- DL manuals

- Wascomat

- Washer

- EXSM 350 HI-TEK

- Operating & Maintenance Manual

Wascomat EXSM 350 HI-TEK Operating & Maintenance Manual

OPERATING & MAINTENANCE MANUAL

EXSM 350 HI-TEK

WARNING: ALL OPERATING AND MAINTENANCE PROCEDURES SHOWN ON THE NEXT

PAGE OF THIS MANUAL MUST BE FOLLOWED DAILY FOR PROPER OPERATION OF

YOUR WASCOMAT MACHINE.

PLEASE ENTER THE FOLLOWING INFORMATION AS IT APPEARS ON THE MACHINE(S)

DATA PLATE(S).

MAKE CERTAIN TO KEEP THIS MANUAL IN A SECURE PLACE FOR FUTURE

REFERENCE.

MACHINE TYPE OR MODEL

MACHINE SERIAL NUMBER(S)

ELECTRICAL CHARACTERISTICS: ________ VOLTS, _______ PHASE, ______ HZ.

471 1562-96/01

95.09

Summary of EXSM 350 HI-TEK

Page 1

Operating & maintenance manual exsm 350 hi-tek warning: all operating and maintenance procedures shown on the next page of this manual must be followed daily for proper operation of your wascomat machine. Please enter the following information as it appears on the machine(s) data plate(s). Make cert...

Page 2

Notice to: owners, operators and dealers of wascomat machines ii improper installation and inadequate maintenance, poor housekeeping and willful neglect or bypassing of safety devices may result in serious accidents or injury. To assure the safety of customers and/or operators of your machine, the f...

Page 3: Safety And Warnings Signs

Safety and warnings signs replace if missing or illegible one or more of these signs must be affixed on each machine as indica- ted, when not included as part of the front instruction panel. Located on the operating instruction sign of the machine: located at the rear of the machine: installation an...

Page 4: Contents

13 contents introduction ...................................................................... 1 technical data .................................................................. 2 installation ........................................................................ 4 safety rules ....................

Page 5: Introduction

1 introduction the hi-tek solid mounted washer/extractor has been developed to cover the heavy duty requirements of hotels, motels, nursing homes, hospitals, professional laundries, restaurants, airlines, ships, schools, colleges and all on-premises laundries where flexibility and quick formula vari...

Page 6: Technical Data

2 technical data exsm 350 hi-tek dry load capacity up to 35 kg 80 lbs overall dimensions width 1115 mm 43 7/8'' depth (at the top) 1098 mm 43 1/4'' height 1520 mm 59 7/8'' net weight 420 kg 925 lbs max. Floor load at extraction ± 14 kn ± 3147 lbs.Force frequency (dynamic force) 10,8 hz crated dimens...

Page 7: Technical Data

3 technical data outline and dimensions 2479 a b d e c f g h i k l t 2 1 u 4 5 6 s r p o m n 3 1 electrical cable connection 2 steam connection 3 drain connection 4 hot water connection 5 hot water connection 6 cold water connection exsm 350 mm inches a 1114 43 7/8'' b 1520 59 7/8 c 1206 47 15/32'' ...

Page 8: Installation

4 installation machine foundation for making the foundation, check with a professional engineer in order to calculate the foundation regarding dynamic and static forces. The machines are designed to be bolted in position to a concrete floor or specially prepared concrete foundation. A template showi...

Page 9: Installation

5 installation measurements for foundation in inches and (mm). A 42 29/32'' (1090) b 43 15/64'' c 3'' (75) d 3 15/16'' (100) e 15 23/64'' (390) f 3 15/16'' (100) g 13 25/64'' (340) fig. 5 h 3'' (77) k 36 13/16'' (935) l 37 1/64'' (940) m 41 9/16'' (1056) n 43 17/32'' (1106) o 51 59/64'' (1319) p 7/8...

Page 10: Installation

6 6 2400 mechanical installation • place wide steel shims on the concrete foundation over the bolts. • lift the machine and lower it in position. Never use the door or the door handle to lift or lower the machine. • check that the machine is level front-to-rear and side-to-side and standing firmly o...

