- DL manuals

- Walker Rider Lawnmowers

- Lawn Mower

- MBSSD

- Owner's Manual

Walker Rider Lawnmowers MBSSD Owner's Manual

Summary of MBSSD

Page 1

Owner’s manual safety, assembly, operating, and maintenance instructions and illustrated parts manual model mbssd (27 hp) please read and save these instructions effective date: 03-31-08 for safety, read all safety and operation p/n 2000-1 instructions prior to operating machine ™.

Page 2: Foreword

Foreword thank you. . . For purchasing a walker mower. Every effort has been made to provide you with the most reliable mower on the market, and we are sure you will be among our many satisfied custom- ers. If for any reason this product does not perform to your expectations, please contact your loc...

Page 3: Table of Contents

Table of contents owner’s manual general information ________________ 1 highlighted information _____________ 1 glossary ____________________________ 1 identifying number locations ________ 1 engine serial number location ______ 2 servicing of engine and drivetrain components ______________ 2 specif...

Page 4: Table of Contents

Table of contents checking/servicing _________________ 47 security of air filtration components ____ 47 battery ______________________________ 47 cleaning the terminals _______________ 47 charging the battery _________________ 47 tire pressure ________________________ 47 wheel nuts torque __________...

Page 5: General Information

General information 1 highlighted information walker manufacturing recommends that any ser- vice requiring special training or tools be performed by an authorized walker mower dealer. There are several general practices to be aware of in the area of safety. Most accidents associated with the oper- a...

Page 6: General Information

General information 2 tractor serial number location mower deck serial number location engine serial number location refer to the engine manual that accompanies this manual for the location of the engine serial number. For the mower model covered by this manual, an engine manual is available from ko...

Page 7: Specifications

Specifications 3 model mbssd engine manufacturer/model kohler command ch740, 2 cyl. Ohv (air-cooled) displacement 44.0 cu. In. (725 cc) hp (@ 3600 rpm) 27.0 max. Rpm (no load) 3600 ± 100 governed rpm 3600 ± 100 max. Torque [ft-lb (n · m) @ rpm] 42.7 (57.9) @ 3000 idle rpm 1200 ± 75 spark plug type c...

Page 8: Specifications

Specifications 4 model mbssd transmission (continued) service brake dynamic braking through transaxles parking brake (internal) mechanical lockout for each transaxle (single lever control) neutral transmission release by manual dump valve final drive direct drive axle from transaxle transmission flu...

Page 9: Specifications

Specifications 5 model mbssd mower deck width of cut 60 in. (152 cm) cutting height 1 to 5 in. (3 to 13 cm) height adjustment 17 positions - 1/4 in. (1 cm) increments blade size 60 in. (152 cm) sd model 20-1/2 in. (52 cm) three (3) clockwise-rotating blades deck suspension torsion-flex frame with ca...

Page 10: Component Identification

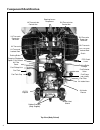

Component identification 6 front view and right side view note: control identification shown in operating instructions section. Tilt-up latch deck caster wheels counterweight spring and protective cover deck support arm tilt bar deck handle forward speed control (fsc) friction adjustment deck discha...

Page 11: Component Identification

Component identification 7 rear view and left side view left hand drive wheel fuel tank and cap muffler fuel pickup line footrests spread tail wheel tailpipe footrest catch assembly battery (not visible).

Page 12: Component Identification

Component identification 8 top view (body raised) fuel tank lh transaxle expansion reservoir rh transaxle lockout rod lh transaxle lockout rod rubber bumpers (body support) fuel tank cap fuel pickup line muffler heat shield lh transaxle lh transmission control arm rh transmission control arm rh tran...

Page 13: Safety Instructions

Safety instructions 9 pay particular attention to any information labeled danger, warning, caution, important, and note in this manual. When you see the safety alert symbol ( ), read, understand, and follow the instructions. Fail- ure to comply with safety instructions may result in personal injury....

Page 14: Safety Instructions

Safety instructions 10 6. Do not wear loose fitting clothing that could get caught in moving parts. Do not operate this machine while wearing shorts; always wear adequate protective clothing, including long pants. Wearing safety glasses, safety shoes, and a helmet is advisable and required by some l...

Page 15: Safety Instructions

Safety instructions 11 6. Disengage the blade clutch and put the fsc in the neutral-park position before starting the engine (an ignition interlock switch normally prevents starting of the machine if these controls are in the operating position). 7. Do not run the engine in a confined area without a...

