- DL manuals

- Warmworld

- Boiler

- FFC 30/60

- Installation & service instructions manual

Warmworld FFC 30/60 Installation & service instructions manual

Summary of FFC 30/60

Page 1

Condensing boilers natural gas only gc no. 41 555 15 41 555 16 serial number: 0087 ffc 30/60 & ffc 65/80 installation & service instruc- tions note to the installer: please leave these instructions adjacent to the meter..

Page 2

Technical data type & destination sedbuk rating heat input, net heat input, gross heat output 80-60ºc heat output 50-30ºc setting pressure, 20mb line gas consumption for cv 39.0 mj/m ³ after 10 minutes main burner (aeromatic) gas control burner injector pilot injector gas connection installation lif...

Page 3

Contents section page technical data 1 introduction 2 boiler location 3 gas supply 3 flueing 3 air supply 4 water supply 4 condensate drain 4 sealed systems 5 electricity supply 5 installation 5 removing case 6 boiler mounting box 6 flue and air duct 6 terminal 6 twin pipe assembly 6 plumbing 7 gas ...

Page 4

Important. It is important that no external control devices are directly connected to this appli- ance - unless covered by these ‘installation and servicing instructions’ or otherwise recommended by the manufacturer. If in doubt, please enquire. Any direct connection of a control device not recommen...

Page 5

7. Because the flue gases and terminal are at very low temperature it is not necessary to fit a terminal guard to protect against burns. If a guard is required for any other reason the following is recommended. For the concentric terminal: model k3 6.5 x 11 (plastic coated) (gc no 393554) for the tw...

Page 6

Sealed systems a sealed system should follow the guidelines given in the code of practice bs 7074 :1. It should include a safety valve to bs 6750 pt 1. Fitted close to the boiler, without an intermediate valve to the system and in a position where it can be tested. It should be preset to operate at ...

Page 7

Condensing boiler 6 14/06/01 removal of the case refer to fig. 6 1. Lower the electrical cover. This is detached by pulling the cover towards you and carefully lowering. Care should be taken to prevent strain on the cables and connections. 2. Remove the case by unscrewing the two pozidrive screws lo...

Page 8

Condensing boiler 7 06/06/01 2. Pipes must be clipped every 1000mm, minimum. 3. The condensate connection from the boiler mounting box must be connected to the boiler condensate drain trap. (see fig. 12) 4. All connections should be made with the socket end furthest from the boiler. 5. Only centrace...

Page 9

Condensing boiler 8 06/06/01 be in a minimum of 19mm pipe. External runs must be made in a minimum of 32mm pipe, starting inside the building, and if possible insulated to defer prob- lems from freezing. Whichever method is used it should be checked during commissioning to prove there is a leakfree ...

Page 10

Condensing boiler 9 06/06/01 commissioning general the elimination of air from systems is essential to minimise the occurrence of heat exchanger and general system noise. It is particularly important for lightweight boilers. Metal swarf and flux chemicals make a very aggres- sive mixture, the destru...

Page 11

Condensing boiler 10 06/06/01 continue running for 15 minutes, venting every 5 minutes. The pilot is factory set. The main gas valve, gv2, gradually raises the pressure to the set point. Allow at least 60 seconds for the final pressure to stabilise. Important. It is essential when setting the burner...

Page 12

Fig.1 commission check list (hydraulic) the key points which must be observed closely, are shown below. With radiator valves and vents open fill the system. Do not use pump. Do not light gas check for and rectify leaks. Drain to flush system. Refill system, adding 3/4 of the inhibitor. Do not light ...

Page 13

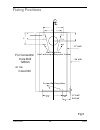

Condensing boiler 12 06/06/01 installation dimensions fig.2 pipe connections & locations service access.

Page 14

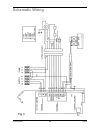

Condensing boiler 13 14/12/00 schematic wiring fig.3.

Page 15

Condensing boiler 14 06/06/01 physical wiring diagram fig.4.

Page 16

Condensing boiler 15 06/06/01 fixing positions fig.5 l c 17 kw 24 kw 24 kw 60 0 22 wall fixing holes 2 lower wall fixing holes core drill 128mm use 2 at the top and any other 2 below 6 6 17 kw for concentric 270 or i ie core drill.

Page 17

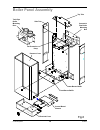

Condensing boiler 16 06/06/01 boiler panel assembly control board chassis electrical cover top trim front burner baffle side trim fig.6 pressure cover concentric flue boiler mounting box fan protection hoop lower burner baffle twin pipe boiler mounting box.

Page 18

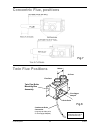

Condensing boiler 17 06/06/01 concentric flue, positions twin flue positions fig.7 fig.8 flue duct air duct 100mm condensate drain connection (connects to drain point on flue spigot adapter) flue spigot adapter drain point twin pipe boiler mounting box assembly connects to optional condensate drain ...

Page 19

Condensing boiler 18 10/04/00 fault finding the electrical sequence in the boiler is very straightforward and faults can easily be tracked down if this simple sequence is followed. System controls - - - - flue stat - - - - overheat stat - - - - pressure switch - - - - control board - - - - ignition ...

Page 20

Condensing boiler 19 fault diagnosis.

Page 21

Condensing boiler 20 06/06/01 servicing health and safety statement : this product contains no asbestos. Routine to ensure continued efficient operation of the appliance it is recommended that it is checked and serviced at regular intervals. The frequency of servicing will depend upon the particular...

Page 22

Condensing boiler 21 6/03/00 2. Gas valve lower the electrical tray. Turn the gas cock off. Pull off the electrical connector from the gas valve. Release the pilot feed tube. Undo the four shoulder bolts at each end of the valve. Take care to support the valve as it is released. Replacement is the r...

Page 23

Condensing boiler 22 6/03/00 8. Electrode and ht lead lower the electrical tray. Remove the case pull off the ht lead from the control board. Undo the left and right screws holding the front burner baffle. Remove the front baffle. Release the tube nut holding the electrode to the pilot burner. Caref...

Page 24

Condensing boiler 23 06/06/01 spares control board fig.9 control knob electrical tray earth 1st line spares: item part number gc number primary heat exchanger (17 kw) m0142 primary heat exchanger (24 kw) m0593 secondary heat exchanger (17 kw) m0502 secondary heat exchanger (17 kw) m0797 burner (17 k...

Page 25

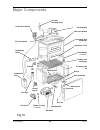

Condensing boiler 24 6/03/00 major components condensate trap air pressure switch gas valve gas cock rubber ‘o’ ring ( 3 places ) flue thermostat fan assembly secondary heat exchanger fibre washer ( 2 places ) flow pipe control sensor o/h stat primary heat exchanger gas manifold ht lead pilot assemb...

Page 26

1020_2026 service instructions issue d 14-06-01.P65 25 14/06/01 example condensate disposal methods fig.11 75mm running trap air break strap-on boss 1:20 fall ( 2.5 degrees ) washing machine trap air gap air gap 110mm soil pipe or drain soakaway insulate against freezing 150mm land drain filled with...

Page 27

M3818 1 hanham business park, memorial road, bristol, bs15 3je. Telephone: 0117 949 8800 fax: 0117 949 8888 the company reserves the right to change specification without notice. Your statutory rights are not affected..