Page 11: Installation

7 installation 0277 1795 electrical installation although the machines are fitted with a thermal overload in the motor windings and a separate fuse for the control circuit, a separate three-phase common-trip circuit breaker must be installed for all three-phase machines. For proper overcurrent prote...

Page 12: Installation

8 installation 14 15 2367 2368 water connection note all plumbing must conform to national and local plumbing codes. Incoming water lines do not require non-return or back-suction valves, as the machine is already fitted with a siphon breaker. However, all incoming lines must be fitted with shut-off...

Page 13: Installation

9 installation steam connection (optional steam heating) the steam inlet pipe must be fitted with a manual cut-off valve in order to facilitate installation and service operations. Attach the filter supplied with the machine to the manual cut-off valve. Conncection hoses should be of the quality req...

Page 14: Installation

10 1. Drop the knop into the larger opening in the supply injector lid. 2. Tighten securely. Do not overtighten! Do not use pliers or other tools to tighten the knobs! 1. Stretch the multi-rubber ring b and select the correct size ring which will fit snugly on the chemical tube you are using. Ring a...

Page 15: Important:

11 24 25 2399 1763 start-up and safety checklist before initial start-up of a wascomat washer- extractor, the following safety checks must be performed: • make sure the machine is properly bolted to the floor. • make sure that all electrical and plumbing connections have been made in accordance with...

Page 16: Safety Rules

12 safety rules safety rules • the machine is designed for water washing only. • machines must not be used by children. • all installation operations are to be carried out by qualified personnel. Licensed personnel are necessary for all electric power wiring. • the interlock of the door must be chec...

Page 17: General

13 mechanical and electrical design general the door and the electronic timer with display and keyboard are fitted at the front of the machine. All control and indicating components, i.E. Relays, delay unit, etc are assembled under the top cover, easily accessible from the top of the machine for sim...

Page 18: Machine Construction

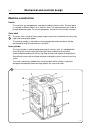

14 mechanical and electrical design 29 machine construction panels the machines are equipped with a top panel made of stainless steel. The front panel is available in different colours or in stainless steel. The coloured panels are made of phosphatized steel plate. For servicing purposes, the panels...

Page 19

15 mechanical and electrical design 30 back gable and bearing the back gable and the bearing trunnion housing are constructed of a webbed heavy casting for extra rigidity. The bearings are protected against filtration of water by three seals. An intermediate safety outlet provides an escapement for ...

Page 20: Control Unit

16 mechanical and electrical design control unit the control panel (1), mounted at the front, includes all components necessary for operating the machine, such as display window, control switches and a key-operated switch. The printed circuit board (2) with the microprocessor-controlled electronic t...

Page 21: Relays

17 32 mechanical and electrical design 0301 relays the hi-tek model employs seven relays. The relays control: • the wash windings of the wash motor • the distribution windings of the wash motor • the extraction motor • the switching back to low speed extraction if too high unbalance is indicated. Co...

Page 22: Drive Motors

18 mechanical and electrical design 33 2372 drive motors drive motor description the four-speed operation of the wash cylinder is achieved by two motors. One 2-speed motor for wash speed (12-pole drive) and distribution speed (8-pole drive) and one 2-speed motor for extraction speeds (4-pole drive, ...

Page 23

19 mechanical and electrical design 34 2403 drive motor function when the stator winding is charged, a magnetic field will occur, which in turn will rotate the motor at a fixed rpm depending upon the number of poles in the winding. The 12-pole winding gives the wash speed and the 8-pole winding in t...

Page 24

20 mechanical and electrical design 35 0304 motor connections wash/distribution motor: 1, 2 and 3: wash speed (12-pole winding). 4, 5 and 6: distribution speed (8-pole winding). 7 and 9: motor overload protector. Extract motor: 1, 2 and 3: extract speed (2-pole winding). 4, 5 and 6: extract speed (4...

