- DL manuals

- WARPP

- Welding System

- INTIG-PULSE series

- Operating Manual

WARPP INTIG-PULSE series Operating Manual

-

1

-

INTIG- PULSE

Digital Inverter

MMA/TIG / Pulse TIG

Welding Machines

Operating manual

WARPP ENGINEERS PVT. LTD

.

B-1005, 10

TH

FLOOR, WESTERN EDGE II, NEAR METRO MALL,

OFF.WESTERN EXPRESS HIGHWAY, BORIVALI (E,)

MUMBAI-400 063.

TEL: 91-22-28542272 /73/74 / 32404434 Fax91-22-28542275.

E-mail:sales@warpp.co.in Web Site: www.warpp.co.in

Summary of INTIG-PULSE series

Page 1

- 1 - intig- pulse digital inverter mma/tig / pulse tig welding machines operating manual warpp engineers pvt. Ltd . B-1005, 10 th floor, western edge ii, near metro mall, off.Western express highway, borivali (e,) mumbai-400 063. Tel: 91-22-28542272 /73/74 / 32404434 fax91-22-28542275. E-mail:sales...

Page 2

- 2 - thank you for selecting warpp brand inverter welding machine. In order to keep the operator safe, away from unexpected accidents, and enjoy full benefits offered by our quality products during welding, please read the instruction in details prior to operation. Complying with procedures defined...

Page 3

- 3 - usage & features in tig series pulse tig welders include 315 a, and 400a types, can perform dc tig, pulse tig, and dc mma, used for mild steel, alloy steel, stainless steel, copper, silver, and titanium welding. This series welder enjoy reasonable static characteristic and sound dynamic charac...

Page 4

- 4 - avoid being electric shocked and burnt z never touch on the hot electrical units. Z please instruct the authorized electrician to ground the welder case by using proper sized copper wire. Z please instruct the authorized electrician to connect the welder to power supply by using proper- sized,...

Page 5

- 5 - avoid being hurt by moving parts z never let the finger, hair, and cloth near the rotary cooling fan and wire feeder rollers. Z when feeding wire, don’t let the bottom of gun near your eyes, face and body, to prevent being harmed by wire. Avoid gas bottle falling or gas regulator breaking z ga...

Page 6

- 6 - (4) the distance between welder and wall must be more than 20cm, between welders more than 10cm to ensure enough heat radiation. (5) when using water cooled gun, must be care of not being frozen. 2 . requirement of input supply: (1) input volt must be standard sine wave, effective value 350 ~ ...

Page 7

- 7 - 4.1 for mma welding: (1) connect welding cable to welding machine tightly. (2) reset the circuit beaker on the rear panel of the machine (3) connect the input power cable to the disconnected switchboard, then power on. 4.2 for tig welding: (1) well-connect welding cable with welder (+), and we...

Page 8

- 8 - this series welding machines apply igbt soft switch inverter technology. 3- phase input volt are rectified by rectifier, inverted into hf ac, reduced by hf transformer, rectified and filtered by hf rectifier, then output dc power suitable for welding. After this process, the welder’s dynamical...

Page 9

- 9 - 1.2 rear panel illustration and parts number reference fig.5: rear panel 1.3 control panel the machine’s control panel drawing for mode selection and parameters preset shows as figure (6). Control panel includes led alphanumeric display, tuning knob, diode indicator lamps. Fig.6: control panel...

Page 10

- 10 - switch between “2- step” (non-autolock) and “4-step” (autolock) on tig “2-step” refers to start welding while push torch trigger, stop welding while releasing it. “4-step” refers to starting-arc current while firstly pushing torch trigger, then current slopes up to where can welding normally ...

Page 11

- 11 - 8 、 pulse ratio: time ratio between length of peak value current and length of whole single pulse, can be used for controlling penetration in all-position or thin sheet welding. 9 、 pulse frequency: frequency of pulse output. 10 、 base current: current of arc-stand in pulse output. 11 、 down ...

