- DL manuals

- WARRIOR

- Floor Machine

- 200

- Operating Instructions Manual

WARRIOR 200 Operating Instructions Manual

Summary of 200

Page 1

Models: warrior 200 warrior 200-10 warrior 200-05 operating instructions (eng) 200 psi 760-172 read these instructions before using the machine.

Page 2

2 machine data log / overview overview the warrior is an electric powered carpet extractor intended for commercial use. This appliance applies a cleaning solution to the carpet and then vacuums the soiled water back into the recovery tank..

Page 3

3 table of contents machine data log / overview. . . . . . . . . . . . . . . . . . 2 table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 how to use this manual . . . . . . . . . . . . . . . . . . . . . . 4 safety important safety instructions . . . . . . . . .5 hazard intensity...

Page 4

4 how to use this manual this manual contains the following sections: • how to use this manual • safety • operations • maintenance • parts list the how to use this manual section will tell you how to find important information for ordering correct repair parts. Parts may be ordered from authorized d...

Page 5: Save These Instructions

5 safety important safety instructions when using an electrical appliance, basic precaution must always be followed, including the following: read all instructions before using this machine. This machine is for commercial use. To reduce the risk of fire, electric shock, or injury: connect to a prope...

Page 6

6 safety the following symbols are used throughout this guide as indicated in their descriptions: hazard intensity level there are three levels of hazard intensity identified by signal words -warning and caution and for safety. The level of hazard intensity is determined by the following definitions...

Page 7

7 safety grounding instructions this product is for commercial use only. Electrical: in the usa this machine operates on a standard 15 amp 115v, 60 hz, a.C. Power circuit. The amp, hertz, and voltage are listed on the data label found on each machine. Using voltages above or below those indicated on...

Page 8

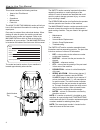

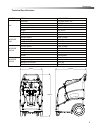

8 operations technical specifications m o de l i t e m m e a s u r e all electrical 115volt, 60hz, 15a solution pump 200psi solution capacity 13 gal recovery capacity 11 gal height 43 inches length 30 inches width 22 inches warrior 200 vacuum motor dual 2-stage weight - empty 115 lbs weight-full sol...

Page 9

9 operations controls 1. Vacuum accessory tool hook-up 2. Solution pump switch 3. Vacuum 1 switch 4. Vacuum 2 switch 5. Heater switch with on light (units with heat only) 1 2 3 4 5 6 7 8 9 10 6. Adjustable pressure relief valve 7. Heater temperature light (units with heat only) 8. Breaker for vacuum...

Page 10

10 operations machine operation care must be exercised in the use of all chemicals. Chemicals are poisonous and can pose a health risk. Read and follow manufacturers instructions regarding dangers and correct usages. The internal parts of the pump used in the machine are suitable for use with most c...

Page 11

11 operations pre-run inspection 1. Check all fittings and connectors for proper assembly. 2. Check all hoses for leaks. Repair or replace any damaged hoses. 3. Check power cord(s) for any damage. If damaged, replace. Equipment set-up 1. Plug power cord from machine into properly grounded wall outle...

Page 12

12 operations cleaning always use defoamer if foaming occurs. Foam will suspend large particles that may damage vacuum(s) as well as allow liquid into the vacuum motor(s) without activating the float shutoff. 1. Prior to cleaning, make certain that the nozzle is functioning properly. A. To check, ho...

Page 13

13 maintenance periodic maintenance twice a month, flush a white vinegar solution (one quart vinegar to two gallons of water) or anti-browning solution (mixed as directed) through the machine. This will prevent build-up of alkaline residue in the system. Periodically inspect all hoses, electrical ca...

Page 14

14 maintenance only qualified maintenance personnel are to perform the following repairs. Vacuum motor replacement 1. Turn off all switches and unplug machine. 2. Remove hardware under front of machine to access component compartment. 3. Remove vacuum motor cover and disconnect motor wires. 4. Remov...

Page 15

15 maintenance solution pump replacement only qualified maintenance personnel are to perform the following repairs. Pump replacement kits 200 psi cam & bearing kit 512-070 valve & o-rings kit 512-025 plunger & seals kit 512-050

Page 16

16 maintenance only qualified maintenance personnel are to perform the following repairs. Pressure regulator for best results with the pressure regulator, we recommend that you clean and lubricate the piston and u-cup with superlube lubricant monthly or when pressure drop seems excessive. 1. Turn un...