Page 16: Safety Instructions

Safety instructions 12 maintenance 1. To prevent accidental starting of the engine when servicing or adjusting the machine, remove the key from the ignition switch and disconnect the spark plug wires. 2. To reduce fire hazards, keep the engine free of grass, leaves, excessive grease, and dirt. 3. Ke...

Page 17: Safety Instructions

Safety instructions 13 safety, control, and instruction decals safety, control, and instruction decals are installed on the machine; if any are missing, illegible, or damaged, a replacement should be ordered and installed before putting the machine into operation. The decal part number is listed bel...

Page 18: Safety Instructions

Safety instructions 14 belt routing drive belt drive belt walker p/n 2731 walker p/n 2731 carlisle p/n r3vx1250-2 carlisle p/n r3vx1250-2 belt twist belt twist drive pulley drive pulley walker p/n 2240-1 walker p/n 2240-1 belt twist belt twist 2749 2749 blade pulley blade pulley walker p/n 2240 walk...

Page 19: Assembly Instructions

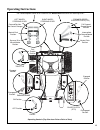

Assembly instructions 15 setup instructions walker mowers are shipped partially assembled to our distribution network, and are typically assembled by the selling dealer. For any additional assembly besides the following, contact your walker dealer. Battery service raise mower body up for battery acc...

Page 20: Assembly Instructions

Assembly instructions 16 battery charging 1. Charge the battery at 15 amps for 10 minutes. Do not exceed 20 amps maximum recom- mended charging rate. Charge until specific gravity is at least 1.250. Total charging time should not exceed one (1) hour. 2. After charging the battery, adjust the electro...

Page 21: Assembly Instructions

Assembly instructions 17 pto shaft guard installation position the shaft guard as shown and mount with two 1/4-20 x 1/2 in. Bolts. Pto shaft guard installation tilt-up roller wheel installation mount the two (2) tilt-up roller wheels on the brackets on the rear skirt of the deck housing using the p/...

Page 22: Assembly Instructions

Assembly instructions 18 4. Reaching under the tractor, join the pto tube to the pto shaft (align arrow decals). Slide the pto tube onto the spline shaft on the tractor pto drive shaft. Mower deck installation (pto shaft connection) 5. Slide the deck the rest of the way on the deck arms. Mower deck ...

Page 23: Assembly Instructions

Assembly instructions 19 deck leveling 1. Position mower on a smooth, level surface. Set the cutting height to the highest position - 5 in. (127 mm) - for easy access under the deck to measure blade height. Refer to adjusting cutting height in operating instructions . Note: a block of wood cut 5 in....

Page 24: Assembly Instructions

Assembly instructions 20 preoperating checklist before operating the mower for the first time, and as a routine before daily operations, it is important to make sure the mower is properly prepared and ready for operation. The following is a list of items to be checked. (for a mower with frequent ope...

Page 25: Assembly Instructions

Assembly instructions 21 check function of safety interlock switches refer to operating instructions to check for proper operation of safety switches, both during engine starting and with the operator leaving the seat with tractor moving forward or with mower blades en- gaged. Check and clean grass ...

Page 26: Operating Instructions

Operating instructions 22 control identification, location, and function ignition switch the ignition switch is located on the right front of the body and is used to start and stop the engine. The switch has three positions: “o” is the off position, run is the position the key returns to after start...

Page 27: Operating Instructions

Operating instructions 23 engine choke the choke control lever (black knob) is located on the left side of the seat. To start a cold engine, move the choke control forward to the on position. After engine starts, move choke control toward the off position, keeping enough choke to allow the engine to...

Page 28: Operating Instructions

Operating instructions 24 parking brake the parking brake functions by locking a detent arm internally into the transaxle. Moving the lever for- ward engages the parking brake; moving the lever backward releases the brake. Important: stop the tractor completely before engaging the parking brake. The...

Page 29: Operating Instructions

Operating instructions 25 throttle blade clutch (pto) parking brake neutral-park position idle position on position off position choke fast throttle position operating controls (top view from drivers point of view) the forward speed control also establishes the neutral-park position of the steering ...

