- DL manuals

- Wallenstein

- Chipper

- BXT4213

- Operator's Manual

Wallenstein BXT4213 Operator's Manual

TRAILER WOOD CHIPPER

MODEL

BXT4213, BXT4214su, BXT4224,

BXT4228su, BXT6224, BXT6228su &

BXT6238

OPERATOR'S MANUAL

BY

EMB MFG INC.

PRINTED IN CANADA

Rev: 290512 PART NUMBER: Z97033

EMB Manufacturing Inc.

4144 Boomer Line · St. Clements, On · N0B 2M0 · Canada

Ph: (519) 699-9283 · Fax: (519) 699-4146

www.embmfg.com

BXT4213 / BXT4214su

BXT4224 / BXT4228su

BXT6224 / BXT6228su

BXT6238

Summary of BXT4213

Page 1

Trailer wood chipper model bxt4213, bxt4214su, bxt4224, bxt4228su, bxt6224, bxt6228su & bxt6238 operator's manual by emb mfg inc. Printed in canada rev: 290512 part number: z97033 emb manufacturing inc. 4144 boomer line · st. Clements, on · n0b 2m0 · canada ph: (519) 699-9283 · fax: (519) 699-4146 w...

Page 2: Table of Contents

2 table of contents warranty .........................................................3 inspection report ........................................4 serial number location ............................ 5 1 introduction .....................................6 2 safety ......................................

Page 3: Warranty

3 warranty warranty effective on products retailed on or after january 1, 2015. Register your product online at www.Surgemaster.Ca within 30 days of purchase to activate warranty. This product is warranted to be free of defects in materials and workmanship under normal use and service, for a period ...

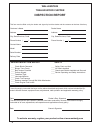

Page 4: Inspection Report

4 ____ safety chain on hitch ____ all decals installed ____ guards and shields installed and secured ____ review operating and safety instructions ____ check blade clearance ____ blower turns freely ____ belt tension checked ____ pulleys aligned ____ fasteners tight ____ lubricate machine ____ check...

Page 5: Serial Number Location

5 serial number location always give your dealer the serial number of your wallenstein trailer wood chipper and feed hopper when ordering parts or requesting service or other information. The serial number plate is located where indicated. Model bxt6238 is shown but the location of the plate is the ...

Page 6: 1 Introduction

6 1 introduction congratulations on your choice of an wallenstein trailer wood chipper to compliment your operation. This equipment has been designed and manufactured to meet the needs of a discerning timber or land- scaping industry. Safe, efficient and trouble free operation of your wallenstein wo...

Page 7: 2 Safety

7 2 safety safety alert symbol why is safety important to you? The safety alert symbol identifies important safety messages on the wallenstein trailer wood chipper and in the manual. When you see this symbol, be alert to the possibility of personal injury or death. Follow the instructions in the saf...

Page 8

8 safety you are responsible for the safe operation and maintenance of your wallenstein trailer wood chipper. You must ensure that you and anyone else who is going to use, maintain or work around the trailer wood chipper be familiar with the using and maintenance procedures and related safety inform...

Page 9

9 2.2 equipment safety guidelines 1. Safety of the operator and bystanders is one of the main concerns in designing and de- veloping equipment. However, every year many accidents occur which could have been avoided by a few seconds of thought and a more careful approach to handling equipment. You, t...

Page 10

10 2.3 safety training 1. Safety is a primary concern in the design and manufacture of our products. Unfortunately, our efforts to provide safe equipment can be wiped out by a single careless act of an operator or bystander. 2. In addition to the design and configuration of equipment, hazard control...

Page 11

11 2.5 preparation 1. Never use the engine and machine until you have read and completely understand this manual, the engine operator's manual and each of the safety messages found on the safety signs on the engine and machine. 2. Personal pro- tection equip- ment including hard hat, safety glasses,...

Page 12

12 2.7 operating safety 1. Please remember it is important that you read and heed the safety signs on the trailer wood chipper. Clean or replace all safety signs if they cannot be clearly read and understood. They are there for your safety, as well as the safety of others. The safe use of this machi...

Page 13

13 2.8 gas motor safety before starting engine, read and understand the operating and maintenance instructions that came with your engine. Warning: do not 1. Do not run engine in an enclosed area. Exhaust gases contain carbon monoxide, an odourless and deadly poison. 2. Do not place hands or feet ne...

