side of the seat and is used to control engine speed. Moving the lever forward toward the fast position increases engine speed; mov...

Page 30: Operating Instructions

Operating instructions 26 forward speed control (fsc) forward speed control (fsc) has two functions: one is to set forward travel speed, and the other is to establish the neutral-park position. When the fsc lever is moved into the forward posi- tion, a friction lock holds any forward speed setting f...

Page 31: Operating Instructions

Operating instructions 27 transmission lockout levers the transmission lockout levers disengage the hy- drostatic transmissons. By lifting the lever on top of the transmission and locking it into place with the lockout cam, the hydrostatic transmissions are re- leased to permit freewheeling. By rele...

Page 32: Operating Instructions

Operating instructions 28 throttle blade clutch (pto) pull up to engage parking brake left wheel steering lever reverse drive wheel motion position right wheel steering lever the forward speed control also establishes the neutral-park position of the steering levers forward speed control lever (fsc)...

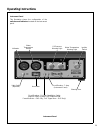

Page 33: Operating Instructions

Operating instructions 29 instrument panel instrument panel this illustration shows the configuration of the switches and indicators located on the instrument panel. Light switch (optional) hourmeter circuit breaker - 10 amp (headlights, safety interlock switch system, fuel solenoid hold, powerfil ®...

Page 34: Operating Instructions

30 operating instructions voltmeter the voltmeter displays battery and charging system voltage. An indication of low or high voltage (the red area) indicates an electrical system failure. The cause of the failure should be determined and cor- rected. Water temperature gauge the water temperature gau...

Page 35: Operating Instructions

Operating instructions 31 light switch (for optional lights) operates headlights (when installed). Hourmeter the hourmeter displays operating time accumu- lated while the ignition switch is in the on position. Circuit breakers two manual reset circuit breakers are located on the instrument panel. Ea...

Page 36: Operating Instructions

Operating instructions 32 3. Move the throttle 1/4 to 1/2 open (toward fast) and turn the ignition switch to the start position to start the engine. Release the key to the run position as soon as the engine starts. Important: if the engine fails to start after approximately 10 seconds of cranking, t...

Page 37: Operating Instructions

Operating instructions 33 adjusting ground speed and steering important: if the dsd52 or dsd62 mower deck is installed on the tractor, make sure the dolly wheel is retracted before moving. 1. Move the fsc out of neutral-park position to the desired forward speed. Do not hold forward on steering leve...

Page 38: Operating Instructions

Operating instructions 34 correct operator hand position on the controls 3. Reverse direction of the mower by pulling both levers backward. Note: smooth action on the steering levers will produce smooth mower operation. Remem- ber to keep the engine and ground speed slow until learning the control r...

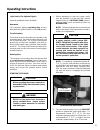

Page 39: Operating Instructions

Operating instructions 35 blade clutch engaged blade clutch disengaged stopping the machine 1. Slow the engine to a fast idle; put the throttle in the 1/2 throttle position. 2. Pull the steering levers to the neutral position and then move the fsc lever backward to the neutral-park position. 3. Dise...

Page 40: Operating Instructions

Operating instructions 36 cutting height is adjusted by positioning the four re- tainer hitch pins in a series of seven vertical holes on the deck support pins. Lift handles have been pro- vided on each end of the deck to assist in raising the deck while positioning the hitch pins. Cutting heights r...

Page 41: Operating Instructions

Operating instructions 37 recommendations for mowing important: operate the engine at full speed when mowing, to allow the engine to produce full horsepower and to increase efficiency of the engine cooling system. • keep the mower deck and discharge chute clean. • mow with sharp blades. A dull blade...

Page 42: Operating Instructions

Operating instructions 38 recommendations for tilt-up deck operation/transport to avoid potential deck and/or tractor damage while using the tilt-up deck, the following recommenda- tions are offered: • do not move the tractor with the deck in the tilt- up position since both the roller wheels (on th...

Page 43: Operating Instructions

Operating instructions 39 grass handling system (ghs) ghs model only pto and blade gear drive rear discharge mower deck deck discharge chute blower body chute assembly powerfil ® delivery spout dump handle grass catcher catcher door exhaust deflector grass-pak ® vane switch exhaust screen (removable...

Page 44: Operating Instructions

Operating instructions 40 general information the grass handling system (ghs) consists of a rear discharge mower deck connected to a 10 in. (25 cm) blower and a rear mounted grass catcher with 7.0 bushel (246 liters) capacity or optional 9.5 bushel (335 liters) capacity. The ghs blower oper- ates an...

Page 45: Operating Instructions

Operating instructions 41 clogging checklist in case of clogging, there will be a distinct change in the sound of the blower, i.E., the blower sound will stop. Also, the mower deck will begin to leave a trail of grass clippings. When this occurs, stop the engine, disconnect the electrical plug on th...

