- DL manuals

- Wascomat

- Washer

- EXSM 230 S

- Operating & Maintenance Manual

Wascomat EXSM 230 S Operating & Maintenance Manual

OPERATING & MAINTENANCE MANUAL

EXSM 230 S and 350 S

WARNING: ALL OPERATING AND MAINTENANCE PROCEDURES SHOWN ON THE NEXT

PAGE OF THIS MANUAL MUST BE FOLLOWED DAILY FOR PROPER OPERATION OF

YOUR WASCOMAT MACHINE.

PLEASE ENTER THE FOLLOWING INFORMATION AS IT APPEARS ON THE MACHINE(S)

DATA PLATE(S).

MAKE CERTAIN TO KEEP THIS MANUAL IN A SECURE PLACE FOR FUTURE

REFERENCE.

MACHINE TYPE OR MODEL

MACHINE SERIAL NUMBER(S)

ELECTRICAL CHARACTERISTICS: ________ VOLTS, _______ PHASE, _______ HZ.

438 9030-16/01

02.32

Summary of EXSM 230 S

Page 1

Operating & maintenance manual exsm 230 s and 350 s warning: all operating and maintenance procedures shown on the next page of this manual must be followed daily for proper operation of your wascomat machine. Please enter the following information as it appears on the machine(s) data plate(s). Make...

Page 2

Notice to: owners, operators and dealers of wascomat machines ii improper installation and inadequate maintenance, poor housekeeping and willful neglect or bypassing of safety devices may result in serious accidents or injury. To assure the safety of customers and/or operators of your machine, the f...

Page 3: Safety And Warnings Signs

Safety and warnings signs replace if missing or illegible one or more of these signs must be affixed on each machine as indica- ted, when not included as part of the front instruction panel. Located on the operating instruction sign of the machine: located at the rear of the machine: installation an...

Page 5: Contents

5 contents introduction .................................................................................................. 7 technical data .............................................................................................. 8 installation .....................................................

Page 7: Introduction

7 introduction introduction the exsm-s model solid mounted washer/extractor has been developed to cover the heavy duty requirements of hotels, motels, nursing homes, hospitals, professional laundries, restaurants, airlines, ships, schools, colleges and all on-premises laundries where flexibility and...

Page 8: Technical Data

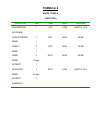

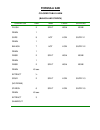

8 exsm 230 s dry load capacity up to 65 lbs overall dimensions width 935 mm 36 7/8'' depth 1100 mm 43 3/8'' height 1430 mm 56 1/4'' net weight 365 kg 805 lbs max. Floor load at extraction 5,0 ± 11.5 kn 1200 ± 2760 lbs.Force frequency (dynamic force) 12 hz crated dimensions volume 1.85 m 3 65 cu.Ft w...

Page 9: Technical Data

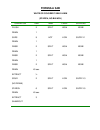

9 exsm 350 s dry load capacity up to 80 lbs overall dimensions width 1085 mm 42 3/4'' depth 1325 mm 52 1/8'' height 1540 mm 60 5/8'' net weight 545 kg 1200 lbs max. Floor load at extraction 6.5 ± 14 kn 1560 ± 3147 lbs.Force frequency (dynamic force) 10,8 hz crated dimensions volume 2.4 m 3 85 cu.Ft ...

Page 10: Technical Data

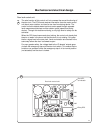

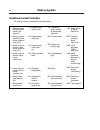

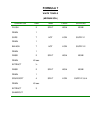

10 technical data outline and dimensions 4897 3 1 5 4 2 a 7 6 b e d c f i h g m l k n o p s 1. Electrical cable connection 2. Steam connection (option) 3. Drain connection 4. Hot water connection 5. Hot water connection 6. Cold water connection 7. Liquid supply connection r t exsm 230 s exsm 350 s m...

Page 11: Installation

11 installation machine foundation the machines are designed to be bolted in position to a concrete floor or specially prepared concrete foundation. A template showing the size of the foundation and positioning of the foundation bolts is available. For installation on an existing concrete floor, the...

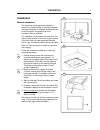

Page 12: Installation

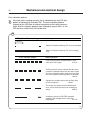

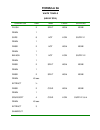

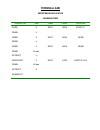

12 installation exsm 230 s measurements for foundation in inches and (mm). A 39 (990) b 37 (940) c 36 3/8 (925) d 33 7/8 (860) e 3 3/4 (95) f 6 5/16 (160) g 7 7/8 (200) h 8 5/32 (207) fig. 5 i 6 5/8 (168) k 4 29/32 (125) l 31 1/2 (800) m 32 1/2 (825) n 35 11/32 (898) o 38 3/4 (985) p 41 27/32 (1063)...