Page 25

21 mechanical and electrical design repair instructions overheated motor, motor not running • wait till motor has cooled down. Motor thermal protectors are automatically reset after appr. 30 minutes. Restart. • possible cause of motor protector releasing repeatedly. Could be oversensitivity of therm...

Page 26: Supply Injection Valve

22 mechanical and electrical design 37 38 0306 0307 supply injection valve construction the valve has a single-inlet with either one, two or three outlets, each with its own solenoid coil. The body is made of heat-resistant polyamid plastic and the solenoids encased in water-tight plastic. The elect...

Page 27

23 mechanical and electrical design 39 0308 repair instructions limescale can block the hole in the valve diaphragm and interfere with the function of the valve. It is therefore advisable to dismantle and clean the valve at certain regular intervals. The frequency depends on operating conditions and...

Page 28: Inlet Valve

24 inlet valve the water inlets have brass bodies with larger cross section of the outlet in order to achieve a shorter filling time for the machine. Construction the valve housing is made of pressed brass. The spring-loaded plunger is made of stainless steel and located at its lower end is a rubber...

Page 29: Drain Valve

25 drain valve description the drain valve is operated by using the pressure in the cold water intake. A tube (1) is connected between the cold water intake and a solenoid valve (2). When the solenoid valve is activated, it opens and allows water to flow into the feeder tube (3). The water presses u...

Page 30: Soap Supply Box

26 mechanical and electrical design 46 1182 soap supply box the three-compartment soap supply box is located at the top of the machine. Viewed from the front, the compartments marked with figures 1, 2 and 3 are used as follows: compartment 1 this compartment is used for adding detergent directly to ...

Page 31: Procedure For Use

27 0149 procedure for use all operations, including the programming of new programs are carried out from the control panel on the front of the machine. During normal use, the programming keys to the left of the panel are inoperative. The control panel comprises the following: • a display window with...

Page 32: Procedure

28 preparation • sort the wash according to the washing instructions on the garment labels. Check that there are no foreign objects in the garments. Pull up zipper fasteners. • open the washing machine door, check that the drum is empty, insert the wash goods and close the door. Automatic washing th...

Page 33: Procedure

29 0152 0153 0154 program information when a program has been selected and prog. Info. Is pressed, further information about the program is shown in the display window's bottom lines. Measuring the detergent five lights on the panel indicate which detergent compartments or connections from the centr...

Page 34: Procedure

30 0156 0155 starting the program press start/hold/rapid adv. Button. The wash cycle will commence and the display window will display wash information as shown in the figure below. Temporary stop • press start/hold/rapid adv.. All active functions (motor, filling with water and heating) are switche...

Page 35: Procedure

31 0155 0157 programmed stop if there is a programmed stop in the program, the machine stops and a buzzer sounds. The buzzer is switched off by pressing start/ hold/rapid adv. The program is restarted by pressing the button again. Tumble drying after the program is completed if door lock and motor a...

Page 36: Procedure

32 0158 0159 procedure manual washing • the lamps above the control buttons indicate which functions are active. Cold water, hot water and flush must be kept pressed to remain active. Other control buttons change function each time they are pressed. • lock the door by pressing the door lock button (...

Page 37: Procedure

33 extract cycle for safety reasons, there is no manual button for the extract cycle. There are two choices if extracting is required during manual operation: • 1. Select one of the standard programs and fast forward to the "extract" cycle. • 2. Program your own program by draining and extracting fo...

Page 38: Programming

0164 programming general the washing machine’s program operation is controlled by a microcomputer and the wash programs are stored in an electronic memory. Program controls are very exact and the wash programs can be easily adapted to the end user’s individual requirements. The machine is supplied w...

Page 39: Programming

0165 programming enter the information text allocate a program number turn the key to ''run'' answer the questions etc. . . Answer the questions turn the key to ''program'' select the sub-program select the sub-program programming - general description programming can be divided into two programming...

Page 40: Programming

0166 programming change the answers to the questions delete the sub-program enter the sub-program enter the information text allocate a program number turn the key to ''run'' using and old program as a background in this operation, an old program is selected as a background for the new one. The answ...

