- DL manuals

- WarmFlow

- Boiler

- COMBI 70

- Installation & Servicing Instructions Manual

WarmFlow COMBI 70 Installation & Servicing Instructions Manual

Summary of COMBI 70

Page 1

Installation & servicing manual for 70/90 combi boiler & 70/90 kabin pak combi leave these instructions with the end user national accreditation of certification bodies bsi r e g is t e r e d f ir m cert. No. Fm 29884 bs 5750 part 2 iso 9002.

Page 2: Servicing

Issue 4 mar ’03 servicing to ensure continued reliable operation and fuel economy it is recommended that the boiler is serviced annually. Warmflow engineering service division provides an excellent back-up service, operating a team of oftec trained engineers who can meet all the servicing, commissio...

Page 3: Installer Must Check:

Before fitting this boiler the installer must check: 1. What the maximum hot water demand is likely to be placed on the boiler. Not every installation is suitable for a combi boiler. Systems requiring very high hot water flow rates may be better suited with an unvented cylinder. 2. That the mains ar...

Page 4

Contents page 1.0 user instructions ................................................................................................................. 3 1.1 introduction ................................................................................................................. 4 1.2 general req...

Page 5: 1.0 User Instructions

1.0 user instructions 1.0.1 boiler control thermostat the boiler control thermostat is located on the front of the boiler facia panel and may be adjusted from 52°c to 85°c. The recommended minimum thermostat setting is 65°c. Below this ‘cold water corrosion’ is likely to occur thus reducing the life...

Page 6

1.1 introduction note: all our domestic appliances have been independently tested and accredited as exceeding the minimum sedbuk efficiency levels required for its type, in compliance with the building regulations approved document l1 2001 for england and wales and the building standards (scotland) ...

Page 7

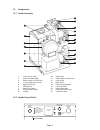

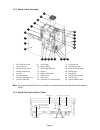

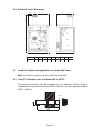

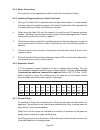

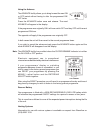

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 1.3 components 1.3.1 combi assembly 1. Automatic air vents 2. Boiler heat exchanger 3. Boiler control and limit stat 4. 12 litre esxpansion vessel 5. Boiler data plate 6. Rdb burner 7. Boiler drain valve 8. Pressure relief valve 9. Strainer 10. Filling lo...

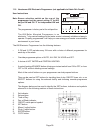

Page 8

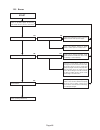

1 2 3 4 5 6 7 8 9 10 11 12 13 16 17 18 20 19 22 21 24 23 14 15 1.3.3 kabin combi assembly 1. Flue terminal guard 2. Low level flue 3. Service access hatch 4. Control panel cover 5. Controls 6. Pressure vessel 7. Control panel flap lock 8. Control panel flap 9. Door panel 10. Burner reset 11. Burner ...

Page 9

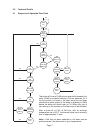

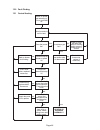

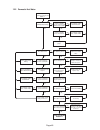

2.0 technical details 2.1 sequence of operation flow chart yes no yes dhw tank stat satisfied flow switch closed timer calling for heat power on dhw pump only runs hw limit stat tripped burner fires burner stops ch selected burner fires ch pump only runs boiler stat satisfied boiler limit stat tripp...

Page 10

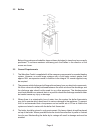

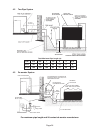

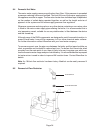

2.2 baffles front before firing make sure the baffles have not been dislodged in transit and are correctly positioned. To achieve maximum efficiency push the baffles in the direction of the arrows as shown. 2.3 general requirements 1. The warmflow combi is supplied with all the necessary components ...

Page 11

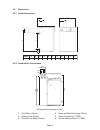

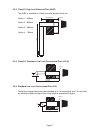

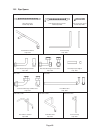

1 8045 8000 8130 1620 1310 460 820 rear view 2 3 4 5 6 2.4 dimensions 2.4.1 combi dimensions 2.4.2 combi boiler connections all dimensions are given in mm. 1. Cold mains (15mm) 2. Heating flow (22mm) 3. Domestic hot water (22mm) 4. Pressure relief discharge (15mm) 5. Spare connection (1” bsp) 6. Cen...