Page 13: Installation

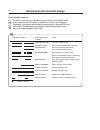

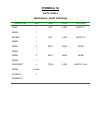

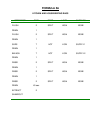

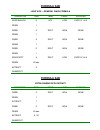

13 installation exsm 350 s measurements for foundation in inches and (mm). A 42 29/32" (1090) b 43 15/64" (1100) c 3" (75) d 3 15/16" (100) e 15 23/64" (390) f 3 15/16" (100) g 13 25/64" (340) fig. 6 h 3" (77) k 36 13/16" (935) l 37 1/64" (940) m 41 9/16" (1056) n 43 17/32" (1106) o 51 59/64" (1319)...

Page 14: Installation

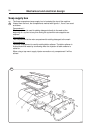

14 installation 7 8 9 1757 1758 1759 mechanical installation • place wide steel shims on the concrete foundation over the bolts. • lift the machine and lower it in position. Never use the door or the door handle to lift or lower the machine. • check that the machine is level front-to-rear and side-t...

Page 15: Installation

15 installation electrical installation although the machines are fitted with a thermal overload in the motor windings and fuses for the control circuit, a separate circuit breaker must be installed for each machine. For proper overcurrent protection, check the data plate at the rear of the machine....

Page 16: Installation

16 installation connection of external units (optional equipment) electrical installation must be carried out by an authorized personnel! All optional equipment connected must be emc-approved to en 50081-1 or en 50082- 2. Connector x149-1. Connector for external start/stop/pause function for machine...

Page 17: Installation

17 installation water connections all plumbing must conform to national and local plumbing codes. All intake connections to the machine are to be fitted with manual shut-off valves and filters, to facilitate installation and servicing. The machine is equipped with an integral air gap (siphon braker)...

Page 18: Installation

18 14 1761 drain connection connect a 3'' (75 mm) flexible hose to the drain outlet of the machine. The drain hose must not have any sharp bends and must slope from the machine to assure proper drainage. The outlet must open freely to the main drain. Do not reduce the size of the drain connection fr...

Page 19: Installation

19 installation steam connection (optional steam heating) the steam inlet pipe must be fitted with a manual cut-off valve in order to facilitate installation and service operations. Attach the filter supplied with the machine to the manual cut-off valve. Conncection hoses should be of the quality re...

Page 20: Installation

20 1 2 installing top-mount manifold for connection of liquid supplies remove the cover and cover support over the soap box. If comp 3 has a metal plate at the rear, bend it all the way as shown. Pull the manifold knobs up and forward. 1. Loosen both knobs so that one side of the metal fingers under...

Page 21: Installation

21 1. Drop the knob into the larger opening in the supply manifold lid. 2. Tighten securely. Do not overtighten! Do not use pliers or other tools to tighten the knobs! 1. Select the correct size rubber ring which will fit snugly on the chemical tube you are using. Ring a is used for tubes with Ø5/16...

Page 22: Function Control and

22 21 22 23 24 1762 4948 4944 4945 function control and safety check list in the machine cylinder, you will find the warranty registration card, a copy of the warranty policy and other pertinent material. The warranty card should be completed and sent to wascomat. All other items should be placed in...

Page 23

23 add detergent and softner. Choose a program. Press start to begin test cycle the machine will start up and the display window will show cycle information. Check that: • the drum is rotating normally at all program steps and that there are no unusual noises. • there are no leaks from the water/ste...

Page 24: Safety Rules

24 safety rules safety rules • this machine is designed for water washing only. • all installation operations are to be carried out by qualified personnel. Licensed personnel are necessary for all electric power wiring. • the interlock of the door must be checked daily for proper operation and must ...

Page 25: General

25 mechanical and electrical design general the door and the electronic timer with display and keyboard are fitted at the front of the machine. All control and indicating components, i.E. Relays, delay unit, etc are assembled under the top cover, easily accessible from the top of the machine for sim...

Page 26: Machine Construction

26 mechanical and electrical design machine construction panels the machines are equipped with a top panel and front panel made of stainless steel. Colored panels are made of phosphatized steel. For servicing purposes, the panels can be easily removed. Outer shell the outer shell is made of heavy ga...

Page 27

27 mechanical and electrical design 5015 back gable and bearing the back gable and the bearing trunnion housing are constructed of a webbed heavy casting for extra rigidity. The bearings are protected against infiltration of water by three neoprene seals. An intermediate safety outlet provides an es...

Page 28: Description

28 description the machine door lock consists of the following: • the locking unit, located behind the front panel below the detergent dispenser. The unit consists of a solenoid which locks the door, and two microswitches. Switch s4a indicates that the door is locked and switch s3 indicates that the...