Page 12

- 12 - display 806: water insufficient protection 1.3.4 power on/off lamp: display red when power on 2. Procedures of tig welding 2.1”2-step” push torch trigger pre-gas flow arc-start arc-starting current constant current tig arc welding up-slope normal welding pulse tig arc welding release torch tr...

Page 13

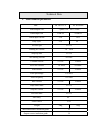

- 13 - 3.1 tig welding parameters sheet thickness ( mm ) tungsten electrode diameter ( mm ) wire diameter ( mm ) welding current ( a ) gas flow rate ( l/min ) clearance ( mm ) 0.4 1.0-1.6 0-1.0 5-30 4-5 1 1.0 1.0-1.6 0-1.6 10-30 5-7 1 1.5 1.0-1.6 0-1.6 50-70 6-9 1 2.5 1.6-2.4 1.6-2.4 70-90 6-9 1 3.0...

Page 14

- 14 - repair & maintenance warning: should not open up case freely, the max volt inside machine will be 600v. Must take safe precautions to prevent from being electric shocked while in maintenance. 1. Apparently misunderstand failures normal phenomenon occurs in welding (1) welder doesn’t work whil...

Page 15

- 15 - 3. Troubleshooting 3.1 routine checking procedure prior to maintenance 1. Check if the input volt has the phase to be lost, and range are between 340-420v. 2. Check if the power input cables are correctly and firmly. 3. Check if the ground leads are connected correctly and firmly. 4. Check if...

Page 16

- 16 - technical data 1. Main technical parameters item in tig-315 p in tig-400 p rated output volt 3 phase 350 ~ 465 v/50hz rated input volt 13.8kva 18.4kva rated input current 21a 28a duty cycle 35% 60 % pre-flow gas 0.1-15s striking arc current 10 - 160a slope up time 0.1-10s arc-starting current...

Page 18

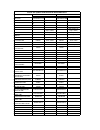

- 18 - appendix a: ordinary failures, probable cause & countermeasures № trouble probable cause remedies 1 indicator lamp does not light on and doesn’t work when machine switches on. ① phase missing ② fuse size ( 2a ) breaks ③ input cable break down ① inspect power source ② inspect fan, power source...

Page 19: Front Panel

Front panel encoder for encoder for parameter s l ti (enc01) parameter setting (enc01) selection (enc01) output connector mcb (mcb001) output connector euro type (ocn- euro-s) 2 pin connector male (con2pnm).

Page 20: Rear Panel

Rear panel rear panel fan (fan002).

Page 21: Top View

Top view p drive card (pcb-drv- 01u) display pcb (pcb- dsp-tigpls-01) control main pcb (pcb- transformer (ctrax004) tigpls-315i).

Page 22: Right View

Right view snubber card o c t p t ti g snubber card (pcb-snb-04) over current protection pcb (pcb33) ac capacitor igbt (igbt50r12) capacitor (cap002) input bridge module (ibdg003) hf pcb (pcb-hf-01) mov dc capacitor f c it hf t f water flow switch (wfs-50w) mov (mov001) dc capacitor (cap001) fan cap...

Page 23: Left View

Left view secondary thrust coil (s-thcl) insulation transformer (instrx001) main transformer (mtrax006-p) (s thcl) snubber pcb for output frm (pcb-snb- isolation pcb output rectifier m d l (pcb-snb- out-01) (pcb-iso-02) output choke (chk001) module (frm001) current sensor (cs001).

Page 24

Part/code spec. Part/code spec. Main pcb pcb-tigpls-315i pcb-tigpls-400i drive card pcb-drv-01u pcb-drv-01u display pcb pcb-dsp-tigpls- 01 pcb-dsp-tigpls- 01 igbt igbt50r12 na igbt50r12 na snubber card pcb-snb-04 pcb-snb-04 igbt with snubber card igbt50r12snb 50r12snb ( 50 amps 1200v) igbt50r12snb 5...