- DL manuals

- Walker

- Lawn Mower

- Walker Mowers

- Operator's Manual

Walker Walker Mowers Operator's Manual

Summary of Walker Mowers

Page 1

Operator’s manual safety, assembly, operating, and maintenance instructions model mbs29 please read and save these instructions beginning s/n: 125598 for safety, read all safety and operation effective date: 01-09-12 instructions prior to operating machine p/n 2000-7.

Page 2: Foreword

Foreword thank you. . .For purchasing a walker mower. Every effort has been made to provide you with the most reliable mower on the market, and we are sure you will be among our many satisfied custom ers. If for any reason this product does not perform to your expectations, please contact your local...

Page 3: Table of Contents

Table of contents general information ________________ 1 highlighted information _____________ 1 glossary ____________________________ 1 identifying number locations ________ 1 engine serial number location _______ 2 servicing of engine and drivetrain components ______________ 2 specifications _____...

Page 4: Table of Contents

Table of contents cleaning ____________________________ 48 engine air cleaner system _____________ 48 turbine precleaner ___________________ 48 cummins/fleetguard optiair™ air cleaner 48 engine cooling system ________________ 50 cooling air intake system ______________ 50 cylinder head cooling fins ...

Page 5: General Information

General information 1 highlighted information walker manufacturing recommends that any ser vice requiring special training or tools be performed by an authorized walker mower dealer. There are several general practices to be aware of in the area of safety. Most accidents associated with the oper ati...

Page 6: General Information

General information 2 serial number tractor serial number location serial number mower deck serial number location engine serial number location refer to the engine manual that accompanies this manual or the photo below for the location of the en- gine serial number. Serial number engine serial numb...

Page 7: Specifications

Specifications 3 model mbs29 engine manufacturer/model kohler command pro ® ech749, 2 cyl., ohv, gasoline (air-cooled), electronic fuel injection (efi) displacement cu. In. (cc) 45.6 (747) max power hp (kw) 29.0 (21.6) @ 3600 rpm governed rpm 3600 max. Torque lb·ft (n·m) 44 (60) idle rpm 1200 spark ...

Page 8: Specifications

Specifications 4 model mbs29 transmission (continued) transmission fluid factory service 20w-50 multi-viscosity motor oil (minimum sl grade oil) transmission oil capacity qt (l) 2.4 (2.3) transmission cooling cooling fan mounted on drive pulley oil filter hydro-gear ® p/n 52114 (walker p/n 2026-6) g...

Page 9: Specifications

Specifications 5 model mbs29 curb weight lb (kg) tractor only 745 (338) tractor with drd52 deck 1188 (539) tractor with dsd60 deck 1280 (581) drive belts engine pto walker p/n 2230 ground drive walker p/n 2248 seat contour-molded, with nylon backed vinyl cover and integral foam cushion (suspension) ...

Page 10: Component Identification

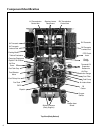

Component identification 6 front view and right side view note: control identification shown in operating instructions section. Deck discharge shield deck caster wheels tilt bar deck handle footrests counterweight springs and protective covers tilt-up latch forward speed control (fsc) friction adjus...

Page 11: Component Identification

Component identification 7 rear view and left side view battery (not visible) left hand drive wheel fuel pickup line muffler fuel tank and cap footrest catch assembly footrests tailpipe spread axle tail wheel oil fill dipstick.

Page 12: Component Identification

Component identification 8 top view (body raised) rh transaxle lockout rod clutch linkage muffler heat shield lh transmission control arm lh transaxle lockout rod lh transaxle rh transaxle parking brake fuel pickup line fuel tank rh transmission control arm air filter cover cummins/fleetguard optiai...

Page 13

Safety instructions - before operating 9 pay particular attention to any information labeled danger, warning, caution, important, and note in this manual. When you see the safety alert symbol ( ), read, understand, and follow the instructions. Fail ure to comply with safety instructions may result i...

Page 14

Safety instructions - before operating 10 6. Do not wear loose fitting clothing that could get caught in moving parts. Do not operate this ma- chine while wearing shorts; always wear ade- quate protective clothing, including long pants. Wearing safety glasses, safety shoes, and a hel- met is advisab...

Page 15

Safety instructions - operating 11 1. Operate the mower only in daylight or in good artificial light with good visibility of the area being mowed. 2. Sit on the seat when starting the engine and op- erating the machine. Keep feet on the deck foot- rests at all times when the tractor is moving and/ o...