Page 29

29 mechanical and electrical design 4697 fig. 29 x96 x95 x94 x93 x99 x98 x97 x90 x91 x92 door lock control unit red led, an indicator relay re3 29 door lock control unit the sole function of this control unit is to oversee the correct functioning of the door lock. The cpu board receives information ...

Page 30

30 mechanical and electrical design meaning/cause level-sensing device indicates water in drum when door lock is open. 2.19 hz auxiliary relay for motor indicates that the motor contactor is activated when the door lock is open (this error indication pattern does not occur when the excess-speed-moni...

Page 31

31 mechanical and electrical design fig. 31 31 4942 e10 motor control unit, microprocessor-controlled. Controls direction of rotation and speed of motor. The mcu is also used for imbalance detection and calculating weight of wash load. E10

Page 32

32 mechanical and electrical design control unit.

Page 33

33 x146-1 471 75 98 01 1 2 3 4 1 2 5 1 2 3 4 1 2 5 l1 l2 mechanical and electrical design 4989 supply unit 33 fig. 33 f11, f12 fuses, incoming power supply f21, f22 fuses, motor control unit x1 main input k21, 22 heating relays (only if heated) f12 f11 x146 x1 k22 k21 f22 f21.

Page 34: Motor

34 mechanical and electrical design motor in machines with a frequency control the same motor is used for wash speed, distribution speed and extraction. The motor is located on a motor mounting plate, and drives the drum via a belt. The tension of this drive belt can be adjusted by moving the entire...

Page 35: Repair Instructions

35 mechanical and electrical design repair instructions overheated motor, motor not running • wait until motor has cooled down. Motor guards are automatically reset after 30 minutes. Restart, machine. • possible cause of motor guards releasing repeatedly: low voltage, faulty windings, faulty bearing...

Page 36

36 mechanical and electrical design motor control unit e10 x301 x304 x308 x302 lc2 x312 x311 36 fig. 36 4744 lc2 suppression filter connectors x301 serial communication with pcu x302 input, lock confirmation x304 relay output x308 imbalance input x311 main power input x312 connection, motor and ther...

Page 37

37 mechanical and electrical design motor control unit the motor control unit communicates with the pcu board via a serial duplex interface. With the aid of the mcu, the pcu can not only control the speed the motor is to have at any given moment, but also control the acceleration and deceleration ra...

Page 38

38 mechanical and electrical design there is a cooling fan on the mcu. The fan starts up automatically when the heat sink reaches a temperature of approx. 65 ° c, which can arise during extraction if the load is unfavourable or if the ambient temperature is high. When the machine power supply is fir...

Page 39

39 mechanical and electrical design x311: main power input input voltage: single-phase or dc three-phase: 200 v-15%(=170 v) - 240 v+10% (264 v) x312: output to motor and input thermal protection device (klixon) the output is connected to a thermal protection device, located on the motor windings, wi...

Page 40

40 led pattern of flashes error code/message cause on display heat sink too hot heat sink on mcu too hot. Motor too hot motor thermal protection device activated no interlock mcu has received start command, but not received interlock signal. No motor comm communication error mcu – pcu – short in mot...

Page 41

41 mechanical and electrical design pattern indicating “ok” flickering when mcu current-limiting function is activated. Approx. 5 seconds 4712 fig. 40 40 39 4708 yellow led green led x301 x302 x304 x308 x311 x313 x312 in 170 and 220 l machines only fault-finding there are fault-finding charts for al...

Page 42

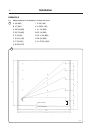

42 mechanical and electrical design extraction during extraction, the motor speeds follow an extraction sequence which is always the same. This extraction sequence is used for all standard programs 991-999 for clarus machines. The table shows the extraction speeds during the various phases of the se...

Page 43

43 mechanical and electrical design imbalance measurement at the start of every extraction sequence the system monitors variations in the motor torque while the drum is operating at distribution speed. If these variations are too great, it indicates that the load is unevenly distributed in the drum....

Page 44: Supply Injection Valve

44 mechanical and electrical design 42 43 1161 1185 supply injection valve construction the valve has a single-inlet with either one, two or three outlets, each with its own solenoid coil. The body is made of heat-resistant polyamid plastic and the solenoids encased in water-tight plastic. The elect...

Page 45

45 mechanical and electrical design 44 45 46 1186 1187 1181 repair instructions limescale can block the hole in the valve diaphragm and interfere with the function of the valve. It is therefore advisable to dismantle and clean the valve at certain regular intervals. The frequency depends on operatin...

Page 46: Inlet Valve

46 mechanical and electrical design inlet valve the water inlets have brass bodies with larger cross section of the outlet in order to achieve a shorter filling time for the machine. Construction the valve housing is made of pressed brass. The spring-loaded plunger is made of stainless steel and loc...

