- DL manuals

- Wallenstein

- Chipper

- BX102S

- Operator's Manual

Wallenstein BX102S Operator's Manual

EMB Manufacturing Inc.

4144 Boomer Line · St. Clements, Ontario · N0B 2M0 · Canada

www.wallensteinequipment.com

PRINTED IN CANADA

REV 310117

PART NUMBER: Z97085

Keep this manual with the

machine at all times

Do not attempt to start or operate the equipment without thoroughly

reviewing this manual for safe and proper operation.

BX72S

BX102S

BX32S

BX52S

BX "S" SERIES 3 POINT HITCH

WOOD CHIPPER

MODEL BX32S, BX52S, BX72S & BX102S

OPERATOR'S MANUAL

Summary of BX102S

Page 1

Emb manufacturing inc. 4144 boomer line · st. Clements, ontario · n0b 2m0 · canada www.Wallensteinequipment.Com printed in canada rev 310117 part number: z97085 keep this manual with the machine at all times do not attempt to start or operate the equipment without thoroughly reviewing this manual fo...

Page 2: Table of Contents

2 table of contents delivery inspection report 4 serial number location 5 label information 5 1 introduction 6 2 safety ...

Page 3: Warranty

3 warranty effective on products retailed on or after january 1, 2015. Register your product online at www.Wallensteinequipment.Com within 30 days of purchase to activate warranty. This product is warranted to be free of defects in materials and workmanship under normal use and service, for a period...

Page 4: Delivery Inspection Report

4 wallenstein bx "s" series 3 point hitch wood chipper delivery inspection report this form must be filled out by the dealer and signed by both the dealer and the customer at the time of delivery. To activate warranty, register your product online at www wallensteinequipment com ____________________...

Page 5: Serial Number Location

5 serial number location always give your dealer the serial number of your wallenstein 3 point hitch wood chipper and feed hopper when ordering parts or requesting service or other information. The serial number plates are located where indicated. The bx52s is shown, but the serial location is the s...

Page 6: 1 Introduction

6 1 introduction congratulations on your choice of a wallenstein bx series 3 point hitch wood chipper to compliment your operation. This equipment has been designed and manufactured to meet the needs of a discerning timber or landscaping industry. Safe, efficient and trouble free operation of your w...

Page 7: 2 Safety

7 2 safety safety alert symbol why is safety important to you? The safety alert symbol identifies important safety messages on the wallenstein 3 point hitch wood chipper and in the manual. When you see this symbol, be alert to the possibility of personal injury or death. Follow the instructions in t...

Page 8

8 safety you are responsible for the safe operation and maintenance of your wallenstein 3 point hitch wood chipper. You must ensure that you and anyone else who is going to use, maintain or work around the 3 point hitch wood chipper be familiar with the operating and maintenance procedures and relat...

Page 9

9 2 2 equipment safety guidelines 1. Safety of the operator and bystanders is one of the main concerns in designing and developing equipment. However, every year many accidents occur which could have been avoided by a few seconds of thought and a more careful approach to handling equipment. You, the...

Page 10

10 2 3 safety training 1. Safety is a primary concern in the design and manufacture of our products. Unfortunately, our efforts to provide safe equipment can be wiped out by a single careless act of an operator or bystander. 2. In addition to the design and configuration of equipment, hazard control...

Page 11

11 2 5 maintenance safety 1. Good maintenance is your responsibility. Poor maintenance is an invitation to trouble. 2. Follow good shop practices. • keep service area clean and dry. • be sure electri- cal outlets and tools are properly grounded. • use adequate light for the job at hand. 3. Make sure...

Page 12

12 2 8 operating safety 1. Please remember it is important that you read and heed the safety signs on the 3 point hitch wood chipper. Clean or replace all safety signs if they cannot be clearly read and understood. They are there for your safety, as well as the safety of others. The safe use of this...

Page 13

13 2 9 sign-off form wallenstein follows the general safety standards specified by the american society of agricultural and biological engineers (asabe) and the occupational safety and health administration (osha). Anyone who will be using and/or maintaining the 3 point hitch wood chipper must read ...

Page 14: 3 Safety Signs

14 3 safety signs 1. Keep safety signs clean and legible at all times. 2. Replace safety signs that are missing or have become illegible. 3. Replaced parts that displayed a safety sign should also display the current sign. 4. Safety signs in section 3 each have a part number displayed with it. Use t...

Page 15

Z94118 z94118 z94117 z94117 z94120 z94120 z94118 z94118 z94117 z94117 z94120 z94120 z94120 z94120 z94203 z94203 75mm 3.0” z94232 z94232 z94127 z94127 z94127 z94127 z94120 z94120 z94119 z94143 z94143 z94144 z94144 z94127 z94127 z94145 z94145 z94120 z94120 z94203 z94203 75mm 3.0” z94232 z94232 z94240 ...