Page 41: Controls

37 controls the key switch turn the switch to the program position if the wash program is to be programmed or changed. If for any reason you wish to discontinue programming and start again, turn the switch to the run position and then back to program again. Any programming that you have done so far ...

Page 42: Programming

38 erase this button can be used in three different ways: • deleting a complete program. Press erase when the display window displays the adjacent text. A warning text will then be displayed. Press enter, enter the program number with the number keys and press enter again. • deleting a section of a ...

Page 43: Programming

39 yes, no, number keys these keys are used to answer the different questions which are found under each sub- program. All answers must be followed by pressing enter for the answer to be registered. Text the key for text is used for entering the explanatory text which is displayed when prog.Info. Is...

Page 44: Programming A New Program

40 programming a new program if you make a mistake or get stuck, there is always a final resort: turn the key to the run position and then to program again. Any programming you have carried out so far will be lost but other programs will not be affected. Turn the key turn the key to the program posi...

Page 45: Programming

41 programming press: ja klar press: red. Upp red. Ner 0180 0181 progr.Mode select sequence prewash 01 paus with buzzer y/n n normal action during filling y/n n gentle action during filling y/n n red. Opp red. Ned progr.Mode select sequence prewash 01 normal action during filling y/n n gentle action...

Page 46: Programming

42 drum volume level (units) (litres) low high 150 40 80 230 45 90 red. Ned number keys press: press: 0184 0185 0188 programming 87 88 89 progr.Mode select sequence prewash 01 paus with buzzer y/n n normal action during filling y/n n progr.Mode select sequence prewash 01 paus with buzzer y/n n norma...

Page 47: Programming

43 0190 0191 0192 programming 91 92 93 progr. Mode select sequence prewash 01 level 000 units level reset 000 units temperature 000 ° c progr.Mode select sequence prewash 01 level reset 000 units temperature 000 ° c washtime 00 min. 00 sec. Progr.Mode select sequence prewash 01 temperature 000 ° c w...

Page 48: Programming

44 press: press: 0193 0194 press: 0195 94 95 96 programming water filling one or several water valves can be selected. If you decide to use hot and cold water, both valves will be open while filling is in progress. The hot water valve will be automatically closed if the pre-set temperature is exceed...

Page 49: Programming

45 press: 0196 0197 98 programming drain pause with signal if the question is answered with yes, the washing machine will stop before the sub-program starts and a buzzer will sound. Normal action/gentle action/distribution select the method of working while draining. Distribution action is used befo...

Page 50: Programming

46 press: press: 0201 0202 programming programming complete • when ’’end of sequence’’ appears on the third line of the display window and all questions are answered, press edit down. • answer no to the question ’’end prog. Session y/n?’’ if there are more sub- programs to be answered. Answer yes if...

Page 51: Programming

47 programming gentle action answer yes if the machine is to operate on gentle action during cooling. The machine will operate on normal action if the answer is no. Times cold water is supplied in stages by the water valve opening and closing according to a particular pattern. The time for an openin...

Page 52: Programming

48 0207 programming example: • on time 212-158 ° f (100-70 ° c) 8 seconds. • on time 158 ° f (70 ° c) - end 13 seconds. • end temp. 113 ° f (45 ° c). • wash temperature 194 ° f (90 ° c). The following takes place: • when the water in the drum reaches 194-158 ° f (90-70 ° c), the water valve is on 8 ...

Page 53: Programming

49 text each program can be provided with two types of informative text: • 1. A program name which is always displayed when the program is selected when washing. This text is programmed when the program number i selected. See under the heading ’’program names’’ later on in the manual. • 2. Informati...

Page 54: Programming

50 press: 0215 programming times for normal action and gentle action the times for rotating and stationary drum during normal and gentle action can be programmed. All times can be selected within the range of 0-30 seconds with 1 second intervals. Press enter when ’’to end. Press enter’’ is displayed...