Page 47: Description

47 mechanical and electrical design description the drain valve is a motor-operated diaphragm valve which allows rapid emptying thanks to its large cross-section. This is a self-clearing design, so there is no need for a lint filter. Main parts of the valve: • motor plus gear • piston rod with trape...

Page 48: Instructions For Repair

48 mechanical and electrical design fig. 51 when the motor is activated and begins to rotate, the piston rod is turned upwards via the gear, the diaphragm is pressed upwards with the piston and presses against the valve seat: the valve closes. The connection for overfilling is connected to the upper...

Page 49: Tensioning of Return Spring

49 mechanical and electrical design pin of return spring tongue of spring stop screw 4749 51 tensioning of return spring with the valve housing removed: - turn the return spring so that the “tongue” of the spring is resting against the stop screw. - position the valve housing over the return spring ...

Page 50: Soap Supply Box

50 mechanical and electrical design 52 1182 soap supply box the three-compartment soap supply box is located at the top of the machine. Viewed from the front, the compartments marked with figures 1, 2 and 3 are used as follows: compartment 1 this compartment is used for adding detergent directly to ...

Page 51: Operating Instructions

51 1 supply signals a b 2 3 4 5 start stop 6 1 program step 7 final extract doorlock delay door unlocked 2 3 4 5 prewash mainwash rinse operating instructions operating instructions the emerald series program unit controls the various functions of the machine in a certain time sequence with the aid ...

Page 52: Operating Instructions

52 operating instructions washing • press the button for the desired program. • now the leds alongside the program sym- bols will show what the selected program consists of. • press the button(s) for any options required. Gentle actions consists of 6 seconds rotation, as opposed to 18 seconds pause ...

Page 53: Operating Instructions

53 • now the display will show the clock symbol and two digits. The two digits are the time left before the wash will be finished. The two digits indicating time left will not appear when the machine is first installed. Each program needs to have been used at least once before the time left will be ...

Page 54: Start

54 start operating instructions for coin-operated machines select a wash program, then insert the number of coins corresponding to the figure shown on the display. As each coin is added the machine counts backwards towards 00 on the display. The machine will not start until the display shows 00. • p...

Page 55: Doorlock Delay

55 doorlock delay door unlocked rapid advance whole steps in programs can be skipped using rapid advance. • press and hold the start button until the program indicator leds have moved past the program steps you wish to skip. Program end after final extraction, the led by the "doorlock delay" comes o...

Page 56: Programming

56 a 1 1 4 3 2 6 5 8 7 9 programming coin-operated machines in coin-operated machines the prices for the various programs have to be programmed in. Values from the coin mechanism (the accumulated value) can be read out with the aid of the service program. If a machine is fitted with a coin mechanism...

Page 57: Programming

57 programming codes 91 and 92 are used to store the values for coin slots 1 and 2. For mechanisms with only one slot, only code 91 is used. The values to be stored are the ratio of one coin to the other. For example: if the coin slots are for a 10 cent coin and a 50 cent coin. The value 10 should b...

Page 58: Programming

58 programming price programming: • press the relevant wash program selector button. When programming the price of a wash program plus options, press both the relevant program selector button and the option button. • keep the price-programming button activated. Now the display shows 00 plus the coin...

Page 59: Hospitality Wash Formulas

59 hospitality wash formulas for hotels/motels, restaurants, retirement communities, schools and universities, commercial and institutional laundries. Wash programs 1 white uniforms sheets & pillow- cases (light soil) 2 white uniforms sheets & pillow- cases (light/ medium soil) 3 white uniforms, she...

Page 60: Healthcare Wash Formulas

60 healthcare wash formulas for nursing homes, hospitales and medical center. Wash programs 1 white uniforms sheets & pillow- cases (very light soil) 2 white uniforms sheets & pillow- cases (medium/ heavy soil) 3 white uniforms, sheets, pillow- cases (medium/ heavy soil) 4 white uniforms sheets, pil...

Page 61: Shirt Laundry Formulas

61 shirt laundry formulas wash programs 1 shirts (starch, cold rinses) 2 shirts (starch, warm rinses) 3 shirts (no starch) (may use with formula 5 or 6) 4 shirts (no starch, no bleach) (may use with formula 5 or 6) 5 one starch injection with extract 6 two starch injections with extract 7 short rins...

Page 62

62 electronic program control unit description the program control unit is electronic and consists of a circuit board with components. On one half are the microprocessor, program memory (eprom), power supply circuits, temperature and level control devices and so on. On the other half are the relays ...

Page 63

63 mechanical and electrical design operating time, accumulated coin value, eprom no. The machine’s built-in service program can be used to check the machine’s accumulated opera- ting time, the accumulated coin value (for coin- operated machines), and the program eprom part number. Accumulated opera...

