- DL manuals

- WarmFlow

- Boiler

- Boilerhouse B120HE

- User Manual

WarmFlow Boilerhouse B120HE User Manual

Boiler Manual

Incorporating:

User Instructions

Installation Instructions

Service Instructions

Guarantee Terms & Conditions

High Efficiency

Condensing Boilers

For use with Kerosene only

Models covered by this manual:

B-Series

Boilerhouse

B70HE

B90HE

B120HE

U-Series

Utility

U70HE

U90HE

U120HE

U150HE

Utility Pumped

UP70HE

UP90HE

UP120HE

UP150HE

Utility System

US70HE

US90HE

US120HE

Utility Combi

UC70HE

UC90HE

UC120HE

K-Series

Kabin Pak

K70HE

K90HE

K120HE

K150HE

Kabin Pak Pumped

KP70HE

KP90HE

KP120HE

KP150HE

Kabin Pak System

KS70HE

KS90HE

KS120HE

Kabin Pak Combi

KC70HE

KC90HE

KC120 HE

LEAVE THIS MANUAL WITH THE END USER

Cert. no. FM29884

Summary of Boilerhouse B120HE

Page 1

Boiler manual incorporating: user instructions installation instructions service instructions guarantee terms & conditions high efficiency condensing boilers for use with kerosene only models covered by this manual: b-series boilerhouse b70he b90he b120he u-series utility u70he u90he u120he u150he u...

Page 2: Commissioning

Commissioning this appliance must be commissioned. Failure to commission the boiler will invalidate the warranty. After commissioning, ensure that the boiler passport is completed and returned. Servicing to ensure continued reliable operation, fuel economy and to validate the guarantee, it is recomm...

Page 3: Contents

Page 1 contents 1 user instructions ......................................................................................................... 3 1.1 dual thermostat ......................................................................................................................... 3 1.2 high lim...

Page 4

Page 2 10 installation requirements ................................................................................. 70 10.1 general requirements ............................................................................................................. 70 10.2 sealed systems .......................

Page 5: 1 User Instructions

Page 3 1 user instructions 1.1 dual thermostat the radiator temperature is regulated via the boiler control thermostat. The thermostat is user adjustable from 45°c at its minimum setting (dial „0‟) to 75°c at its maximum setting (dial „5‟). In order to provide an additional level of safety there is ...

Page 6

Page 4 1.4 system pressure – system & combi boilers when the boiler is connected to a sealed system the system pressure should be periodically checked. The minimum pressure, as indicated by the black needle, is 0.5 bar when the boiler is cold and 2.5 bar when the boiler is at normal operating temper...

Page 7

Page 5 2 condensing boiler installation requirements the warmflow condensing boiler can be fitted to most installations using standard practices and techniques. There are however a number of considerations that must be taken into account. 1. All existing systems must be properly flushed to remove an...

Page 8: Check:

Page 6 3 before fitting a combi boiler the installer must check: 1. What the maximum hot water demand placed on the boiler is likely to be. Not every installation is suitable for a combi boiler. Systems requiring very high hot water flow rates may be better suited with a warmflow unvented cylinder. ...

Page 9: 4 General Information

Page 7 4 general information 4.1 introduction note: all our domestic appliances have been independently tested and accredited as exceeding the minimum sedbuk efficiency levels required for their type, in compliance with the building regulations approved document l1a, l1b for england and wales, the b...

Page 10

Page 8 the heating system should be installed by a competent installer in accordance with the recommendations laid down by the building services compliance guide, oftec and sound engineering practice. In order to comply with building regulations, the boiler passport and or oftec forms cd10 for insta...

Page 11

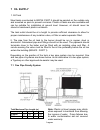

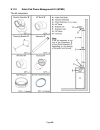

4.4 baffle positioning models up to 120 he the primary heat exchanger baffles consist of one heavy baffle stack (4mm thick) at the bottom, 3 lighter baffle stacks (3mm thick) in the middle and 1 baffle plate (3mm thick) at the top. Upon installation or after servicing, ensure the baffles are in the ...

Page 12

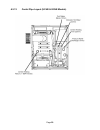

4.5 components 4.5.1 b-series boilerhouse – casing components & key components 1 4 5 6 2 3 p ag e 1 0 1. Boiler assembly 2. Top front casing (removable) 3. Top rear casing (removable) 4. Sides & rear casing 5. Front casing (removable) 6. Bottom front casing 1. Heat exchanger 2. Condensing unit 3. Au...

