- DL manuals

- WARPP

- Welding System

- IN ARC-I series

- Operating Manual

WARPP IN ARC-I series Operating Manual

Summary of IN ARC-I series

Page 1

1 in arc-i / in tig-i series inverter arc welding machines operating manual warpp engineers pvt. Ltd. B-1005, western edge ii, western express highway, near metro mall, borivali (e), mumbai-400 066. Tel: 91-22-28542272/ 73/74. Fax: 91-22-28542275. E-mail:sales@warpp.Co.In web site: www.Warpp.Co.In.

Page 2: Index

2 thank you for selecting warpp brand inverter welding machine. In order to keep you safe away from unexpected accidents, and enjoy full benefits offered by our quality products during welding, please read the instruction in details prior to operation. Complying with procedures defined in this manua...

Page 3

3 usage & features this series inverter arc welding machines include 2 welding combinations: in arc (smaw) & in tig (smaw/tig) with different specifications of rated current: 400a, 500a, 630a, etc., which are novelty high-efficient and energy-saving dc arc welders, not only are used in carbon steel ...

Page 4

4 proper-sized copper wire. Z please instruct the authorized electrician to connect the welder to power supply by using proper- sized, well-insulated copper wire. Z when operating in the damp, space limited area, must ensure well-insulated between body and work piece z when operating in the high-ris...

Page 5

5 avoid being hurt by welding machine while in transport z when moving the welding machine by fork-lift truck or crane, nobody can be allowed for standing downright the route of the moving welder, in case being hurt by the falling welding machine. Z the ropes or wires which used for hanging up the w...

Page 6

6 3. Installation the machines are portably designed, can be effortlessly moved by operators without fix-up. But it should be settled in even and dry places with well ventilation. 3.1 smaw mode (1) ensure firmly connection to welding cable. (2) connect to remote controller( if needed) (3) adjust eve...

Page 7

6 3. Installation the machines are portably designed, can be effortlessly moved by operators without fix-up. But it should be settled in even and dry places with well ventilation. 3.1 smaw mode (1) ensure firmly connection to welding cable. (2) connect to remote controller( if needed) (3) adjust eve...

Page 8

7 this series welding machines apply igbt soft switch inverter technology. 3- phase input volt are rectified by rectifier, inverted into hf ac, reduced by hf transformer, rectified and filtered by hf rectifier, then output dc power suitable for welding. After this process, the welder’s dynamical res...

Page 9

8 1.1 front panel illustration and parts number reference (1) “amp/volt” meter when meter mode switch indicates to “amp”, the meter displays preset value while in open load, and display practical value of welding current while in actual working. To “volt”, display practical value while in welding. (...

Page 10

8 (11) “remote control/ tig” cable socket it is used to connect with remote control cable to adjust welding current, arc force current or down-slope time through remote control box when it is on the “remote control” mode, used to weld in extended distance. To weld in normal distance on tig, it is us...

Page 11

11 2.1.1 shift between two working styles: (1) shift from down-slope to non-down-slope switch to “tig” mode, pull tig torch trigger, then loose it, open load voltage of power source will disappear to indicate working style being shifted to non-down-slope. (2) shift from non-down-slope to down-slope ...

Page 12

10 (1) “amp” meter it displays preset value while in open load, and displays practical value of welding current while in actual working. (2) “welding current” regulation knob (3) “arc force current/ down-slope” regulation knob (4) socket 1 connect to remote control cable. (5) socket 2 connect to wel...

Page 13

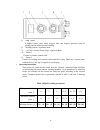

11 table 2 tig welding parameters attention: on smaw, when welding current is low and cable length of stick holder is short(no more than 40m), arc force current should be adjusted in the range of 1-7 . As to large welding current and long cable of stick holder, where volt potential difference is ver...

Page 14

12 2.2 working styles on tig mode of type stg series can be divided into 2 working styles: scratch arc-start and high frequency arc-start. 2.2.1 shift between two working styles: shift scratch arc-start to high frequency arc-start (1)switch to “tig” mode, then pull tig torch trigger, then loose it, ...

Page 15

13 auto-lock non-auto lock fig. Hf arc-start procedure flow sheet (5) never let welding machine be bumped into or stacked up by heavy objects. (6) ensure good ventilation (7) temperature of cooling water is no more than 30 and no less than 0 . The water must be clean without impurity for fear of blo...

Page 16

14 (8) if the air switch on rear panel trips when the machine has worked with large current for a long time, operator should power off the switch, then start the machine in 5 minutes. Remember before starting the machine, turn on the air switch on the rear panel, power on the switch box. The machine...