Page 46: Operating Instructions

Operating instructions 42 • check that the openings in the removable air exhaust screen in the grass catcher are not plugged. If the screen is clogged, refer to cleaning the ghs exhaust screen in this section. Remember, anything that restricts airflow or material flow along the entire path from the ...

Page 47: Operating Instructions

Operating instructions 43 grass catcher screen removal for cleaning dumping the catcher for dumping, the catcher either tailgate dumps into a disposal area or dumps into the optional dump bag. The dump bag is a reusable nylon fabric bag designed to conveniently move grass clippings from the catcher ...

Page 48: Operating Instructions

Operating instructions 44 3. Hook the bottom of the bag over the rear bumper while lifting on the handle strap. 4. Tilt the catcher back to dump into the bag by lifting on the catcher lift handle on the lower front corner of the catcher with the one hand while continuing to hold up on the bag strap ...

Page 49: Operating Instructions

Operating instructions 45 power dump components fork power dump ram actuator rear body panel, rh lift channel cable guide grass catcher door actuator arm catcher door gas spring catcher door cable rod guide cable assembly rear body panel, lh gas spring actuator mount assembly dog leg assembly rubber...

Page 50: Maintenance Instructions

Maintenance instructions 46 maintenance schedule chart - recommended service intervals - model mdd service item daily 25 hours 100 hours 200 hours yearly every 2years ref. Page check engine crankcase oil level x 48 check coolant level in radiator and overflow tank x 60 clean radiator screen and cool...

Page 51: Maintenance Instructions

Maintenance instructions kubota tips 47 important tips for care of the kubota engine fuel system • fuel must be clean - free from water, dirt, and or- ganic material. Fuel contamination will greatly short- en the life of the fuel injection pump and injectors. • change fuel filters on a regular basis...

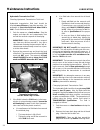

Page 52: Maintenance Instructions

Maintenance instructions lubrication 48 lubrication proper lubrication is an important maintenance pro- cedure. It reduces wear and makes the machine quieter and easier to operate. Engine oil engine break-in oil no special break-in oil is required. The engine is serviced with 10w-30, service class s...

Page 53: Maintenance Instructions

Maintenance instructions lubrication 49 oil drain location (view from left side of tractor) 4. Before removing the oil filter, clean the area around the filter to keep dirt and debris out of the engine. Oil filter location 5. Remove the old oil filter and wipe off the filter mounting surface on the ...

Page 54: Maintenance Instructions

Maintenance instructions lubrication 50 ident lubrication no. No. Location type places ident lubrication no. No. Location type places 1 deck caster wheel fork pivot grease 2 2 blade drive gearbox oil* 2 3 tee gearbox, deck oil* 1 4 deck caster wheel bearing grease 2 5 pto shaft guard hinge oil 1 6 u...

Page 55: Maintenance Instructions

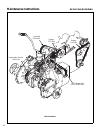

Maintenance instructions lubrication 51 13 2 2 3 4 4 15 15 16 16 14 14 10 11 12 13 18 19 17 21 21 23 24 25 22 20 27 28 29 28 & 38 26 30 30 31 31 32 34 33 36 37 37 35 33 34 39 40 1 1 5 6 8 8 9 9 7 7 7 7 chassis and deck lubrication points.

Page 56: Maintenance Instructions

Maintenance instructions lubrication 52 mower deck gearbox lubrication note: these instructions apply to all mower decks with gear-driven blades. Refer to dsd52 or dsd62 mower deck lubrication in this section for the dsd52 or dsd62 deck with belt-driven blades. The mower deck gearboxes (tee gearbox ...

Page 57: Maintenance Instructions

Maintenance instructions lubrication 53 2. Check the oil level in the belt drive gearbox ev- ery 100 hours (or sooner if a visible oil leak has developed). With the deck in the normal oper- ating position, remove the level plug in the side of the gearcase. Add sae e.P. (extreme pres- sure) 90w oil t...

Page 58: Maintenance Instructions

Maintenance instructions lubrication 54 hydrostatic transmission fluid checking hydrostatic transmission fluid level hydrostatic transmission fluid level should be checked every 25 hours of machine operation. It is preferable to check the fluid level when fluid is cold. Check fluid level as follows:...

Page 59: Maintenance Instructions

Maintenance instructions lubrication/cleaning 55 3. Reinstall the lower drain plug, making sure the rubber o-ring on the plug is in place and in good condition. 4. Refill the transmission through the air bleed plug hole until it is as full as possible. Important: avoid fluid contamination when filli...

Page 60: Maintenance Instructions

Maintenance instructions cleaning 56 turbine precleaner the turbine precleaner is mounted on a remote air intake tube connected to the donaldson air cleaner. A spinning fan driven by the intake airflow separates dust from the air, giving the initial stage of air clean- ing. Dust particles are exhaus...