Page 64

64 mechanical and electrical design to check in service mode enter code 43. The first two digits of a four-digit number will now be displayed, e.G. 13. Enter code 44. The last two digits of a four-digit number will now be displayed, e.G. 47. This means that the machine’s accumulated operating time i...

Page 65

65 mechanical and electrical design to check in service mode enter code 41. The first two digits of a four-digit number will now be displayed, e.G. 06. Enter code 42. The last two digits of a four-digit number will now be displayed, e.G. 58. This means an accumulated coin value of 658 currency units...

Page 66

66 mechanical and electrical design program eprom part no. (check in service mode) enter code 51. The letter a and two digits will be displayed, e.G. A47. ”a” denotes part no. (article no.). Enter code 52. The display will show (e.G.) 195. Enter code 53. The display will show (e.G.) 803. Enter code ...

Page 67: Level Control

67 mechanical and electrical design level control description the "level control", which is located on the circuit board, is a pressure switch which monitors the different water levels in the drum by sensing the air pressure in a tube which is connected to the bottom of the drum. As the water rises ...

Page 68: Built-In Service Program

68 built-in service program the machine has a built-in service program to facilitate function checking and fault-finding. This program may only be used by train- ed and authorized service personnel. To switch on service mode • remove the machine top and the cover for the program unit circuit board. ...

Page 69: Service Program

69 service program error codes given below is a brief summary of all the error codes and their causes. Error code cause 11 detergent signal 1, liquid detergent. 12 detergent compartment 2, cold water /detergent signal 2, liquid detergent. 13 detergent compartment 3, cold water /detergent signal 3, l...

Page 70: Service Program

70 service program error code cause 37 led test 41-42 coin mechanism (see page 39, program control unit). 43-44 counter (hours) for accumulated operating time (see page 39, program control unit). 45 last error code flagged. 51-54 program eprom part number (see page 39, program control unit). 91 coin...

Page 71: Trouble Shooting

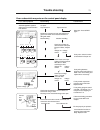

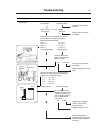

71 1 supply signals a b 2 3 4 5 start stop 6 1 program step 7 final extract doorlock delay door unlocked 2 3 4 5 prewash mainwash rinse trouble shooting if the power supply to the machine should be cut while it is operating, the program unit has a memory which stores the program selected for about 3...

Page 72: Trouble Shooting

72 error codes given below is a brief summary of all the error codes and their causes. Starting on page 5 of this section there are fault-finding charts for all error codes. At the end of the chapter there are also charts for faults which do not generate error codes. Error code cause 01e water level...

Page 73: Trouble Shooting

73 trouble shooting error codes which may arise on the control panel display error code/symptoms fault-finding cause/action check that the manual water valves (taps) are open. Taps turned on. Taps turned off. Restart the program and use rapid advance to get to main wash. Check that the machine is fi...

Page 74: Trouble Shooting

74 open door. Close door and try to restart the machine. Error code returns no error code set program control unit to service mode (see ”to switch on service mode”). The door status switch will now be indicated by the led (illustrated). Press in the door status switch manually and check if this is i...

Page 75: Trouble Shooting

75 trouble shooting error codes which may arise on the control panel display open door. Close door and try to restart the machine. Error code returns no error code start service program and activate door lock (code 23, press start). Check input voltage to door lock, pcb connector x71 between termin-...

Page 76: Trouble Shooting

76 trouble shooting error codes which may arise on the control panel display error code/symptoms fault-finding cause/action are there water in the drum? Yes no disconnect the level tube from the program pcb. Turn the machine’s wall switch off and on again. Start a program. Error code 06e no error co...

Page 77: Trouble Shooting

77 trouble shooting error codes which may arise on the control panel display error code/symptoms fault-finding cause/action turn the machine’s wall switch off and on. Start a program. Error code 06 no error code is there a valve still drawing water? Yes no turn the wall switch off and on. Disconnect...

Page 78: Trouble Shooting

78 trouble shooting error codes which may arise on the control panel display 10e the water level is above the safety level set for after drain. Is water visible in the drum? Yes no remove the water drain valve from the drum. Is there water at the bottom of the drum? Yes no disconnect the level tube ...

Page 79: Trouble Shooting

79 trouble shooting turn the machine’s wall switch off and on again. Start a program. Error code returns no error code unscrew the program control unit pcb. Remove the eprom, then refit the same one. Check that the eprom is turned the right way and that all its leg connectors enter the holder correc...

Page 80: Trouble Shooting

80 trouble shooting when start is pressed wash programs will run, but the water level will not be optimally adjusted. Turn the machine’s wall switch off and on again. Start a program. Error code returns no error code 14e level system not tempera- ture-calibrated error codes which may arise on the co...