Page 16

Safety instructions - operating 12 14. The maximum recommended slope operat- ing angle is 15 degrees or 26% grade. When operating the machine on a slope, reduce speed and use caution to start, stop, and maneuver. To prevent tipping or loss of control of the machine, avoid sharp turns or sudden chang...

Page 17

Safety instructions - maintenance 13 1. To prevent accidental starting of the engine when servicing or adjusting the machine, remove the key from the ignition switch and disconnect the spark plug wires. 2. To reduce fire hazards, keep the engine free of grass, leaves, excessive grease, and dirt. 3. ...

Page 18: Safety Instructions

Safety instructions 14 safety, control, and instruction decals safety, control, and instruction decals are installed on the machine; if any are missing, illegible, or damaged, a replacement should be ordered and installed before putting the machine into operation. The decal part number is listed bel...

Page 19: Safety Instructions

Safety instructions 15 safety, control, and instruction decals safety, control, and instruction decals are installed on the machine; if any are missing, illegible, or damaged, a replacement should be ordered and installed before putting the machine into operation. The decal part number is listed bel...

Page 20: Safety Instructions

Safety instructions 16 safety, control, and instruction decals safety, control, and instruction decals are installed on the machine; if any are missing, illegible, or damaged, a replacement should be ordered and installed before putting the machine into operation. The decal part number is listed bel...

Page 21: Safety Instructions

Safety instructions 17 safety, control, and instruction decals safety, control, and instruction decals are installed on the machine; if any are missing, illegible, or damaged, a replacement should be ordered and installed before putting the machine into operation. The decal part number is listed bel...

Page 22: Assembly Instructions

Assembly instructions 18 setup instructions walker mowers are shipped partially assembled to our distribution network, and are typically assembled by the selling dealer. For any additional assembly besides the following, contact your walker dealer. Battery service caution important battery service, ...

Page 23: Assembly Instructions

Assembly instructions 19 danger battery electrolyte is a poisonous and cor- rosive sulfuric acid solution. • avoid spillage and contact with skin, eyes, and clothing - causes severe burns. • to prevent accidents, wear safety gog- gles and rubber gloves when working with electrolyte. • neutralize aci...

Page 24: Assembly Instructions

Assembly instructions 20 deck caster wheel installation deck discharge deflector shield installation (dsd60) attach the side discharge deflector shield using two (2) 3/8-16 x 1-1/4 in. Bolts, 3/8-16 esna nuts, and 3/8 in. Wave spring washers. The wave washers fit between the two hinging surfaces. Ti...

Page 25: Assembly Instructions

Assembly instructions 21 mower deck installation on tractor deck installation 1. Lightly grease each deck support arm (2) on the tractor. Refer to mower deck installation photo for location of deck support arm. Deck support arms mower deck installation 2. Engage the lh deck carrier frame tube socket...

Page 26: Assembly Instructions

Assembly instructions 22 important: to prevent damage to the mow- er, make sure the pto quick disconnect is se- curely locked on the tractor, with the locking balls fully seated in the groove and the ring in the locked position (refer to the quick discon- nect ring “locked” position illustration). A...

Page 27: Assembly Instructions

Assembly instructions 23 deck leveling 1. Position mower on a smooth, level surface. Set the cutting height to the highest position - 5 in. (127 mm) - for easy access under the deck to measure blade height. Refer to adjusting cutting height in operating instructions. Note: a block of wood cut 5 in. ...

Page 28: Assembly Instructions

Assembly instructions 24 preoperating checklist before operating the mower for the first time, and as a routine before daily operations, it is important to make sure the mower is properly prepared and ready for operation. The following is a list of items to be checked. (for a mower with frequent ope...

Page 29: Assembly Instructions

Assembly instructions 25 check tire pressure deck caster wheel = 20 psi (137 kpa) drive = 15 psi (103 kpa) rear = 20 psi (137 kpa) check functions of warning lights and warning horn turn the ignition key to the run position. Oil pres- sure warning light, engine service light, over tem- perature warn...

Page 30: Operating Instructions

Operating instructions 26 control identification, location, and function caution before operating the mower, become fa- miliar with the location and function of all operator controls. Knowing the location, function, and operation of these controls is important for safe and efficient opera tion of t...

Page 31: Operating Instructions

Operating instructions 27 engine throttle the throttle control lever (red knob) is located on the left side of the seat and is used to control engine speed. Moving the lever forward toward the fast position increases engine speed; moving it back- ward toward the idle position decreases engine speed....