Page 17

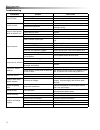

17 maintenance troubleshooting problem cause solution loss of power unit not plugged in connect unit to 3 prong grounded outlet. Dead electrical circuit check building circuit breaker or fuse box. Faulty power cord replace electrical shock receptacle not grounded contact an electrician to check buil...

Page 18: Parts

18 parts.

Page 19

19 control panel 4 1 2 12 10 11 8 9 6 3 5 7.

Page 20

20 control panel ref part no description note 1 415-155 fw, 1/2 ss 2 415-156 fw, 1/2 ss (stand/max od) 3 580-010 q.C. 1/4 fem (close) 4 555-184 elbow 45,street 1/4 5 410-205 ms, 10-32 x 1/2 panphil ss 6 305-075 switch, spst 2-position rocker 7 340-180 boot, seal breaker 8 845-080 control panel 9 475...

Page 21

21 control panel with heat 5.

Page 22

22 control panel with heat ref part no description note 1 415-155 fw, 1/2 ss 2 415-156 fw, 1/2 ss (stand/max od) 3 580-010 q.C. 1/4 fem (close) 4 555-184 elbow 45,street 1/4 5 410-205 ms, 10-32 x 1/2 panphil ss 6 305-075 switch, spst 2-position rocker 7 340-180 boot, seal breaker 8 845-080 control p...

Page 23

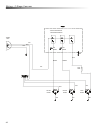

23 electrical with 2 stage vacuum 3 8 7 5 4 1 2 6 9 10

Page 24

24 electrical with 2 stage vacuum ref part no description note 1 400-165 locknut, 1/2 steel/strain relief 2 410-205 ms, 10-32 x 1/2 panphil ss 3 335-005 stain relief, 12 gauge 4 325-015 connector, 5 position, push wire 5 415-125 fw, 1/4 ss 6 465-084 brkt, cord strain relief 7 315-015 cord, 25’ black...

Page 25

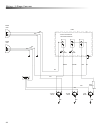

25 electrical with heat / 3 stage vacuum 3 5 2 1 6 7 4 9 8.

Page 26

26 electrical with heat / 3 stage vacuum ref part no description note 1 400-165 locknut, 1/2 steel/strain relief 2 410-205 ms, 10-32 x 1/2 panphil ss 3 335-005 stain relief, 12 gauge 4 325-015 connector, 5 position, push wire 5 415-125 fw, 1/4 ss 6 465-084 brkt, cord strain relief 7 315-015 cord, 25...

Page 27

27 frame 1 2 3 4 6 5 6 7 8 9.

Page 28

28 frame ref part no description note 1 455-075 caster, swivel 4” 2 455-090 hubcap, 5/8 shaft 3 400-010 hex nut, 1/4 x 20 zinc 4 415-120 fw, 1/4 zinc 5 415-165 fw, 5/8 ss 6 455-085 hubcap, 9.5 wheel 7 455-080 wheel, 12 x 2.25 8 845-090 frame, base, warrior 9 405-088 bolt, 1/4 x 3/4 carr zinc.

Page 29

29 heater 1 2 4 5 4 3 3 to quick connect from pump out 2 4 4 to regulator 6 7 11 13 10

Page 30

30 heater ref part no description note 1 572-042 blue neptune 1/4 2 572-125 pulse hose 3/8 3 581-015 crimp ftng, 1/4 hp hose - 1/4 mpt svl 4 581-065 crimp ftng, 3/8 pulse hose – 1/4 mpt svl 5 490-005 foamed casing, round 1850w 6 425-040 clamp #60 7 555-636 tee, 1/4 street extruded 8 555-184 elbow 45...

Page 31

31 labels 3b 1 2 3a.

Page 32

32 labels ref part no description note 1 703-006 decal warrior lh 2 703-007 decal warrior rh 3a 703-008 decal warrior w/heat 3b 703-009 decal warrior wo /heat.

Page 33

33 pump 12 14 2 7 7 13 15 6 1 9 11 1 to solution outlet 2 from solution tank 2 3 3 15 6 5 7 4 1 9 11 12 7 to solution tank 16 17.