Page 30: Operating Instructions

Operating instructions 26 starting the engine 1. Before attempting to start the engine, make sure the operator is in the seat, the forward speed control is in neutral-park position, and the blade clutch and parking brake are disengaged. Note: release parking brake to prevent extra load on the starte...

Page 31: Operating Instructions

Operating instructions 27 1. Move the fsc out of neutral-park position to the desired forward speed. Do not hold for- ward on steering levers. It is not necessary to hold the fsc lever in position since a friction lock maintains the selected lever position (and forward travel speed). Note: this is e...

Page 32: Operating Instructions

Operating instructions 28 correct operator hand position on the controls 3. Reverse direction of the mower by pulling both levers backward. Note: smooth action on the steering levers will produce smooth mower operation. Remem- ber to keep the engine and ground speed slow until learning the control r...

Page 33: Operating Instructions

Operating instructions 29 blade clutch disengaged stopping the machine 1. Slow the engine to idle; put the throttle in the idle position. 2. Pull the steering levers to the neutral-park position and then move the fsc lever backward to the neutral-park position. 3. Disengage the blade clutch. Importa...

Page 34: Operating Instructions

Operating instructions 30 adjusting cutting height cutting height is adjusted from operators seat using the height peddle to assist in raising the deck while positioning the height adjustment lever and hitch pin. 1. Disengage pto and stop tractor. 2. Push down on height peddle until it latches in th...

Page 35: Operating Instructions

Operating instructions 31 transaxle lockouts important: do not tow this mower with the transmission lockout engaged. Towing can produce excessive internal pressure and damage the transaxle(s). To move the mower with the engine not running (dead battery, maintenance, etc.), the transaxles are unlocke...

Page 36: Operating Instructions

Operating instructions 32 • make sure the mower is leveled properly for a smooth cut. Refer to deck leveling in assembly instructions . • use an alternating stripe mowing pattern for best appearance and vary the direction of the stripe each time the grass is mowed to avoid wear patterns in the grass...

Page 37: Maintenance Instructions

Maintenance instructions 33 maintenance schedule chart - recommended service intervals - model mbssd service item daily 25 hours 100 hours 200 hours 400 hours yearly every 2 years ref. Page check engine crankcase oil level x 35 check/clean engine air cooling system* x 43 check air filter restriction...

Page 38: Maintenance Instructions

Maintenance instructions kohler tips 34 important tips for care of the kohler engine fuel system • fuel must be clean - free from water, dirt, and or- ganic material. • change fuel filter on a regular basis and when contamination is suspected or found in the fuel. Starting/stopping • start engine wi...

Page 39: Maintenance Instructions

Maintenance instructions lubrication 35 lubrication proper lubrication is an important maintenance pro- cedure. It reduces wear and makes the machine quieter and easier to operate. Engine oil engine break-in oil no special break-in oil is required. The engine is serviced with 10w-30, service class s...

Page 40: Maintenance Instructions

Maintenance instructions lubrication 36 3. Remove the dipstick and oil drain plug, and drain oil into a suitable container. Be sure to allow ample time for complete drainage. 4. Before removing the oil filter, clean the area around the filter to keep dirt and debris out of the engine. 5. Remove the ...

Page 41: Maintenance Instructions

Maintenance instructions lubrication 37 mower deck spindle lubrication these spindles are permanently sealed and require no lubrication. Dsd60 mower deck lubrication lubricate the u-joint in the drive shaft every 8 hours with sae general purpose lithium or molybdenum base grease. Transaxle lubricati...

Page 42: Maintenance Instructions

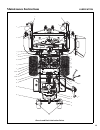

Maintenance instructions lubrication 38 ident lubrication no. No. Location type places ident lubrication no. No. Location type places 1 deck caster wheel fork pivot grease 2 2 deck caster wheel bearing grease 2 3 deck belt tensioner pivot grease 1 4 front deck lift pivot grease 2 5 rear deck lift pi...

Page 43: Maintenance Instructions

Maintenance instructions lubrication 39 13 17 2 4 1 5 6 7 27 9 8 18 & 26 11 19 & 25 24 23 20 18 19 21 20 22 16 14 12 11 10 9 8 7 6 5 3 4 1 2 15 15 chassis and deck lubrication points.

Page 44: Maintenance Instructions

Maintenance instructions lubrication 40 transaxle oil and filter change change the transaxle oil after the initial break-in period of 75-100 hours. Thereafter, change oil every 400 hours of operation as follows: 1. Thoroughly clean the exterior of the transmis- sion housing before servicing. Using a...