Page 61: Maintenance Instructions

Maintenance instructions cleaning 57 1. Release the top and bottom cover latches and remove the air cleaner cover. Wash the cover and vacuator™ valve. Check that these com- ponents are in good condition. The vacuator™ valve is subject to wear and deterioration and should be replaced yearly or when d...

Page 62: Maintenance Instructions

Maintenance instructions cleaning 58 10. Check the air intake hose for cuts, nicks, etc., and the hose clamps for tightness. 11. Reset the air restriction indicator (press button on bottom). Engine cooling system radiator screen and cooling fins to prevent the engine from overheating and possi- ble ...

Page 63: Maintenance Instructions

Maintenance instructions cleaning 59 deck secured in tilt-up position 3. Clean grass buildup underneath the deck using a pressure washer (and scraper if required). Note: while some degree of material buildup in the mower deck housing can be tolerated, a point is finally reached where cutting quality...

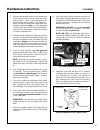

Page 64: Maintenance Instructions

60 maintenance instructions cleaning/ checking/servicing 3. Reinstall the ghs blower drive belt by reversing the removal procedure. Collapse blower belt tightener to remove ghs blower drive belt ghs exhaust screen refer to cleaning the ghs exhaust screen in op- erating instructions . Hydrostatic tra...

Page 65: Maintenance Instructions

61 maintenance instructions checking/servicing check the coolant level in the coolant recovery tank and maintain the coolant level between the full and low marks on the recovery tank. When the engine is cold, the coolant level should be at or slightly above the low mark on the recovery tank. If the ...

Page 66: Maintenance Instructions

62 maintenance instructions checking/servicing charging the battery check the battery charge by measuring the specific gravity of electrolyte; if specific gravity is less than 1.225, the battery will need to be charged as follows: 1. Charge the battery at 15 amps for 10 minutes. Do not exceed 20 amp...

Page 67: Maintenance Instructions

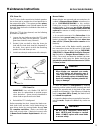

63 maintenance instructions checking/servicing note: blades can be sharpened with an elec- tric blade sharpener, conventional electric grind- er, or a hand file. Mower blade profile for sharpening 6. Check blade balance by positioning the blade horizontally on a blade balancer or use a nail or shaft...

Page 68: Maintenance Instructions

Maintenance instructions checking/servicing 64 fuel lines and clamps every year, inspect the fuel supply line from the tank to engine for deterioration or damage. Also, inspect the fuel line clamps for tightness. Good preventive maintenance calls for complete replacement of fuel lines and clamps eve...

Page 69: Maintenance Instructions

65 maintenance instructions checking/servicing/ replacing/repairing fuel valve open (engine start and run position) if the fuel valve solenoid is not operating properly, the problem may be isolated by first checking the operation of the solenoid as follows: 1. Disconnect the fuel valve solenoid wire...

Page 70: Maintenance Instructions

Maintenance instructions replacing/repairing 66 jackshaft drive belt engine pto belt engine fan belt ghs blower belt (ghs model only) hydrostatic ground drive belt belt locations.

Page 71: Maintenance Instructions

Maintenance instructions replacing/repairing 67 engine pto drive belt (3 groove power band) 1. To remove the engine pto drive belt: a. Remove the jackshaft drive belt from its idler pulley (by pushing down on cold start lever) and let the belt drop down out of the way. Note: step (a) is not essentia...

Page 72: Maintenance Instructions

Maintenance instructions replacing/repairing 68 jackshaft drive belt 1. To remove the jackshaft drive belt: a. Relax the belt by releasing spring tension from the jackshaft drive idler arm using the cold start lever. Jackshaft drive belt (engaged) jackshaft drive belt (disengaged) cold start lever (...

Page 73: Maintenance Instructions

Maintenance instructions replacing/repairing 69 ghs blower drive belt 1. Remove the ghs blower drive belt tension by depressing the idler pulley on the tightener arm. Roll the belt off the blower pulley. The belt should be clear of the blower pulley, allowing free movement of the blower wheel. Blowe...

Page 74: Maintenance Instructions

Maintenance instructions replacing/repairing 70 hydrostatic ground drive belt 1. To remove the hydrostatic ground drive belt: a. Raise the spring-loaded belt tightener arm and idler pulley to relax belt. B. Slide belt off pulleys, then release the idler. Transmission drive pulley spring idler pulley...

Page 75: Maintenance Instructions

Maintenance instructions replacing/repairing 71 engine fan belt 1. To remove the fan belt: a. Loosen the alternator mounting pivot bolt and the alternator bracket tensioner bolt. B. Pivot the alternator as shown to relax and remove belt. Alternator bracket crankshaft pulley engine fan belt tensioner...