Page 32: Operating Instructions

Operating instructions 28 steering levers each drive wheel is controlled by its own indepen- dent steering lever, for both steering function and forward/reverse motion. The fsc lever sets the maximum forward speed, and also sets the for- ward position of the steering levers. The steering levers oper...

Page 33: Operating Instructions

Operating instructions 29 oil pressure warning light the oil pressure warning light indicates that engine oil pressure is below the safe operating level [below 3 to 5 psi (21 to 34 kpa)]. This light (and warning horn) will come on when the ignition is turned on, but should go off after the engine is...

Page 34: Operating Instructions

Operating instructions 30 transaxle lockout rods the transaxle lockout rods disengage the transax- les. By lifting the rods up and locking them into place with the shoulder on the rod in the chassis notch, the transaxles are released to permit free- wheeling. By releasing the rods and recessing them...

Page 35: Operating Instructions

Operating instructions 31 2802-3 operating controls (top view from drivers point of view) forward speed control lever (fsc) blade clutch (pto) neutral-park position forward position (no control change) idle position right wheel steering lever left wheel steering lever parking brake throttle the forw...

Page 36: Operating Instructions

Operating instructions 32 starting the engine caution before operating the mower, read and un- derstand all safety instructions and operat ing instructions. Warning never run the engine in an enclosed or poorly ventilated area. Engine exhaust contains carbon monoxide, an odorless and deadly gas. 1....

Page 37: Operating Instructions

Operating instructions 33 1. Move the fsc out of neutral-park position to the desired forward speed. Do not hold for- ward on steering levers. It is not necessary to hold the fsc lever in position since a friction lock maintains the selected lever position (and for- ward travel speed). Warning in ca...

Page 38: Operating Instructions

Operating instructions 34 forward speed control (fsc) pull steering levers with left hand keep feet on footrest when moving correct operator hand position on the controls 3. Reverse direction of the mower by pulling both levers backward. Note: smooth action on the steering levers will produce smooth...

Page 39: Operating Instructions

Operating instructions 35 blade clutch engaged blade clutch disengaged caution if the cutting blades strike a stationary ob- ject while mowing, stop the mower im- mediately, disconnect the spark plug wires, lift the deck, and inspect the deck and blades thoroughly for damage. Also, make sure the bla...

Page 40: Operating Instructions

Operating instructions 36 warning in case the transmission drive belt breaks during operation, and if the machine is on a slope, the machine will freewheel down the slope. To maintain control, immediately (1) release the steering levers and simultaneously (2) move the fsc to the neutral-park positio...

Page 41: Operating Instructions

Operating instructions 37 height pedal hitch pin height adjustment lever cutting height adjustment components transaxle lockouts important: do not tow this mower faster than 2 mph (3.2 km/h) with the transmission lockout en- gaged. Towing can produce excessive internal pressure and damage the transa...

Page 42: Operating Instructions

Operating instructions 38 important: operate the engine at full throttle when mowing, to allow the engine to produce full horsepower and to increase efficiency of the engine cooling system. • keep the mower deck and discharge shield clean. • mow with sharp blades. A dull blade tears the grass (resul...

Page 43: Operating Instructions

Operating instructions 39 danger do not mow or drive the tractor within 5 feet (1.5 meters) of an embankment or retaining wall with drop off. Recommendations for tilt-up deck operation/transport to avoid potential deck and/or tractor damage while using the tilt-up deck, the following recommenda- tio...

Page 44: Maintenance Instructions

Maintenance instructions 40 maintenance schedule chart - recommended service intervals - model mbs29 service item daily 25 hours 100 hours 200 hours 400 hours yearly every 2 years ref. Page check engine crankcase oil level x 42 check/clean engine air cooling system* x 50 check air filter restriction...

Page 45: Maintenance Instructions

41 maintenance instructions kohler tips important tips for care of the kohler engine fuel system • fuel must be clean - free from water, dirt, and or- ganic material. • change fuel filter on a regular basis and when con- tamination is suspected or found in the fuel. • the fuel pump module is a seale...

Page 46: Maintenance Instructions

42 maintenance instructions lubrication lubrication warning do not attempt to lubricate the machine with the engine running. Disengage the pto clutch, shut off the machine, and re- move the ignition key. Proper lubrication is an important maintenance pro- cedure. It reduces wear and makes the machin...

Page 47: Maintenance Instructions

43 maintenance instructions lubrication 3. Remove the dipstick and open oil drain valve, and drain the oil into a suitable container. Be sure to allow ample time for complete drainage. 4. Before removing the oil filter, clean the area around the filter to keep dirt and debris out of the engine. 5. R...

