- DL manuals

- WarmFlow

- Boiler

- 50/70

- Installation & servicing manual

WarmFlow 50/70 Installation & servicing manual

Summary of 50/70

Page 1

Installation & servicing manual for 50/70 wall mounted boiler (internal) & 50/70 wall mounted boiler (external) leave these instructions with the end user national accreditation of certification bodies bsi r e g is t e r e d f ir m cert. No. Fm 29884 bs 5750 part 2 iso 9002.

Page 2: Commissioning

Page 2 commissioning this appliance must be commissioned. Failure to commission the boiler will invalidate the warranty. After commissioning ensure that the attached guarantee registration card is completed and returned. Servicing to ensure continued reliable operation and fuel economy it is recomme...

Page 3

Page 3 contents page 1.0 user instructions 1.1 thermostat control ......................................................................................................................................... 2 1.2 mains indicator .............................................................................

Page 4: User Instructions

Page 4 1.0 user instructions all our domestic appliances have been independently tested and accredited as exceeding the minimum sedbuk efficiency levels required for its type, in compliance with the building regulations approved document l1 2001 for england and wales and the building standards (scot...

Page 5

Page 5 1.5 user instructions – wall mounted (internal) burner lock-out reset limit stat reset green amber red control thermostat (54 ° c – 84 ° c) burner lock-out reset (from underneath) high limit stat reset (from underneath) ➔ ➔.

Page 6

Page 6 1.6 user instructions – wall mounted (external) high limit reset amber red control thermostat (54 ° c – 84 ° c) green burner lockout reset (from underneath) burner lockout reset (from underneath).

Page 7

Page 7 1.7 components 1.7.1 components – wall mounted boiler (internal) 1. Front casing 2. Combustion chamber door 3. Door gasket 4. Door insulation 5. Top baffle support 6. Top baffle 7. Top casing & insulation 8. 3 / 4 ” bsp flow connection 9. Flue closing plate 10. Mounting plate insulation 1 2 3...

Page 8

Page 8 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 1.7.2 components – wall mounted boiler (external) 1. Flue terminal guard 2. Main casing assembly 3. Combustion chamber door 4. Door gasket 5. Door insulation 6. Insulation heat shield 7. Top baffle support 8. Top baffle 9. Flue elbow 10. Top insula...

Page 9

Page 9 2.0 introduction the boilers are fired by a pressure jet oil burner which is covered by the manufacturer’s parts and labour warranty valid for one year (from boiler date stamp). Optional extended guarantees covering parts and labour are also available (although not applicable to the republic ...

Page 10

Page 10 3.0 dimensions 3.1 50/70 wall mounted boiler (internal) f d d a b e c h j m g k l front view side view rear view n model 50-70 wm j 77 a 450 b 330 c 762 d 79 e 100 f 207 g 86 h 73 k 77 l 90 m 90 n 22 3.2 50/70 wall mounted boiler (external) model 50-70 wme a 502 b 349 c 1023 d 465 e 926 b a ...

Page 11

Page 11 3.3 ‘easy fit’ low level conventional flue (llf-r) 102 792 max 155 min 540 min Ø125 225 max 4.0 installation the boiler installation must be in compliance with bs 5410 and the building regulations. Failure to install and commission in accordance with the instructions contained within this bo...

Page 12

Page 12 it is recommend that the system is further treated with a corrosion inhibitor. These products should be used strictly in accordance with the manufacturers instructions. In areas of hard water a suitable water softener would also be recommended. 4.2 sealed systems all warmflow boilers are sui...

Page 13

Page 13 5.0 boiler installation 5.1 heat exchanger installation 1. Make sure the wall chosen for the installation is flat level and able to support the filled weight of the appliance (128kg) and that the anchor bolts are appropriate for the wall. 2. Place the installation template on the wall making...

Page 14

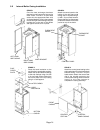

Page 14 5.2 internal boiler casing installation stage 1 once the heat exchanger has been mounted on wall correctly a flue can be fitted. Insert 4 no m5 x 10 pozi head screws into the appropriate hank nuts on the wall bracket. Once in place attach the left and right hand casings using the keyhole slo...

Page 15

Page 15 5.3 wall mounted boiler (external) casing installation stage 1 fit the wall-plate, boiler and flue as per internal wall mounted boiler instructions. The wall-plate for the external boiler can be used as a template. Stage 2 fit the assembled casing onto the wall-plate using self tapping screw...

Page 16

Page 16 6.0 electricity supply 220 – 240v. 1ph, 50 hz the boiler should be wired via a fused double pole isolating switch which should be fitted with a 5 amp fuse. Additionally the external wall mounted boiler should be protected by a ce approved rcd. The external boiler requires a permanent live su...

Page 17

Page 17 6.2.1 control panel wiring (wall mounted boilers – internal) br – brown bl – blue g/y – green/yellow r – red bk – black w – white.

Page 18

Page 18 6.2.2 control panel wiring (wall mounted boilers – external) note: for normal operation the servicing switch should be in the off position otherwise the boiler will run continuously independently of the time clock. Br – brown bl – blue g/y – green/yellow r – red bk – black w – white.