Page 81: Trouble Shooting

81 trouble shooting 17e door status switch open, even though the door lock is locked. Turn the machine’s wall switch off and on again. Start a program. Error code returns no error code set program control unit to service mode. The door status switch and door lock switch will now be indicated by the ...

Page 82: Trouble Shooting

82 trouble shooting 20e interlock signal absent at motor control unit during program operation. Error codes which may arise on the control panel display turn the machine’s wall switch off and on again. Start a program. Error code returns no error code check the voltage between terminals 1 and 2 at p...

Page 83: Trouble Shooting

83 trouble shooting turn the machine’s wall switch off and on again. Fault persists. Machine working check fuses f11, f12, f21 and f22. Fuses sound fuse fault check that the input voltages to the pcb are correct. Measure on pcb connector x72 between the following inputs: x72:1 - 2 ca 1,75 v ~ x72:2 ...

Page 84: Trouble Shooting

84 trouble shooting display blank, but machine is working otherwise. Turn the machine’s wall switch off and on again. Fault persists. Machine working check glass-tube fuses f2 and f3 on program control unit pcb. Rating: 1 a/250 v. Fuses sound fuse fault check that input voltages to pcb are correct. ...

Page 85: Maintenance

85 maintenance maintenance preventive maintenance has been reduced to a minimum by the careful design of reliable components and material. However, the following measures should be taken at regular intervals and in proportion to the hours of service. Make certain that all electrical power to the mac...

Page 86: Maintenance

86 maintenance weekly • remove hose from drain connection and clean inside drain valve. Every three months • remove the cover plates of the machine and check that the v-belt of the motor is undamaged and correctly tensioned. • check that all tubing, piping and connections are free from leaks. • wipe...

Page 87: Trouble-Shooting

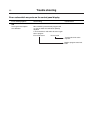

87 trouble-shooting the purpose of the trouble-shooting guide is to facilitate the location an correction of the most common machine problems. Before the top panel is removed, power to the machine is to be switched off at the main source or at the separate circuit breaker. At each trouble-shooting a...

Page 88: Trouble-Shooting

88 1 0 1 a b 2 3 4 5 start stop 6 1 7 final extract doorlock delay 2 3 4 5 prewash mainwash rinse supply signals program step door unlocked if machine does not start a check circuit breaker in the power feed line to the machine. B check door safety switches. C check glass cartridge fuse. D check for...

Page 89: Trouble-Shooting

89 94 93 4985 4936 a if machine does not extract a check for fault indication on display (see under the heading ''fault finding''). If motor does not operate at wash speed. A check for fault indication on display (see under the heading ''fault finding''). B check motor and v-belts. C review procedur...

Page 90: Trouble-Shooting

90 95 96 97 4934 4939 1777 if machine runs slowly on wash speed or there is a slapping or thumping noise: replace v-belts. If a metallic noise can be heard at rear of machine: tighten pulley on motor shaft. If the door is leaking: check door gasket. If gasket is in good condition check the tension, ...

Page 91: Trouble-Shooting

91 98 99 1778 4931 if there is leaking around the glass. A re-cement glass in door gasket, if worn. B replace door gasket if worn. If water does not enter the machine. A check the valve coils on inlet valves. B check wires leading to electric coils. C be sure manual shut-off valves are in open posit...

Page 92: Trouble-Shooting

92 1 a b 2 3 4 5 start stop 6 1 7 final extract doorlock delay 2 3 4 5 prewash mainwash rinse supply signals program step door unlocked 4938 a if water continues to fill without stopping. A check for incorrect programming. B check hose attached to level control unit on the printed circuit board. C c...

Page 93: Trouble Shooting

93 trouble shooting if machine vibrates excessively: a tighten mounting bolts. Fig. 101 101 2408.

Page 95

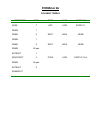

Wascomat “s” model* hospitality wash programs (for hotels/motels, restaurants, retirement communities, schools and universities, commercial and institutional laundries) 1 white uniforms 1a white towels 1b white table 1ab white table sheets & pillow- (medium soil linen (bleach, linen (bleach cases (l...

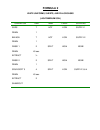

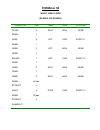

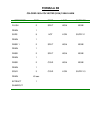

Page 96: Formula 1

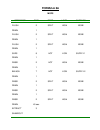

Formula 1 white uniforms, sheets, and pillowcases (light soil) operation time temp level supplies suds/bleach 7 hot low supply 1 & 2 drain 1 rinse 1 2 hot high none drain 1 rinse 2 2 split high none drain 40 sec. Extract 1 rinse 2 split high none drain 1 sour/soft 4 split low supply 3 & 4 drain 40 s...

