- DL manuals

- WARPP

- Welding System

- INARC IH SERIES

- Operation Manual

WARPP INARC IH SERIES Operation Manual

Summary of INARC IH SERIES

Page 1

Inverter dc mma arc welding machine operation manual warpp engineers pvt. Ltd. B-1005, western edge ii, near metro mall, off. Western express highway, borivali (e), mumbai-400 066. Tel:022-28542272 / 73/74 fax:022-28542275. Website:www.Warpp.Co.In email:sales@warpp.Co.In.

Page 2

Safety precautions ● please read this instruction carefully for correct use. ● the objective of the precautions listed in this instruction is to ensure the safe use of machine and prevent you and others from being harmed or injured. ● safety consideration for the welding machine in design and manufa...

Page 3

Accident 1. Safety consideration for the welding machine in design and manufacture. Work to the precautions in this instruction, otherwise it will cause death, serious injury and other major personal accident. 2. For the construction power source of input, the choice of equipment location, the appli...

Page 4

9. Make maintenance and examination and repair, only the damaged part can by use until it is repaired well. 10. Please shut off all input powers when the machine is unused. 11. When use ac arc welding machine in the confined place or high place, please use electric shock-proof device. 1. When make w...

Page 5

1. Never place combustible in the weld location. 2. Never weld near combustible gas. 3. Never close to the combustible when the heat parent metal is just welded. 4. When weld dooryard, ground and wall, please eliminate the combustible on the back. 5. The connection of cable shall surely be insulatio...

Page 6

1. In affirming whether the welding wire is fed, do not peek into the small hole of current contact nozzle. Otherwise welding wire will prick eye and face. 2. When welding wire is fed by hand or welding torch is opened, please do not put the end of welding torch dose to eye, face and other exposure ...

Page 7

Working directions ■ load duration factor load duration factor refers to the ratio that practical work time accounts for the whole work time (10 minutes is 1 cycle). For example, 60% load duration factor means that weld is made for 6 minutes and then zero load is for 4 minutes. Rating load duration ...

Page 8

2. Especially for fuse and other current protectors, for the sake of safety, please use the protector with proper capacity rather than the protector with the too great capacity. 3. Connection of welding end one end connects with the cable of welding tongs, another end connects with welded object by ...

Page 9

Brief introduction to characteristics: ● striking current continuously adjustable ● thrust current continuously adjustable ● welding current continuously adjustable ● digital display current and voltage ● overheat indication and overload protection 2. Main parameters (form 1) performance parameters ...

Page 10

Welding machine principle block diagram (picture 1) welding machine output characteristic (picture 2) . Plank structure and statement 1. Front panel structure and statement front panel (picture3) (1) power light: indicate whether the power is connected or not, the light is on when connecting. (2) ov...

Page 11

(5) negative electrode output: the socket connecting welded work pieces via output cable at manual welding. (6) positive electrode output: the socket connecting soldering tongs at manual welding. (7) arc force: it can change the time of arc stopping of argon arc welding to adjust the button. (8) hot...

Page 12

(2) check whether the automatic air switch is put upward onto the position of connection or not. (3) check whether option switches regulating operating mode and control mode on the front panel are in the right position. 2. Examination under power-supply and no load (1) if power-on is successful, the...

Page 13

Schematic diagram for intermediate plates (picture 7) . Installation and debugging 1. Environment (1) the welding operation shall be operated in a relatively dry environment, and the air humidity should not exceed 90 percent. (2)the ambient temperature should be between -10% ℃ and 40℃. (3)do not wel...

Page 14

(3) to prohibit over voltage! The power voltage is listed in the main technique parameters such as these in form 1, in normal conditions; the voltage auto-compensation circuit in the welder limits the welding current within normal range. If the power voltage exceeds the normal range, the welding mac...

Page 15

Equipping circuit configuration of arc welding (picture8) 4. Installation and debugging (1) after opening the case, check the types and quantity in the case according to contents of packaging card. (2) inarc ih series welding machine adopts three-phase four wire system ac380 (50hz) network sources, ...

Page 16

(3) select the phase sequence properly to make the fan keep rotating (the wind direction is the back panel in and the panel out). (4) according to the welding technological requirements and species of electrode, select the straight polarity dc (the work pieces connect end) or the reverse connection ...

Page 17

(form 3) option of the welding wire with welding current diameter of electrode ( ㎜) welding current(a) diameter of electrode( ㎜) welding current(a) 2.0 30-60 4.0 120-180 2.5 50-100 5.0 180-250 3.2 80-120 6.0 250-400 Ⅶ. Routine maintenance and repair regular maintenance and inspection are done to ens...

Page 18

(form5) maintenance form faults phenomena faults cause/ measures the current indicator light is off. The fan does not rotate and the digital multimeter does not display. Whether the power switch closed or not check whether the input cable and the connecting power network have electric or not check w...

Page 19

Main t f transformer (mtax-b08) output choke (chkb08) fan (fan002) (chkb08) output rectifier module (frm001) snubber pcb for output frm (pcb- snb-out03).

Page 20

Over current protection pcb (pcb-oc-400) potentiometer for current/striking/ mcb (mcb001) (pcb oc 400) arc force (pot001) fan capacitor (cap05) capacitor (cap-ele-02) snubber card (pcb-snb-b08) shunt (shunt001) mov (mov001) input bridge module with surge suppressor pcb (pcb-ib-01) igbt (igbt7512) dc...

Page 21

Main pcb (pcb-arc- 400 ih) control transformer (ctrax-b08) input supply terminal (ist-01) drive card (pcb-drv-03) ( ).

Page 22

Digital display meter (dsp001) knob for the pot (knob001) output connector euro type with strip (ocn-euro-s) p ( ).

Page 23

C f i t cover for input supply terminal (cvr-ist-01).

Page 24

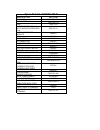

Description part code main pcb pcb-arc-400 ih drive card pcb-drv-03 igbt igbt7512 input bridge module with surge suppressor pcb pcb-ib-01 output rectifier module frm001 fan fan002 capacitor cap-ele-02 dc capacitor cap001 snubber card pcb-snb-b08 mcb mcb001 digital display meter dsp001 shunt shunt001...