Page 13

4.5.2 u-series utility – casing components models up to 120 he 150 he models p ag e 1 1.

Page 14

4.5.3 u-series utility – pre-wired (uhe) key components models up to 120 he 150 he models p ag e 1 2.

Page 15

4.5.4 u-series utility – pumped (uphe) key components models up to 120 he 150 he models p ag e 1 3.

Page 16

Page 14 4.5.5 u-series utility – system (ushe) - key components 4.5.6 u-series utility – combi (uche) - key components.

Page 17

4.5.7 k-series kabin pak – casing components models up to 120 he 150 he models p ag e 1 5.

Page 18

4.5.8 k-series kabin pak - pre-wired (khe) key components models up to 120 he 150 he models p ag e 1 6.

Page 19

4.5.9 k-series kabin pak - pumped (kphe) key components models up to 120 he 150 he models p ag e 1 7.

Page 20

Page 18 4.5.10 k-series kabin pak – system (kshe) - key components 4.5.11 k-series kabin pak – combi (kche) - key components.

Page 21

Page 19 4.5.12 combi control panel layout 1) heating temperature control the heating temperature control adjusts the temperature of the central heating water flowing from the boiler to the radiators. Turn the dial clockwise towards red to increase the temperature and anticlockwise towards blue to re...

Page 22

Page 20 4.5.13 combi pipe layout (uche & kche models).

Page 23: 5 Technical Details

Page 21 5 technical details 5.1 combi sequence of operation flow chart.

Page 24

Page 22 5.2 dimensions 5.2.1 b-series boilerhouse (b70he, b90he & b120he models) a 395 b 600 c 685 d 332 e 118 f 34 g 664 h 97 j 77 k 197 l 371 m 85 n 35 p 30 q 50 r 80 5.2.2 u-series utility (uhe, uphe & ushe models up to 120he).

Page 25

Page 23 5.2.3 u-series utility (150he models) 5.2.4 u-series utility (uche models).

Page 26

Page 24 5.2.5 k-series kabin pak (khe, kphe & kshe models up to 120he) 5.2.6 k-series kabin pak base tray (khe, kphe & kshe models up to 120he).

Page 27

Page 25 5.2.7 k-series kabin pak (150he models) 5.2.8 k-series kabin pak base tray (150he models).

Page 28

Page 26 5.2.9 k-series kabin pak (kche models) 5.2.10 k-series kabin pak base tray (kche models).

Page 29

Page 27 5.3 condensate disposal the warmflow high efficiency condensing boiler is supplied with a factory fitted, self sealing condensate trap. The trap has been fitted inside the boiler casing to the right hand side. The condensate drainage pipe within the boiler is a flexible plastic hose which ca...

Page 30

Page 28 5.4 technical data 5.4.1 b-series boilerhouse (bhe) model b70he b90he b120he nominal heat output kw btu/hr 14.7 50,000 17.6 60,000 21.0 71,650 21.0 71,560 23.5 80,000 27.1 92,380 27.1 92,380 29.0 99,050 32.7 111,600 nominal heat input kw btu/hr 15.3 52,150 18.4 62,600 22.0 75,000 22.0 75,000...

Page 31

Page 29 5.4.2 u-series utility – pre-wired (uhe) model u70he u90he u120he u150he nominal heat output kw btu/hr 14.7 50,000 17.6 60,000 21.0 71,650 21.0 71,560 23.5 80,000 27.1 92,380 27.1 92,380 29.0 99,050 32.7 111,600 33 112,629 38.5 131,362 44 150,128 nominal heat input kw btu/hr 15.3 52,150 18.4...

Page 32

Page 30 5.4.3 u-series utility – pumped (uphe) model up70he up90he up120he up150he nominal heat output kw btu/hr 14.7 50,000 17.6 60,000 21.0 71,650 21.0 71,560 23.5 80,000 27.1 92,380 27.1 92,380 29.0 99,050 32.7 111,600 33 112,629 38.5 131,362 44 150,128 nominal heat input kw btu/hr 15.3 52,150 18...