Page 45: Maintenance Instructions

41 maintenance instructions cleaning cleaning engine air cleaner system cummins/fleetguard optiair™ air cleaner a remote mounted cummins/fleetguard optiair™ air cleaner provides the air filtering function. The paper filter element slides over an outlet tube inside the air cleaner canister with radia...

Page 46: Maintenance Instructions

Maintenance instructions cleaning 42 air restriction gauge location inspect the paper element after every 100 hours of service and replace the element and safety filter yearly (or when dirty or damaged). More frequent replacement may be required when operating in extremely dusty conditions as indica...

Page 47: Maintenance Instructions

43 maintenance instructions cleaning 10. Install the cover with the word “down” properly oriented to the bottom of the canister. Twist the optiair™ cover to the right and put into the "closed" position. Proper orientation of air cleaner cover 11. Check the air intake hose for cuts, nicks, cracks, et...

Page 48: Maintenance Instructions

Maintenance instructions cleaning 44 every 100 hours, inspect and clean the cooling fins (more often when operating in extremely dusty, dirty conditions). Remove the two (2) cooling fin access panels in the engine shroud and clean the cooling fins and external surfaces using compressed air. Make sur...

Page 49: Maintenance Instructions

45 maintenance instructions cleaning 4. Using the tilt bar, raise deck to the tilt-up posi- tion and insert the deck hook into the tilt-up latch on the tractor body. Deck secured in tilt-up position 5. Clean grass buildup underneath the deck using a pressure washer (and scraper if required). Note: i...

Page 50: Maintenance Instructions

Maintenance instructions cleaning 46 transaxle cooling fins keeping the cooling fins on the transaxles clean and free of obstruction is essential to avoid overheating the transmission fluid and shortening transmission life. The cooling fins should be checked every 100 hours; and cleaned if necessary...

Page 51: Maintenance Instructions

47 maintenance instructions checking/servicing checking/servicing security of air filtration components note: the following inspection is only an external inspection and should be done without “disturb- ing” the filtration components. On a daily basis, visually inspect the external condi- tion of th...

Page 52: Maintenance Instructions

48 maintenance instructions checking/servicing note: keep blades sharp - cutting with dull blades not only yields a poor mowing job but slows the cutting speed of the mower and causes extra wear on the engine and blade drive by pulling hard. 1. Stop the engine, remove ignition key, and dis- connect ...

Page 53: Maintenance Instructions

49 maintenance instructions checking/servicing/ replacing/repairing drive belts raise the body and inspect the condition of the four (4) drive belts after every 25 hours of operation -- engine/pto drive and ground drive. If the belts show signs of cracking or deteriorating, the belts should be repla...

Page 54: Maintenance Instructions

Maintenance instructions replacing/repairing 50 engine/pto belt 1. To remove the engine/pto belt: a. Loosen and remove idler tension bolt and jam nut. B. Relax belt by depressing idler arm. C. Roll the belts off the pulley and remove the belts. Jam nut idler tension bolt idler arm pto pulley engine/...

Page 55: Maintenance Instructions

Maintenance instructions replacing/repairing 51 ground drive belt 1. To remove the ground drive belt: a. Raise the spring-loaded idler to relax belt. B. Slide belt off pulleys, then release the idler. Raise idler pulley to relax belt lh transaxle ground drive belt rh transaxle hydro idler arm tensio...

Page 56: Maintenance Instructions

52 maintenance instructions replacing/repairing fuel filter model mbssd is equipped with in-line fuel filters. Visually inspect the filter periodically, and replace the filter yearly. Fuel filter location important: replace the fuel filter only in a clean area where the fuel line and connections wil...

Page 57: Maintenance Instructions

53 maintenance instructions replacing/repairing/ adjustments reinstall the blades following procedure from sharp- en mower blades instructions. If blades are re- placed, always use walker original equipment blades to ensure safety and optimum performance. The quality and performance of replacement b...

Page 58: Maintenance Instructions

54 maintenance instructions adjustments steering handles adjustment - step 2 1. An adjustment range of approximately 3 in. (76.2 mm) is available on the steering handles - the handles can be adjusted forward or aft depending on the arm length of the operator. The handles can be adjusted by loosening...