Page 76: Maintenance Instructions

Maintenance instructions replacing/repairing 72 fuel filter model mdd has two (2) fuel filters. Replace both the in-line filter and the kubota filter element every 400 hours of operation. Fuel filter location important: replace fuel filters only in a clean area where the fuel line and connections wi...

Page 77: Maintenance Instructions

Maintenance instructions replacing/repairing 73 pto shear pin the pto drive shaft connection to the deck gearbox has a shear pin to provide shock load protection to the mower deck drive. This system provides prima- ry shock protection in case of blade impact and will normally shear before the indivi...

Page 78: Maintenance Instructions

Maintenance instructions replacing/repairing 74 reinstall the blades following procedure from sharpen mower blades instructions in checking/ servicing in this section. If blades are replaced, always use walker original equipment blades to ensure safety and optimum performance. The quality and perfor...

Page 79: Maintenance Instructions

Maintenance instructions replacing/repairing 75 ghs blower assembly (and/or blower wheel) ghs blower assembly removal 1. Remove the mower deck. Refer to deck instal- lation in assembly instructions and reverse the procedure to remove the deck. Remove skid bar for ghs blower removal 2. Remove the blo...

Page 80: Maintenance Instructions

76 maintenance instructions replacing/repairing blower wheel installation 1. To install the blower wheel, reverse the remov- al procedures. The front bearing is mounted on the blower wheel shaft, secured by a locking collar. Drive the locking collar clockwise with a punch, and tighten the set screw....

Page 81: Maintenance Instructions

77 maintenance instructions replacing/repairing/ adjustments 4. Reinstall the solenoid. At this point, move the solenoid linkage by hand and check for any binding or dragging of the solenoid plunger and linkage. If the solenoid does not move freely, adjust the solenoid mounting position by bend- ing...

Page 82: Maintenance Instructions

78 maintenance instructions adjustments blade clutch (pto) clutch disengagement/brake action the declutched or disengaged position of the blade clutch idler pulley is adjustable and is set to give belt release without excessive slack and to apply the blade brake. The blade brake is activated by link...

Page 83: Maintenance Instructions

Maintenance instructions adjustments 79 clutch linkage adjustment - disengaged clutch linkage adjustment - engaged transmission control important: the proper adjustment of the trans- mission control stops is essential for efficient oper- ation and life of the transmission. These stops are properly a...

Page 84: Maintenance Instructions

Maintenance instructions adjustments 80 steering lever end play adjustment - step 2 1. Position the fsc lever to the most forward position. 2. Loosen the adjustment nut on each steering le- ver actuator until end play develops between the lever actuator and the adjustment nut (slid- ing on transmiss...

Page 85: Maintenance Instructions

Maintenance instructions adjustments 81 straight ground travel adjustment forward speed control friction lock the fsc friction lock is adjusted to hold the select- ed forward speed when the steering levers are moved and yet the friction is not too heavy to make moving the control difficult (too much...

Page 86: Maintenance Instructions

Maintenance instructions adjustments 82 important: the solenoid linkage should be checked and adjusted any time the solenoid is re- moved and replaced (either reinstalling an existing solenoid or installing a new replacement). Check and adjust the solenoid linkage as follows: 1. Manually pull the fu...

Page 87: Maintenance Instructions

Maintenance instructions electrical system 83 electrical system for troubleshooting, refer to wiring diagram. Important: disconnect both battery cables be- fore unplugging any wiring connectors or making re- pairs on the electrical system. Important: disconnect the battery cables before unplugging a...

Page 88: Maintenance Instructions

84 maintenance instructions electrical system ignition switch circuits off glow plug start run off off off off start glow plug run run start glow plug run run (low) run (high) glow plug start all open 30 + 19 + ac 30 + 17 + 50 + ac 30 + ac 30 + 87 30 + 87a 30 + 87a 30 + 87a 30 + 87a 30 + 87 30 + 87 ...

Page 89

85 '$7( 6(59,&( (1*,1( ,7(0 +2856 0$,17(1$1&($1'6(59,&(5(&25'6+((7 bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb bbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbbb bbbbbbbbbbb...

Page 90: Operator’S Notes

86 operator’s notes.

Page 91

87 limited warranty for walker commercial rider mower 1. What this warranty covers, and for how long: walker manufacturing company will, at its option, repair or replace, without charge, any part covered by this warranty which is found to be defective in material and/or workmanship within one (1) ye...

Page 92

Walker mfg. Co. • 5925 e. Harmony road, fort collins, co 80528 • (970) 221-5614 form no. 010104 printed in usa © 2004 walker mfg. Co sound - model mdd sound test sound test conducted was in accordance with 79/113/eec and was performed on 28 january 98 under the conditions listed: general condition: ...