Page 33

Page 31 5.4.4 u-series utility – system (ushe) model us70he us90he us120he nominal heat output kw btu/hr 14.7 50,000 17.6 60,000 21.0 71,650 21.0 71,560 23.5 80,000 27.1 92,380 27.1 92,380 29.0 99,050 32.7 111,600 nominal heat input kw btu/hr 15.3 52,150 18.4 62,600 22.0 75,000 22.0 75,000 24.4 83,1...

Page 34

Page 32 5.4.5 u-series utility – combi (uche) model uc70he uc90he uc120he nominal heat output kw btu/hr 14.7 50,000 17.6 60,000 21.0 71,650 21.0 71,560 23.5 80,000 27.1 92,380 27.1 92,380 29.0 99,050 32.7 111,600 nominal heat input kw btu/hr 15.3 52,150 18.4 62,600 22.0 75,000 22.0 75,000 24.4 83,17...

Page 35

Page 33 5.4.6 k-series kabin pak – pre-wired (khe) model k70he k90he k120he k150he nominal heat output kw btu/hr 14.7 50,000 17.6 60,000 21.0 71,650 21.0 71,560 23.5 80,000 27.1 92,380 27.1 92,380 29.0 99,050 32.7 111,600 33 112,629 38.5 131,362 44 150,128 nominal heat input kw btu/hr 15.3 52,150 18...

Page 36

Page 34 5.4.7 k-series kabin pak – pumped (kphe) model kp70he kp90he kp120he kp150he nominal heat output kw btu/hr 14.7 50,000 17.6 60,000 21.0 71,650 21.0 71,560 23.5 80,000 27.1 92,380 27.1 92,380 29.0 99,050 32.7 111,600 33 112,629 38.5 131,362 44 150,128 nominal heat input kw btu/hr 15.3 52,150 ...

Page 37

Page 35 5.4.8 k-series kabin pak – system (kshe) model ks70he ks90he ks120he nominal heat output kw btu/hr 14.7 50,000 17.6 60,000 21.0 71,650 21.0 71,560 23.5 80,000 27.1 92,380 27.1 92,380 29.0 99,050 32.7 111,600 nominal heat input kw btu/hr 15.3 52,150 18.4 62,600 22.0 75,000 22.0 75,000 24.4 83...

Page 38

Page 36 5.4.9 k-series kabin pak – combi (kche) model kc70he kc90he kc120he nominal heat output kw btu/hr 14.7 50,000 17.6 60,000 21.0 71,650 21.0 71,560 23.5 80,000 27.1 92,380 27.1 92,380 29.0 99,050 32.7 111,600 nominal heat input kw btu/hr 15.3 52,150 18.4 62,600 22.0 75,000 22.0 75,000 24.4 83,...

Page 39

Page 37 6 electricity supply & wiring details 220 – 240v. 1ph, 50hz the boiler/burner and other external electrical equipment should be wired with heat resistant cable via a fused double pole isolating switch which should be fitted with a 5 amp fuse. The appliance must be effectively earthed and all...

Page 40

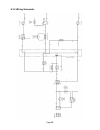

Page 38 6.3 combi wiring details 6.3.1 wiring diagram the 3 p in m ains p lu g m ust be s up pli ed with a p erm an en t live to a llo w th e p um p o ve rru n s ta t a nd rel ay t o o pe rat e..

Page 41

Page 39 6.3.2 wiring schematic.

Page 42

Page 40 6.3.3 fitting a room thermostat to a combi remove the purple wire from no 5 and no 28 on the pcb and wire the thermostat as shown. The room thermostat should be located where it is not subjected to extraneous heat gains, direct sunlight or draughts. 6.3.4 fitting frost protection to a combi ...

Page 43

Page 41 6.4 installation of a warmflow combi optional programmer (pc1) 1. Disconnect the electrical supply. 2. Drop down control box front (2 screws). 3. Disconnect the 6 pin plug from the ch/hw on/off switched. 4. With a sharp knife cut out the outline of the panel knockout through the facia label ...

Page 44

Page 42 6.5 remote timers for combis 6.5.1 installation of a remote two channel programmer (option 1) permanent live supply the boiler must be supplied with a permanent live mains supply via a fused isolator connected to the boiler 3 pin mains plug into the control panel. Failure to connect a perman...

Page 45

Page 43 6.6 optional programmer (pc1) for non-combi models 6.6.1 programmer control box wiring diagram 6.6.2 general requirements 1. The optional programmer as supplied will supply power to the pump and burner via the central heating channel. 2. When connecting to external controls, eg „y‟ plan or „...