Page 12

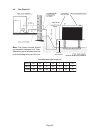

2.4.3 kabin pak combi dimensions model 70/90 j 371 a 892 b 732 c 636 d 373 e 188 f 191 g 376 h 172 102 712 max 225 max 175 min 490 min Ø125 2.5 combi flue options (not applicable to the kabin pak combi) note : low level flue options are rear or left hand outlet only. 2.5.1 ‘easy fit’ telescopic low ...

Page 13

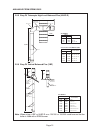

2.5.2 ‘easy fit’ high level balanced flue (hlbf) the hlbf is available in 4 fixed horizontal lengths which are: option 1 – 455mm option 2 – 655mm option 3 – 585mm option 4 – 785mm 2.5.4 standard low level conventional flue (llf) the factory supplied elbow may be extended up to 1m horizontally and 1....

Page 14

2.5.5 easy fit telescopic high level balanced flue (hlbf-r) 2.5.6 easy fit vertical balanced flue (vbf) extension kits as required (packs c or d) pack e or f pack e or f a 175 min 225 max 1570 min 2070 max pack a pack h pitched roof flashing (22" – 45" adjustable) pack b vbf terminal section extensi...

Page 15

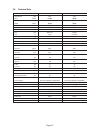

2.6 technical data model nominal heat kw input btu/hr nominal heat kw output btu/hr efficiency at max output (net) % burner head flue mm size in max co 2 % smoke fgt at max output °c water resistance at 20°c ∆t mbar approx fuel l/h flow rate gals/h nozzle make (kerosine) size pump bar pressure psi n...

Page 16

3.0 electricity supply 220 - 240v. 1ph, 50 hz the boiler/burner and other external electrical equipment should be wired via a fused double pole isolating switch which should be fitted with a 5 amp fuse. In order to ensure the safety of the kabin pak combi warmflow recommends that power to the applia...

Page 17

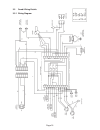

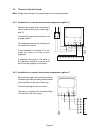

3.3 combi wiring details 3.3.1 wiring diagram p– purple o– orange y– y ellow r– red w– white br – brown bl – blue b– black g/y – green/y ellow page 15.

Page 18

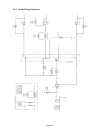

3.3.2 combi wiring schematic break int o the white wire between no 16 on the pcb and the limit st a t and connect in the pressure switch with a wiring block as shown page 16.

Page 19

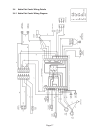

3.4 kabin pak combi wiring details 3.4.1 kabin pak combi wiring diagram p– purple o– orange y– y ellow r– red w– white br – brown bl – blue b– black g/y – green/y ellow gy – grey page 17.

Page 20

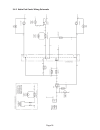

3.4.2 kabin pak combi wiring schematic break int o the white wire between no 16 on the pcb and the limit st a t and connect in the pressure switch with a wiring block as shown page 18.

Page 21

3.5 frost thermostats 3.5.1 combi boilers the switched live from the frost thermostat (the frost thermostat must be supplied by a permanent live) should be connected to number 5 on the boiler terminal block. In order to protect the fabric of the building as well as the boiler and pipework, the therm...

Page 22

3.6 timers for standard combi note : single channel timers or programmers are not recommended. 3.6.1 installation of a remote two channel programmer (option 1) remove the purple wire connecting 5 and 28 and the white wire connecting 3 and 19. Connect the programmer as shown via a fused isolator. Thi...

Page 23

3.6.3 installation of warmflow optional programmer (not applicable to the kabin pak combi) 1. Disconnect the electrical supply. 2. Remove top casing (4 studs) and control box cover (1 screw). 3. Remove 2 screws securing blanking plate/programmer bracket. Remove bracket and blanking plate from the co...

Page 24

3.7 timers for kabin pak combis note : single channel timers or programmers are not recommended. 3.7.1 installation of a remote two channel programmer on off com e n l ch on off com hw 5 3 r c d l n e boiler mains plug isolator to be fitted within boiler casing the hw and ch selector switches on the...