Page 59: Maintenance Instructions

55 maintenance instructions adjustments note: if the engine will not start, check and ad- just the neutral safety switch (refer to neutral switch adjustment - step 6 ). 5. With the fsc in the neutral position and the en- gine running, the wheels should not move. If a drive tire is moving, the contro...

Page 60: Maintenance Instructions

56 maintenance instructions adjustments neutral travel end adjust fsc switch - neutral adjustment - step 6 1. Place the fsc in neutral position. Loosen mounting screws and adjust switch up or down accordingly. Fsc switch location fsc switch adjustment (side view through chassis) forward speed contro...

Page 61: Maintenance Instructions

57 maintenance instructions adjustments/ electrical system pto clutch the declutched or disengaged position of the pto clutch is adjustable and is set to completely release spring tension on the mechanical clutch. The spring in the linkage that engages the clutch should not have any tension on it wh...

Page 62: Tractor and Deck Decals

Item part description location no. No. No. Req’d sd use only genuine walker ® replacement parts. Effective date 03-31-08 58 tractor and deck decals walker product and operation decals 1 2802-2 rh fender body, rh near seat 1 2 2010-4 fuel transfer transfer mount 1 3 5800-6 decal, walker 6-3/4" rear b...

Page 63: Tractor and Deck Decals

Effective date 03-31-08 use only genuine walker ® replacement parts. 59 tractor and deck decals 10 3 20 3 21 22 11 12 4 5 5 6 7 27 23 17 25 24 17 18 16 14 15 26 14 8 19 1 belt r outi ng drive bel t driv e bel t wa lker p/n 273 1 wal ker p /n 27 31 carl isle p/ n r3 vx12 50-2 car lisle p/n r3v x125 0...

Page 64: Body / Chassis Assembly

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 03-31-08 60 body / chassis assembly body & seat assembly 1 2103-1 seat 1 2 2105-1 rear body (includes item # 3) 1 3 2190-1 insulation foam pad 1 4 5845 rubber b...

Page 65: Body / Chassis Assembly

Body / chassis assembly 53 52 f341 54 55 56 f029 f020 f342 f342 f004 f029 51 50 f093 f004 1 f009 f183 15 16 16 15 13 12 f236 f236 f005 f005 14 10 11 7 9 8 3 18 f009 f034 39 f446 40 21 42 f430 f430 41 41 21 43 40 f446 f034 f009 20 f034 f442 f246 5 5 6 4 f009 f009 f009 f009 19 f002 f025 f004 f348 f347...

Page 66

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 03-31-08 62 main component power transmission pto drive assembly 1 4850 handle grip 1 2 2358 clutch lever (includes item # 1) 1 3 5830-4 grease fitting (90 deg....

Page 67

Main component power transmission f012 f046 35 34 31 f336 f241 26 27 28 f013 26 f241 f388 f168 f091 29 f093 20 f009 f009 15 16 16 17 refer to body / chassis assembly f020 22 f013 21 f034 f029 f185 f178 f034 refer to engine group f008 1 2 f024 4 5 f004 f031 f009 f024 4 6 10 f034 f009 f031 11 8 8 9 12...

Page 68: Engine Group

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 03-31-08 64 engine group fuel tank assembly 1 8046-9 fuel tank, 5.0 gallon, gas 2 (includes item # 3) 2 5082-2 fuel cap seal 2 3 5082 fuel tank cap 2 (includes ...

Page 69: Engine Group

Effective date 03-31-08 use only genuine walker ® replacement parts. 65 engine group f164 f050 f201 f002 f002 f025 f005 44 43 45 39 38 41 35 34 42 37 40 f050 f185 f184 f184 f185 1 3 2 4 5 3 2 5 6 f185 f184 f184 f185 6 7 17 18 19 f009 20 21 20 f002 f002 22 23 f025 f025 22 to engine 24 25 24 f439 f175...

Page 70

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 03-31-08 66 hydrostatic ground drive assemblies parking brake assembly 1 2358-6 5/16-18 x 1-3/4 stud 2 2 2300-2 parking brake hydro mount, rh 1 3 5103-2 pivot b...

Page 71

Hydrostatic ground drive assemblies refer to engine group refer to body / chassis assembly refer to main component power transmission refer to main component power transmission f231 f171 f035 12 13 14 f034 f009 f009 f336 8 9 f183 7 5 6 10 f009 1 2 f009 f034 f009 3 16 16 8 8 4 3 f009 15 f009 1 f009 f...