Page 46

Page 44 6.6.3 programmer installation 1. Disconnect electrical supply. 2. Drop down control box front (2 screws). 3. Secure control box to the horizontal casing bracket (2 screws) and right hand side (1 screw). 4. Connect the thermostat, circulating pump and the mains supply to the leads on the rear...

Page 47

Page 45 6.6.4 honeywell ‘y’ plan – independent ch & dhw (fully pumped only) note: before fitting programmer, remove loop between 3 and 12 on the terminal block..

Page 48

Page 46 6.6.5 honeywell ‘s’ plan – independent ch & dhw (fully pumped only) note: before fitting programmer, remove loop between 3 and 12 on the terminal block..

Page 49: 7 Oil Supply

Page 47 7 oil supply 1. Oil tank steel tanks constructed to bs799: part 5 should be painted on the outside only and mounted on piers to prevent corrosion. Plastic oil tanks are also available and can be suitable for installation at ground level. However, oil should never be stored in translucent pla...

Page 50

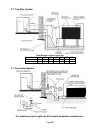

Page 48 7.2 two pipe system total maximum pipe length (m) head h(m) 0.0 0.5 1.0 1.5 2.0 3.0 3.5 id 8mm 35 30 25 20 15 8 6 id 10mm 100 100 100 90 70 30 20 7.3 de-aerator system for maximum pipe length and lift contact de-aerator manufacturer..

Page 51

Page 49 7.4 one pipe lift system total maximum pipe length (m) head h(m) 0.0 0.5 1.0 1.5 2.0 3.0 3.5 id 8mm 35 30 25 20 15 8 6 id 10mm 100 100 100 90 70 30 20 note: the pump vacuum should not exceed a maximum of 0.4 bar. Above this, gas is released from the oil thus leading to burner lockout..

Page 52

Page 50 7.5 instructions for the use of bio fuel to ensure consistency, the fuel supplier must be able to demonstrate compliance with a recognised quality control and management system to ensure high standards are maintained within the storage, blending and delivery processes. The installation oil s...

Page 53

Page 51 installer/servicer notes 1. During the burner installation, check that the gasoil and bio fuel blends are in accordance with riello recommendations (please refer to the chapters “technical data” and “guidance for the use of bio fuel blends within the burner technical manual). 2. If a bio ble...

Page 54: 8 Flues

Page 52 8 flues 8.1 flue options, components & dimensions the use of any flue system other than that supplied or recommended by the manufacturer will invalidate the warranty. The following flue options are available from warmflow: fbf low level balanced flue kit hbf high level balanced flue kit vbf ...

Page 55

Page 53 8.1.2 condensing boiler flue kits fire safety as with a metal flue system, where a plastic flue system is used within a building which is „compartmentalised‟ as defined by the building regulations, care must be taken to ensure that the installation of the flue does not contravene the regulat...

Page 56

Page 54 8.1.3 he low level balanced flue kit (fbf) the kit comprises: fit flue thermostat 1. Fit the flue thermostat before fitting the flue kit. Fit starter piece 2. Remove the appropriate casing panel cut-out using snips. Fit the boiler adapter (a). 3. Lubricate the seals then insert the starter a...

Page 57

Page 55 measure and cut flue terminal 4. Cut a hole through the wall and fit a non-combustible sleeve. 5. Lubricate then fit the flue terminal (c) and measure the excess length, x. 6. Cut x mm from the outer pipe of the terminal then x mm from the inner pipe. Connect terminal and air hose 7. Lubrica...

Page 58

Page 56 8.1.4 he high level balanced flue kit (hbf) the kit comprises: fit flue thermostat 1. Fit the flue thermostat before fitting the flue kit. Fit starter piece 2. Remove the top panel casing cut-out using snips. Fit the boiler adapter (a). 3. Lubricate the seals, then insert the starter assembl...

Page 59

Page 57 4. Lubricate and fit the extension (c) and bend (d) then secure with the locking bands. 5. Fit the air inlet spigot and gasket to the burner. Attach the flexible air hose to the burner and starter assembly and secure with the jubilee clips. Measure and cut flue terminal i. Cut a hole through...