Page 34

34 pump ref part no. Description notes: 1 555-452 plug 1/4 mpt hex 2 581-065 crimp ftng, 3/8 x 1/4 mpt svl 3 572-125 pulse hose 3/8” 4 530-005 regulator, 200 psi 5 555-002 adpt, 1/4 m x 1/4 f 6 425-005 clamp, #8 hose 7 555-208 elbow 90, 1/4 street extruded 8 555-325 hose barb 90, 1/2 barb x 1/4 mpt ...

Page 35

35 pump with heat 2 3 3 12 13 from heater (see page 29) 14 6 5 7 4 1 9 11 12 7 to solution tank 15 16 2 from solution tank 2 7 14 6 1 9 11 1 to heater.

Page 36

36 pump with heat ref part no. Description notes: 1 555-452 plug 1/4 mpt hex 2 581-065 crimp ftng, 3/8 x 1/4 mpt svl 3 572-125 pulse hose 3/8” 4 530-005 regulator, 200 psi 5 555-002 adpt, 1/4 m x 1/4 f 6 425-005 clamp, #8 hose 7 555-208 elbow 90, 1/4 street extruded 8 555-325 hose barb 90, 1/2 barb ...

Page 37

37 recovery 21 10 17 9 7 1 10 12 13 10 5 20 16 14 8 2 4 19 3 15 18 11 6 21.

Page 38

38 recovery ref part no. Description notes: 1 545-100 dump valve, 1 1/2” 2 585-210 clear cover, 6” c/w ring 3 590-020 pvc elb 1 1/2” 90, s x fipt 4 475-125 gasket 6” access cover clear 5 400-116 locknut, 5/16 x18 nylon ss 6 405-026 bolt, 1/4 x 1-1/2 zinc 7 405-615 cs, 1/4 x 1/2 ss (hex hd) 8 410-125...

Page 39

39 solution 1 2 3 4 5 6 7 8 9 11 12 13 14 15 16 17 18 19 10 20 1 2 4.

Page 40

40 solution ref part no. Description notes: 1 555-705 terminal bolt 3/8 x 3/8 2 425-005 clamp, #6 3 350-115 hook ,strap 4 585-110 nylon 90 barb, 1/2 x 3/8 npt 5 400-005 hex nut 1/4 ss 6 410-226 ms, 14-20 x 3/4 allan 7 410-205 ms, 10-32 x 1/2 ss 8 560-034 strainer acorn 9 415-120 fw, 1/4 zinc 10 415-...

Page 41

41 vacuum, 2-stage / 3-stage 4 12a 12b 12a 12b 11a 11b 10 9 8 7 6 5 4 3 2 1.

Page 42

42 vacuum, 2-stage / 3-stage ref part no. Description notes: 1 400-135 locknut, 1/4 x 20 nylon zinc 2 410-221 ms, 10-32 1-1/2 rh soc 3 425-020 clamp, #32 4 415-120 fw, 1/4 zinc 5 415-115 fw, #10 ss 6 355-220 manifold, dual vacuum 7 475-072 gasket, vacuum manifold 8 405-065 6” bolt 9 410-136 sms, 8 x...

Page 43

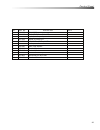

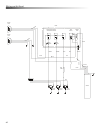

43 wiring - 2 stage vacuum -vacuum-vacuum-pump switchswitchswitch motor motor motor -power cord blk wht wht brown orange grn grn grn grn grn 13amp 13amp 3amp -vacuum -vacuum -pump -cb -cb fuse m m m m blue wht wht blk m m m m m.

Page 44

44 wiring - 3 stage vacuum wht wht m m m -cb -cb -vacuum m m m -pump -vacuum m m m -vacuum-vacuum-pump switchswitchswitch motor motor motor -power cord -panel -power cord fuse grn grn grn grn grn grn blk blk wht wht wht wht blk blk blue brown orange 13amp 13amp 3amp.

Page 45

45 wiring with heat m black red black white yellow w h it e heater grn m blue fuse 3 amp -cb -cb m -vacuum m m m -pump -vacuum-vacuum-pump switchswitchswitch motor motor motor -power cord -panel -power cord -heat switch brown orange red yellow wht white grn grn wht wht blk blk -thermo light grn 13am...