Page 16

16 z94118 z94118 z94117 z94117 50 z94426 z94426 z94120 z94120 z94118 z94118 z94117 z94117 z94120 z94120 z94119 z94240 540 rpm 1000 rpm z94240 z94241 z94241 z94242 z94242 z94144 z94120 z94120 z94251 remember - if safety signs have been damaged, removed, become illegible or parts are replaced without ...

Page 17: 4 Operation

17 4 operation operating safety • please remember it is important that you read the operator's manual and heed the safety signs on the 3 point hitch wood chipper. They are there for your safety, as well as the safety of others. The safe use of this machine is strictly up to you, the operator. • pers...

Page 18

18 4 2 machine components the wallenstein bx series wood chipper is designed for chipping wood in a fast and efficient manner. Major components of the bx base model chippers are illustrated here. Please review this section, many of the component descriptions here are used throughout the manual to ex...

Page 19

19 19 models bx52, bx72 and bx102 series upper rotor housing hood deflector discharge chute adjustable ski folding feed hopper discharge latch handle manual tube ledger blade twig breaker pto shaft lower link pins top link rotor lock feed hopper latch deflector adjustor rotor blade ledger setting ga...

Page 20

20 4 3 machine break-in although there are no operational restrictions on the wood chipper when used for the first time, it is recommended that the following mechanical items be checked: a. After operating for 1 hour: 1. Ensure the machine is in safe condition before checking any components. (see se...

Page 21

21 4 5 pto driveline a pto drive line is supplied with the machine. To accompany the variety of 3 point hitch geometry available today, the drive line can be too long for most machines or too short for others. It is very important that the drive line be free to telescope but not to bottom out when g...

Page 22

22 this section describes the 3 point hitch, pto and attachments. The bx32s, bx52s & bx72s are category i 3 point hitch and are quick hitch & imatch compatible. Bx102s is category ii 3 point hitch only and is quick hitch & imatch compatible. For maximum life and safety, pto connection should be as l...

Page 23

23 14 ensure that the pto driveline has been cut to size (see section 4 5) install the pto drive line: a. Slide the collar back on the yoke, align the splines and slide the yoke on the tractor. B. Release the collar and make sure the locking pin clicks into position. Note be sure the telescoping po...

Page 24

24 models bx52, bx72, bx92 & bx102 series the discharge chute is designed with a spring- loaded latch handle that allows the chute to be positioned 270° then locked into position with the latch. 1. Push down on the latch handle until the chute lock pin disengages. 2. Use the latch and grip handles t...

Page 25

25 4 7 4 bx72s / 102s hood deflector: the discharge chute is equipped with a hood deflec- tor on the end of the chute to direct the chips exactly where desired. The deflector is held in position by a slotted position handle. 1. Grasp the handle and lift slightly to clear the handle cogs 2. Move the ...

Page 26

26 1. Position the tractor / wood chipper at the work site. 2. Set the tractor brake and block / chock the wheels. 3. Lower the chipper, ensure that the machine is resting on the ground and is level and stable. 4. All models except the bx32 series: while holding the feed hopper, release the latch pi...

Page 27: Operating Safety

27 4 9 field operation operating safety • please remember it is important that you read the operator's manual and heed the safety signs on the 3 point hitch wood chipper. They are there for your safety, as well as the safety of others. The safe use of this machine is strictly up to you, the operator...

Page 28

28 after following all operating safety and preparation procedures the chipper should be set up and ready to run (4.8). Tractor or power pack engine manual should also be reviewed. 4 10 starting procedure these procedures can be applied to all versions of the bx chipper. 4 10 1 tractor a. Ensure all...

Page 29

29 the bx wood chipper is a strong, rugged machine that is built to a straight-forward design which provides consistent chipping of logs. Capacity: 3" (8cm) in diameter for the bx32s. 5" (13cm) in diameter for the bx52s. 7" (17cm) in diameter for the bx72s. 10" (25cm) in diameter for the bx102s. Alw...

Page 30

30 4 11 1 unplugging: although the machine is designed to handle a wide variety of material without any problem, occasionally it may plug. If the machine plugs, follow this procedure to unplug: 1. Enure the machine is in safe condition before beginning to unplug "safe condition" procedure: • disenga...

Page 31: Transport Safety

Z94242 31 transport safety • do not exceed a safe travel speed. • always follow and obey applicable highway rules and regulations. • be sure all lights, markers and smv sign required by the traffic regulations are in place, clean and working. • check 3 point hitch connections and ensure they are saf...

Page 32: Storage Safety

32 storage safety • store the unit in an area away from human activity. • do not permit children to play on or around the stored machine. • store the unit in a dry, level area. Support the frame with planks if required. 6 storage after the season's use or when the machine will not be used for a peri...

Page 33

33 maintenance safety • good maintenance is your responsibility. Poor maintenance is an invitation to trouble. • follow good shop practices. • keep service area clean and dry. • be sure electrical outlets and tools are properly grounded. • use adequate light for the job at hand. • make sure there is...