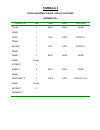

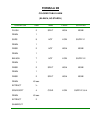

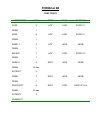

Page 97: Formula 2

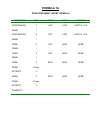

Formula 2 white uniforms, sheets, and pillowcases (light/medium soil) operation time temp level supplies suds 7 hot low supply 1 drain 1 bleach 7 hot low supply 2 drain 1 rinse 1 2 split high none drain 40 sec. Extract ½ rinse 2 2 split high none drain 1 sour/soft 3 4 split low supply 3 & 4 drain 40...

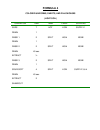

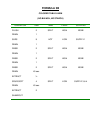

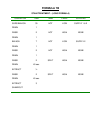

Page 98: Formula 3

Formula 3 white uniforms, sheets, and pillowcases (medium soil) operation time temp level supplies flush 2 split high none drain 1 suds 7 hot low supply 1 drain 1 bleach 7 hot low supply 2 drain 1 rinse 1 2 split high none drain 40 sec. Extract ½ rinse 2 2 split high none drain 1 sour/soft 3 4 cold ...

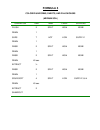

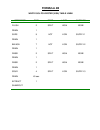

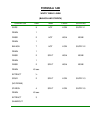

Page 99: Formula 4

Formula 4 colored uniforms, sheets, and pillowcases (light soil) operation time temp level supplies suds 7 hot low supply 1 drain 1 rinse 1 2 split high none drain 1 rinse 2 2 split high none drain 40 sec. Extract ½ rinse 3 2 split high none drain 1 sour/soft 4 split low supply 3 & 4 drain 40 sec. E...

Page 100: Formula 5

Formula 5 colored uniforms, sheets, and pillowcases (medium soil) operation time temp level supplies flush 2 split high none drain 1 suds 7 hot low supply 1 drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 40 sec. Extract ½ rinse 2 split high none drain 1 sour/soft 4 split low s...

Page 101: Formula 6

Formula 6 white towels (light soil) operation time temp level supplies suds/bleach 7 hot low supply 1 & 2 (no drain) cheater/rinse 1 hot high none drain 1 rinse 2 2 hot high none drain 1 rinse 2 split high none drain 40 sec. Extract 1 sour/soft 4 split low supply 3 & 4 drain 40 sec. Extract 3 shakeo...

Page 102: Formula 7

Formula 7 white towels (medium soil) operation time temp level supplies flush 2 split high none drain 1 suds 7 hot low supply 1 drain 1 bleach 7 hot low supply 2 drain 1 rinse 2 split high none drain 40 sec. Extract ½ rinse 2 split high none drain 1 sour/soft 4 split low supply 3 & 4 drain 40 sec. E...

Page 103: Formula 1A

Formula 1a white towels (medium soil, short program) operation time temp level supplies suds 7 hot low supply 1 drain 1 bleach 7 hot low supply 2 drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 1 sour/soft 4 cold low supply 3 & 4 drain 40 sec. Extract 3 shakeout.

Page 104: Formula 2A

Formula 2a colored towels operation time temp level supplies suds 7 hot low supply 1 drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 40 sec. Extract 1 sour/soft 4 cold low supply 3 & 4 drain 40 sec. Extract 3 shakeout.

Page 105: Formula 3A

Formula 3a white towels (heavy soil) operation time temp level supplies flush 2 split high none drain 1 suds 8 hot low supply 1 drain 1 rinse 2 hot high none drain 1 bleach 7 hot low supply 2 drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 40 sec. Extract ½ rinse 2 cold high no...

Page 106: Formula 4A

Formula 4a bedspreads/delicates (cold water / gentle action) operation time temp level supplies suds 5 cold high supply 1 drain 1 rinse 2 cold high none drain 1 rinse 2 cold high none drain 40 sec. Extract 1 sour/soft 4 cold low supply 3 & 4 drain 40 sec. Extract 2 shakeout.

Page 107: Formula 5A

Formula 5a kitchen and housekeeping rags operation time temp level supplies flush 2 split high none drain 1 flush 2 split high none drain 1 suds 7 hot low supply 1 drain 1 bleach 7 hot low supply 2 drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain ...

Page 108: Formula 6A

Formula 6a mops operation time temp level supplies flush 2 split high none drain 1 flush 2 split high none drain 1 flush 2 split high none drain 1 suds 8 hot low supply 1 drain 1 rinse 2 hot high none drain 1 bleach 7 hot low supply 2 drain 1 rinse 2 split high none drain 1 rinse 2 split high none d...