Page 60

Page 58 8.1.5 he vertical balanced flue kit (vbf) the kit comprises: fit flue thermostat 1. Fit the flue thermostat before fitting the flue kit. Fit starter piece 2. Remove the top panel casing cut-out using snips. Fit the boiler adapter (a). 3. Lubricate the seals, then insert the starter assembly ...

Page 61

Page 59 connect 1 st extension and air hose 4. Lubricate then fit the 1st extension and secure with the locking band. 5. Fit the air inlet spigot and gasket to the burner. Attach the flexible air hose to the burner and starter assembly and secure with the jubilee clips. Measure and cut terminal 6. F...

Page 62

Page 60 8.1.6 warmflow he boiler flue components: 80/125 Ø note: 1. Flue fitting kit required. 2. If the terminal is less than 2 metres above ground level, a terminal guard must be fitted. 3. Extension pipes and flue adapter lengths quoted are effective lengths and not the actual length of the piece...

Page 63

Page 61 8.1.7 flue length calculation note: 1. All flues can utilise any combination of bends, straights, adapters and terminals. 2. Ensure flue is arranged such that it falls continuously towards the boiler. 3. The low level, high level and vertical balanced flue systems can use any combination of ...

Page 64

Page 62 8.1.8 plume management kits plume management kits are available for our range of appliances. 8.1.9 utility plume management kit (upmk).

Page 65

Page 63 remove terminal end 1. Hold the terminal assembly (a) in place and extract the terminal end (b) by gripping and pulling firmly. Cut off excess material 2. Using a suitable saw, cut off the highlighted portion of the end of the terminal assembly (a) then de-burr the cut edge. Fit diverter elb...

Page 66

Page 64 8.1.10 kabin pak plume management kit (kpmk) the kit comprises:.

Page 67

Page 65 1. Fit diverter assembly seals apply suitable lubricant to the two diverter assembly seals (supplied loose) then fit to the end of the boiler flue pipe noting the correct orientation. The seals must be fitted as shown with the outer surface sloping away from the end of the pipe to allow the ...

Page 68

Page 66 8.1.11 flexible flue liner kit (hfl & vfl) these boiler connection kits (f16 or f18) contain: installation instructions fit flue thermostat 1. Fit the flue thermostat before fitting the flue. Fit starter piece 2. Remove the top casing panel cut-out using snips. Fit the boiler adapter (a). 3....

Page 69

Page 67 connect 1 st extension and air hose 4. Lubricate then fit the 1 st extension and secure with the locking band. 5. Fit the air inlet spigot and gasket to the burner. Attach the flexible air hose to the burner and starter assembly and secure with the jubilee clips. Connect to closure plate ins...

Page 70

Page 68 8.2 flue terminal locations minimum distances to terminals in millimetres as measured from the top of the chimney or the rim of a low level discharge opening a directly below an opening, air brick, opening window etc. 600 b horizontally to an opening, air brick, opening window etc. 600 c bel...

Page 71

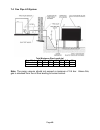

Page 69 9 air supply for combustion & ventilation (see bs5410) 9.1 open flue boilers when the boiler is sited in a cellar where the only access for combustion and ventilation air is at high level then the combustion air should be ducted to low level. Combustion air supply boiler in room open flue bo...

Page 72

Page 70 10 installation requirements the boiler installation must be in compliance with bs5410 : part 1 and the building regulations. 10.1 general requirements 10.1.1 hearth the boiler has a hearth temperature of between 50°c and 85°c and should be stood on a rigid, non-porous, non-combustible base,...

Page 73

Page 71 10.2 sealed systems 10.2.1 expansion vessel refer to bs7074: part 1 and bs5449 for details of expansion vessel sizing. The values given in the table below are for total system volumes which include the primary water capacity of the boiler which can be found in the technical data section of t...

Page 74

Page 72 10.2.5 low pressure switch where there is a catastrophic loss of water from the system the boiler thermostats may fail to operate which would result in serious damage to the appliance. To prevent this it is recommended that a low pressure cut out switch set at 0.2 bar is fitted to the system...

Page 75: 11 Burners

Page 73 11 burners 11.1 rdb burner 11.2 oil pump the burner is supplied for use with a one pipe system. For use on a two pipe system, it is necessary to remove the return port plug and fit a small by-pass plug as shown..