Page 14

14 2.9 refuelling safety 1. Handle fuel with care. It is highly flammable. 2. Allow engine to cool for 5 minutes before refu- elling. Clean up spilled fuel before restarting engine. 3. Do not refuel the machine while smoking or when near open flame or sparks. 4. Fill fuel tank outdoors. 5. Prevent f...

Page 15: Sign-Off Form

15 2.14 sign-off form wallenstein follows the general safety standards specified by the american society of agricultural and biological engineers (asabe) and the occupational safety and health administration (osha). Anyone who will be using and/or maintaining the trailer wood chipper must read and c...

Page 16: 3 Safety Sign Locations

16 remember - if safety signs have been damaged, removed, become illegible or parts replaced without safety signs, new signs must be applied. New safety signs are available from your authorized dealer. 3 safety sign locations 3.1 3 - panel safety signs the types of safety signs and locations on the ...

Page 17

17 remember - if safety signs have been damaged, removed, become illegible or parts replaced without safety signs, new signs must be applied. New safety signs are available from your authorized dealer. 3.2 2 - panel safety signs the types of safety signs and locations on the equipment are shown in t...

Page 18: 4 Operation

18 4 operation the wallenstein trailer wood chippers are de- signed to chip or chop scrap lumber, small trees, brush, limbs and other wood debris. The chipped material is fine enough to be composted or used in a variety of ways. It is the responsibility of the owner or opera- tor to read this manual...

Page 19

19 4.2 machine components the wallenstein trailer wood chipper is a rotor with blades for chipping wood. A hinged feed hopper moves the wood material into the rotor. Each rotor is designed with cutting blades and a twig-breaker to generate the small pieces of wood. A stationary blade at the rear of ...

Page 20

20 4.3 machine break-in although there are no operational restrictions on the wood chipper when used for the first time, it is recommended that the following mechanical items be checked: a. After operating for 1 hour: 1. Check alignment of pulleys. Align as required. 2. Check belt tension. Adjust as...

Page 21

21 4.5.1 gas engine manual / elec- tric start bxt4213: honda gx390 bxt4214su: subaru ex40 always read the engine operator's manual sup- plied with the machine for the detailed operating procedures. • ignition switch: this key operated switch con- trols the electric power to the engine. Off turn key ...

Page 22

22 4.5.2. Gas engine electric start bxt4224, bxt6224: honda gx690 bxt4228su, bxt6228su: subaru eh72fi bxt6238: kohler ch980 before starting to work, all operators should famil- iarize themselves with the location and function of controls. 1. Gas engine: before starting, read the engine manufacturers...

Page 23

23 aligned attached 4.6 ball & coupler the wood chipper should always be located on a level, dry area that is free of debris and other foreign objects. When attaching the machine to a tow unit, follow this procedure: 1. Make sure that all bystanders, especially small children, are clear of the worki...

Page 24

24 3. Lower the feed hopper down into its working configuration: a. Remove the nuts on the hopper anchor bolts, b. Unpin and the feeder hopper latch c. Carefully lower the hopper and secure it with the with the nuts on the anchor bolts. Fig. 14 feed hopper 4.7 machine set-up follow this procedure to...

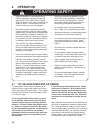

Page 25: Operating Safety

25 4.8 field operation the operator has the responsibility of being fa- miliar with all operating and safety procedures and following them. Although the trailer wood chipper is easy to use, each operator should review this section to famil- iarize himself with the detailed safety and operat- ing pro...

Page 26

26 4.8.2. Starting procedure a. The wood chipper should be set up and ready to run. (see 4.7) b. Set park brake if connected to tow vehicle. C. Lower the support leg stand and secure with the snapper pin. D. Close the choke if the engine is cold. (not available for fuel injected subaru) e. Move the ...

Page 27

27 the bx wood chipper is a strong, rugged ma- chine that is built to a straight-forward design which provides consistent chipping of logs up to 4" (102mm) in diameter for the bxt4213, bxt4214su and 6" (153mm) in diameter for the bxt4224, bxt6224, bxt4228su, bxt6228su, bxt6238. Always wear personal ...

Page 28: Warning

28 fig. 17 severe plug 4.8.6 unplugging: although the machine is designed to handle a wide variety of material without any prob- lem, occasionally it plugs. When the machine plugs, follow this procedure to unplug: a. Clear the area of bystanders, especially small children. B. Stop the engine, remove...

Page 29

29 fig. 18 fuel tank 4.8.8 refuelling: bxt4213, bxt4214su models have an en- gine mounted fuel tank. Bxt4224, bxt4228su models have the fuel tank located in the front frame and is ac- cessed by lifting the tool box lid. Bxt6224 bxt6228su, bxt6238 models have the fuel tank located in the front frame ...