Page 19

Page 19 7.0 technical data 50/70 wm & wm-e 14.6 – 20.5 max mid 23.3 20.0 79,600 68,200 20.5 17.6 70,000 60,000 rdb1 t2 short 100 or 127 4 or 5 185 170 11.5 0 – 1 danfoss 60 ° s le 0.6 0.5 8 8 116 116 2.4 2 0.53 0.44 2 x 3 / 4 ”bsp 17.8 3.92 3.1 21.0 110 128 c c model output range kw range setting no...

Page 20

Page 20 8.0 air supply for combustion and ventilation (see bs 5410) 8.1 open flue boilers when the boiler is sited in a cellar where the only access for combustion and ventilation air is at high level then the combustion air should be ducted to low level. Combustion air supply boiler in room air sup...

Page 21

Page 21 9.0 flues 9.1 conventional flues the flue should be designed in accordance with the local bye-laws and the clean air act. Draught stabilisers are not recommended for oil fired boilers. Sharp bends or horizontal runs should be avoided and the flue should terminate 2 feet (600 mm) above the ri...

Page 22

Page 22 these are minimum dimensions and are only quoted as a guideline but they will satisfy the requirements of all uk building regulations. Where the flue terminal is within 1 metre of any plastic material, such material should be shielded from the effects of the combustion products of the flue. ...

Page 23

Page 23 9.3 installation of a low level conventional flue (llf-r) 1. Make a suitable sized hole in the wall for the flue kit. Using the paper template provided. The cavities must be sealed from the hole. 2. Remove the top panel (kitchen and utility models) and the combustion chamber lid. 3. Remove t...

Page 24

Page 24 1. Using the template supplied cut a 4” hole through the wall, minimum 300mm above the ground. 2. Cut plastic vent tube to suit wall thickness and insert into the hole in the wall. 3. Remove plastic air inlet cover on the burner. Attach the air intake gasket and adapter to the burner using t...

Page 25

Page 25 9.5 wall mounted boiler (external) flue adaptors 9.5.1 fitting vertical flue adaptor (option a) remove the flue terminal (4 screws) and fit the vertical flue adaptor as shown (4 screws). 9.5.2 fitting vertical flue adaptor (option b) flue terminal vertical flue adaptor (vfa – wma) side view ...

Page 26: 0.5

Page 26 10.0 oil supply 1. Oil tank steel tanks constructed to bs 799 part 5 1987 should be painted on the outside only and mounted on piers to prevent corrosion. Plastic oil tanks are also available and can be suitable for installation at ground level. However, kerosine should never be stored in tr...

Page 27: 0.5

Page 27 i.D. 8 mm i.D. 10 mm 0.5 35 100 0.5 30 100 1 25 100 1.5 20 90 lift h (m) 2 15 70 3 8 30 3.5 6 20 10.2 two pipe system approved site gauge 20mm per metre slope water separator total maximum pipe length (m) 10.3 de-aerator system for maximum pipe length and lift contact de-aerator manufacturer...

Page 28

Page 28 10.4 one pipe lift system 20mm per metre slope approved site gauge water separator note: the pump vacuum should not exceed a maximum of 0.4 bar. Above this gas is released from the oil thus leading to burner lock out. Total maximum pipe length (m) 0.5 35 100 0.5 30 100 1 25 100 1.5 20 90 2 1...

Page 29

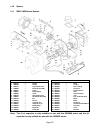

Page 29 11.0 rdb burner 11.1 components the burner is fitted with the correct nozzle and the pressure set. All that is further required before commissioning, is to connect the oil and electricity supply. 1. Pump 5. Air damper adjustment screw 2. Control box 6. Air tube connection (b/f) or inlet cove...

Page 30

Page 30 11.3 air damper adjustment the setting is purely indicative. Each installation however, has its own unpredictable working conditions: actual nozzle output; positive or negative pressure in the combustion chamber, the need of excess air, etc. All these conditions may require a different air-d...

Page 31

Page 31 12.0 servicing & commissioning 12.1 commissioning note: it is recommended that an oftec trained and registered technician be used. It is the responsibility of the installer to ensure that the boiler is properly commissioned. See bs 5410. Failure to do so may invalidate the warranty. Combusti...

Page 32

Page 32 13.0 fault finding is there a supply voltage to terminal 12 in the control panel or to the control thermostat. Expect 240v ± 10%..

Page 33

Page 33 14.0 spares 14.1 rdb 1 wm burner spares no code 3513007 description 1 3005787 • gasket 2 3006384 • flange 3 3001079 • cup-shaped head 4 3008860 • electrode assembly 5 3008875 • screw 6 3008861 • nozzle holder 7 3008862 • collar 8 3008794 • high voltage lead 9 3008647 • air damper assembly 10...

Page 34

Page 34 14.2 short parts list (boiler) code boiler control thermostat 2131 boiler limit thermostat 281 drain cock 618 top baffle 2428 top baffle holder 2448 baffle 2361 boiler cleaning brush 2470 door gasket 2457 door insulation 2456 door insulation shield 2440 vertical flue adaptor a vfa – wm a ver...

Page 35

Page 35.

Page 36: For Parts, Service

This manual is accurate at the date of printing (e&oe) but will be superseded and should be disregarded if specifications and/or appearances are changed in the interests of continued product improvement. Code 2614 lisburn lissue industrial estate, moira road, lisburn, co antrim, n ireland, bt28 2rf ...