Page 25

4.0 oil supply 1. Oil tank steel tanks constructed to bs 799 part 5 1987 should be painted on the outside only and mounted on piers to prevent corrosion. Plastic oil tanks are also available and can be suitable for installation at ground level. However, oil should never be stored in translucent plas...

Page 26

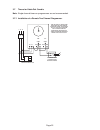

0.5 35 100 0.5 30 100 1 25 100 1.5 20 90 i.D. 8 mm i.D. 10 mm lift h (m) total maximum pipe length (m) 2 15 70 3 8 30 3.5 6 20 4.2 two pipe system 4.3 de-aerator system for maximum pipe length and lift contact de-aerator manufacturer. De-aerator may be above or below burner and must be positioned ou...

Page 27

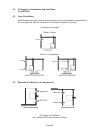

4.4 one pipe lift 20mm per metre slope approved site gauge water separator note: the pump vacuum should not exceed a maximum of 0.4 bar. Above this gas is released from the oil thus leading to burner lock out. Total maximum pipe length (m) 0.5 35 100 0.5 30 100 1 25 100 1.5 20 90 2 15 70 3 8 30 3.5 ...

Page 28

5.0 flues 5.1 conventional flues the flue should be designed in accordance with the local bye-laws and the clean air act. Draught stabilisers are not recommended for oil fired boilers. Sharp bends or horizontal runs should be avoided and the flue should terminate 2 feet (600 mm) above the ridge of t...

Page 29

Terminal position min distance a below gutters, soil pipes or drain pipes 1000 b from a door, window or air vent 600 c above ground, flat roof or balcony level 600 d below eaves or balconies 1000 e from an internal or external corner 600 f from a terminal facing the terminal 600 g from a surface fac...

Page 30

6.0 air supply for combustion and ventilation (see bs 5410) 6.1 open flue boilers when the boiler is sited in a cellar where the only access for combustion and ventilation air is at high level then the combustion air should be ducted to low level. Combustion air supply boiler in room boiler in compa...

Page 31

6.3 installation of flues optional extension pieces easy fit vertical balanced flue (vbf) easy fit high level balanced flue (hlbf) standard low level conventional flue (llf) easy fit low level conventional flue (llf-r) easy fit balanced flue (bf-r) easy fit high level balanced flue (hlbf-r) riello r...

Page 32

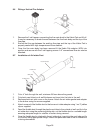

6.3.1 installation of a balanced flue (bf-r, hlbf-r & vbf) 1. Make a suitable sized hole in the wall or ceiling for the flue kit. Add the dimensions given on pages 6 (dimension g) and 8 (flue vertical dimension). The cavities around the opening must be sealed and protected by a non-combustable sleev...

Page 33

6.3.2 installation of telescopic low level conventional flue installation instructions as per the balanced flue except there is only an inner seal, the burner does not require modification and there is no flexible hose to be fitted. In addition the low level flue should only protrude through the wal...

Page 34

8.0 installation the boiler installation must be in compliance with bs 5410 part 1 1997 and the building regulations. 8.1 hearth the boiler hearth temperature is between 50 o c and 85 o c and should be stood on a rigid, non-porous, non-combustible base, which is not softened by warmth to comply with...

Page 35

8.3.4 boiler connections all connections to the appliance should be made with compression fittings. 8.3.5 additional requirements for a kabin pak combi 1. Although the kabin pak is manufactured from galvanised sheet it is recommended that after a period of weathering (approx 4-8 weeks) that the kabi...

Page 36

8.4 domestic hot water the mains water supply pressure must be less than 5 bar. If this pressure is exceeded a pressure reducing valve must be fitted. The final 600 mm of the mains supply pipe to the appliance must be in copper. The flow rate of water from individual taps is dependant on the number ...

Page 37

8.6 fitting a vertical flue adaptor 1. Remove the 2 self tappers connecting the flue main body to the kabin pak and lift off. It may be necessary to break the seal between the flue main body and the top of the flue pipe. 2. Ensure that the gap between the existing flue pipe and the top of the kabin ...

Page 38

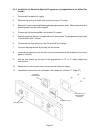

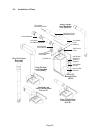

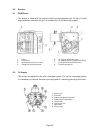

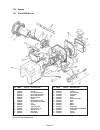

9.0 burners 9.1 rdb burner the burner is fitted with the correct nozzle and the pressure set. All that is further required before commissioning, is to connect the oil and electricity supply. 1. Pump 5. Air damper adjustment screw 2. Control box 6. Air tube connection (supplied with bf kit) 3. Reset ...