Page 109: Formula 7A

Formula 7a stain treatment (short formula) operation time temp level supplies suds/bleach 7 hot low supply 1 & 2 drain 1 suds/bleach 8 hot low supply 1 & 2 drain 1 rinse 2 hot high none drain 1 rinse 2 hot high none drain 1 rinse 2 split high none drain 40 sec. Extract ½ rinse 2 split high none drai...

Page 110: Formula 1B

Formula 1b white table linen (bleach, no starch) operation time temp level supplies flush 2 split high none drain 1 suds 9 hot low supply 1 drain 1 rinse 2 hot high none drain 1 bleach 7 hot low supply 2 drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 40 sec. Extract ½ sour 4 c...

Page 111: Formula 2B

Formula 2b colored table linen (bleach, no starch) operation time temp level supplies flush 2 split high none drain 1 suds 9 hot low supply 1 drain 1 rinse 2 hot high none drain 1 bleach 7 hot low supply 2 drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 40 sec. Extract ½ sour/s...

Page 112: Formula 3B

Formula 3b colored table linen (no bleach, no starch) operation time temp level supplies flush 2 split high none drain 1 suds 9 hot low supply 1 drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 40 sec. Extract ½ sour/soft 4 split low supply 3 & 4 ...

Page 113: Formula 4B

Formula 4b white 100% polyester (visa) table linen operation time temp level supplies flush 2 split high none drain 1 suds 9 hot low supply 1 drain 1 bleach 7 hot low supply 2 drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 1 sour 4 split low supply 3 drain 40 sec. Extract 1 sh...

Page 114: Formula 5B

Formula 5b colored 100% polyester (visa) table linen operation time temp level supplies flush 2 split high none drain 1 suds 9 hot low supply 1 drain 1 rinse 1 2 split high none drain 1 rinse 2 split high none drain 1 rinse 2 cold high none drain 1 sour 3 cold low supply 3 drain 40 sec. Extract 1 sh...

Page 115: Formula 6B

Formula 6b chef coats operation time temp level supplies suds 5 hot low supply 1 drain 1 suds 8 hot low supply 1 drain 1 rinse 1 2 hot high none drain 1 bleach 7 hot low supply 2 drain 1 rinse 2 2 split high none drain 40 sec. Extract ½ rinse 2 split high none drain 1 sour/soft 4 split low supply 3 ...

Page 116: Formula 7B

Formula 7b stain treatment – (long formula) operation time temp level supplies suds/bleach 30 hot low supply 1 & 2 drain 1 rinse 2 hot high none drain 1 bleach 7 hot low supply 2 drain 1 rinse 2 hot high none drain 1 rinse 2 split high none drain 40 sec. Extract ½ rinse 2 split high none drain 40 se...

Page 117: Formula 1Ab

Formula 1ab white table linen (bleach and starch) operation time temp level supplies suds 9 hot low supply 1 drain 1 rinse 2 hot high none drain 1 bleach 7 hot low supply 2 drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 40 sec. Extract ½ sour 2 split low supply 3 (no drain) st...

Page 118: Formula 2Ab

Formula 2ab colored table linen (bleach and starch) operation time temp level supplies flush 2 split high none drain 1 suds 9 hot low supply 1 drain 1 bleach 7 hot low supply 2 drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 40 sec. Extract ½ sour 2 split low supply 3 (no drain...

Page 119: Formula 3Ab

Formula 3ab white or colored table linen (starch, no bleach) operation time temp level supplies flush 2 split high none drain 1 suds 9 hot low supply 1 drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 40 sec. Extract ½ sour 2 split low supply 3 (n...

Page 120: Formula 4Ab

Formula 4ab bedspreads/delicates (warm water) operation time temp level supplies suds 5 split high supply 1 drain ½ rinse 2 split high none drain ½ rinse 2 split high none drain 40 sec. Extract ½ sour/soft 4 split low supply 3 & 4 drain 40 sec. Extract 2 shakeout.

Page 121: Formula 5Ab

Formula 5ab light soil – general wash formula operation time temp level supplies suds/bleach 9 hot low supply 1 & 2 drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 1 rinse 2 split high none drain 1 sour/soft 4 split low supply 3 & 4 drain 40 sec. Extract 3 shakeout formula 6ab ...

Page 122: Formula 7Ab

Formula 7ab test program on all selecta-28 machines, program 7ab is a test program. The test program should be run whenever you start-up a machine and after performing service and troubleshooting to be sure it is operating properly. This is the test program, step-by-step: 1. Fill to low level with c...

Page 124

Wascomat laundry equipment • 461 doughty blvd., inwood, ny 11096 • tel: (516) 371-4400 • www.Wascomat.Com sales & administration fax: (516) 371-4204 / e-mail: sales@wascomat.Com spare parts tel: (516) 371-2000 / fax: (516) 371-4029 / e-mail: parts@wascomat.Com • technical support tel: (516) 371-0700...