Page 17

15 technical data main technical parameters description parameters 400 500 630 primary power voltage/frequency 3 phase 380v±10%/50hz rated output capacity 14.4kw 20kw 27.7kw rated input current 28a 38a 52a rated duty cycle 60% range of output current 20 ~ 400a 20 ~ 500a 50 ~ 630a output voltage of o...

Page 18

16 z in arc / in tig-400 i no. Tab item qua. Memo 1 k1 air switch 1 2 d1 3-phase rectifier module 1 small 3 l1 polypropylene capacitor 1 4 c30 polypropylene capacitor 1 5 c4 igbt module 1 6 m1 、 m2 voltage sensitive resistance 2 7 r1 ceramic dielectric capacitor 1 8 c8 ~ c17 ceramic dielectric capac...

Page 19

17 z in arc / in tig-500 i no. Tab item qua. Memo 1 k1 air switch 1 2 d1 3-phase rectifier module 1 big 3 l1 polypropylene capacitor 1 4 c30 polypropylene capacitor 1 5 c4 ~ 5 igbt module 2 6 m1 、 m2 voltage sensitive resistance 2 7 r1 ceramic dielectric capacitor 1 8 c8 ~ c19 ceramic dielectric cap...

Page 20

18 z in arc / in tig-630 i no. Tab item qua. Memo 1 k1 air switch 1 2 d1 3-phase rectifier module 1 3 l1 polypropylene capacitor 1 4 c30 polypropylene capacitor 1 5 c4 ~ 5 igbt module 2 6 m1 、 m2 voltage sensitive resistance 2 7 r1 ceramic dielectric capacitor 1 8 c8] ~ c21 ceramic dielectric capaci...

Page 21

19 appendix a: common failures, probable cause & countermeasures № phenomena reason solving methods 1 after power on, it doesn’t work. Phase missing power source, in fuse ( 2a ) in welder is broken. Cable is broken check power source check if cooling fan, power source transformer and main control bo...

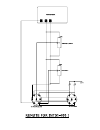

Page 25: Front Panel of Arc Series

Front panel of arc series remote / protection on led (led2) power on led (led1) digital display a / v l panel control switch (kd1) digital display (dsp001) arc-starting current potentiometer (w3) amp / volt switch (kd2) arc-force current / down-slope time welding current potentiometer (w1) p potenti...

Page 26: Front Panel

Front panel voltage/ampere switch (psw01) smaw/tig selection switch (psw01) switch (psw01) led yellow (led y01) 2 / 4 track selection switch (psw01) digital display meter (dsp001) led red (led r01) remote/panel selection switch (psw01) ( ) potentiometer for current (pot001) potentiometer for strikin...

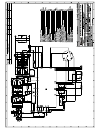

Page 27: Left View

Left view left view fan (fan main ( 002) transformer thrust coil output choke (chk 001) snubber pcb isolation pcb (psb- output rectifier for o/p frm (pcb-snb- out-01) ( iso-01) output rectifier module (frm001).

Page 28: Right View

Right view thermal cut- over current hf t f g thermal cut out snubber card over current protection pcb hf pcb (pcb- hf-01) hf transformer (ctrax007) igbt resonant coil igbt input bridge ac capacitor module fan capacitor p (cap05) solonaid valve shunt insulation mov (mov001) dc capacitor (cap001) (sv...

Page 29: Top View

Top view p drive card (pcb-drv-01) control transformer (ctrax001) input surge suppressor (iss 01) main pcb fuse (f1).

Page 30: Rear Panel

Rear panel rear panel fan mcb.

Page 31

Description intig-315 intig-400 i intig-500 i intig-630 i part code part code part code part code main pcb pcb-tig-315i pcb-tig-400i pcb-500i pcb-tig-630i drive card pcb-drv-01 pcb-drv-01 pcb-drv-01l pcb-drv-01l igbt igbt7512 igbt7512 igbt10012 igbt15012 input bridge module ibdg003 ibdg003 ibdg004 i...

Page 32

Description inarc-315 inarc-400 i inarc-500 i inarc-630 i part code part code part code part code main pcb pcb-arc-315i pcb-arc-400i pcb-arc-500i pcb-arc-630i drive card pcb-drv-01 pcb-drv-01 pcb-drv-01l pcb-drv-01l igbt igbt7512 igbt7512 igbt10012 igbt15012 input bridge module ibdg003 ibdg003 ibdg0...