Page 34: Warning

34 7 1 4 service illustration models bx32 series see service record chart (section 7.1.6) this illustration shows the general location of service points. A location lubricate hinges & pivot points a rotor cover hinge (2 sides) b feed hopper hinges location grease points - 50 hrs or annually 1 rotor ...

Page 35

35 location lubricate hinges & pivot points hood deflector discharge chute swivel flange bearing grease whip b c d every 100 hrs or annually, wash and clean wood chipper, remove entangled material, wood chips, small debris. D c location grease points - 50 hrs or annually 3 rotor main shaft rear roll...

Page 36: Warning

36 see service record chart (section 7.1.6) this illustration shows the general location of service points. B a location lubricate hinges & pivot points a rotor cover hinge (2 sides) b feed hopper hinges location grease points - 50 hrs or annually 1 rotor main shaft front roller flange on a regular ...

Page 37

37 location lubricate hinges & pivot points c hood deflector d discharge chute swivel every 100 hrs or annually, wash and clean wood chipper, remove entangled material, wood chips, small debris. D c location grease points - 50 hrs or annually 2 rotor main shaft rear roller flange grease with one sho...

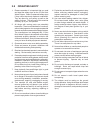

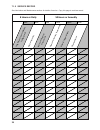

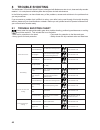

Page 38: 50 Hours Or Annually

38 7 1 5 service record see lubrication and maintenance sections for details of service. Copy this page to continue record. Check check check check adjust clean 50 hours or annually 8 hours or daily tw ig b rea ker, r ot or b la des , led ger bl ad e sec ur e f as ten er s lu br ica te h in ges & pi...

Page 39

39 7 2 maintenance by following a careful service and maintenance program for your machine, you will enjoy many years of trouble-free operation. Put the machine in safe condition before working on this machine: • disengage the pto • shut off the engine • ensure all components have stopped moving • r...

Page 40

40 7 2 4 twig breaker: all models except bx32 series: the twig breaker is a breaker tab located on side of the lower rotor housing. The discharge paddle passes around the twig breaker and helps to break the material into smaller pieces and turn it into mulch. Inspect the twig breaker for damage such...

Page 41: Warning

41 7 2 5 rotor blades: the rotor and ledger blades need to be sharp for the chipper to perform as expected. Periodic inspection is recommended. Keep the blades sharp to reduce the amount of power required during operation. Watch the sharpness of the blades when processing material with a lot of sand...

Page 42

42 7 2 6 ledger blades: each machine is equipped with a ledger (stationary) blade that acts as a shear for the moving rotor blades. The ledger blade is located on the lower rotor housing, mounted on slotted holes for adjustment. There are 4 usable corners on the blade, when the corner facing the rot...

Page 43

43 7 2 7 ledger blade adjusting tool: the ledger blade adjusting tool is located on the lower rotor housing. (tool not included with bx32 series) as the blade wears, it can be rotated or flipped to use a fresh corner. When the blade is moved, it must have its clearance settings adjusted to maintain ...

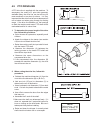

Page 44: Warning

44 a set of v belts transmits rotational power to the rotor. They must be kept properly tensioned and the pulleys aligned to obtain the expected performance and life. To check the tension and alignment, follow this procedure: 1. Clear the area of bystanders, especially small children. 2. Turn machin...

Page 45: 8 Trouble Shooting

45 8 trouble shooting the wallenstein 3 point hitch wood chipper is designed with blades on a rotor to cut, shear and chip wooden material. It is a simple and reliable system that requires minimal maintenance. In the following section, we have listed many of the problems, causes and solutions to the...

Page 46

46 obstructed discharge. Clear debris from discharge chute . Ensure machine is off feeding in too much material feed smaller amounts into chipper hopper. Feeding material too quickly feed larger material slowly into chipper hopper. Rotor plugged. Inspect and clear chipper hopper lower rotor housing a...

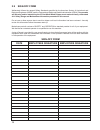

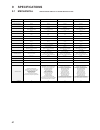

Page 47: 9 Specifications

47 9 specifications 9 1 mechanical specifications subject to change without notice specifications bx32s bx52s bx72s bx102s drive system belt & pulley, pto w/ shearbolt direct drive, pto w/ shearbolt direct drive, pto w/ shearbolt direct drive, pto w/ shearbolt power requirements for maximum capacity...

Page 48

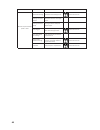

48 9 2 bolt torque checking bolt torque the tables shown below give correct torque values for various bolts and capscrews. Tighten all bolts to the torques specified in chart unless otherwise noted. Check tightness of bolts periodically, using bolt torque chart as a guide. Replace hardware with the ...

Page 49: 10 Accessories

49 #1012l269 #21012l269 ledger clearance setting guage 10 accessories an easy and accurate way of setting the critical clearances between the ledger blade and the rotor chipper blade. Call your dealer for pricing and availability for replacement parts, go to www wallensteinequipment com and click on...

Page 50: Index

50 index a asabe 13 b belt 18, 40 c capacity 29 category i & ii 2 ca...