Page 48: Maintenance Instructions

44 maintenance instructions lubrication mower deck spindle lubrication lubricate each deck spindle grease fitting every 25 hours. Use sae general purpose lithium or molyb- denum base grease for grease fittings. Drd52 or dsd60 mower deck lubrication lubricate the u-joint in the drive shaft every 8 ho...

Page 49: Maintenance Instructions

45 maintenance instructions lubrication elbow screw locking nut down reinstall transaxle elbows 7. Reinstall the elbows. When the elbow begins to be snug, position the elbow as it was when re- moved and tighten the locknut. Reinstall reser- voir hoses to elbows. 8. Fill both reservoirs 1/4-1/2 in. (...

Page 50: Maintenance Instructions

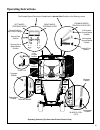

46 maintenance instructions lubrication ident lubrication no. No. Location type places ident lubrication no. No. Location type places 1 deck caster wheel fork pivot grease 2 2 deck caster wheel bearing grease 2 3 front deck lift pivot grease 2 4 rear deck lift pivot grease 2 5 pivot assembly, tilt-u...

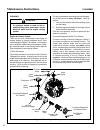

Page 51: Maintenance Instructions

47 maintenance instructions lubrication chassis and deck lubrication points 11 2 1 1 2 3 4 5 6 27 7 18 & 26 9 25 14 20 18 21 22 20 15 17 10 9 8 7 6 5 4 3 14 16 28 23 17 12 24 19 13.

Page 52: Maintenance Instructions

48 maintenance instructions cleaning cleaning caution if a pressure washer is used on the ex- posed working parts, avoid water on the electrical parts and the engine cooling system. Engine air cleaner system there are two main components in the engine air cleaner system: a turbine precleaner and a c...

Page 53: Maintenance Instructions

49 maintenance instructions cleaning important: use only cummins/fleetguard air filter elements for replacement (walker 2090-1 and 2090-3). Aftermarket filters may not seal properly or filter efficiently. Canister primary filter element air cleaner components (shown with cover removed) important: th...

Page 54: Maintenance Instructions

50 maintenance instructions cleaning 9. Insert and seat the safety filter and primary el- ement carefully into the canister, applying pres- sure at the outer rim of the filter; not at the flexible center. Make sure the filter element is completely in place before installing the cover. Note: do not u...

Page 55: Maintenance Instructions

51 maintenance instructions cleaning danger make sure to keep hands clear of exhaust pipe, muffler, and moving parts when checking airflow. Check airflow with hand cooling system airflow every 100 hours, inspect and clean the cooling fins (more often when operating in extremely dusty, dirty conditio...

Page 56: Maintenance Instructions

52 maintenance instructions cleaning 3. Install tilt bar into front of deck. Tilt bar installed 4. Using the tilt bar, raise deck to the tilt-up posi- tion and insert the deck hook into the tilt-up latch on the tractor body. Tilt-up hook and latch connected tilt-up hook tilt-up latch deck secured in...

Page 57: Maintenance Instructions

53 maintenance instructions cleaning transaxle housing keeping the housing on the transaxles clean and free of obstruction is essential to avoid overheat- ing the transmission fluid and shortening transmis- sion life. The housing should be checked every 100 hours; and cleaned if necessary. To clean ...

Page 58: Maintenance Instructions

54 maintenance instructions checking/servicing checking/servicing danger to prevent accidental starting of the en- gine when servicing or adjusting the ma- chine, remove the key from the ignition switch and disconnect the spark plug wires. Security of air filtration components note: the following in...

Page 59: Maintenance Instructions

55 maintenance instructions checking/servicing cleaning the terminals if battery terminals are corroded, remove battery from the mower. Using a wire brush, remove corro- sion with a solution of one part baking soda and four parts water. Rinse with clean water. Coat the terminals with petroleum jelly...

Page 60: Maintenance Instructions

56 maintenance instructions checking/servicing 4. If the blade cutting edge is dull or nicked, it should be sharpened. Remove blades for sharp- ening by grasping the end of the blade using a rag or a thick, padded glove, while loos ening and removing the bolt and washer that mounts the blade. 5. Gri...

Page 61: Maintenance Instructions

57 maintenance instructions checking/servicing fuel lines and clamps note: the fuel system after the fuel pump module is pressurized and should only be serviced by a walk- er dealer or authorized kohler service dealer. Every year, inspect the fuel lines from the tanks to engine for deterioration or ...