Page 76

Page 74 11.3 electrode setting when removing or replacing the nozzle, move the electrodes forward to avoid the risk of damage. The electrodes are slackened by unscrewing the brass post that passes from the electrode holder out of the side of the burner. When work is complete, ensure the electrodes a...

Page 77

Page 75 12 commissioning & servicing 12.1 commissioning note: it is the responsibility of the installer to ensure that the boiler is properly commissioned by an oftec trained and registered technician. Failure to do so will invalidate all warranties. Before firing ensure that all the baffles are in ...

Page 78: 13 Burner Fault Finding

Page 76 13 burner fault finding 13.1 riello rdb.

Page 79: 14 Combi Fault Finding

Page 77 14 combi fault finding 14.1 central heating.

Page 80

Page 78 14.2 domestic hot water.

Page 81

Page 79 15 optional boiler mounted digital timer 15.1 operating instructions 15.1.1 after installation when you first install the cr2032 battery (by removing the clear plastic strip from the rear of the timer) you must press the „reset‟ button, the lcd display will display fully for 3 seconds. Then ...

Page 82

Page 80 15.1.2 built in programme for convenience, the timer module has a built in programme, however, it can be easily adjusted (see section 15.1.5 to change the programmes). The timer offers 3 options for both ch and hw programme period. Off: off all the time. Auto: to run your time schedule for p...

Page 83

Page 81 15.1.5 to set programme period press and hold day button and press min until the correct programme period is displayed. Set day programme period 1 on/off switching mon – fri time schedule sat – sun time schedule ch/ch1 hw/ch2 ch/ch1 hw/ch2 period 1 on 06:30 06:30 07:30 07:30 period 1 off 22:...

Page 84

Page 82 15.1.8 mode select 1. Press select to toggle through on / auto / off modes as indicated by the timer status. 2. On mode turns on the timer. 3. Off mode turns off the timer. 4. Auto mode runs the set programme. 15.1.9 manual select this function is only applicable when your timer is set on au...

Page 85: 16 Spares

Page 83 16 spares 16.1 rdb 2.2 spares no code 3514157 3514257 3514557 description 1 3005787 ● ● ● gasket 2 3006384 ● ● ● flange 3 3020494 ● cup-shaped head 3 3020258 ● cup-shaped head 3 3020055 ● cup-shaped head 4 3008860 ● ● ● electrode assembly 5 3008875 ● ● ● screw 6 3008861 ● ● ● nozzle holder 7...

Page 86

Page 84 16.2 rdb 3.2 spares no code 3748941 description 1 3005795 ● gasket 2 3008637 ● flange 3 3005714 ● end ring 4 3005713 ● diffuser disc 5 3007714 ● blast tube assembly 6 3006552 ● electrode bracket 7 3007513 ● electrode assembly 8 3008794 ● high voltage lead 9 3008957 ● collar 10 3008876 ● pres...

Page 87

Page 85 16.3 pipe spares utility pumped & system models – up70he, up90he, up120he, us70he, us90he & us120he kabin pak pumped & system models – kp70he, kp90he, kp120he, ks70he, ks90he & ks120he 150he pumped models – up150he & kp150he from boiler to pump (22mm) 3017 pump flow pipe (22mm) 3015 expansio...

Page 88

Page 86 16.3 pipe spares cont’d utility and kabin pak combi models – uc70he, uc90he, kc70he & kc90he from boiler to gate valve 3097 from gate valve to pump 3098 ch flow from pump 3100 from plate heat exchanger to boiler return 3096 expansion vessel pressure hose 3020 from heat store to plate heat ex...

Page 89

Page 87 16.4 short parts list - boiler part description flow switch tank & boiler control thermostat boiler limit thermostat (combi models) tank limit thermostat pump overrun thermostat plate heat exchanger twin head pump 15/60 pump (for replacement head) 3 pole relay auto air vent c/w check valve p...

Page 90

Page 88 17 your guarantees, terms & conditions 1. Warmflow guarantees the boiler, including all controls, plate heat exchangers, pipework and unions, and associated equipment contained within the boiler casing, and the burner and flue system, if supplied by warmflow, are guaranteed against defective...

Page 92

This manual is accurate at the date of printing (e&oe) but will be superseded and should be disregarded if specifications and/or appearances are changed in the interests of continued product improvement. Code 3307 issue 4 feb 2012.