Page 55: Programming

51 0218 0219 press: programming program names you can now give the program a name which will be displayed when the program is selected during washing. The text can be up to 29 characters long. The way in which text is entered described under the heading ’’text’’ earlier in the manual. Saving program...

Page 56: Programming

52 press: 0222 0167 programming starting from a previously saved program if you make a mistake or get stuck, there is always a final resort: turn the key to the run position and then to program again. Any programming you may have carried out so far will be lost but other programs will not be affecte...

Page 57: Programming

53 press: ... 0225 0226 press: programming the cursor will appear on the first line of this sub- program. Use edit up and edit down to move within the sub-program to reach the line(s) to be altered. Note enter is to be used only as an acknowledgement when sub-questions are to be altered. Use buttons...

Page 58: Programming

54 number keys press: or or nej press: klar 0229 0230 programming no progr. Mode select sequence prewash 01 paus with buzzer y/n y normal action during filling y/n y gentle action during filling y/n n progr.Mode select sequence prewash 01 normal action during filling y/n n gentle action during filli...

Page 59: Programming

55 altering text the text that is displayed when a program is selected and prog.Info is pressed can be altered. Go to the position between two sub-programs (see the section ’’looking through the program’’). Press text and enter. Any text that might have been programmed in the old program is displaye...

Page 60: Service Information

56 service information service information the machine's electrical power connection cable must be provided with a safety ground to avoid breakdowns in the machine's electronic program controls. If interference problems do occur, check first that the machine is properly grounded. The machine's opera...

Page 61: Maintenance

57 maintenance maintenance preventive maintenance has been reduced to a minimum by the careful design of reliable components and material. However, the following measures should be taken at regular intervals and in proportion to the hours of service. Important! Make certain that all electrical power...

Page 62: Trouble-Shooting

58 if machine does not start a check circuit breaker in the power feed line to the machine. B check door safety switches. C check glass cartridge fuse. D check electrical auxiliary contact on extract relay. E check for fault indication on display (see under the heading ''service information'').' if ...

Page 63: Trouble-Shooting

59 trouble-shooting 142 1810 if machine does not extract a check for fault indication on display (see under the heading ''service information''). B check extract relay and relay coil for proper operation. If motor does not operate at wash speed. A check for fault indication on display (see under the...

Page 64: Trouble-Shooting

60 trouble-shooting the purpose of the trouble-shooting guide is to facilitate the location and correction of the most common machine problems. Before the top panel is removed, power to the machine is to be switched off at the main source or at the separate circuit breaker. At each trouble-shooting ...

Page 65: Trouble-Shooting

61 trouble-shooting 144 2379 if machine runs slowly on wash speed or there is a slapping or thumping noise: replace v-belts. If a metallic noise can be heard at rear of machine: tighten pulley on motor shaft. If the door is leaking: check door gasket. If gasket is in good condition check the tension...

Page 66: Trouble-Shooting

62 trouble-shooting 147 148 1778 1806 if there is leaking around the glass. A re-cement glass in door gasket, if worn. B replace door gasket if worn. If water does not enter the machine. A check the value coils on inlet valves. B check vires leading to electric coils. C be sure manual shut-off valve...

Page 67: Trouble-Shooting

63 trouble-shooting 1812 fig. 149 if water continues to fill without stopping. A check for incorrect programming. B check hose attached to level control unit on the printed circuit board. C check inlet valves for dirt underneath the valve diaphragm. To localize, shut off power. If water continues to...

Page 68: Trouble Shooting

64 trouble shooting if machine vibrates excessively: a tighten mounting bolts. If safety fuse blows at the beginning of the cycle: a replace fuse. B disconnect wires leading to the delay circuit of the door lock. Replace fuse and start. If the machine now works, replace delay circuit. Fig. 152 fig. ...

Page 69: Trouble-Shooting

65 trouble-shooting 2166 153 if machine vibrates excessively. A check the unbalance detector switch. Note the electronic timer has a built in service program that can be useful when troubleshooting. Contact service personnel for further information. Fig. 153.