Page 62: Maintenance Instructions

58 maintenance instructions replacing/repairing replacing/repairing danger to prevent accidental starting of the engine when replacing parts or repairing the machine, remove the key from the ignition switch and disconnect the spark plug wires. Important: always use genuine factory re- placement part...

Page 63: Maintenance Instructions

59 maintenance instructions replacing/repairing engine/pto belt 1. To remove an engine/pto belt: a. Remove wire lock pins (4), open belt guards. B. Roll the belt off the pulley and remove the belt. Engine/pto belt (belt guards open) (engine hidden for clarity) 2. To replace an engine/pto belt: a. Re...

Page 64: Maintenance Instructions

60 maintenance instructions replacing/repairing ground drive belt 1. To remove the ground drive belt: a. Remove belt tensioner stop wing nut. B. Raise the spring-loaded idler to relax belt. C. Slide belt off pulleys, then release the idler. 2. A. Reverse the procedure to install the ground drive bel...

Page 65: Maintenance Instructions

61 maintenance instructions replacing/repairing fuel filter model mbs29 is equipped with a 10 micron in-line fuel filter between the fuel tank and the fuel pump module. Replacement of this filter is recommended every 200 hours of operation or more frequently un- der extremely dusty or dirty conditio...

Page 66: Maintenance Instructions

62 maintenance instructions replacing/repairing danger when blades are operated over sandy soil, and if blades are allowed to wear, a “slot” may be worn into the wing tip of blade. Eventually a piece of the blade may break off creating a serious potential for injury or damage. • check the blades for...

Page 67: Maintenance Instructions

63 maintenance instructions replacing/repairing replacing deck drive belt 1. To remove the deck drive belt: a. Remove deck footrest and two (2) covers over the rh and lh blade spindles. B. Loosen belt tensioner stop bolt and turn in- ward until retracted 1 in. (2.5 cm) from the operating position. C...

Page 68: Maintenance Instructions

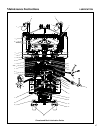

64 maintenance instructions adjustments adjustments transmission control important: the proper adjustment of the tran- saxle control stops is essential for efficient opera- tion and life of the transaxle. These stops are prop- erly ad justed at the factory and should only require read justment if th...

Page 69: Maintenance Instructions

65 maintenance instructions adjustments step 3 - neutral position adjustment 1. With the forward speed control (fsc) in neu- tral-park, the lever should be straight up. Adjust by loosening the jam nuts on the fsc rod and turn the rod to attain the straight up position. Tighten the jam nuts. Fsc posi...

Page 70: Maintenance Instructions

66 maintenance instructions adjustments warning the following adjustments are made with the engine running. Keep all body parts and tools away from rotating and hot com- ponents, and secure all loose clothing. 4. With the body lowered and the fsc in neu- tral-park, start the engine. With the engine ...

Page 71: Maintenance Instructions

67 maintenance instructions adjustments step 6 - fsc neutral switch adjustment 1. Place the fsc in neutral-park position. Loosen mounting screws and adjust switch up or down accordingly. Fsc switch fsc neutral switch location note: adjust the switch downward for quicker activation. Switch closed in ...

Page 72: Maintenance Instructions

68 maintenance instructions adjustments blade clutch (pto) clutch engagement/belt tension the clutch engagement and pto belt tension are ad- justed using the clutch actuator link. After installing new pto belts, after 10 hours and every 100 hours thereafter, check and adjust for the clutch spring as...

Page 73: Maintenance Instructions

69 maintenance instructions adjustments clutch spring assembly (spring uncompressed) knuckle joint *note: factory preset dimensions. Reset to these dimensions prior to adjustment if compo- nents have been disassembled. 2-1/8 in.* (53.98 mm) 6 in.* (152.4 mm) clutch actuator link 6-1/4 in.* (158.75 m...

Page 74: Maintenance Instructions

70 maintenance instructions adjustments step 2 - blade brake band adjustment after the maximum pulley travel is set, adjust the working travel of the clutch idler pulley by adjusting the brake band nut and make the following adjust- ment as needed: 1. Adjust the blade brake band, using the adjust- m...

Page 75

71 limited warranty for walker model mbs29 rider mower 1. What this warranty covers, and for how long: walker manufacturing company will, at its option, repair or replace, without charge, any part covered by this warranty which is found to be defective in material and/or workmanship within one (1) y...

Page 76

Walker mfg. Co. • 5925 e. Harmony road, fort collins, co 80528 • (970) 221-5614 form no. 010912 printed in usa www.Walkermowers.Com © 2014 walker mfg. Co.