Page 39

Attention before assembling or removing the nozzle, loosen the screw (a) and move the electrodes away from the nozzle. 9.3 electrical connections the boiler control equipment and the burner are provided ex works, it is only necessary to connect a 230v 50hz supply in accordance with the electrical dr...

Page 40

10.0 commissioning and servicing 10.1 commissioning note : it is recommended that an oftec trained and registered technician should be used. It is the responsibility of the installer to ensure that the boiler is properly commissioned. See bs 5410. Failure to do so may invalidate the warranty. Combus...

Page 41

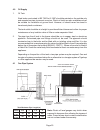

P 1 2 3 4 5 6 l n heating supply water g horstmann timers & controls ltd: newbridge road, bath. 626 oem - warmflow 220-250v 50hz 5(2)a t.55 11.0 horstmann 626 electronic programmer (not applicable to kabin pak combi) user instructions note: ensure selection switch on the rear of the programmer is at...

Page 42

Setting the time of day press the set button so that the set indicator is pointing to the clock position on the front of the programmer. The day of the week indicator will now flash. Use the plus(+) or minus(-) buttons to move the day of the week indicator to the current day of the week. Numbers rel...

Page 43

Adjust the flashing time as required by using the (+) and (-) buttons then press enter. The display will now show ‘1 off’ and the first programmed off time for the day will flash. This can be altered in the same way as the ‘1 on’. Follow the same procedure for the 2nd and 3rd on/off times rememberin...

Page 44

1. Hot water on indicator. 2. Central heating on indicator. 3. Advance button. 4. Hot water programme select button. 5. Central heating programme select button. 6. Programme positions. 7. Central heating programme indicator. 8. Hot water programme. Programme selection the following programmes can be...

Page 45

Using the advance the advance facility allows you to bring forward the next on or off period without having to alter the programmed on/ off times. Press the advance button once and release. The word advance will appear in the display. If the programmer was originally on it will now switch off and st...

Page 46

12.0 fault finding 12.1 central heating no switch on power, set selectors for ch on and dhw off. Set all controls to call for heat. Does the burner fire? Is lockout lamp on burner or panel lit? Is high limit thermostat lamp lit? Is there continuity across the boiler stat connections 17 and 18 on the...

Page 47

12.2 domestic hot water switch on power, set selectors to ch off and dhw on. Is dhw pump working? Is there continuity across connection 20 and 21 on the pcb? Check wiring, replace tank thermostat. Is there continuity across 25 and 27? Check wiring, replace relay, replace pcb. Check wiring, replace p...

Page 48

Does burner motor start? Yes no start switch on electricity supply. Set all boiler controls and external controls to call for heat. Burner operating satisfactorily. Press reset button. Check for pump seizure. Faulty capacitor or faulty motor. Check for correct fitting of photocell, or change photoce...

Page 49

13.0 spares 13.1 riello rdb burner no code 3748757 description 16 3008654 • pump 17 3007162 • ‘o’ ring 18 3008653 • filter ‘o’ ring 19 3003602 • connector 20 3005720 • flexible 21 3008644 • tube 22 3008876 • pressure gauge 23 3000443 • joint 24 3008648 • coil 25 3008650 • motor 25 3002836 • motor 26...

Page 50

13.2 pipe spares ch pump to boiler flexible pipe 2056 plate heat exchanger to boiler flexible pipe 2057 boiler to pressure vessel flexible pipe 2056 flow switch to strainer pipe 1999 from ch pump pipe 1996 plate heat exchanger to boiler pipe 1997 plate heat exchanger to flow switch pipe 1992 hw pump...

Page 51

13.3 short parts list part description code flow switch 1476 tank & boiler control thermostat 2131 boiler limit thermostat 281 tank limit thermostat 2126 plate heat exchanger 599 twin head grundfoss pump 2130 grundfoss 15/60 pump (for replacement head) 602 3 pole relay 1827 auto air vent c/w check v...

Page 52: For Parts, Service &

This manual is accurate at the date of printing but will be superseded and should be disregarded if specifications and/or appearances are changed in the interests of continued product improvement. Code 991 for parts, service & warranty contact for technical assistance contact warmflow on tel: (028) ...