Page 72: Steering Control Assemblies

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 03-31-08 68 steering control assemblies steering lever & fsc assemblies 1 5862 fsc knob 1 2 4170 fsc lever assembly * (includes item # 4) 3 2170-1 step washer 1...

Page 73: Steering Control Assemblies

Effective date 03-31-08 use only genuine walker ® replacement parts. 69 steering control assemblies 2 1 f059 f386 f373 24 6 7 f024 f093 f093 f427 4 5 f009 f183 9 8 f373 f008 f183 f009 f035 f167 25 f345 26 23 f188 28 29 30 f005 f385 27 f198 19 19 21 f188 f198 f345 25 26 28 30 f005 27 29 f003 f352 f32...

Page 74: Electrical Assembly

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 03-31-08 70 electrical assembly electrical assembly 1 8960-15 ignition switch w/keys 1 (includes items # 2, 3 & f349) 2 7854 plastic tip, red 1 3 8960-3 key set...

Page 75: Electrical Assembly

Electrical assembly e a f g c b d l o m n k j i h end views are shown from back of plug detail d pur pur yel wht blk blk red org detail b pur/red pur detail k detail l detail o pur/red pur/red grn grn detail e brn brn yel yel/brn detail j brn brn pur/red pur/red pur/red org pur/red pur/red blu blu d...

Page 76

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 03-31-08 72 60 inch complete carrier frame assembly (p/n 2911) spring and pivot mount components 1 2744-1 spring clip bracket 1 2 5975-3 cable tie (50# x 7") 2 ...

Page 77

Effective date 03-31-08 use only genuine walker ® replacement parts. 73 60 inch complete carrier frame assembly (p/n 2911) f166 1 4 3 2 2 3 f117 f117 5 6 f014 f215 f014 6 f215 f048 f048 18 f132 f050 11 f436 10 8 12 8 8 f263 f432 8 10 9 7 f263 f432 36 f241 f241 f241 f013 f040 35 37 f298 40 38 f241 f2...

Page 78

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 03-31-08 74 dsd60 deck assembly (p/n 2910) deck housing components 1 2110 hood latch assembly 2 2 2786-4 locking finger 2 3 2786-1 footrest, dsd60 (includes ite...

Page 79

Dsd60 deck assembly (p/n 2910) f009 8 7 7 f025 1 3 5 1 f025 f002 f025 7 f009 25 28 f050 f029 f002 f067 f318 8 7 6 6 f002 47 48 49 50 51 53 52 f108 f241 f276 f055 f045 f075 f435 31 30 36 f034 44 f043 f013 45 46 45 f276 f055 f045 23 f005 20 21 f039 f059 f033 20 22 f014 f014 f059 f039 1 f025 11 f029 13...

Page 80: Mulch Kit

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 03-31-08 76 mulch kit mulch kit 1 2691-4 baffle, rh 1 2 2691-2 vee, rh 1 3 2691-5 center skirt 1 4 2691-1 vee, lh 1 5 2691-3 skirt, lh 1 fasteners f004 1/4-20 k...

Page 81: Mulch Kit

Mulch kit 1 f004 f004 f029 f029 f029 f029 f029 f029 f029 f029 f029 f029 f029 f004 f004 f004 f004 f004 f004 f004 f004 2 4 5 3 refer to dsd60 deck assembly effective date 03-31-08 use only genuine walker ® replacement parts. 77.

Page 82: Wiring Schematic

Item part description no. No. No. Req’d item part description no. No. No. Req’d use only genuine walker ® replacement parts. Effective date 03-31-08 78 wiring schematic relay - c relay - b relay - a 15 amp circuit breaker optional lights optional lights optional lights hour meter b a m s1 s2 g batte...

Page 83

79 limited warranty for walker model mbssd rider mower 1. What this warranty covers, and for how long: walker manufacturing company will, at its option, repair or replace, without charge, any part covered by this warranty which is found to be defective in material and/or workmanship within one (1) y...

Page 84

Walker mfg. Co. • 5925 e. Harmony road, fort collins, co 80528 • (970) 221-5614 form no. 033108 printed in usa www.Walkermowers.Com © 2008 walker mfg. Co sound - model mbs sound test sound test conducted was in accordance with 2000/14/ec and was performed on 6 july 07 under the conditions listed: ge...