Page 30: Transport Safety

30 transport safety • do not exceed a safe travel speed. • always follow and obey applicable highway rules and regulations. • be sure all lights and markers required by the traffic regulations are in place, clean and working. • inspect rims for dents or damage, check wheel lugs and tighten if requir...

Page 31: Operating Safety

31 operating safety • store the unit in an area away from human activity. • do not permit children to play on or around the stored machine. • store the unit in a dry, level area. Support the frame with planks if required. 6 storage after the season's use or when the machine will not be used for a pe...

Page 32

32 maintenance safety • good maintenance is your responsibility. Poor maintenance is an invitation to trouble. • follow good shop practices. - keep service area clean and dry. - be sure electrical outlets and tools are properly grounded. - use adequate light for the job at hand. • make sure there is...

Page 33

33 every 100 hrs or annually. Wash and clean wood chipper, remove entangled material, wood chips, small debris on a regular basis check all nuts, bolts and screws and ensure they are all properly secured grease pivot point & hinges: inspect daily, grease every 40 hours or weekly tire pressure: check...

Page 34

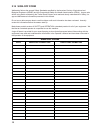

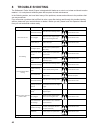

34 7.1.4 service record see lubrication and maintenance sections for details of service. Copy this page to continue record. Check check check clean sharpen grease grease adjust clean 8 hours or daily 50 hours or annually 100 hours or annually tw ig break er, cho p bl ock , bl ad es, k ni ve s secur ...

Page 35

35 7.2 maintenance by following a careful service and maintenance pro- gram for your machine, you will enjoy many years of trouble-free operation. Review your engines instruction manual for specific instructions / requirements 7.2.1 cleaning air cleaner 1. Place all controls in neutral, stop and dis...

Page 36

36 7.2.4 belt tension the machine is designed with a centrifugal clutch on the engine shaft when engaged is used to drive the rotor plate sheave. When the belt is in disrepair or loose, the ability to efficiently drive rotor may be affected. Therefore it is important to periodically check the condit...

Page 37

37 7.2.5 sheave alignment a set of v belts transmits rotational power to the rotor. They must be kept properly tensioned and the sheaves aligned to obtain the expected performance and life. For maximum accuracy, have your sheaves aligned with a laser alignment tool. Contact your dealer for informati...

Page 38: Warning

38 7.2.6 blade and breaker maintenance: the rotor and ledger blades need to be sharp for the chipper to perform as expected. Periodic inspec- tion is recommended. Keep the blades sharp to reduce the amount of power required during operation. Watch the sharpness of the blades when processing material...

Page 39: Warning

39 ledger blades: each machine is equipped with a ledger (stationary) blade that acts as a shear for the moving rotor blades. The ledger blade is designed with 4 usable corners. When the corner facing the rotor blade rounds over, remove the blade and re-install with a different corner facing the rot...

Page 40: 8 Trouble Shooting

40 8 trouble shooting the wallenstein trailer wood chipper is designed with blades on a rotor to cut, shear and shred wooden material. It is a simple and reliable system that requires minimal maintenance. In the following section, we have listed many of the problems, causes and solutions to the prob...

Page 41: 9 Specifications

41 specifications subject to change without notice model bxt4213 / 4214su bxt4224 / 4228su bxt6224 / 6228su / 6238 drive system engine 13hp honda / 14hp subaru 24hp honda / 28hp subaru 24hp honda / 28hp subaru / 38hp kohler chipper capacity 6" dia.(15.2 cm) max. 12" slab (30.5cm) chipper housing ope...

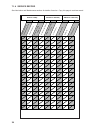

Page 42

42 9.2 bolt torque checking bolt torque the tables shown below give correct torque values for various bolts and capscrews. Tighten all bolts to the torques specified in chart unless otherwise noted. Check tightness of bolts periodically, using bolt torque chart as a guide. Replace hardware with the ...

Page 43: 10 Accessories

43 10 accessories call your dealer for pricing and availability for replacement parts, go to www.Embmfg.Com and click on "parts and manuals" to download the latest parts manual for you model splitter, then call your dealer to order. For bxt series chippers an easy and accurate way of setting the cri...

Page 44: Index

44 index a accessories .................... 43 air cleaner ...................... 35 asabe .................................. 15 b ball hitch ......................... 23 belt guard ....................... 19 belt tension .................... 36 blade .................................. 38 breaker .....